ASTM B232/B232M-99

(Specification)Standard Specification for Concentric-Lay-Stranded Aluminum Conductors, Coated-Steel Reinforced (ACSR)

Standard Specification for Concentric-Lay-Stranded Aluminum Conductors, Coated-Steel Reinforced (ACSR)

SCOPE

1.1 This specification covers concentric-lay-stranded conductors made from round aluminum 1350-H19 (extra hard) wires and round, coated steel core wire(s) for use as overhead electrical conductors (Explanatory Note 1 and Explanatory Note 2).

1.2 ACSR covered by this specification has nine types of coated steel core wire which are designated by abbreviations as follows (Explanatory Note 2):

1.2.1 ACSR/GA-ACSR using Class A zinc-coated steel wire,

1.2.2 ACSR/GB-ACSR using Class B zinc-coated steel wire,

1.2.3 ACSR/GC-ACSR using Class C zinc-coated steel wire,

1.2.4 ACSR/MA-ACSR using Class A Zn-5A1-MM coated steel wire,

1.2.5 ACSR/MB-ACSR using Class B Zn-5A1-MM coated steel wire,

1.2.6 ACSR/MC-ACSR using Class C Zn-5A1-MM coated steel wire,

1.2.7 ACSR/HS-ACSR using Class A zinc-coated high-strength steel wires,

1.2.8 ACSR/MS-ACSR using Class A Zn-5A1-MM coated high-strength steel wires, and

1.2.9 ACSR/AZ-ACSR using aluminum-coated (aluminized) steel wire.

1.3 The values stated in inch-pound or SI units are to be regarded separately as standard. The values in each system are not exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

1.3.1 For density, resistivity and temperature, the values stated in SI units are to be regarded as standard.

Note 1—The aluminum and temper designations conform to ANSI Standard H35.1/H35.1M; Aluminum 1350 corresponds to UNS No. A91350 in accordance with Practice E527.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: B 232/B 232M – 99

Standard Specification for

Concentric-Lay-Stranded Aluminum Conductors, Coated-

Steel Reinforced (ACSR)

This standard is issued under the fixed designation B 232/B 232M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This specification covers concentric-lay-stranded con- 2.1 The following documents of the issue in effect on date

ductors made from round aluminum 1350-H19 (extra hard) of material purchase form a part of this specification to the

wires and round, coated steel core wire(s) for use as overhead extent referenced herein:

electrical conductors (Explanatory Note 1 and Explanatory 2.2 ASTM Standards:

Note 2). B 230/B 230M Specification for Aluminum 1350-H19 Wire

1.2 ACSR covered by this specification has nine types of for Electrical Purposes

coated steel core wire which are designated by abbreviations as B 263 Test Method for Determination of Cross-Sectional

follows (Explanatory Note 2): Area of Stranded Conductors

1.2.1 ACSR/GA-ACSR using Class A zinc-coated steel B 341/B 341M Specification for Aluminum-Coated (Alu-

wire, minized) Steel Core Wire for Aluminum Conductors, Steel

1.2.2 ACSR/GB-ACSR using Class B zinc-coated steel Reinforced (ACSR/AZ)

wire, B 354 Terminology Relating to Uninsulated Metallic Elec-

1.2.3 ACSR/GC-ACSR using Class C zinc-coated steel trical Conductors

wire, B 498/B 498M Specification for Zinc-Coated (Galvanized)

1.2.4 ACSR/MA-ACSR using Class A Zn-5A1-MM coated Steel Core Wire for Aluminum Conductors, Steel Rein-

steel wire, forced (ACSR)

1.2.5 ACSR/MB-ACSR using Class B Zn-5A1-MM coated B 500 Specification for Metallic Coated Stranded Steel

steel wire, Core for Aluminum Conductors, Steel-Reinforced

1.2.6 ACSR/MC-ACSR using Class C Zn-5A1-MM coated (ACSR)

steel wire, B 606 Specification for High-Strength Zinc-Coated (Galva-

1.2.7 ACSR/HS-ACSR using Class A zinc-coated high- nized) Steel Core Wire for Aluminum and Aluminum-

strength steel wires, Alloy Conductors, Steel Reinforced

1.2.8 ACSR/MS-ACSR using Class A Zn-5A1-MM coated B 682 Specification for Standard Metric Sizes of Electrical

high-strength steel wires, and Conductors

1.2.9 ACSR/AZ-ACSR using aluminum-coated (alumi- B 802/B 802M Specification for Zinc-5 % Aluminum-

nized) steel wire. Mischmetal Alloy-Coated Steel Core Wire for Aluminum

1.3 The values stated in inch-pound or SI units are to be Conductors, Steel Reinforced (ACSR)

regarded separately as standard. The values in each system are B 803 Specification for High-Strength Zinc-5 %

not exact equivalents; therefore, each system shall be used Aluminum-Mischmetal Alloy-Coated Steel Core Wire for

independently of the other. Combining values from the two Aluminum and Aluminum-Alloy Conductors, Steel Rein-

systems may result in nonconformance with the specification. forced

1.3.1 For density, resistivity and temperature, the values E 29 Practice for Using Significant Digits in Test Data to

stated in SI units are to be regarded as standard. Determine Conformance with Specifications

E 527 Practice for Numbering Metals and Alloys (UNS)

NOTE 1—The aluminum and temper designations conform to ANSI

2.3 ANSI Documents:

Standard H35.1/H35.1M; Aluminum 1350 corresponds to UNS No.

ANSI H35.1 American National Standard Alloy and Tem-

A91350 in accordance with Practice E 527.

per Designation Systems for Aluminum

1 2

This specification is under the jurisdiction of ASTM Committee B-1 on Annual Book of ASTM Standards, Vol 02.03.

Electrical Conductors and is the direct responsibility of Subcommittee B01.07 on Annual Book of ASTM Standards, Vol 14.02.

Conductors of Light Metals. Annual Book of ASTM Standards, Vol 01.01.

Current edition approved April 10, 1999. Published June 1999. Originally Available from the American National Standards Institute, 11 West 42nd Street,

published as B 232 – 48T. Last previous edition B 232 – 97. 13th Floor, New York, NY 10036.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

B 232/B 232M

ANSI H35.1M American National Standard for Alloy and core wire, coating Class B in accordance with Specification

Temper Designations Systems for Aluminum [Metric] B 802/B 802M.

2.4 NIST Document:

3.2.9 ACSR/MC—reinforced with Zn-5A1-MM coated steel

NBS Handbook 100—Copper Wire Tables

core wire, coating Class C in accordance with Specification

2.5 Aluminum Association Document:

B 802/B 802M.

Publication 50, Code Words for Overhead Aluminum Elec-

3.2.10 ACSR/MS—reinforced with high-strength Zn-

trical Conductors

5A1-MM coated steel core wire in accordance with Specifica-

tion B 803.

3. Terminology

3.2.11 ACSR/AZ—reinforced with aluminized steel core

3.1 Definitions:

wire in accordance with Specification B 341/B 341M.

3.1.1 Galvanized—zinc coated.

3.1.2 Aluminized—aluminum coated.

4. Classification

3.2 Abbreviations:

3.2.1 Zn-5A1-MM—zinc-5 % aluminum-mischmetal alloy.

4.1 For the purpose of this specification conductors are

3.2.2 ACSR—aluminum conductor, steel reinforced.

classified as follows (Explanatory Notes 1 and 2):

3.2.3 ACSR/GA—reinforced with galvanized steel core

4.1.1 Class AA—For bare conductors usually used in over-

wire, coating Class A in accordance with Specification B 498/

head lines. These conductors are divided into two types as

B 498M.

follows:

3.2.4 ACSR/GB—reinforced with galvanized steel core

4.1.1.1 Conductors used for regular over-head line construc-

wire, coating Class B in accordance with Specification B 498/

tion, and

B 498M.

4.1.1.2 Conductors having a high ratio of mechanical

3.2.5 ACSR/GC—reinforced with galvanized steel core

strength to current-carrying capacity used for overhead ground

wire, coating Class C in accordance with Specification B 498/

wires and for extra-long span construction.

B 498M.

3.2.6 ACSR/HS—reinforced with high-strength galvanized 4.1.2 Class A—For conductors to be covered with weather-

resistant materials.

steel core wire in accordance with Specification B 606.

3.2.7 ACSR/MA—reinforced with Zn-5A1-MM coated steel

core wire, coating Class A in accordance with Specification 5. Ordering Information

B 802/B 802M.

5.1 Orders for material under this specification shall include

3.2.8 ACSR/MB—reinforced with Zn-5A1-MM coated steel

the following information:

5.1.1 Quantity of each size, stranding, and class,

Available from the National Institute of Standards and Technology (NIST),

5.1.2 Conductor size, circular-mil area or AWG (Section 9

Gaithersburg, MD 20899.

and Table 1),

Available from the Aluminum Association, Inc., 900 19th Street, NW, Suite

300, Washington, DC 20006.

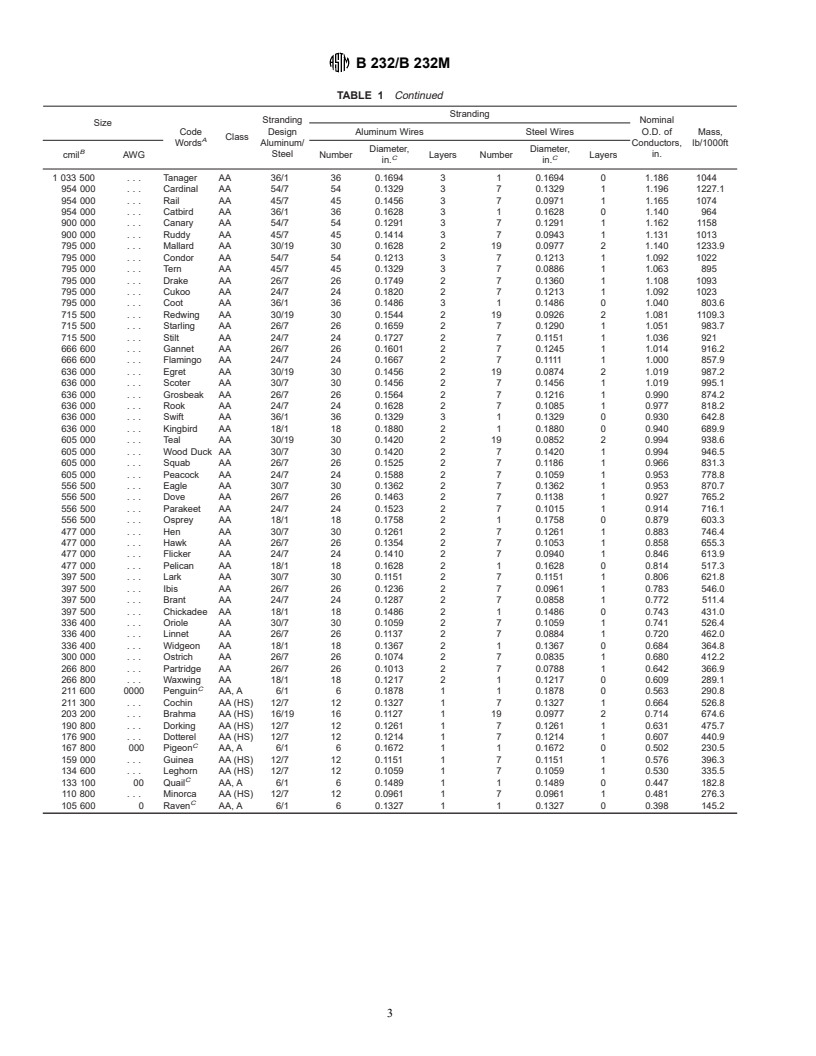

TABLE 1 Construction Requirements of Aluminum Conductors, Steel Reinforced (ACSR)

Stranding

Stranding Nominal

Size

Code Design Aluminum Wires Steel Wires O.D. of Mass,

Class

A

Words Aluminum/ Conductors, lb/1000ft

Diameter, Diameter,

B

cmil AWG Steel Number Layers Number Layers in.

C C

in. in.

2 312 000 . . . Thrasher AA 76/19 76 0.1744 4 19 0.0814 2 1.802 2523

2 167 000 . . . Kiwi AA 72/7 72 0.1735 4 7 0.1157 1 1.735 2301

2 156 000 . . . Bluebird AA 84/19 84 0.1602 4 19 0.0961 2 1.762 2508

1 780 000 . . . Chukar AA 84/19 84 0.1456 4 19 0.0874 2 1.602 2072

1 590 000 . . . Falcon AA 54/19 54 0.1716 3 19 0.1030 2 1.545 2042

1 590 000 . . . Lapwing AA 45/7 45 0.1880 3 7 0.1253 1 1.504 1790

1 510 000 . . . Parrot AA 54/19 54 0.1672 3 19 0.1003 2 1.505 1938

1 510 000 . . . Nuthatch AA 45/7 45 0.1832 3 7 0.1221 1 1.466 1700

1 431 000 . . . Plover AA 54/19 54 0.1628 3 19 0.0977 2 1.465 1838

1 431 000 . . . Bobolink AA 45/7 45 0.1783 3 7 0.1189 1 1.427 1611

1 351 000 . . . Martin AA 54/19 54 0.1582 3 19 0.0949 2 1.424 1735

1 351 000 . . . Dipper AA 45/7 45 0.1733 3 7 0.1155 1 1.386 1521

1 272 000 . . . Pheasant AA 54/19 54 0.1535 3 19 0.0921 2 1.382 1634

1 272 000 . . . Bittern AA 45/7 45 0.1681 3 7 0.1121 1 1.345 1432

1 272 000 . . . Skylark AA 36/1 36 0.1880 3 1 0.1880 0 1.316 1286

1 192 500 . . . Grackle AA 54/19 54 0.1486 3 19 0.0892 2 1.338 1531

1 192 500 . . . Bunting AA 45/7 45 0.1628 3 7 0.1085 1 1.302 1342

1 113 000 . . . Finch AA 54/19 54 0.1436 3 19 0.0862 2 1.293 1430

1 113 000 . . . Bluejay AA 45/7 45 0.1573 3 7 0.1049 1 1.259 1254

1 033 500 . . . Curlew AA 54/7 54 0.1383 3 7 0.1383 1 1.245 1329

1 033 500 . . . Ortolan AA 45/7 45 0.1515 3 7 0.1010 1 1.212 1163

B 232/B 232M

TABLE 1 Continued

Stranding

Stranding Nominal

Size

Code Design Aluminum Wires Steel Wires O.D. of Mass,

Class

A

Words Aluminum/ Conductors, lb/1000ft

Diameter, Diameter,

B

Steel in.

cmil AWG Number Layers Number Layers

C C

in. in.

1 033 500 . . . Tanager AA 36/1 36 0.1694 3 1 0.1694 0 1.186 1044

954 000 . . . Cardinal AA 54/7 54 0.1329 3 7 0.1329 1 1.196 1227.1

954 000 . . . Rail AA 45/7 45 0.1456 3 7 0.0971 1 1.165 1074

954 000 . . . Catbird AA 36/1 36 0.1628 3 1 0.1628 0 1.140 964

900 000 . . . Canary AA 54/7 54 0.1291 3 7 0.1291 1 1.162 1158

900 000 . . . Ruddy AA 45/7 45 0.1414 3 7 0.0943 1 1.131 1013

795 000 . . . Mallard AA 30/19 30 0.1628 2 19 0.0977 2 1.140 1233.9

795 000 . . . Condor AA 54/7 54 0.1213 3 7 0.1213 1 1.092 1022

795 000 . . . Tern AA 45/7 45 0.1329 3 7 0.0886 1 1.063 895

795 000 . . . Drake AA 26/7 26 0.1749 2 7 0.1360 1 1.108 1093

795 000 . . . Cukoo AA 24/7 24 0.1820 2 7 0.1213 1 1.092 1023

795 000 . . . Coot AA 36/1 36 0.1486 3 1 0.1486 0 1.040 803.6

715 500 . . . Redwing AA 30/19 30 0.1544 2 19 0.0926 2 1.081 1109.3

715 500 . . . Starling AA 26/7 26 0.1659 2 7 0.1290 1 1.051 983.7

715 500 . . . Stilt AA 24/7 24 0.1727 2 7 0.1151 1 1.036 921

666 600 . . . Gannet AA 26/7 26 0.1601 2 7 0.1245 1 1.014 916.2

666 600 . . . Flamingo AA 24/7 24 0.1667 2 7 0.1111 1 1.000 857.9

636 000 . . . Egret AA 30/19 30 0.1456 2 19 0.0874 2 1.019 987.2

636 000 . . . Scoter AA 30/7 30 0.1456 2 7 0.1456 1 1.019 995.1

636 000 . . . Grosbeak AA 26/7 26 0.1564 2 7 0.1216 1 0.990 874.2

636 000 . . . Rook AA 24/7 24 0.1628 2 7 0.1085 1 0.977 818.2

636 000 . . . Swift AA 36/1 36 0.1329 3 1 0.1329 0 0.930 642.8

636 000 . . . Kingbird AA 18/1 18 0.1880 2 1 0.1880 0 0.940 689.9

605 000 . . . Teal AA 30/19 30 0.1420 2 19 0.0852 2 0.994 938.6

605 000 . . . Wood Duck AA 30/7 30 0.1420 2 7 0.1420 1 0.994 946.5

605 000 . . . Squab AA 26/7 26 0.1525 2 7 0.1186 1 0.966 831.3

605 000 . . . Peacock AA 24/7 24 0.1588 2 7 0.1059 1 0.953 778.8

556 500 . . . Eagle AA 30/7 30 0.1362 2 7 0.1362 1 0.953 870.7

556 500 . . . Dove AA 26/7 26 0.1463 2 7 0.1138 1 0.927 765.2

556 500 . . . Parakeet AA 24/7 24 0.1523 2 7 0.1015 1 0.914 716.1

556 500 . . . Osprey AA 18/1 18 0.1758 2 1 0.1758 0 0.879 603.3

477 000 . . . Hen AA 30/7 30 0.1261 2 7 0.1261 1 0.883 746.4

477 000 . . . Hawk AA 26/7 26 0.1354 2 7 0.1053 1 0.858 655.3

477 000 . . . Flicker AA 24/7 24 0.1410 2 7 0.0940 1 0.846 613.9

477 000 . . . Pelican AA 18/1 18 0.1628 2 1 0.1628 0 0.814 517.3

397 500 . . . Lark AA 30/7 30 0.1151 2 7 0.1151 1 0.806 621.8

397 500 . . . Ibis AA 26/7 26 0.1236 2 7 0.0961 1 0.783 546.0

397 500 . . . Brant AA 24/7 24 0.1287 2 7 0.0858 1 0.772 511.4

397 500 . . . Chickadee AA 18/1 18 0.1486 2 1 0.1486 0 0.743 431.0

336 400 . . . Oriole AA 30/7 30 0.1059 2 7 0.1059 1 0.741 526.4

336 400 . . . Linnet AA 26/7 26 0.1137 2 7 0.0884 1 0.720 462.0

336 400 . . . Widgeon AA 18/1 18 0.1367 2 1 0.1367 0 0.684 364.8

300 000 . . . Ostrich AA 26/7 26 0.1074 2 7 0.0835 1 0.680 412.2

266 800 . . . Partridge AA 26/7 26 0.1013 2 7 0.0788 1 0.642 366.9

266 800 . . . Waxwing AA 18/1 18 0.1217 2 1 0.1217 0 0.609 289.1

C

211 600 0000 Penguin AA, A 6/1 6 0.1878 1 1 0.1878 0 0.563 290.8

211 300 . . . Cochin AA (HS) 12/7 12 0.1327 1 7 0.1327 1 0.664 526.8

203 200 . . . Brahma AA (HS) 16/19 16 0.1127 1 19 0.0977 2 0.714 674.6

190 800 . . . Dorking AA (HS) 12/7 12 0.1261 1 7 0.1261 1 0.631 475.7

176 900 . . . Dotterel AA (HS) 12/7 12 0.1214 1 7 0.1214 1 0.607 440.9

C

167 800 000 Pigeon AA, A 6/1 6 0.1672 1 1 0.1672 0 0.502 230.5

159 000 . . . Guinea AA (HS) 12/7 12 0.1151 1 7 0.1151 1 0.576 396.3

134 600 . . . Leghorn AA (HS) 12/7 12 0.1059 1 7 0.1059 1 0.530 335.5

C

133 100 00 Quail AA, A 6/1 6 0.1489 1 1 0.1489 0 0.447 182.8

110 800 . . . Minorca AA (HS) 12/7 12 0.0961 1 7 0.0961 1 0.481 276.3

C

105 600 0 Raven AA, A 6/1 6 0.1327 1 1 0.1327 0 0.398 145.2

B 232/B 232M

TABLE 1 Continued

Stranding

Stranding Nominal

Size

Code Design Aluminum Wires Steel Wires O.D. of Mass,

Class

A

Words Aluminum/ Conductors, lb/1000ft

Diameter, Diameter,

B

Steel in.

cmil AWG Number Layers Number Layers

C C

in. in.

101 800 . . . Petrel AA (HS) 12/7 12 0.0921 1 7 0.0921 1 0.461 253.8

C

83 690 1 Robin AA, A 6/1 6 0.1181 1 1 0.1181 0 0.354 115.0

80 000 . . . Grouse AA (HS) 8/1 8 0.1000 1 1 0.1670 0 0.367 148.8

C

66 360 2 Sparate AA, A 7/1 7 0.0974 1 1 0.1299 0 0.325 106.63

C

66 360 2 Sparrow AA, A 6/1 6 0.1052 1 1 0.1052 0 0.316 91.2

C

41 740 4 Swanate AA, A 7/1 7 0.0772 1 1 0.1029 0 0.257 66.95

C

41 740 4 Swan AA, A 6/1 6 0.0834 1 1 0.0834 0 0.250 57.35

33 090 5 . . . A 6/1 6 0.0743 1 1 0.0743 0 0.223 45.51

C

26 240 6 Turkey AA, A 6/1 6 0.0661 1 1 0.0661 0 0.198 36.02

A

Code words shown in this column are obtained from, “Publication 50, Code Words for Overhead Aluminum Electrical Conductors”, by the Aluminum Association. They

are provided here for information only.

B

Conversion factors:

1 cmil 5 5.067 E – 0.4 mm

1 in. 5 2.54E+01mm

1 lb/1000ft 5 1.488E+00 kg/km

1ft 5 3.048E–01m

1lb 5 4.536E–01kg

1 lbf 5 4.448 E – 03LN

C

These code names apply to Class AA Bare Aluminum Conductors, Steel Reinforced (ACSR) as shown above. They do not apply to Class A products shown in the

above table.

5.1.3 Number of wires, aluminum and steel (see Tables 1-5), 5.1.10 Special package marking, if required (see 17.4).

5.1.4 Type of steel core wire and type and area density (if

6. Requirement for Wires

applicable) of coating (see 6.2),

5.1.5 Direction of lay of outer layer of aluminum wires if 6.1 Before stranding, the aluminum wire used shall meet the

other than right-hand (see 8.2), requirements of Specification B 230/B 230M.

5.1.6 Special tension test, if desired (see 15.3), 6.2 Before stranding, the steel core wire used shall meet the

5.1.7 Place of inspection (Section 16), requirements of Specification B 341/B 341M, B 498/B 498M,

5.1.8 Package size and type (see 17.1), B 606, B 802/B 802M, or B 803, whichever is applicable.

5.1.9 Heavy wood lagging, if required (see 17.3), and

TABLE 2 Construction Requirements—Aluminum Conductors, Steel Reinforced (ACSR)

Stranding Nominal

Outside

Size,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.