ASTM D1770-94(2000)e1

(Test Method)Standard Test Method for Neps, Vegetable Matter, and Colored Fiber in Wool Top

Standard Test Method for Neps, Vegetable Matter, and Colored Fiber in Wool Top

SCOPE

1.1 This test method covers the determination of the number of neps and pieces of vegetable matter by size classes, and the number of colored fibers, in 15 g samples of wool top.

1.2 This test method is applicable to wool top in any form. Note 1 - For the determination of number of neps per specified mass of cotton samples, refer to Test Method D 1446.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation: D 1770 – 94 (Reapproved 2000)

Standard Test Method for

Neps, Vegetable Matter, and Colored Fiber in Wool Top

This standard is issued under the fixed designation D 1770; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Adjunct references were corrected editorially in July 2006.

1. Scope 3.1.2 laboratory sample, n—a portion of material taken to

represent the lot sample, or the original material, and used in

1.1 Thistestmethodcoversthedeterminationofthenumber

the laboratory as a source of test specimens.

of neps and pieces of vegetable matter by size classes, and the

2 3.1.3 lot, n—in acceptance sampling, that part of a consign-

number of colored fibers, in 15 g samples of wool top.

ment or shipment consisting of material from one production

1.2 This test method is applicable to wool top in any form.

lot.

NOTE 1—Forthedeterminationofnumberofnepsperspecifiedmassof

3.1.4 nep, n—one or more fibers occurring in a tangled and

cotton samples, refer to Test Method D 1446.

unorganized mass.

1.3 This standard does not purport to address all of the

3.1.4.1 Discussion—For the purpose of this test method, the

safety concerns, if any, associated with its use. It is the

mass of unorganized fibers retains its identity upon removal

responsibility of the user of this standard to establish appro-

from a fibrous strand.

priate safety and health practices and determine the applica-

3.1.5 test specimen, n— for wool top, a length of specified

bility of regulatory limitations prior to use.

mass taken at random from a length of wool top selected as a

laboratory sample.

2. Referenced Documents

3.1.6 top, n—in wool, a continuous untwisted strand of

2.1 ASTM Standards:

wool fibers from which the shorter fibers or noils have been

D 123 Terminology Relating to Textiles

removed by combing.

D 1446 Method of Test for Number of Neps in Cotton

3.1.7 vegetable matter, n— in wool top, the pieces of burrs,

Samples

seeds, shive, leaves, twigs, and grasses which have escaped

D 1776 Practice for Conditioning and Testing Textiles

removal in processing, also foreign vegetable fibers such as

2.2 ASTM Adjuncts:

hemp, sisal, etc., if present.

Nep Scale Standard (1 Photo), Vegetable Matter Standard (1

3.1.8 For definitions of other textile terms used in this test

Photo)

method, refer to Terminology D 123.

3. Terminology

4. Summary of Test Method

3.1 Definitions:

4.1 Four test specimens are taken and examined in accor-

3.1.1 colored fiber, n— in wool top, any fiber the color or

dancewithspecifiedprocedures.Eachobservedneporpieceof

shade of which differs from the normal color or shade of the

vegetable matter is classified by size, by visual comparison

fiber mass of the sample.

with a specified standard size chart. The numbers of each class

of neps and class of vegetable matter pieces, and the number of

coloredfibers,arerecordedforeachspecimen.Fromthesedata

This test method is under the jurisdiction ofASTM Committee D13 onTextiles

the average counts per specimen of 15 g are calculated.

and is the direct responsibility of Subcommittee D13.13 on Wool and Wool Felt.

Current edition approved March 10, 2000. Published April 2000. Originally

5. Significance and Use

approved in 1960. Last previous edition approved in 1994 as D 1770–94.

Foradditionalinformation,referencemaybemadeto“NepsinWorstedSliver,”

5.1 Test Method D 1770 for the determination of neps,

Wool Science Review, Vol 22, March 1963, pp. 28–38.

3 vegetable matter, and colored fiber may be used for the

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

acceptance testing of commercial shipments of wool top but

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

caution is advised because the between-laboratory precision is

the ASTM website.

known to be poor. Comparative tests as directed in 5.1.1 may

Withdrawn.

be advisable.

Available from ASTM International Headquarters. Order Adjunct No.

ADJD1770.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

e1

D 1770 – 94 (2000)

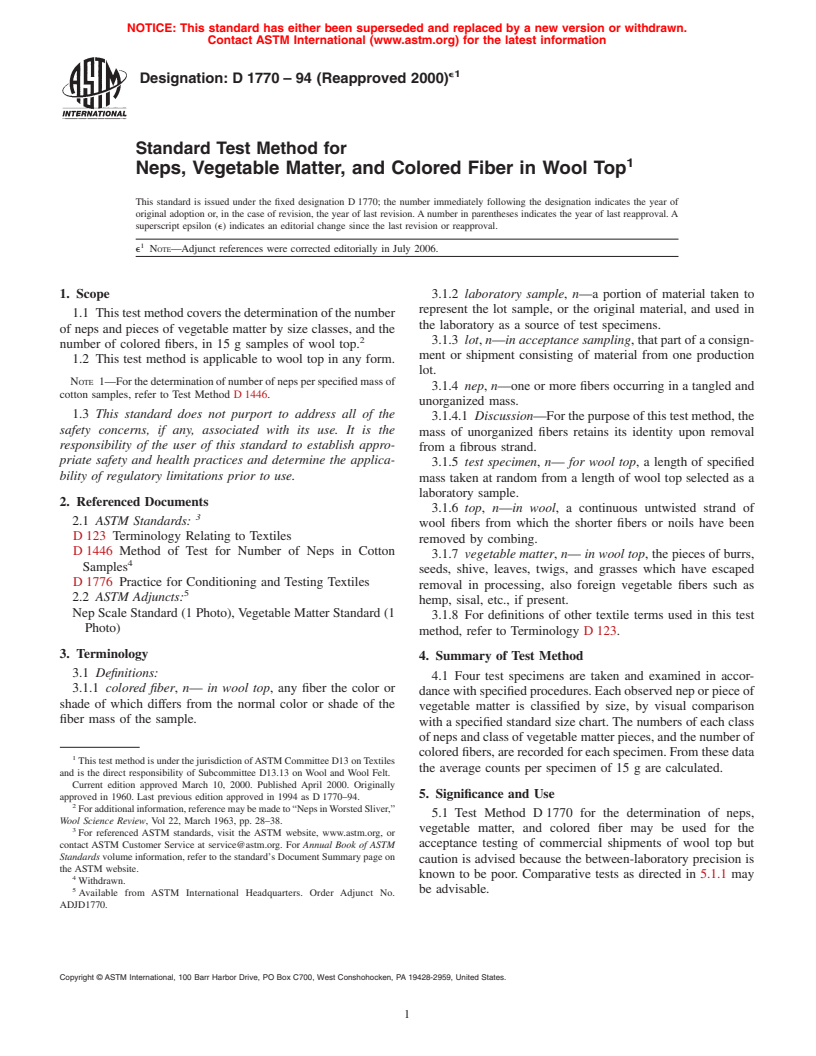

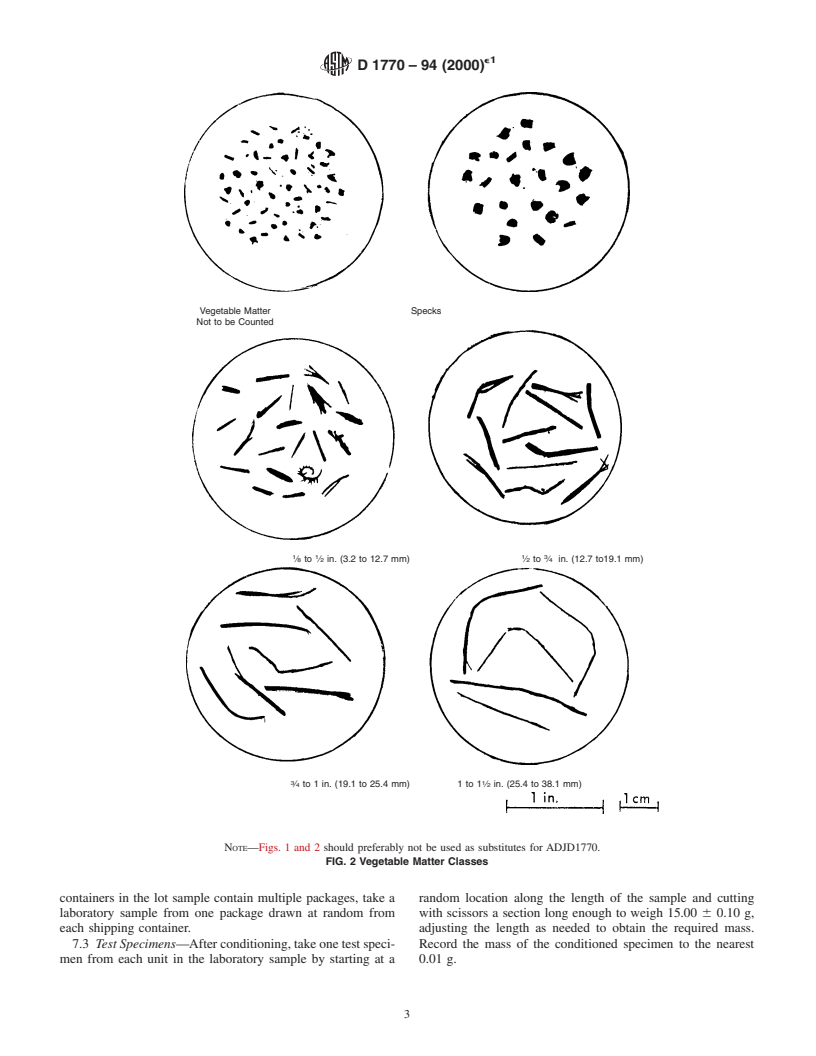

NOTE—Figs. 1 and 2 should preferably not be used as substitutes for ADJD1770.

FIG. 1 Visual Standard

5.1.1 In case of a dispute arising from differences in tests. Alternatively, a white translucent surface with under-

reported test results when using Test Method D 1770 for lighting may be used for all tests. When a translucent surface

acceptance testing of commercial shipments, the purchaser and is used, colored fibers must be reexamined on an over-lighted

the supplier should conduct comparative tests to determine if white surface to avoid inclusion of medullated fibers.

there is a statistical bias between their laboratories. Competent 6.4 Tweezers, with pointed ground ends.

statistical assistance is recommended for the investigation of 6.5 Balance or Scale,capacityatleast25gwithasensitivity

bias.As a minimum, the two parties should take a group of test of 0.01 g.

specimens that are as homogeneous as possible and that are

7. Sampling

from a lot of material of the type in question. The test

specimens should then be randomly assigned in equal numbers 7.1 Lot Sample—As a lot sample for acceptance testing,

to each laboratory for testing.The average results from the two

take at random the number of shipping containers directed in

laboratories should be compared using Student’s t-test for an applicable material specification or other agreement be-

unpaireddataandanacceptableprobabilitylevelchosenbythe

tween the purchaser and the supplier. Consider shipping

two parties before the testing is begun. If a bias is found, either containers to be the primary sampling units.

its cause must be found and corrected or the purchaser and the

NOTE 2—An adequate specification or other agreement between the

supplier must agree to interpret future test results in the light of

purchaser and the supplier requires taking into account the variability

the known bias.

between shipping containers, between laboratory samples within a ship-

ping container, and between test specimens within a laboratory sample to

6. Apparatus

provide a sampling plan with a meaningful producer’s risk, consumer’s

risk, acceptable quality level, and limiting quality level.

6.1 Nep Scale Standard, see Fig. 1 and ADJD1770.

6.2 Vegetable Matter Standard, see Fig. 2 and ADJD1770. 7.2 Laboratory Sample—As a laboratory sample for accep-

6.3 Examination Surfaces, consisting of a dark surface tance testing, take from each shipping container in the lot

illuminated from above for nep test and a white surface sample the first 3 yd (3 m) of material from the lead end of the

illuminated from above for vegetable matter and colored fiber strand that has a clean, uniform appearance. If the shipping

e1

D 1770 – 94 (2000)

Vegetable Matter Specks

Not to be Counted

1 1 1 3

⁄8 to ⁄2 in. (3.2 to 12.7 mm) ⁄2 to ⁄4 in. (12.7 to19.1 mm)

3 1

⁄4 to 1 in. (19.1 to 25.4 mm) 1 to 1 ⁄2 in. (25.4 to 38.1 mm)

NOTE—Figs. 1 and 2 should preferably not be used as substitutes for ADJD1770.

FIG. 2 Vegetable Matter Classes

containers in the lot sample contain multiple packages, take a random location along the length of the sample and cutting

laboratory sample from one package drawn at random from with scissors a section long enough to weigh 15.00 6 0.10 g,

each shipping container. adjusting the length as needed to obtain the required mass.

7.3 Test Specimens—Afterconditioning,takeonetestspeci- Record the mass of the conditioned specimen to the nearest

men from each unit in the laboratory sample by starting at a 0.01 g.

e1

D 1770 – 94 (2000)

8. Conditioning

N = average number of neps of nep size class i per 15 g of

i

wool top,

8.1 Bringthelaboratorysamplestomoistureequilibriumfor

n = total number of neps of nep size class i in the four

obtaining test specimens in the standard atmosphere for testing

i

specimens, and

textiles as directed in Practice D 1776. Preconditioning is not

w = combined mass of the four specimens, in grams.

necessary.

10.5 Vegetable Matter—Calculate to the nearest 0.1 unit-

9. Procedure

the average number of vegetable matter pieces of each size

class per 15 g of wool top, using Eq 3:

9.1 Test each weighed specimen, in the prevailing atmo-

sphere if preferred, as follows:

V 5 v 3 15/w (3)

j j

9.1.1 Draw a portion not exceeding one-tenth of the speci-

where:

men and spread it over the prescribed examination surface.

V = average number of vegetable matter pieces of size

j

9.1.2 Remove with tweezers each colored fiber and reserve

class j per 15 g of wool top,

for counting.

v = total number of vegetable matter pieces of size class

j

9.1.3 Also remove with tweezers each nep (except those

j in the four specimens, and

obviouslysmallerthansize1onthenepscale,Fig.1),andeach

w = combined mass of four specimens, in grams.

piece of vegetable matter (except those obviously smaller than

10.6 Combined “Defects”— If the term “defects”

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.