ASTM D7351-07

(Test Method)Standard Test Method for Determination of Sediment Retention Device Effectiveness in Sheet Flow Applications

Standard Test Method for Determination of Sediment Retention Device Effectiveness in Sheet Flow Applications

SIGNIFICANCE AND USE

This test method quantifies the ability of a sediment retention device (SRD) to retain eroded sediments caused by sheet flowing water under full-scale conditions. This test method may also assist in identifying physical attributes of SRDs that contribute to their erosion control performance.

The effectiveness of SRDs is installation dependent. Thus, replicating field installation techniques is an important aspect of this test method. This test method is full-scale and therefore, appropriate as an indication of product performance, for general comparison of product capabilities, and for assessment of product installation techniques.

Note 1—Test Method D 5141 is an alternate test method for evaluating sediment retention device effectiveness, if it is not necessary to simulate field installation conditions.

Note 2—The quality of the result produced by this standard is dependent on the competence of the personnel performing it, and the suitability of the equipment and facilities used. Agencies that meet the criteria of Practice D 3740 are generally considered capable of competent and objective testing/sampling/inspection/etc. Users of this standard are cautioned that compliance with Practice D 3740 does not in itself assure reliable results. Reliable results depend on many factors: Practice D 3740 provides a means of evaluating some of those factors.

SCOPE

1.1 This test method establishes the guidelines, requirements and procedures for evaluating the ability of Sediment Retention Devices (SRDs) to retain sediment when exposed to sediment-laden water "sheet" flows.

1.2 This test method is applicable to the use of an SRD as a vertical permeable interceptor designed to remove suspended soil from overland, nonconcentrated water flow. The function of an SRD is to trap and allow settlement of soil particles from sediment laden water. The purpose is to reduce the transport of eroded soil from a disturbed site by water runoff.

1.3 The test method presented herein is intended to indicate representative performance and is not necessarily adequate for all purposes in view of the wide variety of possible sediments and performance objectives.

1.4 The values stated in SI units are to be regarded as standard. The inch-pound values given in parentheses are provided for information purposes only.

1.5 All observed and calculated values shall conform to the guidelines for significant digits and rounding established in Practice D 6026.

1.5.1 The procedures used to specify how data are collected/recorded and calculated in this standard are regarded as the industry standard. In addition, they are representative of the significant digits that should generally be retained. The procedures used do not consider material variation, purpose for obtaining the data, special purpose studies, or any consideration for the users objectives; and it is common practice to increase or reduce significant digits of reported data to commensurate with these considerations. It is beyond the scope of this standard to consider significant digits used in analysis methods for engineering design.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D7351 −07

StandardTest Method for

Determination of Sediment Retention Device Effectiveness

in Sheet Flow Applications

This standard is issued under the fixed designation D7351; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

1.1 This test method establishes the guidelines, require-

ments and procedures for evaluating the ability of Sediment

2. Referenced Documents

Retention Devices (SRDs) to retain sediment when exposed to

2.1 ASTM Standards:

sediment-laden water “sheet” flows.

D653 Terminology Relating to Soil, Rock, and Contained

1.2 This test method is applicable to the use of an SRD as a

Fluids

vertical permeable interceptor designed to remove suspended

D698 Test Methods for Laboratory Compaction Character-

soil from overland, nonconcentrated water flow. The function

istics of Soil Using Standard Effort (12 400 ft-lbf/ft (600

of an SRD is to trap and allow settlement of soil particles from

kN-m/m ))

sediment laden water. The purpose is to reduce the transport of

D3740 Practice for Minimum Requirements for Agencies

eroded soil from a disturbed site by water runoff.

Engaged in Testing and/or Inspection of Soil and Rock as

1.3 The test method presented herein is intended to indicate

Used in Engineering Design and Construction

representative performance and is not necessarily adequate for

D5141 TestMethodforDeterminingFilteringEfficiencyand

all purposes in view of the wide variety of possible sediments

Flow Rate of the Filtration Component of a Sediment

and performance objectives.

Retention Device

D6026 Practice for Using Significant Digits in Geotechnical

1.4 The values stated in SI units are to be regarded as

Data

standard. The inch-pound values given in parentheses are

provided for information purposes only.

3. Terminology

1.5 All observed and calculated values shall conform to the

3.1 For definitions of terms used in this test method, see

guidelines for significant digits and rounding established in

Terminology D653.

Practice D6026.

1.5.1 Theproceduresusedtospecifyhowdataarecollected/

4. Summary of Test Method

recorded and calculated in this standard are regarded as the

4.1 Sediment-laden water is allowed to “sheet flow” up to

industry standard. In addition, they are representative of the

and seep through, over, and/or under an installed sediment

significant digits that should generally be retained. The proce-

retention device (SRD). At a minimum, the amount (via water

dures used do not consider material variation, purpose for

and soil weight) of sediment-laden flow is measured both

obtaining the data, special purpose studies, or any consider-

upstream and downstream of the SRD.

ation for the user’s objectives; and it is common practice to

increase or reduce significant digits of reported data to com-

4.2 The measurement of sediment that passes through, over,

mensurate with these considerations. It is beyond the scope of

and/or under the SRD compared to the amount in the upstream

this standard to consider significant digits used in analysis

flow is used to quantify the effectiveness of the SRD in

3,4

methods for engineering design.

retaining sediments .

1.6 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

responsibility of the user of this standard to establish appro-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

1 3

ThistestmethodisunderthejurisdictionofASTMCommitteeD18onSoiland Sprague, C.J. (2004), “Testing the Effectiveness of Sediment Retention

Rock and is the direct responsibility of Subcommittee D18.25 on Erosion and Devices”, StormCon ‘04, Palm Desert, CA, (digital proceedings).

Sediment Control Technology. Sprague, C.J. and Carpenter, T. (2004), “A New Procedure for Testing the

Current edition approved May 1, 2007. Published June 2007. DOI: 10.1520/ Effectiveness of Sediment Retention Devices”, Conf. XXXV, International Erosion

D7351-07. Control Assoc., Philadelphia, pp. 265-275.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7351−07

5. Significance and Use soil type to be used for testing shall be loam with target grain

sizesandplasticityindexasshowninTable1,unlessotherwise

5.1 This test method quantifies the ability of a sediment

specified.

retention device (SRD) to retain eroded sediments caused by

6.1.4 A loader for moving the soil to the mixer—Afront-end

sheet flowing water under full-scale conditions. This test

loader of sufficient reach and capacity to dump a prescribed

method may also assist in identifying physical attributes of

amount of soil into the mixing tank.

SRDs that contribute to their erosion control performance.

6.1.5 A variable discharge apparatus from the mixer—A

5.2 The effectiveness of SRDs is installation dependent.

variable discharge apparatus from the mixer – A valve-

Thus, replicating field installation techniques is an important

controlled discharge hose that allows for controlled, uniform

aspect of this test method. This test method is full-scale and

discharge from the mixing tank.

therefore, appropriate as an indication of product performance,

6.1.6 Soil and water sampling equipment —Sampling jars

for general comparison of product capabilities, and for assess-

(at least 12 per test) for taking “grab” samples periodically

ment of product installation techniques.

during the test.

NOTE 1—Test Method D5141 is an alternate test method for evaluating

6.1.7 Excavating/compacting machinery for cleaning and

sediment retention device effectiveness, if it is not necessary to simulate

preparing the test area — Earthmoving and compacting

field installation conditions.

NOTE 2—The quality of the result produced by this standard is equipment is needed to prepare/replace the soil in the installa-

dependent on the competence of the personnel performing it, and the

tion zone.

suitability of the equipment and facilities used. Agencies that meet the

6.1.8 A scaled collection system adequate to handle the

criteria of Practice D3740 are generally considered capable of competent

released runoff— A tank mounted on scales of sufficient

and objective testing/sampling/inspection/etc. Users of this standard are

volume to collect all runoff passing the SRD.

cautioned that compliance with Practice D3740 does not in itself assure

reliable results. Reliable results depend on many factors: Practice D3740

6.2 Retention Area:

provides a means of evaluating some of those factors.

6.2.1 Anon-permeable, smooth, 3:1 slope surface (at least 5

6. Apparatus

m long) immediately below the mixer discharge shall be

provided to spread the discharge to the width of the retention

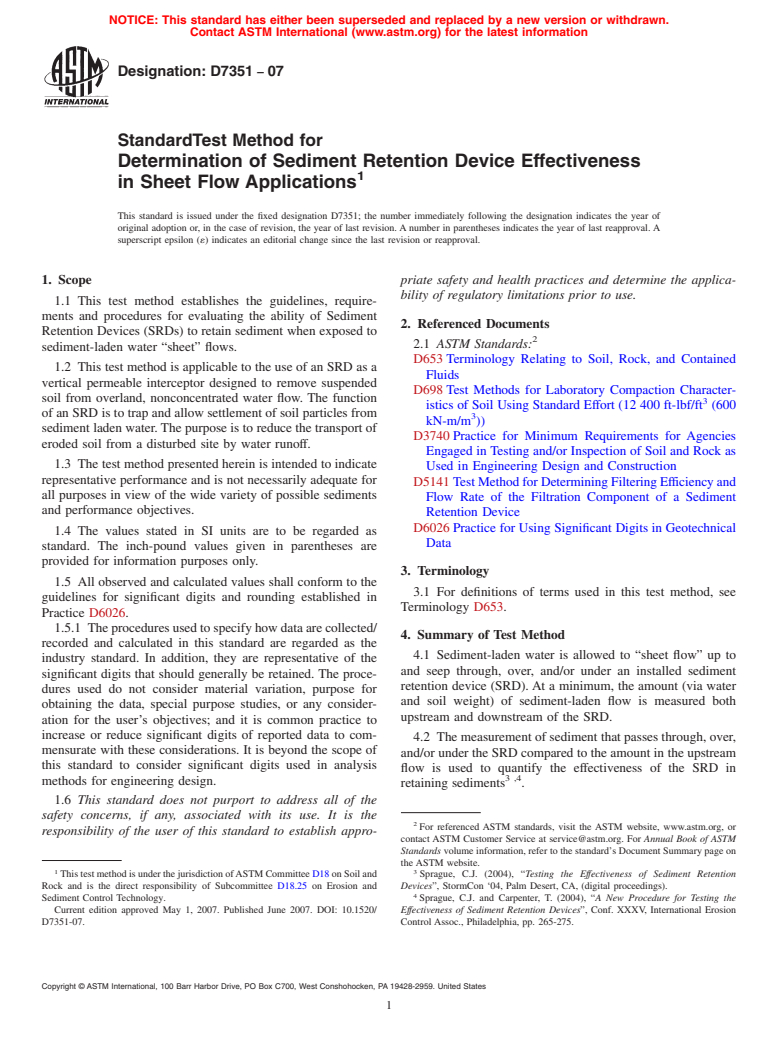

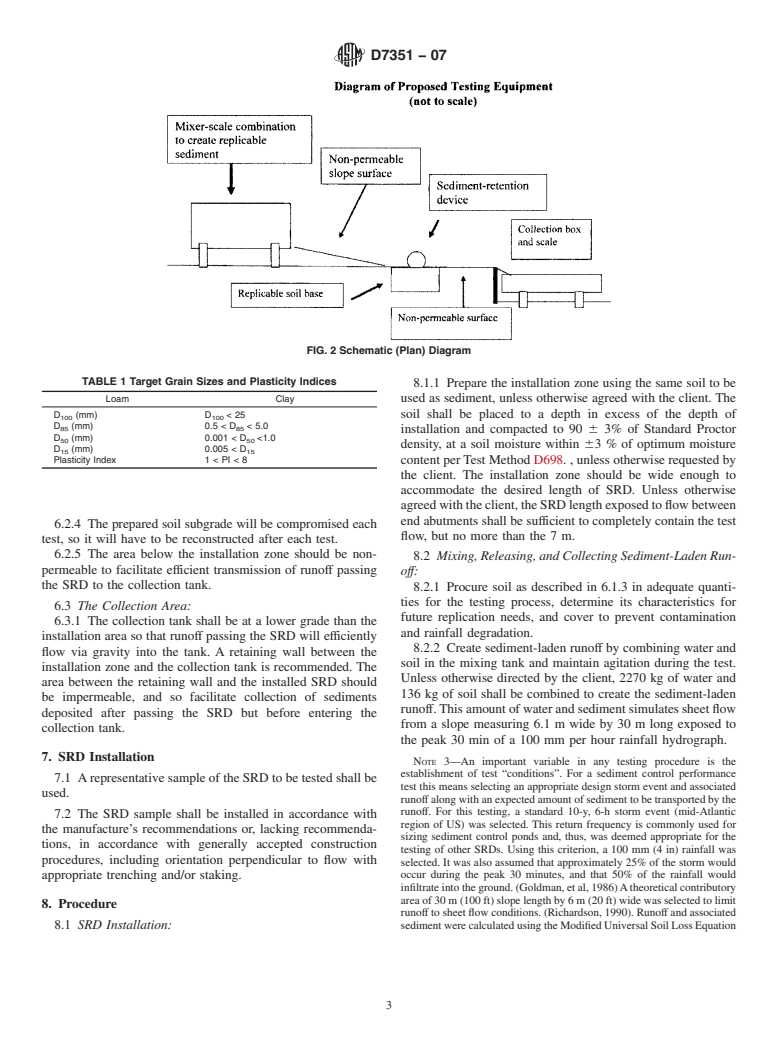

6.1 Equipment required. (See Fig. 1 and Fig. 2)

zone (length of the SRD installation) and to provide a retention

6.1.1 Combination mixing tank and scale—A tank with an

zone above the installation zone.

internal paddle mixer device mounted on scales capable of

6.2.2 An installation zone approximately 2 m wide by the

holding/weighing 4500 kg of sediment-laden water.

intended length of the SRD installation (typically 20 ft)

6.1.2 A clean water source and pumping equipment—A

comprised of prepared soil subgrade to allow full-scale instal-

sourceofwaterandassociatedpumpingequipmentsufficientto

lation of the SRD to be tested.

repeatedly fill the mixing tank in a timely manner.

6.1.3 A consistent soil stockpile —A stockpile of soil in 6.2.3 The center of the installed SRD should be placed in

sufficient quantity to both create sediment-laden water and to the center of the installation zone each time to replicate height

create/replace subgrade in the installation zone. The general of water as it relates to volume retained.

FIG. 1Profile Schematic

D7351−07

FIG. 2Schematic (Plan) Diagram

TABLE 1 Target Grain Sizes and Plasticity Indices

8.1.1 Prepare the installation zone using the same soil to be

Loam Clay used as sediment, unless otherwise agreed with the client. The

D (mm) D <25 soil shall be placed to a depth in excess of the depth of

100 100

D (mm) 0.5 < D <5.0

85 85

installation and compacted to 90 6 3% of Standard Proctor

D (mm) 0.001 < D <1.0

50 50

density, at a soil moisture within 63 % of optimum moisture

D (mm) 0.005 < D

15 15

Plasticity Index 1 < PI < 8 content perTest Method D698. , unless otherwise requested by

the client. The installation zone should be wide enough to

accommodate the desired length of SRD. Unless otherwise

agreedwiththeclient,theSRDlengthexposedtoflowbetween

end abutments shall be sufficient to completely contain the test

6.2.4 The prepared soil subgrade will be compromised each

flow, but no more than the 7 m.

test, so it will have to be reconstructed after each test.

6.2.5 The area below the installation zone should be non-

8.2 Mixing, Releasing, and Collecting Sediment-Laden Run-

permeable to facilitate efficient transmission of runoff passing

off:

the SRD to the collection tank.

8.2.1 Procure soil as described in 6.1.3 in adequate quanti-

ties for the testing process, determine its characteristics for

6.3 The Collection Area:

future replication needs, and cover to prevent contamination

6.3.1 The collection tank shall be at a lower grade than the

and rainfall degradation.

installation area so that runoff passing the SRD will efficiently

8.2.2 Create sediment-laden runoff by combining water and

flow via gravity into the tank. A retaining wall between the

soil in the mixing tank and maintain agitation during the test.

installation zone and the collection tank is recommended. The

Unless otherwise directed by the client, 2270 kg of water and

area between the retaining wall and the installed SRD should

136 kg of soil shall be combined to create the sediment-laden

be impermeable, and so facilitate collection of sediments

runoff.Thisamountofwaterandsedimentsimulatessheetflow

deposited after passing the SRD but before entering the

from a slope measuring 6.1 m wide by 30 m long exposed to

collection tank.

the peak 30 min of a 100 mm per hour rainfall hydrograph.

7. SRD Installation

NOTE 3—An important variable in any testing procedure is the

establishment of test “conditions”.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.