ASTM F694-02

(Test Method)Standard Test Method for Heel-Attaching Strength of Women's Shoes

Standard Test Method for Heel-Attaching Strength of Women's Shoes

SCOPE

1.1 This test method covers the determination of heel attachment strength on women's and misses' shoes through application of a static load to the heel. Shoe heels may be made of various materials, including wood, plastic, leather, or rubber. The heels may be attached to the shoe body with nails, screws, staples, cement, or a combination of these.

1.2 This test method is applicable for testing heel heights 11/2 in. (38 mm) and higher. (Heel heights are manufactured in 1/8-in. increments.) This testing is applicable for front or back of heel.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F694–02

Standard Test Method for

1

Heel-Attaching Strength of Women’s Shoes

This standard is issued under the fixed designation F694; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (ε) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Summary of Test Method

1.1 This test method covers the determination of heel 3.1 A shoe is mounted vertically on a mounting form and

attachment strength on women’s and misses’ shoes through secured with holding clamps. Pressure is applied to the shoe

applicationofastaticloadtotheheel.Shoeheelsmaybemade heel by means of a vertical piston and a hand-operated

ofvariousmaterials,includingwood,plastic,leather,orrubber. hydraulic pump. A hydraulic pressure gage indicates the

The heels may be attached to the shoe body with nails, screws, amount of pressure in pounds-force (or newtons) exerted

staples, cement, or a combination of these. against the heel. This pressure, when multiplied by the lever

1.2 This test method is applicable for testing heel heights arm through which it is applied, gives the torque value for

1

1 ⁄2 in. (38 mm) and higher. (Heel heights are manufactured in heel-attaching strength.

1

⁄8-in. increments.) This testing is applicable for front or back

4. Significance

of heel.

4.1 Heel-attaching strength is an important factor in the

2. Terminology

design of a safe and comfortable shoe that adequately supports

2.1 Definitions: the foot.

2.1.1 heel breast, n—theforwardfaceoftheheel.Itisoften

5. Apparatus

concave towards the shank.

3

2.1.2 insole, n—that part of the shoe which is between the 5.1 Self-Contained Device, consisting of a hand-operated

hydraulicpump,apiston,apressuregage,andasuitablemount

foot and the outsole, and to which the upper is fastened during

manufacture. It may or may not be covered on the foot side by with security clamps to hold the test specimen rigidly in

position as sketched in Fig. 1 and Fig. 2.

an aesthetic material referred to as a socklining.

2.1.3 outsole, n—the bottom sole of the shoe, the surface of

2

NOTE 1—The area of the piston head on this tester is 0.9968 in. (6.43

which is exposed to wear. 2 2 2

cm ). This is sufficiently close enough to 1.000 in. (6.43 cm ) to permit

2.1.4 pricker points, n—in testing footwear, a modification

a direct gage reading of pounds-force (or newtons) exerted on the heel.

1

ofthefootforminwhichneedlepointsofsteel ⁄8in.(3.2mm)

6. Sampling

long are used to prevent vertical movement of the test

specimen.

6.1 Tests should be made on each new style shoe, and on

2.1.5 shank, n—the steel or wood piece inserted in the arch any shoe where the construction method or material is

of the shoe for reinforcement.

changed,suchaslengthofnail,insolematerial,nailingpattern,

2.1.6 shankboard, n—the back part of the insole which is etc.

fabricated from a firm fibreboard. It is contoured to the arch of

6.2 Conduct routine testing to determine if adequate heel-

the foot for support. attaching strength is being maintained.

2.1.7 top lift, n—thetoporouterlayerorwearingsurfaceof

6.3 Perform random testing on a sufficient number of shoes

leather, rubber, plastic, or composition on the heel of a shoe. from production or from stock to give reliable results.

2.1.8 For definitions of other terms relating to footwear,

2

7. Preparation of Apparatus and Test Specimens

refer to the Footwear Products Glossary.

7.1 Temporarily mount the test specimen on the shoe-

mounting form.

1

This method is under the jurisdiction ofASTM Committee F13 on Safety and

Traction for Footwear and is the direct responsibility of Subcommittee F13.20 on

Construction.

Current edition approved July 10, 2002. Published August 2002. Originally

published as F694–80. Discontinued January 2001 and reinstated as F694–02.

2 3

Manual on Standards for the Footwear Industry, available from Footwear AsuitabledeviceisavailablefromCreativity,Inc.,58RantoulSt.,Beverly,MA

Products Assn., 1611 N. Kent St., Arlington, VA 22209. 01915 and Whitely Industries, Inc., 14 Everberg Road, Woburn, MA 01801.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F694–02

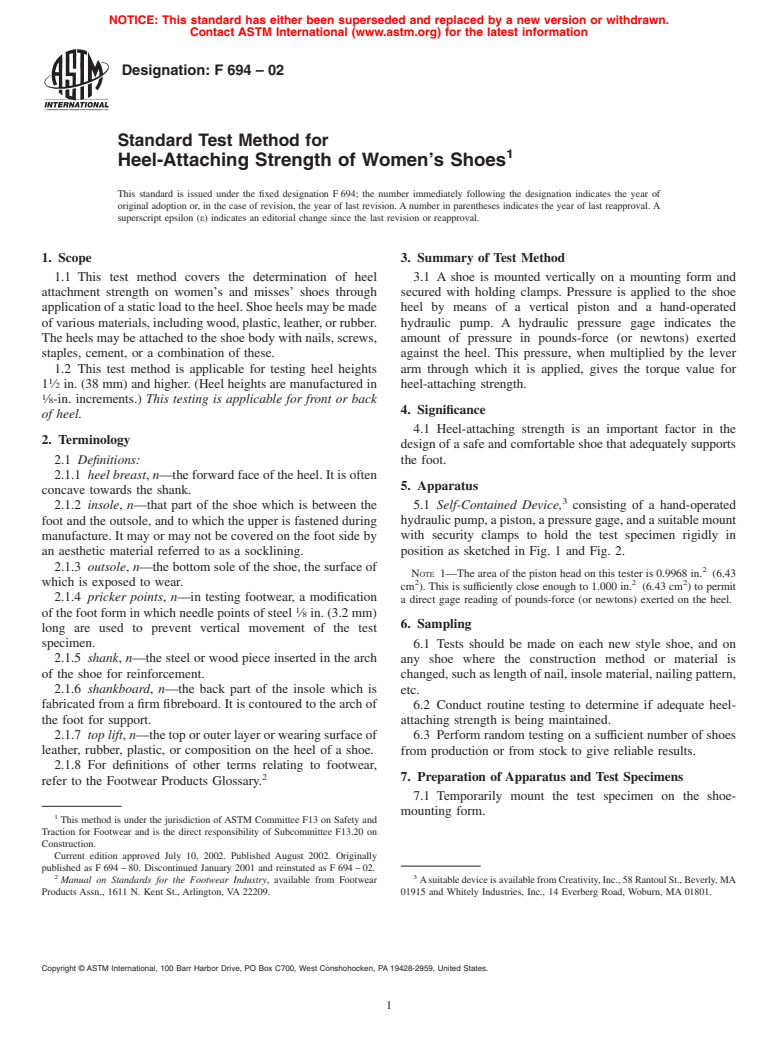

a. Upper clamp operating screw h. Piston

b. Upper clamp operating arm j. Pump handle

c. Upper clamp k. Pressure control valve

d. Shoe mounting form l. Reservoir

e. Shoe holding points m. Machine base

f. Shoe heel n. Machine base support

g. Shoe securing clamp o. Pressure gage with maximum reading pointer

FIG. 1 Test Apparatus (Front View)

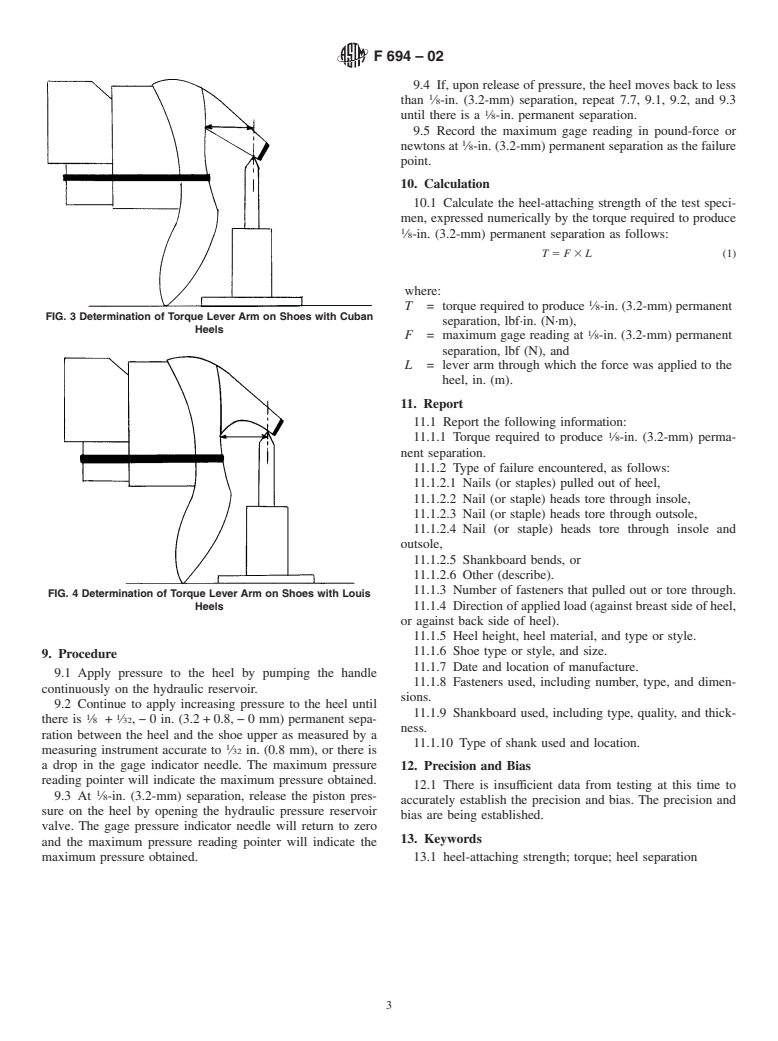

FIG. 2 Test Apparatus (End View)

7.2 Positionpressurepistononthetestingapparatussoasto 7.5.2 For o

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.