ASTM D402/D402M-14

(Test Method)Standard Test Method for Distillation of Cutback Asphalt (Withdrawn 2023)

Standard Test Method for Distillation of Cutback Asphalt (Withdrawn 2023)

SIGNIFICANCE AND USE

4.1 This procedure measures the amount of the more volatile constituents in cutback asphalt. The properties of the residue after distillation are not necessarily characteristic of the bitumen used in the original mixture, nor of the residue which may be left at any particular time after field application of the cutback asphalt. The presence of silicone in the cutback asphalt may affect the distillation residue by retarding the loss of volatile material after the residue has been poured into the residue container.

SCOPE

1.1 This test method covers a distillation test for cutback asphaltic (bituminous) products.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D402/D402M − 14 American Association State

Highway and Transportation Officials Standard

AASHTO No.: T78

27/74 (88)

Standard Test Method for

1

Distillation of Cutback Asphalt

This standard is issued under the fixed designation D402/D402M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Summary of Method

1.1 This test method covers a distillation test for cutback 3.1 Two hundred millilitres of the sample are distilled in a

asphalts. 500-mLflask,atacontrolledrate,toatemperatureintheliquid

of 360°C [680°F], and the volumes of distillate obtained at

1.2 The values stated in either SI units or inch-pound units

specified temperatures are measured. The residue from the

are to be regarded separately as standard. The values stated in

distillation, and also the distillate, may be tested as required.

each system may not be exact equivalents; therefore, each

system shall be used independently of the other. Combining

4. Significance and Use

values from the two systems may result in non-conformance

4.1 This procedure measures the amount of the more vola-

with the standard.

tile constituents in cutback asphalt. The properties of the

1.3 This standard does not purport to address all of the

residue after distillation are not necessarily characteristic of the

safety concerns, if any, associated with its use. It is the

bitumen used in the original mixture, nor of the residue which

responsibility of the user of this standard to establish appro-

may be left at any particular time after field application of the

priate safety and health practices and determine the applica-

cutbackasphalt.Thepresenceofsiliconeinthecutbackasphalt

bility of regulatory limitations prior to use.

may affect the distillation residue by retarding the loss of

volatile material after the residue has been poured into the

2. Referenced Documents

residue container.

2

2.1 ASTM Standards:

D86 Test Method for Distillation of Petroleum Products at

5. Apparatus

Atmospheric Pressure

5.1 Distillation Flask, 500-mL side-arm, having the dimen-

D370 Practice for Dehydration of Oil-Type Preservatives

sions shown in Fig. 1.

E1 Specification for ASTM Liquid-in-Glass Thermometers

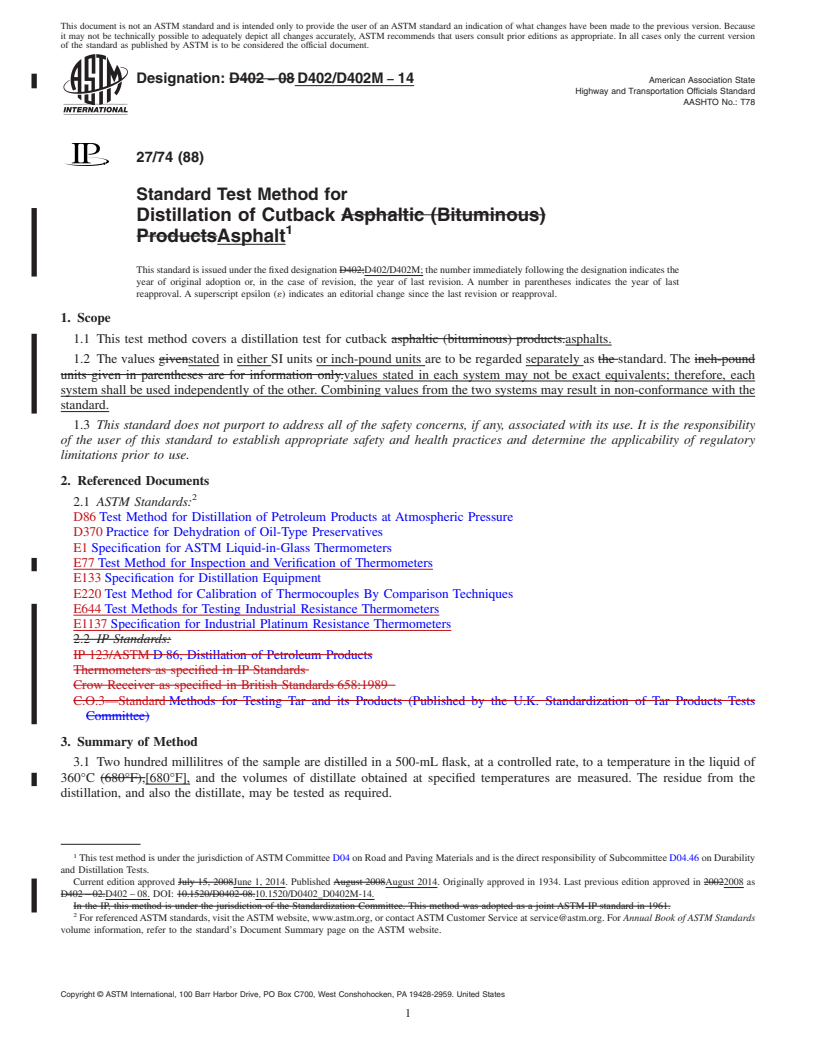

E77 Test Method for Inspection and Verification of Ther- 5.2 Condenser, standard glass-jacketed, of nominal jacket

mometers

length from 200 to 300 mm and overall tube length of 450 6

E133 Specification for Distillation Equipment 10 mm (see Fig. 3).

E220 Test Method for Calibration of Thermocouples By

5.3 Adapter, heavy-wall (1-mm) glass, with reinforced top,

Comparison Techniques

having an angle of approximately 105°. The inside diameter at

E644 Test Methods for Testing Industrial Resistance Ther-

the large end shall be approximately 18 mm, and at the small

mometers

end, not less than 5 mm. The lower surface of the adapter shall

E1137 SpecificationforIndustrialPlatinumResistanceTher-

be on a smooth descending curve from the larger end to the

mometers

smaller. The inside line of the outlet end shall be vertical, and

the outlet shall be cut or ground (not fire-polished) at an angle

of 45 6 5° to the inside line.

1

This test method is under the jurisdiction of ASTM Committee D04 on Road

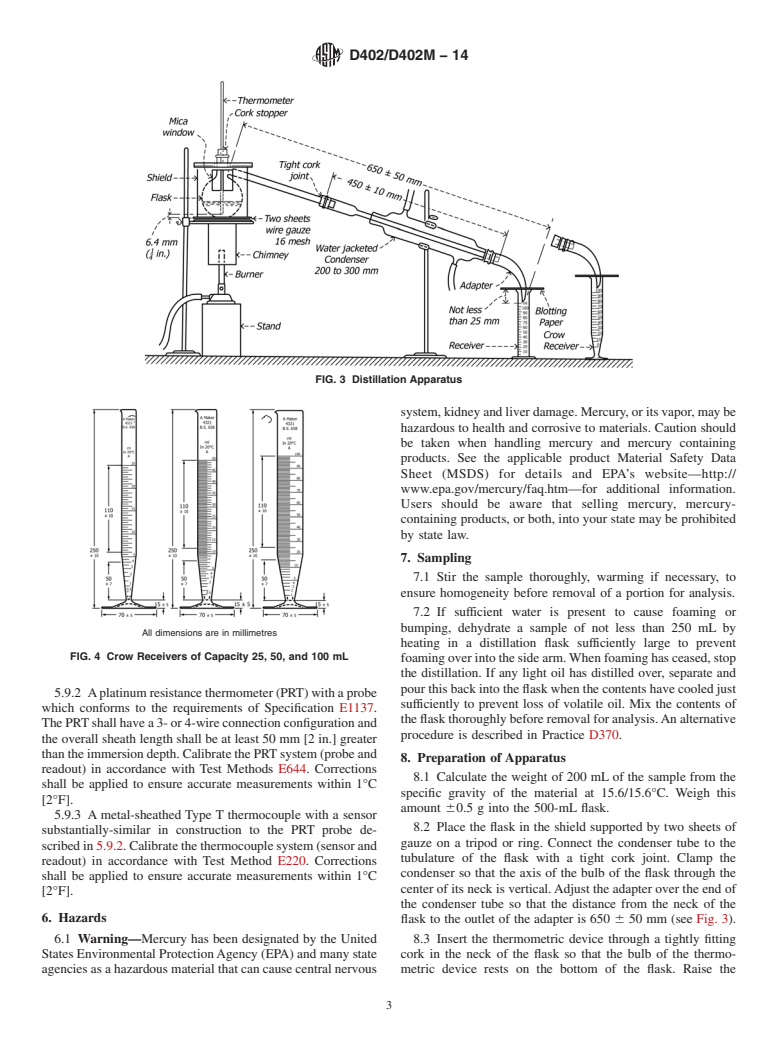

5.4 Shield, steel, lined with 3-mm fire proof insulation and

and Paving Materials and is the direct responsibility of Subcommittee D04.46 on

Durability and Distillation Tests.

fitted with transparent mica windows, of the form and dimen-

Current edition approved June 1, 2014. Published August 2014. Originally

sionsshowninFig.2,usedtoprotecttheflaskfromaircurrents

approved in 1934. Last previous edition approved in 2008 as D402 – 08. DOI:

and to reduce radiation. The cover (top) shall be made in two

10.1520/D0402_D0402M-14.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or parts of 6.4-mm fire proof insulation.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

2

5.5 Shield and Flask Support—Two 15-cm sheets of 16-

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. mesh Chromel wire gauze on a tripod or ring.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D402/D402M − 14

FIG. 1 Distillation Flask

FIG. 2 Shield

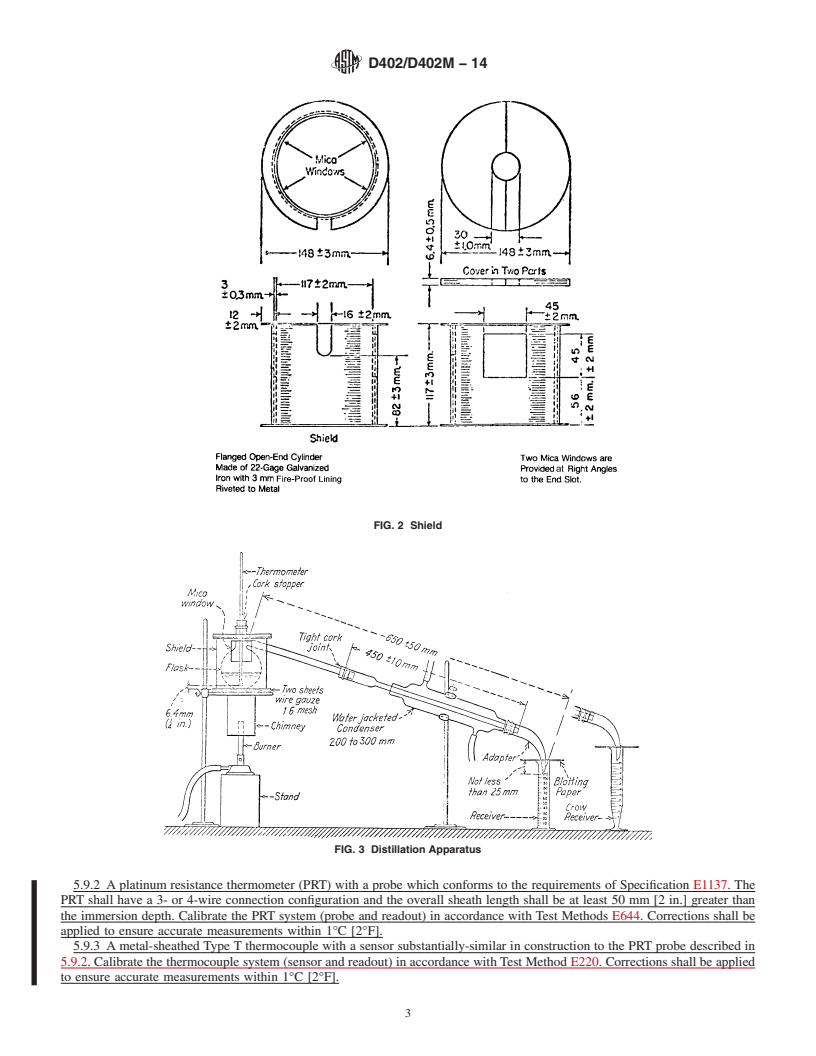

NOTE1—Receiversofsmallercapacityhaving0.1-mLdivisionsmaybe

5.6 Heat Source:

used when low volumes of total distillate are expected and the added

5.6.1 Adjustable Tirrill-type gas burner or equivalent.

accuracy required.

5.6.2 An electric heater equipped with a transformer ca

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D402 − 08 D402/D402M − 14 American Association State

Highway and Transportation Officials Standard

AASHTO No.: T78

27/74 (88)

Standard Test Method for

Distillation of Cutback Asphaltic (Bituminous)

1

ProductsAsphalt

This standard is issued under the fixed designation D402;D402/D402M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers a distillation test for cutback asphaltic (bituminous) products.asphalts.

1.2 The values givenstated in either SI units or inch-pound units are to be regarded separately as the standard. The inch-pound

units given in parentheses are for information only.values stated in each system may not be exact equivalents; therefore, each

system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the

standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D86 Test Method for Distillation of Petroleum Products at Atmospheric Pressure

D370 Practice for Dehydration of Oil-Type Preservatives

E1 Specification for ASTM Liquid-in-Glass Thermometers

E77 Test Method for Inspection and Verification of Thermometers

E133 Specification for Distillation Equipment

E220 Test Method for Calibration of Thermocouples By Comparison Techniques

E644 Test Methods for Testing Industrial Resistance Thermometers

E1137 Specification for Industrial Platinum Resistance Thermometers

2.2 IP Standards:

IP 123/ASTM D 86, Distillation of Petroleum Products

Thermometers as specified in IP Standards

Crow Receiver as specified in British Standards 658:1989

C.O.3—Standard Methods for Testing Tar and its Products (Published by the U.K. Standardization of Tar Products Tests

Committee)

3. Summary of Method

3.1 Two hundred millilitres of the sample are distilled in a 500-mL flask, at a controlled rate, to a temperature in the liquid of

360°C (680°F),[680°F], and the volumes of distillate obtained at specified temperatures are measured. The residue from the

distillation, and also the distillate, may be tested as required.

1

This test method is under the jurisdiction of ASTM Committee D04 on Road and Paving Materials and is the direct responsibility of Subcommittee D04.46 on Durability

and Distillation Tests.

Current edition approved July 15, 2008June 1, 2014. Published August 2008August 2014. Originally approved in 1934. Last previous edition approved in 20022008 as

D402 – 02.D402 – 08. DOI: 10.1520/D0402-08.10.1520/D0402_D0402M-14.

In the IP, this method is under the jurisdiction of the Standardization Committee. This method was adopted as a joint ASTM-IP standard in 1961.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D402/D402M − 14

4. Significance and Use

4.1 This procedure measures the amount of the more volatile constituents in cutback asphaltic products. asphalt. The properties

of the residue after distillation are not necessarily characteristic of the bitumen used in the original mixture, nor of the residue

which may be left at any particular time after field application of the cutback asphaltic product. asphalt. The presence of silicone

in the cutback asphalt may affect the distillation residue by retarding the loss of volatile material after the residue has been poured

into the residue container.

5. Apparatus

5.1 Distillation Flask, 500-mL side-arm, having the dimensions shown in Fig. 1.

5.2 Condenser, standard glass-jacketed, of nominal jacket length from 200 to 300 mm and overall tube length of 450 6 10 mm

(see Fig. 3).

5.3 Adapter, heavy-wall (1-mm) glass, with reinforced top, having an angle of approximately 105°. The inside diameter at the

large end shall be approximately 18 mm, and at th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.