ASTM E1077-14

(Test Method)Standard Test Methods for Estimating the Depth of Decarburization of Steel Specimens

Standard Test Methods for Estimating the Depth of Decarburization of Steel Specimens

SIGNIFICANCE AND USE

5.1 These test methods are used to detect surface losses in carbon content due to heating at elevated temperatures, as in hot working or heat treatment.

5.2 Results of such tests may be used to qualify material for shipment according to agreed upon guidelines between purchaser and manufacturer, for guidance as to machining allowances, or to assess the influence of processing upon decarburization tendency.

5.3 Screening tests are simple, fast, low-cost tests designed to separate non-decarburized samples from those with appreciable decarburization. Based on the results of such tests, the other procedures may be utilized as applicable.

5.4 Microscopical tests require a metallographically polished cross section to permit reasonably accurate determination of the depth and nature of the decarburization present. Several methods may be employed for estimation of the depth of decarburization. The statistical accuracy of each varies with the amount of effort expended.

5.5 Microindentation hardness methods are employed on polished cross sections and are most suitable for hardened specimens with reasonably uniform microstructures. This procedure can be used to define the depth to a specific minimum hardness or the depth to a uniform hardness.

5.6 Chemical analytical methods are limited to specimens with simple, uniform shapes and are based on analysis of incremental turnings or after milling at fixed increments.

5.7 Microscopical tests are generally satisfactory for determining the suitability of material for intended use, specification acceptance, manufacturing control, development, or research.

SCOPE

1.1 These test methods cover procedures for estimating the depth of decarburization of steels irrespective of the composition, matrix microstructure, or section shape. The following basic procedures may be used:

1.1.1 Screening methods.

1.1.2 Microscopical methods.

1.1.3 Microindentation hardness methods.

1.1.4 Chemical analysis methods.

1.2 In case of a dispute, the rigorous quantitative or lineal analysis method (see 7.3.5 and 7.3.6) shall be the referee method. These methods can be employed with any cross-sectional shape. The chemical analytical methods generally reveal a greater depth of decarburization than the microscopical methods but are limited to certain simple shapes and by availability of equipment. These techniques are generally reserved for research studies. The microindentation hardness method is suitable for accurate measurements of hardened structures with relatively homogeneous microstructures.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E1077 − 14

Standard Test Methods for

Estimating the Depth of Decarburization of Steel

1

Specimens

This standard is issued under the fixed designation E1077; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

INTRODUCTION

These test methods may be used to estimate the average or greatest depth of decarburization in

hardened or non-hardened steel products. The test methods described range from simple screening

tests to more statistically rigorous test methods depending upon the needs of the investigation.

1. Scope 2. Referenced Documents

2

1.1 These test methods cover procedures for estimating the

2.1 ASTM Standards:

depth of decarburization of steels irrespective of the

A941TerminologyRelatingtoSteel,StainlessSteel,Related

composition, matrix microstructure, or section shape. The

Alloys, and Ferroalloys

following basic procedures may be used:

E3Guide for Preparation of Metallographic Specimens

1.1.1 Screening methods.

E7Terminology Relating to Metallography

1.1.2 Microscopical methods.

E340Test Method for Macroetching Metals and Alloys

1.1.3 Microindentation hardness methods.

E350Test Methods for Chemical Analysis of Carbon Steel,

1.1.4 Chemical analysis methods.

Low-Alloy Steel, Silicon Electrical Steel, Ingot Iron, and

Wrought Iron

1.2 In case of a dispute, the rigorous quantitative or lineal

E384Test Method for Knoop and Vickers Hardness of

analysis method (see 7.3.5 and 7.3.6) shall be the referee

Materials

method. These methods can be employed with any cross-

E407Practice for Microetching Metals and Alloys

sectional shape. The chemical analytical methods generally

E415Test Method for Analysis of Carbon and Low-Alloy

reveal a greater depth of decarburization than the microscopi-

cal methods but are limited to certain simple shapes and by Steel by Spark Atomic Emission Spectrometry

E1951Guide for Calibrating Reticles and Light Microscope

availability of equipment. These techniques are generally

reserved for research studies. The microindentation hardness Magnifications

method is suitable for accurate measurements of hardened

structures with relatively homogeneous microstructures. 3. Terminology

1.3 The values stated in SI units are to be regarded as 3.1 Definitions:

standard. No other units of measurement are included in this

3.1.1 Fordefinitionsoftermsusedinthesetestmethods,see

standard.

Terminology E7 and Terminology A941.

1.4 This standard does not purport to address all of the 3.2 Definitions of Terms Specific to This Standard:

safety concerns, if any, associated with its use. It is the

3.2.1 average depth of decarburization—the mean value of

responsibility of the user of this standard to establish appro-

five or more measurements of the total depth of decarburiza-

priate safety and health practices and determine the applica-

tion.

bility of regulatory limitations prior to use.

3.2.2 average free-ferrite depth—the mean value of five or

more measurements of the depth of complete decarburization.

1

These test methods are under the jurisdiction of ASTM Committee E04 on

Metallography and are the direct responsibility of Subcommittee E04.14 on

2

Quantitative Metallography. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Jan. 1, 2014. Published March 2014. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1985. Last previous edition approved in 2005 as E1077–01(2005). Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/E1077-14. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E1077 − 14

3.2.3 complete decarburization—loss of carbon content at 5.7 Microscopical tests are generally satisfactory for deter-

the surface of a steel specimen to a level below the solubility miningthesuitabilityofmaterialforintendeduse,specification

limit of carbon in ferrite so that only ferrite is present. acceptance, manufacturing control, development, or research.

3.2.4 free-ferrite depth—theperpendiculardistancefromthe

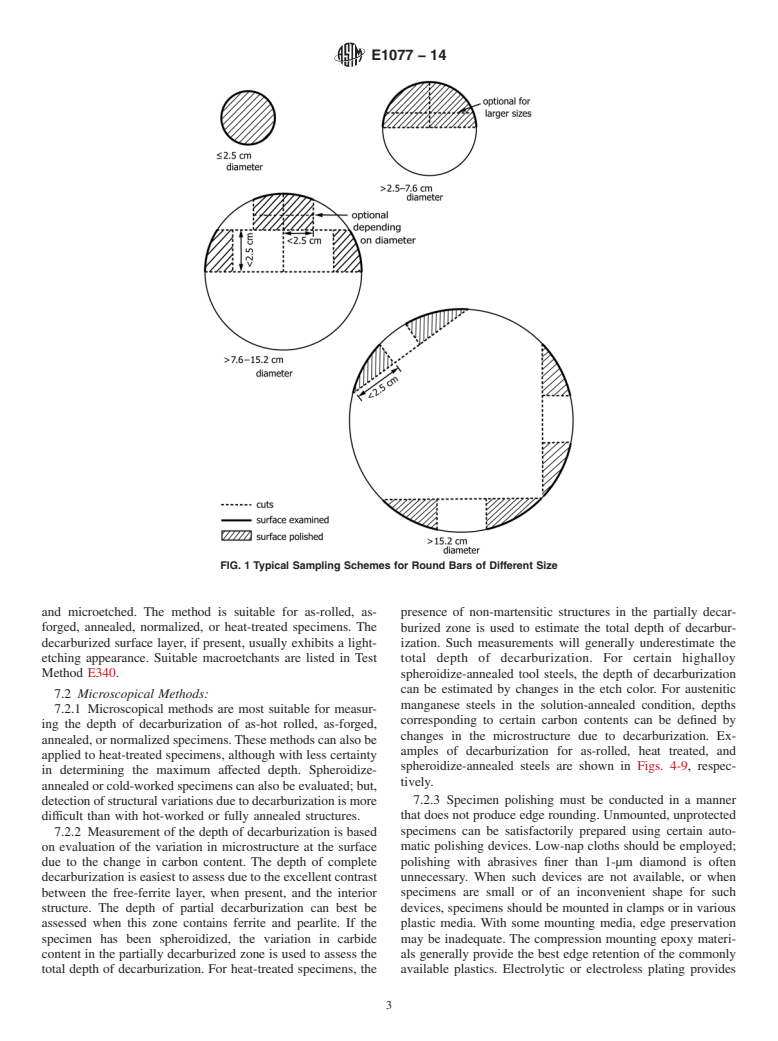

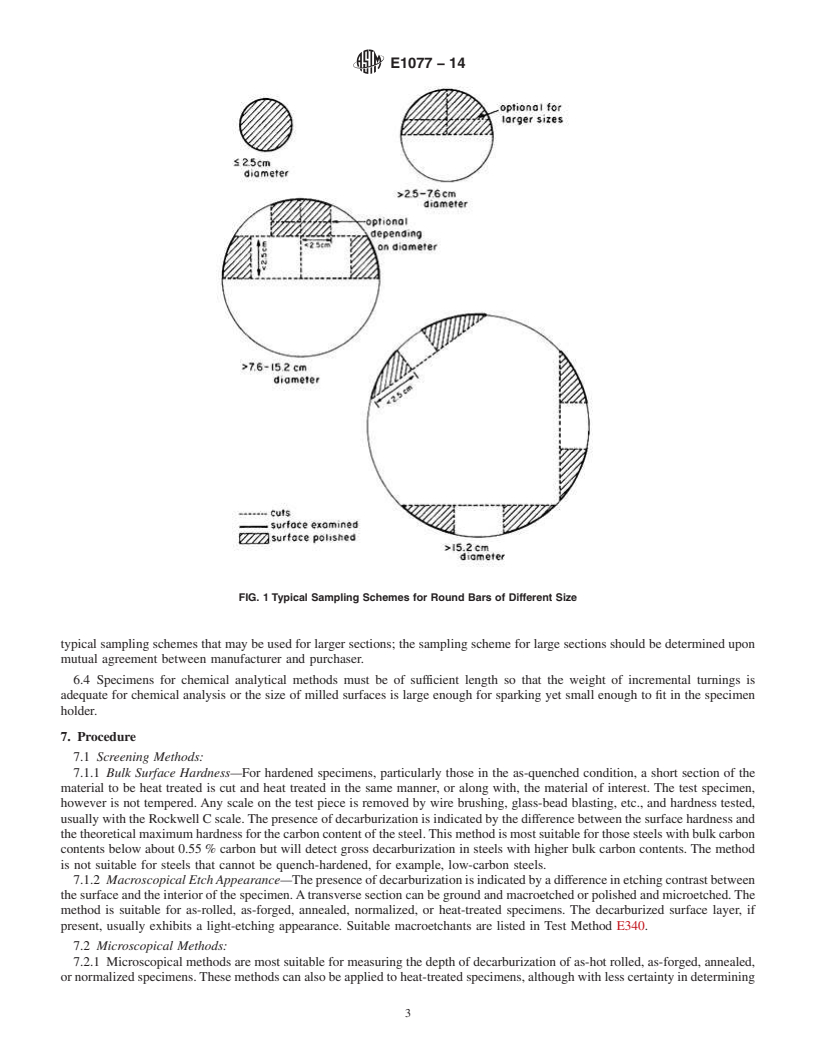

6. Sampling

surface of the specimen to that location where the structure is

6.1 Samples should be taken at locations that are represen-

no longer fully ferritic, that is, other transformation products

tative of the bulk specimen. The location and number of

are observed.

samplestakendependsonthenatureofthematerialtobetested

NOTE 1—The term fre

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E1077 − 01 (Reapproved 2005) E1077 − 14

Standard Test Methods for

Estimating the Depth of Decarburization of Steel

1

Specimens

This standard is issued under the fixed designation E1077; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

INTRODUCTION

These test methods may be used to estimate the average or greatest depth of decarburization in

hardened or non-hardened steel products. The test methods described range from simple screening

tests to more statistically rigorous test methods depending upon the needs of the investigation.

1. Scope

1.1 These test methods cover procedures for estimating the depth of decarburization of steels irrespective of the composition,

matrix microstructure, or section shape. The following basic procedures may be used:

1.1.1 Screening methods.

1.1.2 Microscopical methods.

1.1.3 Microindentation hardness methods.

1.1.4 Chemical analysis methods.

1.2 In case of a dispute, the rigorous quantitative or lineal analysis method (see 7.3.5 and 7.3.6) shall be the referee method.

These methods can be employed with any cross-sectional shape. The chemical analytical methods generally reveal a greater depth

of decarburization than the microscopical methods but are limited to certain simple shapes and by availability of equipment. These

techniques are generally reserved for research studies. The microindentation hardness method is suitable for accurate

measurements of hardened structures with relatively homogeneous microstructures.

1.3 The values stated in SI units are to be regarded as standard. The inch-pound equivalents are in parentheses and may be

approximate.No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

A941 Terminology Relating to Steel, Stainless Steel, Related Alloys, and Ferroalloys

E3 Guide for Preparation of Metallographic Specimens

E7 Terminology Relating to Metallography

E340 Test Method for Macroetching Metals and Alloys

E350 Test Methods for Chemical Analysis of Carbon Steel, Low-Alloy Steel, Silicon Electrical Steel, Ingot Iron, and Wrought

Iron

E384 Test Method for Knoop and Vickers Hardness of Materials

E407 Practice for Microetching Metals and Alloys

E415 Test Method for Atomic Emission Vacuum Spectrometric Analysis of Carbon and Low-Alloy Steel

1

These test methods are under the jurisdiction of ASTM Committee E04 on Metallography and are the direct responsibility of Subcommittee E04.14 on Quantitative

Metallography.

Current edition approved May 1, 2005Jan. 1, 2014. Published May 2005March 2014. Originally approved in 1985. Last previous edition approved in 20012005 as

ε1

E1077 – 01 .(2005). DOI: 10.1520/E1077-01R05.10.1520/E1077-14.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E1077 − 14

E1951 Guide for Calibrating Reticles and Light Microscope Magnifications

3. Terminology

3.1 Definitions:

3.1.1 For definitions of terms used in these test methods, see Terminology E7 and Terminology A941.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 average depth of decarburization—the mean value of five or more measurements of the total depth of decarburization.

3.2.2 average free-ferrite depth—the mean value of five or more measurements of the depth of complete decarburization.

3.2.3 complete decarburization—loss of carbon content at the surface of a steel specimen to a level below the solubility limit

of carbon in ferrite so that only ferrite is present.

3.2.4 free-ferrite depth—the perpendicular distance from the surface of the specimen to that location where the structure is no

longer ful

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.