ASTM F421-15(2021)

(Test Method)Standard Test Method for Measuring Groove and Void Depth in Passenger Car Tires

Standard Test Method for Measuring Groove and Void Depth in Passenger Car Tires

SIGNIFICANCE AND USE

5.1 The groove (void) depth affects the tire’s ability to develop tractive forces in various operating environments. Groove (void) depth also defines the state of wear of a tire and is used in the determination of the rate of wear.

SCOPE

1.1 This test method describes standard procedures for measuring the groove and void depth in passenger car tires.

1.2 Any mechanical, optical, or electronic device capable of measuring groove (void) depth can be used, but only the contact methodology is described here. Noncontact methodology is beyond the scope of this test method.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F421 − 15 (Reapproved 2021)

Standard Test Method for

Measuring Groove and Void Depth in Passenger Car Tires

ThisstandardisissuedunderthefixeddesignationF421;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1 circumferential line, n— on a tire, any real or imagi-

nary circle on the surface of a tire, lying in a plane that is

1.1 This test method describes standard procedures for

perpendicular to the spin axis. F538

measuring the groove and void depth in passenger car tires.

3.1.2 element, n—an isolated (totally bounded by void)

1.2 Any mechanical, optical, or electronic device capable of

projection. F538

measuring groove (void) depth can be used, but only the

3.1.3 groove, n—a void that is relatively narrow compared

contact methodology is described here. Noncontact methodol-

to its length. F538

ogy is beyond the scope of this test method.

3.1.4 groove average depth, [L], n—the average of all tire

1.3 The values stated in SI units are to be regarded as the

groove depth measurements in a single groove. F538

standard. The values given in parentheses are for information

3.1.5 groove (void) depth, [L], n—a measurement of the

only.

perpendiculardistancefromarealorcalculatedreferenceplane

1.4 This standard does not purport to address all of the

defined by edges of two adjacent ribs (lugs) to the lowest point

safety concerns, if any, associated with its use. It is the

of contact in the groove (void).

responsibility of the user of this standard to establish appro-

3.1.5.1 Discussion—The reader is cautioned that the probe

priate safety, health, and environmental practices and deter-

tip used for the depth measurement must have a sufficiently

mine the applicability of regulatory limitations prior to use.

small cross-section compared to the width of the void being

1.5 This international standard was developed in accor-

measured. The probe must be able to reach the bottom of the

dance with internationally recognized principles on standard-

void without contacting the tread elements that form the sides

ization established in the Decision on Principles for the

of the void.

Development of International Standards, Guides and Recom-

Special consideration should be given to measuring sipes.

mendations issued by the World Trade Organization Technical

(See definition in Terminology F538.) Since the sipe is

Barriers to Trade (TBT) Committee.

substantially narrower than a major groove, a very small

2. Referenced Documents diameter probe tip must be used to achieve an accurate

measurement of sipe depth. F538

2.1 ASTM Standards:

3.1.6 irregular wear, n—a type of treadwear characterized

D4483 Practice for Evaluating Precision for Test Method

by substantial variations of tread loss both from projection to

Standards in the Rubber and Carbon Black Manufacturing

projection and frequently from point to point on a given

Industries

projection. F538

F538 Terminology Relating to the Characteristics and Per-

formance of Tires

3.1.7 projection, n—a pavement contacting area of the tread

F1426 Practice for Identifying Tire Tread Surface Irregular

band, bounded by void. F538

Wear Patterns Resulting from Tire Use

3.1.8 rib, n—a continuous circumferential projection. F538

3. Terminology 3.1.9 treadwear indicator, n—a raised portion of a groove

bottom or void bottom that is molded in a tire at fairly regular

3.1 Definitions:

intervals around the circumference to provide a visual indica-

tion that most of a tread has been worn away. F538

This test method is under the jurisdiction of ASTM Committee F09 on Tires

and is the direct responsibility of Subcommittee F09.30 on Laboratory (Non-

3.1.10 uniform wear, n—a type of treadwear characterized

Vehicular) Testing.

by equal tread loss both from projection to projection and from

Current edition approved April 1, 2021. Published April 2021. Originally

point to point on a given projection, resulting in a smooth

approved in 1975. Last previous edition approved in 2015 as F421 – 15. DOI:

appearance of all parts of the tread pattern. F538

10.1520/F0421-15R21.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3.1.11 void, n—a volume (in the tread band) defined by the

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

lack of rubber, the depth dimension of this volume may vary

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. from point to point in (on) the tread band. F538

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F421 − 15 (2021)

4. Summary of Test Method 6.1.6 The accuracy shall be to within 0.025 mm (0.001 in.)

for distances up to 12.7 mm (0.5 in.) and to within 0.125 mm

4.1 This test method gives the detailed procedures and the

(0.005 in.) for distances from 12.7 to 25 mm (0.5 to 1 in.).

needed precautions for the measurement of the groove or void

6.1.7 The overall variability for a series of repeated mea-

depth of the tread pattern in a tire. Calculations for various

surements on the flat surface shall be within 620 % of one

types of average groove or void depths are given in addition to

division.

the required nomenclature for effective communication of the

6.1.8 Calibration shall be made using gauge blocks with

groove or void measurement results.

dimensions traceable to the National Institute of Standards and

Technology primary standard.

5. Significance and Use

5.1 The groove (void) depth affects the tire’s ability to

7. Preparation

develop tractive forces in various operating environments.

7.1 Gauge Zero Adjustment—Place the foot of the gauge

Groove (void) depth also defines the state of wear of a tire and

against a non-deformable flat surface such as a glass plate and

is used in the determination of the rate of wear.

adjust dial to zero.

6. Apparatus

7.2 Preparation of Tire:

6.1 Gauge:

7.2.1 Mount the tire on an approved width rim and inflate to

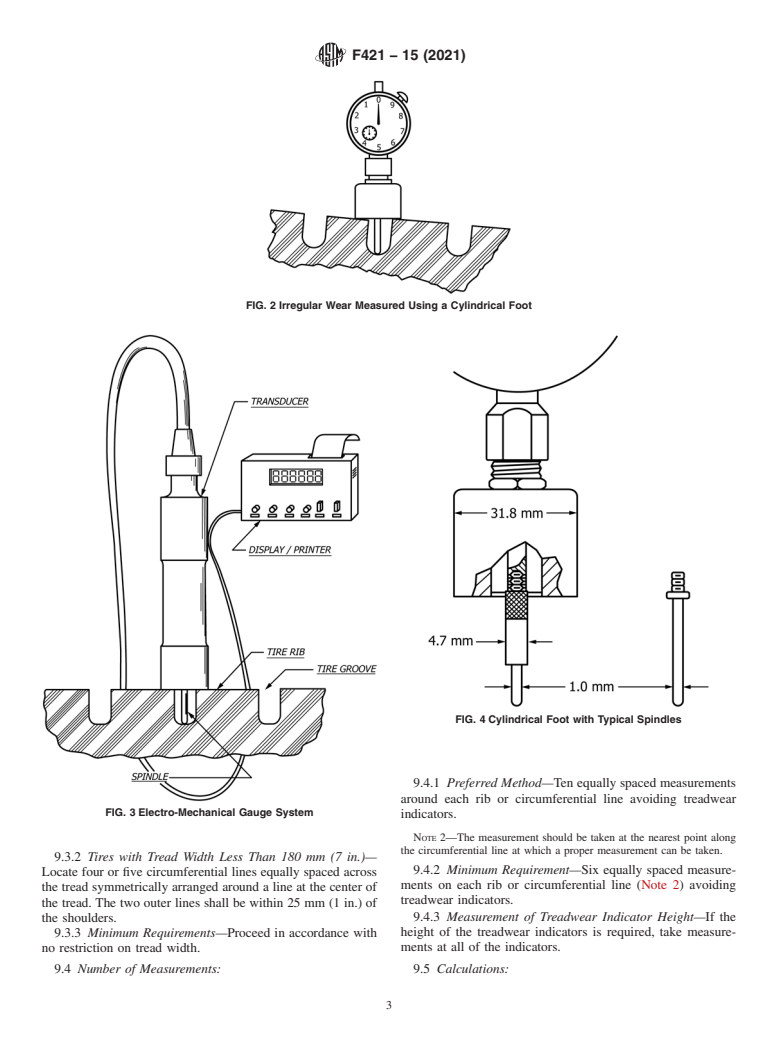

6.1.1 The apparatus shall consist of a mechanical or electro-

the required pressure.

mechanical depth gauge fitted with a foot through which a

7.2.2 The tire shall be in temperature equilibrium with the

spindle passes. The foot may have any of a variety of shapes,

environment in which it is measured.

including but not limited to cylindrical, semi-cylindrical, and

NOTE 1—For purposes of this test method, temperature equilibrium

rectangular. The reference surface of the foot shall be made of

exists if the gauge pressure remains within 7 kPa (1 psi) of the required

a non-deformable material, ground planar and perpendicular to

inflation pressure during the complete measurement process.

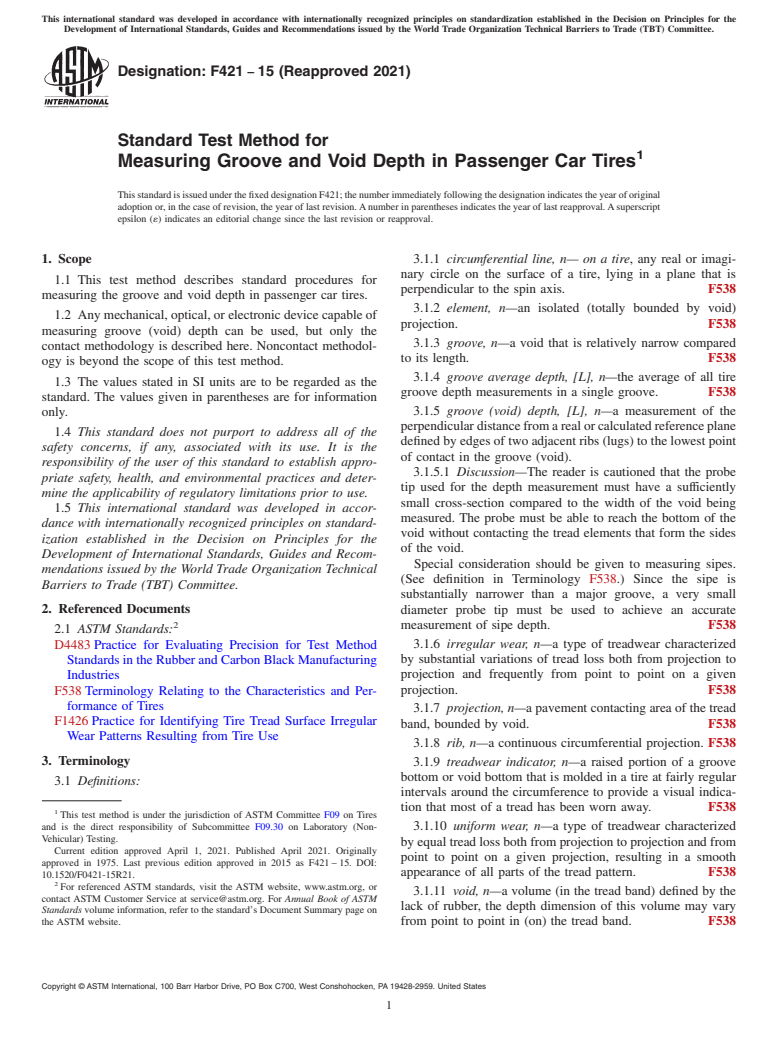

the gauge spindle. Examples of mechanical gauges and typical

7.2.3 The tire must be dry and free of any foreign material

available gauge feet are illustrated in Figs. 1 and 2. A typical

that would interfere with accurate measurement.

electro-mechanical gauge system is illustrated in Fig. 3.

7.2.4 Avoid the rubber vents on the t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.