ASTM C1139-14

(Specification)Standard Specification for Fibrous Glass Thermal Insulation and Sound Absorbing Blanket and Board for Military Applications (Withdrawn 2019)

Standard Specification for Fibrous Glass Thermal Insulation and Sound Absorbing Blanket and Board for Military Applications (Withdrawn 2019)

ABSTRACT

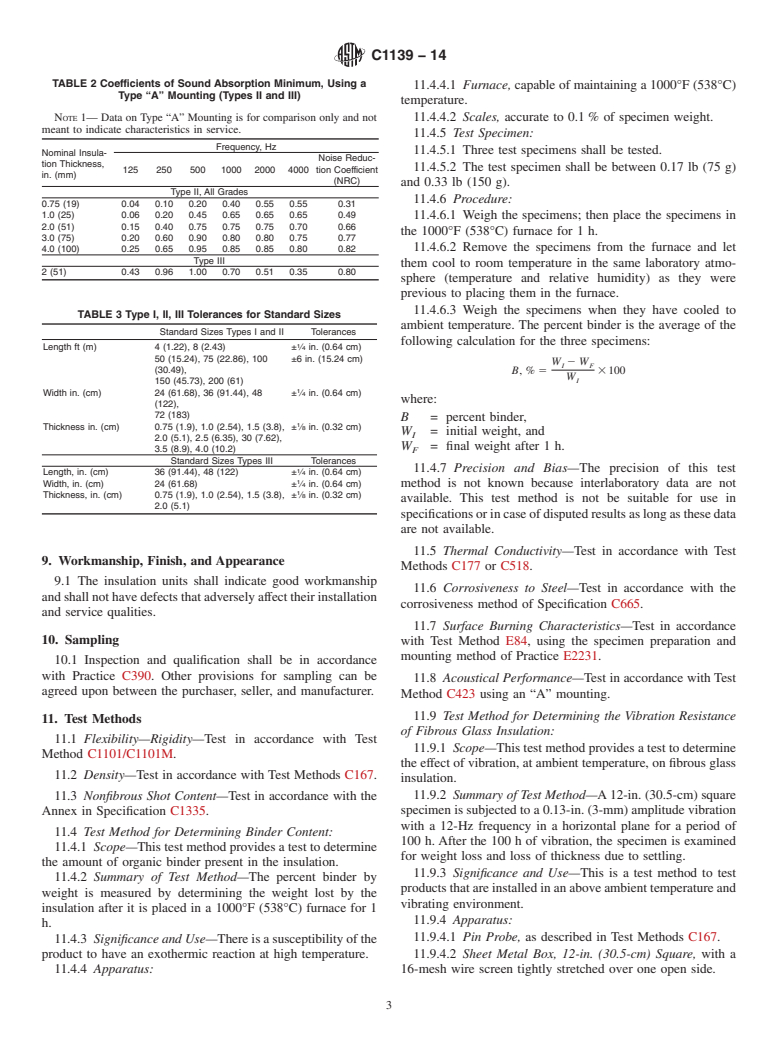

This specification covers unfaced flexible fibrous glass blanket and faced board used for thermal and sound absorbing insulation for military applications as a replacement for MIL-I-22023D. The fibrous glass felt shall be of the following types and grades: Types I and II (Grades 1, 2, 3, 4, 5, and 6). The insulation shall be composed of glass, processed from a molten state into a fibrous form, bonded with a chemical binder. The following test methods shall be performed: flexibility and rigidity; density; determining binder content; thermal conductivity; corrosiveness to steel; surface burning characteristics; determining the vibration resistance of fibrous glass insulation; maximum use temperature; and determination of flashover potential of a lining material using a quarter-scale room fire test.

SCOPE

1.1 This specification covers unfaced flexible fibrous glass blanket and faced board used for thermal and sound absorbing insulation at temperatures up to 450°F (232°C) for military applications as a replacement for MIL-I-22023D.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This specification measures and describes the response of materials, products, or assemblies to heat and flame under controlled conditions, but does not by itself incorporate all factors required for fire hazard or fire risk assessment of the materials, products, or assemblies under actual fire conditions.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.5 The following hazard caveat pertains only to the test method section of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This specification covers unfaced flexible fibrous glass blanket and faced board used for thermal and sound absorbing insulation at temperatures up to 450°F (232°C) for military applications as a replacement for MIL-I-22023D.

Formerly under the jurisdiction of Committee C16 on Thermal Insulation, this specification was withdrawn in March 2019. This standard is being withdrawn without replacement due to its lack of applicability to industry.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C1139 −14

Standard Specification for

Fibrous Glass Thermal Insulation and Sound Absorbing

1

Blanket and Board for Military Applications

This standard is issued under the fixed designation C1139; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope C177Test Method for Steady-State Heat Flux Measure-

ments and Thermal Transmission Properties by Means of

1.1 This specification covers unfaced flexible fibrous glass

the Guarded-Hot-Plate Apparatus

blanket and faced board used for thermal and sound absorbing

C390Practice for Sampling and Acceptance of Thermal

insulation at temperatures up to 450°F (232°C) for military

Insulation Lots

applications as a replacement for MIL-I-22023D.

C411Test Method for Hot-Surface Performance of High-

1.2 Thevaluesstatedininch-poundunitsaretoberegarded

Temperature Thermal Insulation

as standard. The values given in parentheses are mathematical

C423TestMethodforSoundAbsorptionandSoundAbsorp-

conversions to SI units that are provided for information only

tion Coefficients by the Reverberation Room Method

and are not considered standard.

C518Test Method for Steady-State Thermal Transmission

1.3 This specification measures and describes the response

Properties by Means of the Heat Flow Meter Apparatus

of materials, products, or assemblies to heat and flame under

C665SpecificationforMineral-FiberBlanketThermalInsu-

controlled conditions, but does not by itself incorporate all

lation for Light Frame Construction and Manufactured

factors required for fire hazard or fire risk assessment of the

Housing

materials, products, or assemblies under actual fire conditions.

C1101/C1101MTest Methods for Classifying the Flexibility

orRigidityofMineralFiberBlanketandBoardInsulation

1.4 Thevaluesstatedininch-poundunitsaretoberegarded

C1335Test Method for Measuring Non-Fibrous Content of

as standard. The values given in parentheses are mathematical

Man-Made Rock and Slag Mineral Fiber Insulation

conversions to SI units that are provided for information only

D1448Test Method for Micronaire Reading of Cotton Fi-

and are not considered standard.

bers

1.5 The following hazard caveat pertains only to the test

E70Test Method for pH of Aqueous Solutions With the

method section of this specification. This standard does not

Glass Electrode

purport to address all of the safety concerns, if any, associated

E84Test Method for Surface Burning Characteristics of

with its use. It is the responsibility of the user of this standard

Building Materials

to establish appropriate safety and health practices and

E176Terminology of Fire Standards

determine the applicability of regulatory limitations prior to

E2231Practice for Specimen Preparation and Mounting of

use.

Pipe and Duct Insulation Materials to Assess Surface

Burning Characteristics

2. Referenced Documents

2 3

2.2 U.S. Military Standards:

2.1 ASTM Standards:

C167Test Methods forThickness and Density of Blanket or MIL-STD-167-1 Mechanical Vibrations of Shipboard

Equipment (Type 1 Environmental and Type II Internally

Batt Thermal Insulations

C168Terminology Relating to Thermal Insulation Excited)

MIL-Y-1140Yarn, Cord, Sleeving, Cloth and Tape-Glass

MIL-A-3316Adhesives, Fire Resistant, Thermal Insulation

1

This specification is under the jurisdiction of ASTM Committee C16 on

MIL-E-17970 Enamel, Non-Flaming Semi-Gloss White

Thermal Insulation and is the direct responsibility of Subcommittee C16.23 on

MIL-C-20079 Cloth, Glass; Tape, Textile Glass And

Blanket and Loose Fill Insulation.

Thread, Glass And Wire-Reinforced Glass

CurrenteditionapprovedFeb.1,2014.PublishedJuly2014.Originallyapproved

in 1990. Last previous edition approved in 2008 as C1139–08. DOI: 10.1520/

C1139-14.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

Standards volume information, refer to the standard’s Document Summary page on Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://

the ASTM website. www.dodssp.daps.mil.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1139−14

3. Terminology of 450°F (232°C), the insulation shall not crack, warp, flame,

glow, smolder, or show evidence of fused fibers.

3.1 Definitions—Terminology C168 and Terminology E176

shall apply to the terms used in this specification.

7.4 The nonfibrous material (shot) content shall not be

greater than 1.5% by weight

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.