ASTM E479-91(2000)

(Guide)Standard Guide for Preparation of a Leak Testing Specification

Standard Guide for Preparation of a Leak Testing Specification

SCOPE

1.1 This standard is intended as a guide. It enumerates factors to be considered in preparing a definitive specification for maximum permissible gas leakage of a component, device, or system. The guide relates and provides examples of data for the preparation of leak testing specifications. It is primarily applicable for use in specifying halogen leak testing methods.

1.2 Two types of specifications are described:

1.2.1 Operational specifications (OS), and

1.2.2 Testing specifications (TS):

1.2.2.1 Total, and

1.2.2.2 Each leak.

1.3 This standard does not purport to address the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E 479 – 91 (Reapproved 2000)

Standard Guide for

Preparation of a Leak Testing Specification

This standard is issued under the fixed designation E479; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope leakage. The operational fluid usually is not detectable with

2 commercially available leak detectors. The leak test must be

1.1 This standard is intended as a guide. It enumerates

performed with a suitable test gas containing a tracer to which

factors to be considered in preparing a definitive specification

the detector is sensitive. The pressure magnitude and pressure

for maximum permissible gas leakage of a component, device,

direction may vary greatly from operational conditions. These

or system.The guide relates and provides examples of data for

and other factors are to be considered and evaluated when the

the preparation of leak testing specifications. It is primarily

leaktestingperformedtotherequirementsoftheTSistoresult

applicable for use in specifying halogen leak testing methods.

in a product that meets most of the OS requirements. In

1.2 Two types of specifications are described:

addition, should a product be tested with a detector or tracer

1.2.1 Operational specifications (OS), and

probe from point to point, allowance should be made for the

1.2.2 Testing specifications (TS):

possibilityoftwoormoreleaks,eachcausinglessleakagethan

1.2.2.1 Total, and

thetotalleakagemaximum,butaddinguptoanamountgreater

1.2.2.2 Each leak.

than allowed.

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

4. Specification Content and Units

responsibility of the user of this standard to establish appro-

4.1 The content and units of the specification should relate

priate safety and health practices and determine the applica-

the following data:

bility of regulatory limitations prior to use.

4.1.1 Mass flow per unit of time, preferably in moles per

2. Referenced Documents second (mol/s).

4.1.2 The pressure differential across the two sides of

2.1 ASTM Standards:

possible leaks, and the direction, in pounds per square inch

E425 Terminology Relating to Leak Testing

(psi) or moles (mol).

E427 Practice for Testing for Leaks Using the Halogen

4.1.3 Any special restrictions or statement of facts that

Leak Detector (Alkali-Ion Diode)

3 might prohibit the use of a particular type of leak testing

E432 Guide for Selection of a Leak Testing Method

method.

3. Terminology 4.1.4 The methods of the leakage specification shall not be

limited to any one particular method unless it is the only one

3.1 Definitions:

suitable. Specific leak testing methods can be selected when

3.1.1 operational specification (OS)—a specification from

careful consideration of the facts is outlined (refer to Guide

which the others are derived. The specification specifies and

E432 or the other applicable documents of Section 2).

states the limits of the leakage rate of the fluid to be used for

the product using criteria such as failure to operate, safety, or

5. Significance and Use

appearance.

5.1 For any product to be tested the geometrical complexity

3.1.2 testing specification (TS)—a specification for the de-

willvarywidely.However,thebasicconceptofdeterminingan

tection, location, or measurement, or a combination thereof, of

operative leakage specification regardless of geometries is

much the same for all, whether it be simple, ordinary, or

This guide is under the jurisdiction of ASTM Committee E07 on Nondestruc- complex.

tive Testing and is the direct responsibility of Subcommittee E07.08 on Leak

5.2 The data required for writing the OS, which is total

Testing.

leakage (moles), time(s), and pressure difference across the

Current edition approved April 15, 1991. Published June 1991. Originally

e1

leak, are either available or can be determined by tests or

published as E479–73. Last previous edition E479–73(1984) .

For ASME Boiler and Pressure Vessel Code applications see related Guide

measurements.

SE-479 in Section II of that Code.

Annual Book of ASTM Standards, Vol 03.03.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E 479 – 91 (2000)

5.3 A user who selects values to be used in a leakage these and other factors are considered, and that required leak

specification as a result of someone else having used the value testing at levels to ensure acceptable quality levels in the final

or simply because of prestige reasons, may find the value or productismadewiththeconsiderationforalessertestingcost.

values unsatisfactory for the product. Often it is necessary to divide the leakage allowance equitably

5.4 A specification that is too restrictive may result in among various components, taking into account the statistical

excessive leak testing costs. A specification that is not restric- probability of the largest allowable leakage occurring in a

tive enough may result in premature product failure, or number of a given set of components.

increased warranty costs, or both. 6.3.2.1 Division of Leakage Allowance Among System

5.5 A typical illustration for determining a leakage specifi- Components—Assume in the previous example that the com-

cation, using the complex geometry of a refrigerant system for pressor,condensingandevaporatingcoils,theexpansionvalve,

an example, will be used throughout this recommended guide. capacity control valve, and sealed thermostat all have to be

Itiswelltopointoutthattheusershouldrealizethatthevalues considered. Also assume that the compressor and evaporating

and test methods selected do not necessarily represent the best coil will both be tested separately before assembly into the

or typical ones for this application. system, as each has a number of fabricated joints more prone

to leakage than the condensing coil. The condensing coil,

considered a continuous length of tubing, can be tested at the

6. Procedure

final system test. All components except the thermostat make

6.1 The example that follows is to be construed as appli-

up some portion of the refrigerant circuit. How then should the

cable to the equipment and testing method cited, and is not to

leakage allowance be divided among them? The usually

be construed as setting up mandatory leakage rates for any

equitable way is to make the division on the basis of the

other equipment or method of testing. The example used to

number of joints in each, considering 25 mm of seam as one

illustrate the use of this guide is as follows: An automotive

“joint.” A tabulation example on this basis follows:

air-conditioning system using Refrigerant-12 (R-12, dichlo-

No. of Joints % of Total

rodifluoromethane)andconsistingofacompressor,condensing

coil, thermostatic expansion valve, evaporating coil, vacuum-

Compressor 36 28

Condensing coil 78 60

operated hot gas bypass capacity control valve, and a sealed

Expansion 7 5

temperature control thermostat.

Capacity control valve 9 7

6.2 OS, Refrigerant Circuit—It is desirable that the re-

Total 130 100

chargeable portions of the system operate three years before

6.4 Factor of Safety for Leak Testing Accuracy—When

requiring additional refrigerant; for the sealed parts, 5 years.

establishing the data for the factor of safety for leak testing

Tests show that 6 oz of the normal charge can be lost before

accuracy and when performed by various people using differ-

serious operational inefficiency begins, and the neoprene con-

ent equipment, facilities, or operating standards, the resulting

necting hoses have a basic permeation rate of 1 oz/year.

data usually will vary tremendously. Results of a round-robin

Inspectionofthesystemshowsthatthevacuumoperatorofthe

testconductedbyASTMresultedinaspreadofthetestdataof

capacity valve and the thermostat are not directly connected to

about one decade. This value is considered valid for leak tests

the refrigerant circuit, and can thus be considered separately.

using procedures and equipment described in Section 2.

6.2.1 Calculations:

Therefore any operational specification may apply a factor of

Leakage to be detected = 6 oz (total loss) − 1 oz 3 3 years = 3 oz

⁄3 or 0.3.

Period = 3 years

6.5 Factor of Safety for Number of Leaks per System—

Rate = 3 oz/3 years = 1 oz/year. Rate (standard units) = 1 oz/year 3

−4 −9

1.8 3 10 (or 0.00018 = R-12 conversion factor) = 7.308 3 10 moles/s. See

Whenaunitordevicehasanumberofpointsthatmayleak,the

6.6.3

leak test is to be performed by point-to-point probing.There is

Pressure—The maximum operating temperature of the system will be 77°C

a possibility that the sum of all leaks smaller than the

at which temperature the pressure of the refrigerant will be about 2.07 MPa.

Pressure difference = 2.07 MPa (internal) − 0.10 MPa (atmosphere) = 1.97

specification total may add up to an amount in excess of it.

MPa.

However, this is dependent upon the number of leak possibili-

6.2.2 Therefore, the following would appear on the appro-

ties or on whether there is any distortion of the normal leak

priate documents: Leakage Specification (Operational):

distribution curve, which covers many decades of sizes. The

−5

3.6 3 10 MPa max at 1.97 MPa pressure difference

factor assigned here may depend upon a judgment of the

−9

(7.308 310 moles/s excluding hose permeation).

probability of such an event occurring, the degree of confi-

6.3 TS, Refrigerant Circuit: dence needed in the leak test, and the safety factor that can be

6.3.1 ForaunittobetestedattheOSlevel,anyinaccuracies afforded.Inthisexample,assumethatthecondensingcoilisof

inthetestcouldcausepossibleunitacceptancewheninfactthe welded aluminum which has a strong tendency to have

−10

unit may leak in excess of the amount allowed. Most testing porosities that leak in the range of 4.06 310 moles/s. For

conditions cannot duplicate operating conditions. Should a this reason, the TS total will be divided by five for this item,

point-by-point probing technique be used, a number of smaller

and by three for the others, that is, a factor of 0.2 and 0.3

leaksmayallowatotalleakageinexcessofthevaluespecified. respectively.

6.3.2 In addition, some portions of the system may be 6.6 Factor of Safety for Test versus Operating Conditions:

purchasedasacompletedoperativecomponent.Theirpotential 6.6.1 Pressure—As a recommendation, the leakage is as-

contribution to the total system leakage must be limited. It is sumed to be proportional to the difference of the squares of the

because of the requirements of the testing specification that pressures on each side of the leak. However, for this example,

E 479 – 91 (2000)

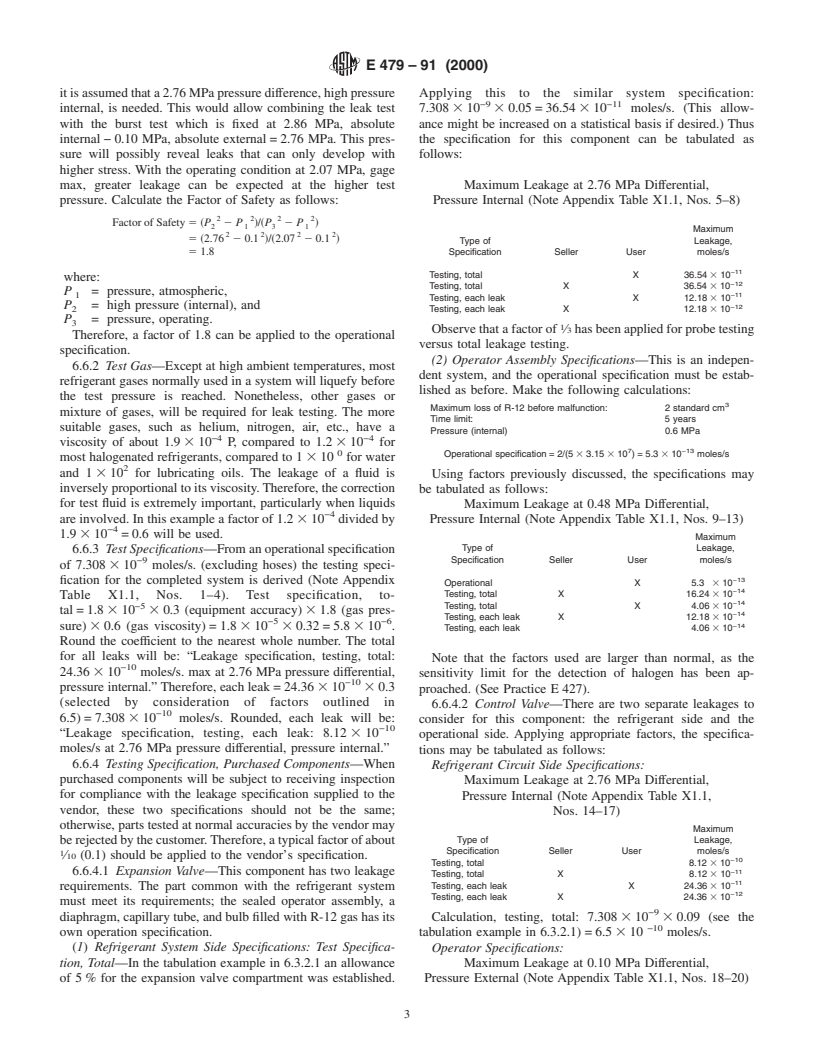

itisassumedthata2.76MPapressuredifference,highpressure Applying this to the similar system specification:

−9 −11

internal, is needed. This would allow combining the leak test 7.308 310 30.05=36.54 310 moles/s. (This allow-

with the burst test which is fixed at 2.86 MPa, absolute ance might be increased on a statistical basis if desired.) Thus

internal−0.10 MPa, absolute external=2.76 MPa. This pres- the specification for this component can be tabulated as

sure will possibly reveal leaks that can only develop with follows:

higher stress. With the operating condition at 2.07 MPa, gage

max, greater leakage can be expected at the higher test Maximum Leakage at 2.76 MPa Differential,

pressure. Calculate the Factor of Safety as follows: Pressure Internal (Note Appendix Table X1.1, Nos. 5–8)

2 2 2 2

FactorofSafety 5 ~P 2 P !/~P 2 P !

2 1 3 1

Maximum

2 2 2 2

5 ~2.76 20.1 !/~2.07 20.1 !

Type of Leakage,

51.8 Specification Seller User moles/s

−11

Testing, total X 36.54 3 10

where:

−12

Testing, total X 36.54 3 10

P = pressure, atmospheric,

−11

Testing, each leak X 12.18 3 10

P = high pressure (internal), and −12

2 Testing, each leak X 12.18 3 10

P = pressure, operating.

Observethatafactorof ⁄3hasbeenappliedforprobetesting

Therefore, a factor of 1.8 can be applied to the operational

versus total leakage testing.

specification.

(2) Operator Assembly Specifications—This is an indepen-

6.6.2 Test Gas—Except at high ambient temperatures, most

dent system, and the operational specification must be estab-

refrigerant gases normally used in a system will liquefy before

lished as before. Make the following calculations:

the test pressure is reached. Nonetheless, other gases or

Maximum loss of R-12 before malfunction: 2 standard cm

mixture of gases, will be required for leak testing. The more

Time limit: 5 years

suitable gases, such as helium, nitrogen, air, etc., have a

Pressure (internal) 0.6 MPa

−4 −4

viscosity of about 1.9 310 P, compared to 1.2 310 for

7 −13

Operational specification = 2/(5 3 3.15 3 10 )=5.3 3 10 moles/s

most halogenated refrigerants, compared to 1 310 for water

and 1 310 for lubricating oils. The leakage of a fluid is

Using factors previously discussed, the specifications may

inverselyproportionaltoitsviscosity.Therefore,thecorrection be tabulated as follows:

for test fluid is extremely important, particularly when liquids

Maximum Leakage at 0.48 MPa Differential,

−4

are involved. In this example a factor of 1.2 310 divided by Pressure Internal (Note Appendix Table X1.1, Nos. 9–13)

−4

1.9 310 =0.6 will be used.

Maximum

Type of Leakage,

6.6.3 Test Specifications—Fromanoperationalspecification

−9 Specification Seller User moles/s

of 7.308 310 moles/s. (excluding hoses) the testing speci-

−13

fication for the completed system is derived (Note Appendix

Operational X 5.3 3 10

−14

Testing, total X 16.24 3 10

Table X1.1, Nos. 1–4). Test specification, to-

−14

−5 Testing, total X 4.06 3 10

tal=1.8 310 30.3 (equipment accuracy) 31.8 (gas pres-

−14

Testing, each leak X 12.18 3 10

−5 −6

−14

sure) 30.6 (gas viscosity)=1.8 310 30.32=5.8 310 .

Testing, each leak 4.06 3 10

Round the coefficient to the nearest whole number. The total

for all leaks will be: “Leakage specification, testing, total:

Note that the factors used are larger than normal, as the

−10

24.36 310 moles/s. max at 2.76 MPa pressure differential,

sensitivity limit for the detection of halogen has been ap-

−10

pressure internal.”Therefore, each leak=24.36 310 30.3

proached. (See Practice E427).

(selected by consideration of factors outlined in

6.6.4.2 Control Valve—There are two separate leakages to

−10

6.5)=7.308 310 moles/s. Rounded, each leak will be:

consider for this component: the refrigerant side and the

−10

“Leakage specification, testing, each leak: 8.12 3 10

operational side. Applying appropriate factors, the specifica-

moles/s at 2.76 MPa pressure differential, pre

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.