ASTM G49-85(2019)

(Practice)Standard Practice for Preparation and Use of Direct Tension Stress-Corrosion Test Specimens

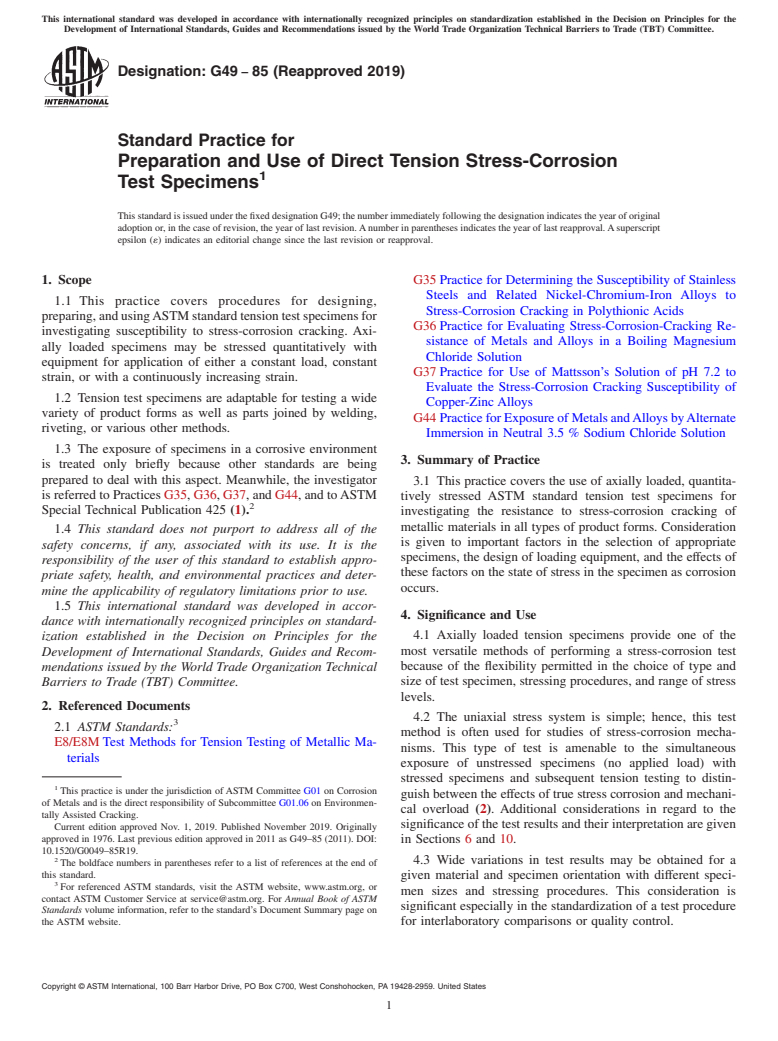

Standard Practice for Preparation and Use of Direct Tension Stress-Corrosion Test Specimens

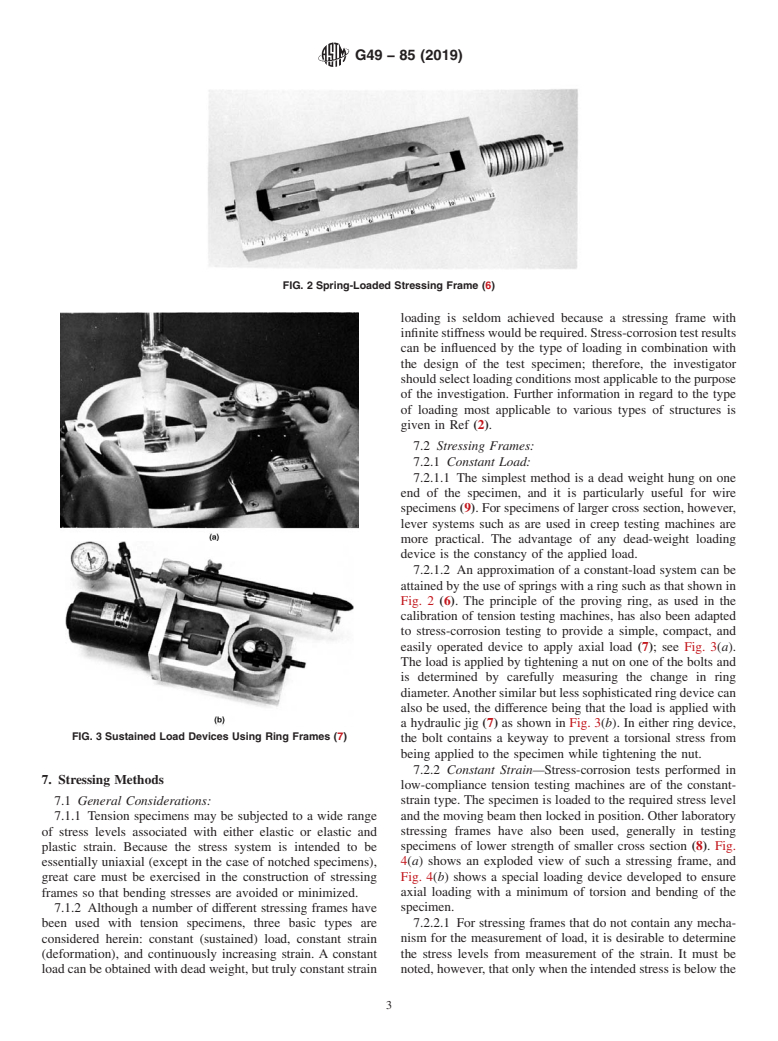

SIGNIFICANCE AND USE

4.1 Axially loaded tension specimens provide one of the most versatile methods of performing a stress-corrosion test because of the flexibility permitted in the choice of type and size of test specimen, stressing procedures, and range of stress levels.

4.2 The uniaxial stress system is simple; hence, this test method is often used for studies of stress-corrosion mechanisms. This type of test is amenable to the simultaneous exposure of unstressed specimens (no applied load) with stressed specimens and subsequent tension testing to distinguish between the effects of true stress corrosion and mechanical overload (2). Additional considerations in regard to the significance of the test results and their interpretation are given in Sections 6 and 10.

4.3 Wide variations in test results may be obtained for a given material and specimen orientation with different specimen sizes and stressing procedures. This consideration is significant especially in the standardization of a test procedure for interlaboratory comparisons or quality control.

SCOPE

1.1 This practice covers procedures for designing, preparing, and using ASTM standard tension test specimens for investigating susceptibility to stress-corrosion cracking. Axially loaded specimens may be stressed quantitatively with equipment for application of either a constant load, constant strain, or with a continuously increasing strain.

1.2 Tension test specimens are adaptable for testing a wide variety of product forms as well as parts joined by welding, riveting, or various other methods.

1.3 The exposure of specimens in a corrosive environment is treated only briefly because other standards are being prepared to deal with this aspect. Meanwhile, the investigator is referred to Practices G35, G36, G37, and G44, and to ASTM Special Technical Publication 425 (1).2

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: G49 − 85 (Reapproved 2019)

Standard Practice for

Preparation and Use of Direct Tension Stress-Corrosion

1

Test Specimens

ThisstandardisissuedunderthefixeddesignationG49;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope G35 Practice for Determining the Susceptibility of Stainless

Steels and Related Nickel-Chromium-Iron Alloys to

1.1 This practice covers procedures for designing,

Stress-Corrosion Cracking in Polythionic Acids

preparing,andusingASTMstandardtensiontestspecimensfor

G36 Practice for Evaluating Stress-Corrosion-Cracking Re-

investigating susceptibility to stress-corrosion cracking. Axi-

sistance of Metals and Alloys in a Boiling Magnesium

ally loaded specimens may be stressed quantitatively with

Chloride Solution

equipment for application of either a constant load, constant

G37 Practice for Use of Mattsson’s Solution of pH 7.2 to

strain, or with a continuously increasing strain.

Evaluate the Stress-Corrosion Cracking Susceptibility of

1.2 Tension test specimens are adaptable for testing a wide

Copper-Zinc Alloys

variety of product forms as well as parts joined by welding,

G44 PracticeforExposureofMetalsandAlloysbyAlternate

riveting, or various other methods.

Immersion in Neutral 3.5 % Sodium Chloride Solution

1.3 The exposure of specimens in a corrosive environment

3. Summary of Practice

is treated only briefly because other standards are being

prepared to deal with this aspect. Meanwhile, the investigator 3.1 This practice covers the use of axially loaded, quantita-

is referred to Practices G35, G36, G37, and G44, and toASTM

tively stressed ASTM standard tension test specimens for

2

Special Technical Publication 425 (1). investigating the resistance to stress-corrosion cracking of

metallic materials in all types of product forms. Consideration

1.4 This standard does not purport to address all of the

is given to important factors in the selection of appropriate

safety concerns, if any, associated with its use. It is the

specimens, the design of loading equipment, and the effects of

responsibility of the user of this standard to establish appro-

these factors on the state of stress in the specimen as corrosion

priate safety, health, and environmental practices and deter-

occurs.

mine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accor-

4. Significance and Use

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the 4.1 Axially loaded tension specimens provide one of the

most versatile methods of performing a stress-corrosion test

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical because of the flexibility permitted in the choice of type and

size of test specimen, stressing procedures, and range of stress

Barriers to Trade (TBT) Committee.

levels.

2. Referenced Documents

4.2 The uniaxial stress system is simple; hence, this test

3

2.1 ASTM Standards:

method is often used for studies of stress-corrosion mecha-

E8/E8M Test Methods for Tension Testing of Metallic Ma-

nisms. This type of test is amenable to the simultaneous

terials

exposure of unstressed specimens (no applied load) with

stressed specimens and subsequent tension testing to distin-

1

This practice is under the jurisdiction of ASTM Committee G01 on Corrosion

guish between the effects of true stress corrosion and mechani-

of Metals and is the direct responsibility of Subcommittee G01.06 on Environmen-

cal overload (2). Additional considerations in regard to the

tally Assisted Cracking.

significance of the test results and their interpretation are given

Current edition approved Nov. 1, 2019. Published November 2019. Originally

approved in 1976. Last previous edition approved in 2011 as G49–85 (2011). DOI:

in Sections 6 and 10.

10.1520/G0049–85R19.

2

4.3 Wide variations in test results may be obtained for a

The boldface numbers in parentheses refer to a list of references at the end of

this standard.

given material and specimen orientation with different speci-

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

men sizes and stressing procedures. This consideration is

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

significant especially in the standardization of a test procedure

Standards volume information, refer to the standard’s Document

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: G49 − 85 (Reapproved 2019)

Standard Practice for

Preparation and Use of Direct Tension Stress-Corrosion

1

Test Specimens

This standard is issued under the fixed designation G49; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope G35 Practice for Determining the Susceptibility of Stainless

Steels and Related Nickel-Chromium-Iron Alloys to

1.1 This practice covers procedures for designing,

Stress-Corrosion Cracking in Polythionic Acids

preparing, and using ASTM standard tension test specimens for

G36 Practice for Evaluating Stress-Corrosion-Cracking Re-

investigating susceptibility to stress-corrosion cracking. Axi-

sistance of Metals and Alloys in a Boiling Magnesium

ally loaded specimens may be stressed quantitatively with

Chloride Solution

equipment for application of either a constant load, constant

G37 Practice for Use of Mattsson’s Solution of pH 7.2 to

strain, or with a continuously increasing strain.

Evaluate the Stress-Corrosion Cracking Susceptibility of

1.2 Tension test specimens are adaptable for testing a wide

Copper-Zinc Alloys

variety of product forms as well as parts joined by welding,

G44 Practice for Exposure of Metals and Alloys by Alternate

riveting, or various other methods.

Immersion in Neutral 3.5 % Sodium Chloride Solution

1.3 The exposure of specimens in a corrosive environment

3. Summary of Practice

is treated only briefly because other standards are being

prepared to deal with this aspect. Meanwhile, the investigator

3.1 This practice covers the use of axially loaded, quantita-

is referred to Practices G35, G36, G37, and G44, and to ASTM tively stressed ASTM standard tension test specimens for

2

Special Technical Publication 425 (1).

investigating the resistance to stress-corrosion cracking of

metallic materials in all types of product forms. Consideration

1.4 This standard does not purport to address all of the

is given to important factors in the selection of appropriate

safety concerns, if any, associated with its use. It is the

specimens, the design of loading equipment, and the effects of

responsibility of the user of this standard to establish appro-

these factors on the state of stress in the specimen as corrosion

priate safety, health, and environmental practices and deter-

occurs.

mine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accor-

4. Significance and Use

dance with internationally recognized principles on standard-

4.1 Axially loaded tension specimens provide one of the

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom- most versatile methods of performing a stress-corrosion test

because of the flexibility permitted in the choice of type and

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee. size of test specimen, stressing procedures, and range of stress

levels.

2. Referenced Documents

4.2 The uniaxial stress system is simple; hence, this test

3

2.1 ASTM Standards:

method is often used for studies of stress-corrosion mecha-

E8/E8M Test Methods for Tension Testing of Metallic Ma-

nisms. This type of test is amenable to the simultaneous

terials

exposure of unstressed specimens (no applied load) with

stressed specimens and subsequent tension testing to distin-

1

This practice is under the jurisdiction of ASTM Committee G01 on Corrosion

guish between the effects of true stress corrosion and mechani-

of Metals and is the direct responsibility of Subcommittee G01.06 on Environmen-

cal overload (2). Additional considerations in regard to the

tally Assisted Cracking.

significance of the test results and their interpretation are given

Current edition approved Nov. 1, 2019. Published November 2019. Originally

approved in 1976. Last previous edition approved in 2011 as G49–85 (2011). DOI:

in Sections 6 and 10.

10.1520/G0049–85R19.

2

4.3 Wide variations in test results may be obtained for a

The boldface numbers in parentheses refer to a list of references at the end of

this standard.

given material and specimen orientation with different speci-

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

men sizes and stressing procedures. This consideration is

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

significant especially in the standardization of a test procedure

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. for interlaboratory comparisons or quality control.

Copyright © ASTM Interna

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: G49 − 85 (Reapproved 2011) G49 − 85 (Reapproved 2019)

Standard Practice for

Preparation and Use of Direct Tension Stress-Corrosion

1

Test Specimens

This standard is issued under the fixed designation G49; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice covers procedures for designing, preparing, and using ASTM standard tension test specimens for investigating

susceptibility to stress-corrosion cracking. Axially loaded specimens may be stressed quantitatively with equipment for application

of either a constant load, constant strain, or with a continuously increasing strain.

1.2 Tension test specimens are adaptable for testing a wide variety of product forms as well as parts joined by welding, riveting,

or various other methods.

1.3 The exposure of specimens in a corrosive environment is treated only briefly because other standards are being prepared

to deal with this aspect. Meanwhile, the investigator is referred to Practices G35, G36, G37, and G44, and to ASTM Special

2

Technical Publication 425 (1).

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

3

2.1 ASTM Standards:

E8E8/E8M Test Methods for Tension Testing of Metallic Materials [Metric] E0008_E0008M

G35 Practice for Determining the Susceptibility of Stainless Steels and Related Nickel-Chromium-Iron Alloys to Stress-

Corrosion Cracking in Polythionic Acids

G36 Practice for Evaluating Stress-Corrosion-Cracking Resistance of Metals and Alloys in a Boiling Magnesium Chloride

Solution

G37 Practice for Use of Mattsson’s Solution of pH 7.2 to Evaluate the Stress-Corrosion Cracking Susceptibility of Copper-Zinc

Alloys

G44 Practice for Exposure of Metals and Alloys by Alternate Immersion in Neutral 3.5 % Sodium Chloride Solution

3. Summary of Practice

3.1 This practice covers the use of axially loaded, quantitatively stressed ASTM standard tension test specimens for

investigating the resistance to stress-corrosion cracking of metallic materials in all types of product forms. Consideration is given

to important factors in the selection of appropriate specimens, the design of loading equipment, and the effects of these factors on

the state of stress in the specimen as corrosion occurs.

4. Significance and Use

4.1 Axially loaded tension specimens provide one of the most versatile methods of performing a stress-corrosion test because

of the flexibility permitted in the choice of type and size of test specimen, stressing procedures, and range of stress levels.

1

This practice is under the jurisdiction of ASTM Committee G01 on Corrosion of Metals and is the direct responsibility of Subcommittee G01.06 on Environmentally

Assisted Cracking.

Current edition approved March 1, 2011Nov. 1, 2019. Published April 2011November 2019. Originally approved in 1976. Last previous edition approved in 20052011

as G49–85(2005).G49–85 (2011). DOI: 10.1520/G0049-85R11.10.1520/G0049–85R19.

2

The boldface numbers in parentheses refer to a list of references at the end of this standard.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’sstandard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

G49 − 85 (2019)

4.2 The uniaxial stress system is simple; hence, this test method is often used for studies of stress-corrosion mechanisms. This

type of test is amenable to the simultaneous exposure of unstressed specimens (no applied load) with stressed specimens and

subseq

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.