ASTM D7793-12

(Specification)Standard Specification for Insulated Vinyl Siding

Standard Specification for Insulated Vinyl Siding

SCOPE

1.1 This specification establishes requirements for insulated vinyl siding, which is vinyl siding with integral foam plastic insulating material, where the vinyl siding is manufactured from rigid PVC compound. Compliance with this standard requires insulated vinyl siding to demonstrate a thermal insulation value of R-2.0 or greater. Other performance requirements and test methods addressed by this standard include materials properties and dimensions, warp, shrinkage, impact strength, expansion, appearance, thermal distortion resistance, and windload resistance. Methods of indicating compliance with this specification are also provided.

Note 1—Insulated vinyl siding is composed of two major components: the vinyl siding and the insulating material. It is intended that the vinyl siding portion comply with Specification D3679. Applicable portions of Specification D3679 are included in this specification. Additional requirements that pertain only to the insulation as a separate material, or to the combination of vinyl siding and insulation as a whole, are also included. For further explanation, see Appendix X1.

1.2 Insulated vinyl siding shall be tested with the insulation material in place or removed, as specified in the applicable requirement or test method.

1.3 The use of PVC recycled plastic in this product shall be in accordance with the requirements in Section 4.

1.4 Insulated vinyl siding produced to this specification shall be installed in accordance with Practice D4756. Reference shall also be made to the manufacturer's installation instructions for the specific product to be installed.

1.5 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 2—There is no known ISO equivalent to this standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D7793 −12 AnAmerican National Standard

Standard Specification for

Insulated Vinyl Siding

This standard is issued under the fixed designation D7793; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This specification establishes requirements for insulated 2.1 ASTM Standards:

vinyl siding, which is vinyl siding with integral foam plastic C297/C297MTest Method for Flatwise Tensile Strength of

insulating material, where the vinyl siding is manufactured Sandwich Constructions

from rigid PVC compound. Compliance with this standard C578Specification for Rigid, Cellular Polystyrene Thermal

requires insulated vinyl siding to demonstrate a thermal insu- Insulation

lation value of R-2.0 or greater. Other performance require- C591Specification for Unfaced Preformed Rigid Cellular

ments and test methods addressed by this standard include Polyisocyanurate Thermal Insulation

materials properties and dimensions, warp, shrinkage, impact C1199TestMethodforMeasuringtheSteady-StateThermal

strength, expansion, appearance, thermal distortion resistance, Transmittance of Fenestration Systems Using Hot Box

and windload resistance. Methods of indicating compliance Methods

with this specification are also provided. C1289Specification for Faced Rigid Cellular Polyisocyanu-

NOTE1—Insulatedvinylsidingiscomposedoftwomajorcomponents:

rate Thermal Insulation Board

the vinyl siding and the insulating material. It is intended that the vinyl

C1363Test Method for Thermal Performance of Building

siding portion comply with Specification D3679. Applicable portions of

Materials and Envelope Assemblies by Means of a Hot

Specification D3679 are included in this specification.Additional require-

Box Apparatus

ments that pertain only to the insulation as a separate material, or to the

combination of vinyl siding and insulation as a whole, are also included. D618Practice for Conditioning Plastics for Testing

For further explanation, see Appendix X1.

D635Test Method for Rate of Burning and/or Extent and

Time of Burning of Plastics in a Horizontal Position

1.2 Insulated vinyl siding shall be tested with the insulation

D696TestMethodforCoefficientofLinearThermalExpan-

material in place or removed, as specified in the applicable

sion of Plastics Between −30°C and 30°C with aVitreous

requirement or test method.

Silica Dilatometer

1.3 The use of PVC recycled plastic in this product shall be

D1042Test Method for Linear Dimensional Changes of

in accordance with the requirements in Section 4.

Plastics Caused by Exposure to Heat and Moisture

1.4 Insulated vinyl siding produced to this specification

D1183Practices for Resistance of Adhesives to Cyclic

shall be installed in accordance with Practice D4756. Refer-

Laboratory Aging Conditions

ence shall also be made to the manufacturer’s installation

D1435Practice for Outdoor Weathering of Plastics

instructions for the specific product to be installed.

D2244Practice for Calculation of Color Tolerances and

Color Differences from Instrumentally Measured Color

1.5 Thevaluesstatedininch-poundunitsaretoberegarded

Coordinates

as standard. The values given in parentheses are mathematical

D2457Test Method for Specular Gloss of Plastic Films and

conversions to SI units that are provided for information only

Solid Plastics

and are not considered standard.

D3679Specification for Rigid Poly(Vinyl Chloride) (PVC)

1.6 This standard does not purport to address all of the

Siding

safety concerns, if any, associated with its use. It is the

D3892Practice for Packaging/Packing of Plastics

responsibility of the user of this standard to establish appro-

D4226Test Methods for Impact Resistance of Rigid Poly-

priate safety and health practices and determine the applica-

(Vinyl Chloride) (PVC) Building Products

bility of regulatory limitations prior to use.

D4756Practice for Installation of Rigid Poly(Vinyl Chlo-

NOTE 2—There is no known ISO equivalent to this standard.

ride) (PVC) Siding and Soffit

This specification is under the jurisdiction of ASTM Committee D20 on

PlasticsandisthedirectresponsibilityofSubcommitteeD20.24onPlasticBuilding For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Products. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved June 1, 2012. Published July 2012. DOI:10.1520/ Standards volume information, refer to the standard’s Document Summary page on

D7793–12. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7793−12

D5206Test Method for Windload Resistance of Rigid Plas- with 6.5 for a specific product during all productions runs for

tic Siding the most recent six-month period.

D5947Test Methods for Physical Dimensions of Solid

3.1.7 vertical coverage—The net vertical distance of the

Plastics Specimens

wall covered by a single insulated vinyl siding panel, disre-

D7209Guide for Waste Reduction, Resource Recovery, and

garding any portions of the panel that are overlapped by

Use of Recycled Polymeric Materials and Products

adjacent panels above or below.

D7445Specification for Rigid Poly(Vinyl Chloride) (PVC)

3.1.8 temperate northern climate—in weather testing, a

Siding with Foam Plastic Backing (Backed Vinyl Siding)

North American metropolitan area testing site located within

E84Test Method for Surface Burning Characteristics of

73 to 100°W longitude and 37 to 45°N latitude.

Building Materials

3.1.9 vinyl siding—a shaped material, made principally

E1753Practice for Use of Qualitative Chemical Spot Test

from rigid poly(vinyl chloride) (PVC), that is used to clad

Kits for Detection of Lead in Dry Paint Films

exterior walls of buildings. In this standard, vinyl siding refers

G147Practice for Conditioning and Handling of Nonmetal-

to the rigid profile to which the insulation is attached.

lic Materials for Natural and Artificial Weathering Tests

2.2 American Society of Civil Engineers (ASCE):

4. Materials and Manufacture

ASCE7-02MinimumDesignLoadsforBuildingsandOther

Structures 4.1 Vinyl Siding:

4.1.1 The vinyl siding, exclusive of foam plastic insulating

2.3 International Code Council–Evaluation Services (ICC-

material, shall be made of one or more layers of poly(vinyl

ES):

chloride) (PVC) compound.Any layers of materials other than

AC05Acceptance Criteria for Sandwich Panel Adhesives

poly (vinyl chloride) (PVC) compound shall be kept to less

2.4 International Standards Organization (ISO):

than 20% by volume. This limitation does not apply to the

ISO/IECGuide 65General requirements for bodies operat-

insulation material.

ing product certification systems

4.1.2 Where rigid PVC recycled plastic as defined in Guide

2.5 Federal Standards:

D7209 is used, the vinyl siding containing the PVC recycled

16 CFR Part 460Labeling and Advertising of Home Insu-

plastic shall meet all of the requirements of Sections 3, 4, and

lation

5.

4.1.3 The vinyl siding material, exclusive of insulation

3. Terminology

material, when tested in accordance with Test Method D635,

3.1 Definitions:

shall not exceed an average extent of burn of 4 in. (100 mm),

3.1.1 center-pinning—aninstallationtechniqueinwhichthe

with an average time of burn not to exceed 10 seconds. A

siding panel is fastened tightly through the nail slot at the

minimum sample thickness of 0.035 in. (0.9 mm) is required.

center length of the panel, in order to cause thermal expansion

(Warning—The flammability testing data, conclusions, and

and contraction to occur equally in both directions from the

recommendations of Test Method D635 relate solely to the

center.

measurement and description of properties for classification of

3.1.2 cohesive failure—in the context of tensile testing, the vinyl siding material in response to flame under controlled

internal separation of the adhesive within the adhesive layer, laboratory conditions and shall not be used for the description

resulting in attachment of adhesive material to the surface of or appraisal of the fire hazard of vinyl siding under actual fire

both substrates conditions.)

3.1.3 insulation; insulating material—foam plastic material

4.2 Foam Plastic Insulation:

that is combined at the factory with a vinyl siding profile to

4.2.1 Thefoamplasticinsulationshallbemadeofoneofthe

form insulated vinyl siding. following materials:

4.2.1.1 Expanded polystyrene complying with Specification

3.1.4 insulated vinyl siding—a vinyl cladding product sold

C578.

with manufacturer-installed foam plastic insulating material as

4.2.1.2 Extruded polystyrene complying with Specification

an integral part of the cladding product. The vinyl cladding

C578

portion of insulated vinyl siding meets the definition of vinyl

4.2.1.3 Polyisocyanurate complying with Specification

siding.

C591 or Specification C1289

3.1.5 nominal—the value that a manufacturer consistently

4.2.2 ThefoamplasticinsulationshallhaveaFlameSpread

uses to represent a specific property or dimension of a vinyl

Index not greater than 75 and a Smoke Developed Index not

siding product in public claims including, but not limited to,

greater than 450 when tested separately under Test Method

product literature, advertisements, quotations, and certificates

E84.

of conformance.

4.3 Adhesives:

3.1.6 process average thickness—the rolling, arithmetic

4.3.1 The suitability for outdoor use of an adhesive used to

meanofaveragespecimenthicknessesmeasuredinaccordance

bond the vinyl siding and the insulation, if any, shall be

determined by the following procedure.

4.3.1.1 Prepare a minimum of 10 samples consisting of two

Available fromAmerican Society of Civil Engineers (ASCE), 1801Alexander

Bell Dr., Reston, VA 20191, http://www.asce.org. Douglas fir-larch blocks or other appropriate substrates,

D7793−12

bonded by the adhesive, in accordance with Test Method 6 ⁄16 in. (1.6 mm) of the nominal width when measured in

C297/C297M. Each block is to be 2.0 inches square. The accordance with 6.3 and 6.4.

adhesive shall be applied and cured in accordance with the 5.1.2 Thickness—These requirements pertain only to mea-

adhesive manufacturer’s instructions. surements of the portions of the vinyl siding that are exposed

(1)The material selected for use as the substrate shall be afterinstallationofthepanel,measuredinaccordancewiththe

capable of withstanding the accelerated aging described in procedurein6.5.Theaveragethicknessofeachspecimenshall

4.3.1.2 without damage or deterioration of the substrate. be no less than 0.035 in. No individual measurement shall be

thinner than 0.003 in. below the nominal thickness. The

NOTE 3—Other appropriate substrates, such as metal or plastic, com-

process average thickness as defined in 3.1.6 shall be no

patible with the adhesive according to the manufacturer’s guidelines, can

thinner than 0.001 in. below the nominal thickness.

be used in place of the Douglas fir-larch blocks. Because in accordance

with 4.3.1.4.1 at least 75% of samples must fail in a cohesive mode, a 5.1.3 Camber—Afulllengthofvinylsiding(typically10or

substrate should be selected that is expected to be stronger than the

12 ft (3.05 or 3.61 m)) shall not have a camber greater than ⁄8

adhesive and which will form a tight bond with the adhesive.

in. (3.2 mm) when measured in accordance with 6.6.

4.3.1.2 Subject 50 percent of the samples to accelerated 5.1.4 Heat Shrinkage—Theaverageheatshrinkageshallnot

exceed3.0%whendeterminedbythemethoddescribedin6.7.

aging under Test Method D1183, Test Condition C, for three

5.1.5 Impact Resistance—The vinyl siding shall have a

cycles.Thelow-temperatureportionofthecycleisnotrequired

minimum impact strength of 60 in.•lbf (6.78 J) when tested in

to be colder than -40°F (-40°C) and the relative humidity

accordance with 6.8.

during this portion of the cycle shall not be greater than 10%

5.1.6 Gloss—The gloss of smooth and embossed vinyl

RH.

siding shall be uniform across the exposed surface. The

4.3.1.3 Condition and test all of the samples in accordance

average of all readings for a panel determined in 6.11.2.5 shall

with Test Method C297/C297M.

not differ from the manufacturer’s specified gloss value more

4.3.1.4 Acceptable Performance:

than the permitted variation in Table 1, and each individual

(1)For a valid test, the mode of failure for no fewer than

reading shall not vary more than 10 points from the average.

75%ofthesamplesshallbecohesive.Onlysamplesthatfailed

Gloss of smooth and embossed vinyl siding shall be tested in

cohesively are counted in the following. The average ultimate

accordance with 6.11.

tensile strength of the samples that were subjected to acceler-

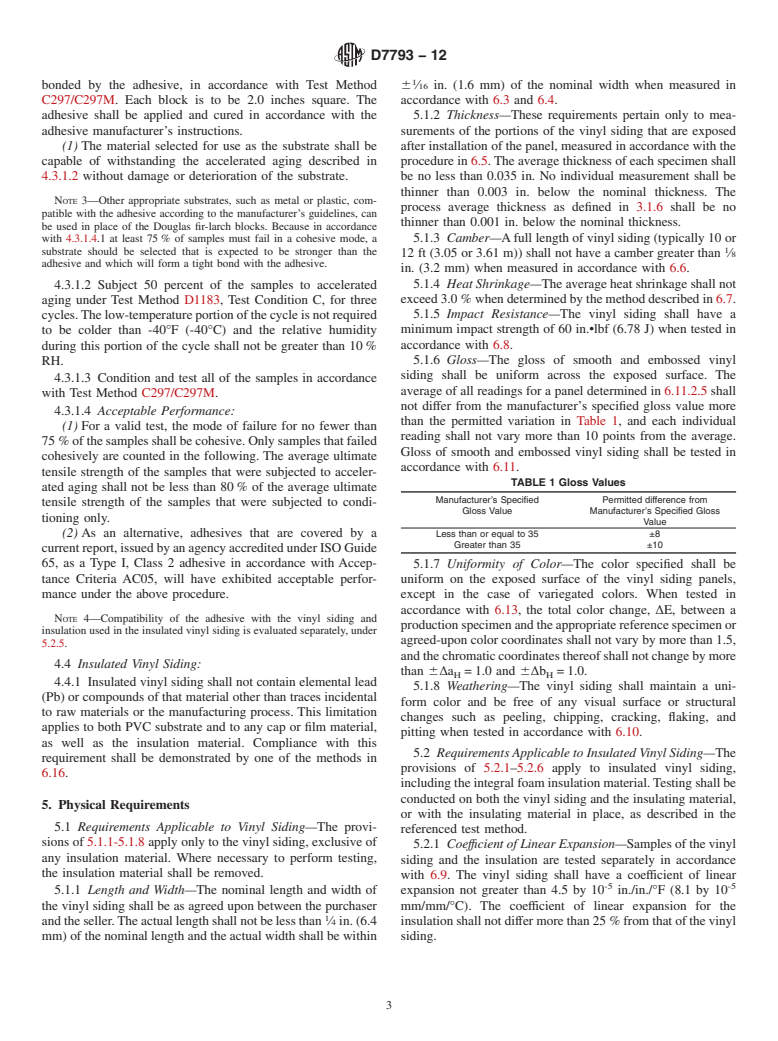

TABLE 1 Gloss Values

ated aging shall not be less than 80% of the average ultimate

Manufacturer’s Specified Permitted difference from

tensile strength of the samples that were subjected to condi-

Gloss Value Manufacturer’s Specified Gloss

tioning only.

Value

(2)As an alternative, adhesives that are covered by a Less than or equal to 35 ±8

Greater than 35 ±10

currentreport,issuedbyanagencyaccreditedunderISOGuide

65, as a Type I, Class 2 adhesive in accordance with Accep- 5.1.7 Uniformity of Color—The color specified shall be

tance Criteria AC05, will have exhibited acceptable perfor- uniform on the exposed surface of the vinyl siding panels,

mance under the above procedure. except in the case of variegated colors. When tested in

accordance with 6.13, the total color change, ∆E, between a

NOTE 4—Compatibility of the adhesive with the vinyl siding and

productionspecimenandtheappropriatereferencespecimenor

insulation used in the insulated vinyl siding is evaluated separately, under

agreed-uponcolorcoordinatesshallnotvarybymorethan1.5,

5.2.5.

andthechromaticcoordinatesthereofshallnotchangebymore

4.4 Insulated Vinyl Siding:

than 6∆a =1.0 and 6∆b =1.0.

H H

4.4.1 Insulated vinyl siding shall not contain elemental lead

5.1.8 Weathering—The vinyl siding shall maintain a uni-

(Pb) or compounds of that material other than traces incidental

form color and be free of any visual surface or structural

to raw materials or the manufacturing process. This limitation

changes such as peeling, chipping, cracking, flaking, and

applies to both PVC substrate and to any cap or film material,

pitting when tested in accordance with 6.10.

as well as the insulation material. Compliance with this

5.2 Requirements Applicable to Insulated Vinyl Siding—The

requirement shall be demonstrated by one of the methods in

provisions of 5.2.1–5.2.6 apply to insulated vinyl si

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.