ASTM E674-12

(Specification)Standard Specification for Industrial Perforated Plate and Screens (Round Opening Series)

Standard Specification for Industrial Perforated Plate and Screens (Round Opening Series)

ABSTRACT

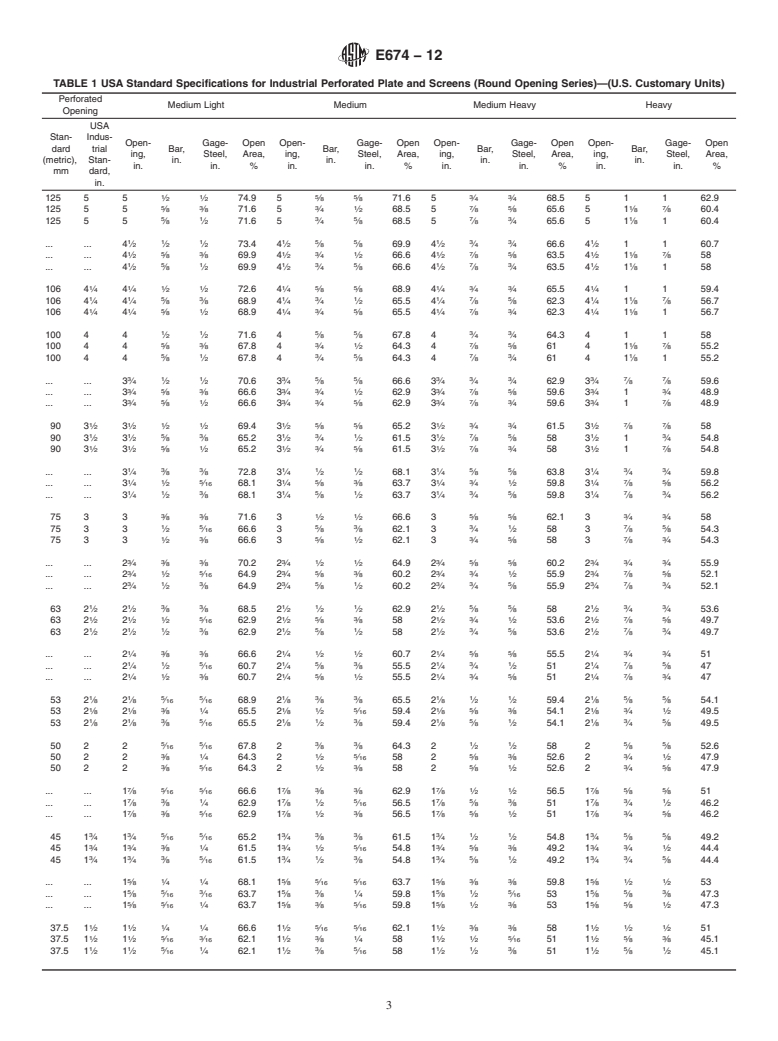

This specification covers the various sizes of round opening perforated plates and screens for general industrial uses, including the separating or grading of materials according to designated nominal particle size, and lists standards for openings punched with various bar sizes and thicknesses of plate for various grades of service. This specification does not apply to perforated plates or screens with square, hexagon, slotted, or other shaped openings.

SCOPE

1.1 This specification covers the sizes of round opening perforated plate and screens for general industrial uses, including the separating or grading of materials according to designated nominal particle size, and lists standards for openings from 5 in. (125 mm) to 0.020 in. (500 μm) punched with bar sizes and thicknesses of plate for various grades of service. Methods of checking industrial perforated plate and screens are included as information in Appendix X3.

1.2 This specification does not apply to perforated plate or screens with square, hexagon, slotted, or other shaped openings.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E674 −12

StandardSpecification for

Industrial Perforated Plate and Screens (Round Opening

1

Series)

This standard is issued under the fixed designation E674; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Industrial perforated plate can be produced in many thousands of combinations of size and shape

of opening, bar size, thickness of material, and type of metal. Such variety is often confusing and, to

the vast majority of perforated plate users, unnecessary, since each usually requires only a very few

specifications.

The purpose of this specification is to simplify this problem by a condensed table of recommended

specifications covering a wide range of openings in which industrial perforated plate is made, with

several recommended bar sizes and thicknesses of plate for each opening, for use in various grades of

service.

By making selections from this specification, the user will be guided to specifications that are being

regularly produced, thus avoiding inadvertent selection of specifications that, because of little or no

demand,areunobtainable,exceptonspecialorder(usuallyquiteexpensiveunlessthequantityordered

is sufficient to justify the cost of special tooling).

Ifauserhasaspecificapplicationforindustrialperforatedplatethatcannotbesolvedbyaselection

from this specification, it is recommended that he consult his perforated plate supplier on the

availability of an acceptable alternative specification.

1. Scope* 1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This specification covers the sizes of round opening

responsibility of the user of this standard to establish appro-

perforated plate and screens for general industrial uses, includ-

priate safety and health practices and determine the applica-

ing the separating or grading of materials according to desig-

bility of regulatory limitations prior to use.

nated nominal particle size, and lists standards for openings

from 5 in. (125 mm) to 0.020 in. (500 µm) punched with bar

2. Referenced Documents

sizes and thicknesses of plate for various grades of service.

2

2.1 ASTM Standards:

Methodsofcheckingindustrialperforatedplateandscreensare

E323 Specification for Perforated-Plate Sieves for Testing

included as information in Appendix X3.

Purposes

1.2 This specification does not apply to perforated plate or

E1638 Terminology Relating to Sieves, Sieving Methods,

screens with square, hexagon, slotted, or other shaped open-

and Screening Media

ings. 3

2.2 ISO Standards:

1.3 The values stated in inch-pound units are to be regarded ISO 2194 Industrial screens —Woven wire cloth, perforated

as standard. The values given in parentheses are mathematical plate and electroformed sheet — Designation and nominal

conversions to SI units that are provided for information only sizes of openings

and are not considered standard.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

1

ThisspecificationisunderthejurisdictionofASTMCommitteeE29onParticle contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

and Spray Characterization and is the direct responsibility of Subcommittee E29.01 Standards volume information, refer to the standard’s Document Summary page on

on Sieves, Sieving Methods, and Screening Media. the ASTM website.

3

Current edition approved June 15, 2012. Published June 2012. Originally Available from International Organization for Standardization (ISO), 1, ch. de

approved in 1979. Last previous edition approved in 2011 as E674 – 11. DOI: la Voie-Creuse, Case postale 56, CH-1211, Geneva 20, Switzerland, http://

10.1520/E0674-12. www.iso.ch.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E674−12

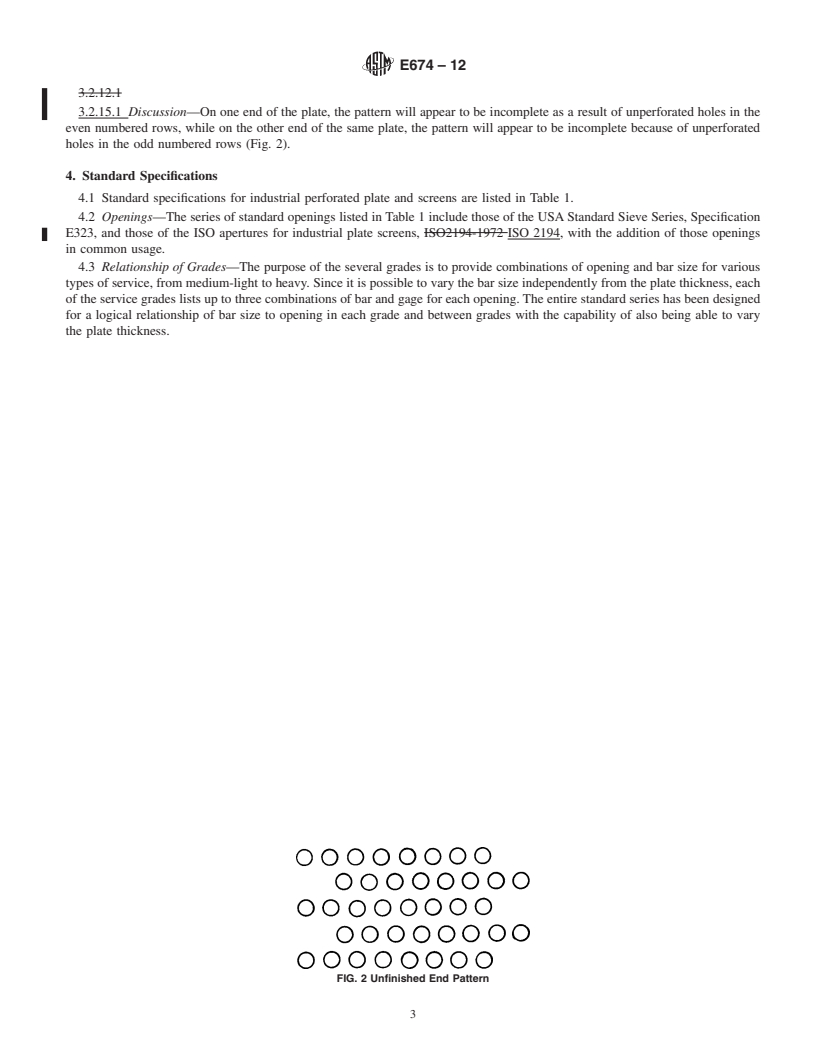

2.3 Other Documents: 3.2.11 perforated pattern, n—the patterns that the perfora-

4

Fed. Std. 123 Marking for Shipments (Civil Agencies) tions are arranged in, usually in a staggered pattern with

4

Mil-Std-129 Marking for Shipment and Storage midpoints nominally at the vertices of isosceles triangles or

square patterns arranged in line with their midpoints nominally

3. Terminology

at the vertices of squares.

3.1 Definitions—For general terms related to sieves, sieving 3.2.12 screen, n—(1) surface provided with apertures of

methods, and screening media, see Terminology E1638. uniform size and shape; (2) another term used interchangeably

3.2 Definitions of

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:E674–11 Designation: E674 – 12

Standard Specification for

Industrial Perforated Plate and Screens (Round Opening

1

Series)

This standard is issued under the fixed designation E674; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

INTRODUCTION

Industrial perforated plate can be produced in many thousands of combinations of size and shape

of opening, bar size, thickness of material, and type of metal. Such variety is often confusing and, to

the vast majority of perforated plate users, unnecessary, since each usually requires only a very few

specifications.

The purpose of this specification is to simplify this problem by a condensed table of recommended

specifications covering a wide range of openings in which industrial perforated plate is made, with

several recommended bar sizes and thicknesses of plate for each opening, for use in various grades of

service.

By making selections from this specification, the user will be guided to specifications that are being

regularly produced, thus avoiding inadvertent selection of specifications that, because of little or no

demand,areunobtainable,exceptonspecialorder(usuallyquiteexpensiveunlessthequantityordered

is sufficient to justify the cost of special tooling).

Ifauserhasaspecificapplicationforindustrialperforatedplatethatcannotbesolvedbyaselection

from this specification, it is recommended that he consult his perforated plate supplier on the

availability of an acceptable alternative specification.

1. Scope*

1.1 This specification covers the sizes of round opening perforated plate and screens for general industrial uses, including the

separating or grading of materials according to designated nominal particle size, and lists standards for openings from 5 in. (125

mm) to 0.020 in. (500 µm) punched with bar sizes and thicknesses of plate for various grades of service. Methods of checking

industrial perforated plate and screens are included as information in Appendix X3.

1.2 This specification does not apply to perforated plate or screens with square, hexagon, slotted, or other shaped openings.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

E323 Specification for Perforated-Plate Sieves for Testing Purposes

E1638 Terminology Relating to Sieves, Sieving Methods, and Screening Media

3

2.2 ISO Standards:

ISO2194-1972 Wire Screens and Plate Screens for Industrial Purposes—Nominal Sizes of Apertures.

1

This specification is under the jurisdiction ofASTM Committee E29 on Particle and Spray Characterization and is the direct responsibility of Subcommittee E29.01 on

Sieves, Sieving Methods, and Screening Media.

Current edition approved Nov.June 15, 2011.2012. Published December 2011.June 2012. Originally approved in 1979. Last previous edition approved in 20092011 as

E674–09.E674 – 11. DOI: 10.1520/E0674-112.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from International Organization for Standardization (ISO), 1, ch. de la Voie-Creuse, Case postale 56, CH-1211, Geneva 20, Switzerland, http://www.iso.ch.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E674 – 12

ISORecommendationR388-1964 Metric Series for Basic Thicknesses of Sheet and Diameters of Wire. ISO 2194 Industrial

screens — Woven wire cloth, perforated plate and electroformed sheet — Designation and nominal sizes of openings

2.3 Other Documents:

4

Fed. Std. 123 Mar

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.