ASTM E2930-13(2021)

(Practice)Standard Practice for Pressure Decay Leak Test Method

Standard Practice for Pressure Decay Leak Test Method

SIGNIFICANCE AND USE

5.1 The equipment, test duration, and technique should be determined before commencement of the test based on the required test sensitivity or accuracy (see Annex A1 and Annex A2). If the test is used to certify that the vessel has a minimum specified leakage rate, then the test equipment and test duration should be chosen to have a resolution ten times less than the specification and an accuracy which is four times less than the specification. The test should be designed so that the total pressure change is less than 10 % of the starting pressure. Leak test specifications should specify the vessel test pressure or differential pressure. If the test specification does not specify a test pressure, then a safe test pressure should be used that complies with the applicable safety standards8.

SCOPE

1.1 This practice describes a method for determining the leakage rate of a vessel subject to a positive pressure difference. The technique is based upon evaluation of the change of mass within the test object based on a pressure decay measurement. The pressure decay measurement uses the ideal gas equation of state and the measured pressures, temperatures, and time to determine the mass loss from the vessel. This method does not apply to deformable vessels.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E2930 − 13 (Reapproved 2021)

Standard Practice for

Pressure Decay Leak Test Method

This standard is issued under the fixed designation E2930; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope SNT-TC-1A Recommended Practice for Nondestructive

Testing Personnel Qualification and Certification

1.1 This practice describes a method for determining the

2.3 AIA Document:

leakage rate of a vessel subject to a positive pressure differ-

NAS-410Certification and Qualification of Nondestructive

ence. The technique is based upon evaluation of the change of

Testing Personnel

masswithinthetestobjectbasedonapressuredecaymeasure-

2.4 ASME Standards:

ment. The pressure decay measurement uses the ideal gas

ASMEBoilerandPressureVesselCodeSectionVArticle10

equationofstateandthemeasuredpressures,temperatures,and

(paragraph T-1044)

time to determine the mass loss from the vessel. This method

does not apply to deformable vessels. 2.5 ISO Standards:

ISO/IEC Guide 98–3Uncertainty of Measurement — Part 3

1.2 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

3. Terminology

responsibility of the user of this standard to establish appro-

3.1 Definitions:

priate safety, health, and environmental practices and deter-

3.1.1 pressure decay test resolution—the resolution of the

mine the applicability of regulatory limitations prior to use.

test that can be derived from the test equipment specifications

1.3 This international standard was developed in accor-

and the volume of the test vessel. The test resolution is

dance with internationally recognized principles on standard-

determined by evaluation of the individual resolutions of the

ization established in the Decision on Principles for the

pressure measurement, temperature measurement, and time

Development of International Standards, Guides and Recom-

measurement for a known vessel volume. The method for

mendations issued by the World Trade Organization Technical

determining the test resolution is give in Annex A1.

Barriers to Trade (TBT) Committee.

3.1.2 pressure decay test accuracy—the test accuracy is the

2. Referenced Documents

estimated accuracy of the test based on a combination of the

2.1 ASTM Standards:

measurement accuracies of contributing variables.The method

E479Guide for Preparation of a Leak Testing Specification

for determining the test accuracy is given in Annex A2.

(Withdrawn 2014)

4. Summary of Test Method

E543Specification forAgencies Performing Nondestructive

Testing

4.1 This practice requires a known volume and the use of

E1316Terminology for Nondestructive Examinations

the pressure rate of decay technique for quantitative measure-

2.2 ANSI/ASNT Standards:

ment of leakage rates.The practice is written to be usable over

ANSI/ASNT-CP-189Standard for Qualification and Certifi-

a wide range of pressures and system volumes.This method is

cation of Nondestructive Testing Personnel

only applicable to the test of non-deformable volumes or

devices. Test devices which may have significant changes in

1 volume due to pressurization should not be tested with this

This practice is under the jurisdiction of ASTM Committee E07 on Nonde-

structive Testing and is the direct responsibility of Subcommittee E07.08 on Leak method. The method requires the measurement of the system

Testing Method.

pressure and temperature as a function of time and as such

Current edition approved June 1, 2021. Published June 2021. Originally

requires that these measurements be made with calibrated

approved in 2013. Last previous edition approved in 2013 as E2930–13. DOI:

10.1520/E2930-13R21.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available fromAerospace IndustriesAssociation ofAmerica, Inc. (AIA), 1000

Standards volume information, refer to the standard’s Document Summary page on WilsonBlvd.,Suite1700,Arlington,VA22209-3928,http://www.aia-aerospace.org.

the ASTM website. Available from American Society of Mechanical Engineers (ASME), ASME

The last approved version of this historical standard is referenced on International Headquarters, Three Park Ave., New York, NY 10016-5990, http://

www.astm.org. www.asme.org.

4 7

AvailablefromAmericanSocietyforNondestructiveTesting(ASNT),P.O.Box Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

28518, 1711 Arlingate Ln., Columbus, OH 43228-0518, http://www.asnt.org. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E2930 − 13 (2021)

instrumentation. The range of the measurement technique can

vary significantly but is generally applicable in the range

-8 -4

greater than1×10 mol/s (2.2 × 10 std cc/s)

5. Significance and Use

5.1 The equipment, test duration, and technique should be

determined before commencement of the test based on the

required test sensitivity or accuracy (see AnnexA1 and Annex

A2). If the test is used to certify that the vessel has a minimum

specifiedleakagerate,thenthetestequipmentandtestduration

should be chosen to have a resolution ten times less than the

specification and an accuracy which is four times less than the

specification. The test should be designed so that the total

pressurechangeislessthan10%ofthestartingpressure.Leak

test specifications should specify the vessel test pressure or

differential pressure. If the test specification does not specify a

test pressure, then a safe test pressure should be used that

FIG. 1 Test Apparatus

complies with the applicable safety standards .

6. Basis of Application

10. Hazards

6.1 The following items are subject to contractual agree-

10.1 In no instance should the test pressure exceed the

ment between parties using or referencing this practice.

maximum allowed vessel design limits.

6.2 Personnel Qualification:

6.2.1 If specified in the contractual agreement, personnel

11. Sampling, Test Specimens, and Test Units

performing examinations to this practice shall be qualified in

11.1 The units for test should be in mol/s or pressure based

accordance with a national or internationally recognized NDT

units of Pa m /s or std cc/s with the units referenced to a

personnel qualification practice or standard such as ANSI/

standard temperature of 0°C or 273.15 K (unless otherwise

ASNT-CP-189, SNT-TC-1A, NAS-410, or a similar document

specified in the test specification).The actual test temperatures

and certified by the employer or certifying agency, as appli-

can vary over the specified operable ranges of the

cable.The practice or standard used and its applicable revision

instrumentation, as long as the temperature is stable enough to

shall be identified in the contractual agreement between the

meet the test resolution requirements.

using parties.

6.3 Qualification of Nondestructive Agencies—If specified

12. Preparation of Apparatus

in the contractual agreement, NDT agencies shall be qualified

12.1 Vessel Preparation—The test vessel should be clean

and evaluated as described in Practice E543. The applicable

and dry. Hydrostatic, bubble, and liquid penetrant testing

revisionofPracticeE543shallbeinthecontractualagreement.

should not be performed prior to a pressure decay test. All

7. Interferences

internalcomponentssubjecttodeformationorfailureshouldbe

removed. Care should be taken where trapped or poorly

7.1 Interferences in the reported leak values could result

accessible volumes may be encountered (double gasket seals)

fromdesorptionofgasesfromthevesseloradsorptionofgases

because they can increase the uncertainty of the test.

into the vessel. In addition, the effect of permeation of gases

out of the test vessel may be significant for very low leak rate

13. Calibration and Standardization

measurements. Eq A2.3 of Annex A2 can be modified to

incorporate these additional effects if appropriate. This test 13.1 The test equipment (pressure measurement, tempera-

assumes a nominal isothermal testing environment. ture measurement, and time measurement) must be appropri-

ately calibrated and traceable to national or international

8. Apparatus

standards. The accuracy of the method depends on the deter-

8.1 The required test equipment includes a pressure gauge/

mination of the test vessel volume as outlined in Annex A3.

transducer of the appropriate range, automated or manual

13.2 Commercial pressure decay systems often use an

timing system for data collection, and a temperature measure-

internal leak standard to determine the volume of the test

ment device along with proper fixtures as shown in Fig. 1.

system. In this case the manufacturer should specify the

accuracy of the determined volume as outlined in Annex A3.

9. Reagents and Materials

9.1 Anon-condensable, inert gas is required for pressuriza-

14. Conditioning

tion of the test vessel. If air is used, the dew point temperature

14.1 The volume and test equipment should be allowed to

must be lower than the tested temperature range.

thermally equilibrate before commencing the test. The test

vessel should not be pressurized beyond the pressure specifi-

See ASME Boiler and Pressure Vessel Code Section V Article 10 (paragraph

T-1044) cations (or design limits).

E2930 − 13 (2021)

15. Procedure N 5 ∆ PV ⁄ ∆ t T ⁄T ,Pa m ⁄s,orStdcc/s (2)

~~ ! ~ !!~ !

R

15.1 Assemble the test system and determine the system

where:

volume (see Annex A3). An isolation valve should be used

V = the vessel volume

between the test vessel and test system for isolation purposes.

R = the universal gas constant 8.3144 J/mol K (8.3144 Pa

m /(mol K)

15.2 Performaleaktestofthetestsystemwiththeisolation

T = the vessel temperature, K

valve closed and ensure that the leakage of the test system is

T = the reference temperature for the units (typically

less than 1% of the target test value for the test vessel. R

273.15 K)

15.3 Determine the test parameters (initial pressure and test

∆P = the change in pressure between successive points

time)andcalculatethetestresolutionandaccuraciesaccording

�t = the change in time in seconds between successive

to Annex A1 and Annex A2. Ensure that the calculated test

points

resolution is at least ten times less than the target leakage rate.

Examples are provided in Eq 3 and 4

Ensure that the test accuracy is at least four times less than the

target leakage rate.

where:

15.4 Pressurize the vessel to the target pressure and close

�P = 10000 Pa (0.1 atm)

the isolation valve 2.

V = 0.0001 m

�t = 100 sec.

15.5 Stabilization Time (Setting Time)—After

T = 273.15

R

pressurization, the temperature and pressure should be moni-

T = 298 K

tored as a function of time over the test duration previously

established in 5.1. The pressure should be recorded at a ~10000 Pa!·0.0001m ·273.15K

23 3

N 5 59.3 310 Pam ⁄s (3)

minimum of ten time intervals during the test sequence. The 100s·293K

temperatureshouldberecordedatthebeginningandendofthe 3

0.1 atm ·100cm ·273.15K

~ !

22 3

N 5 59.3 310 Std cm ⁄s (4)

test to ensure that the temperature is stable to within the

100s·293K

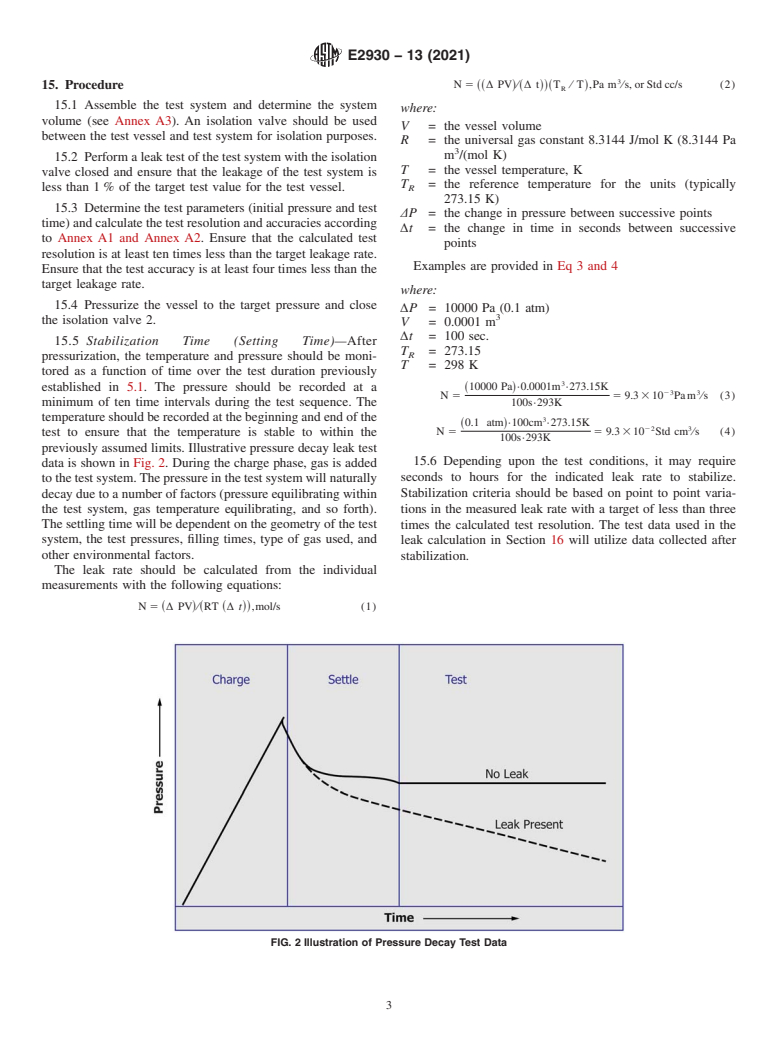

previously assumed limits. Illustrative pressure decay leak test

15.6 Depending upon the test conditions, it may require

data is shown in Fig. 2. During the charge phase, gas is added

seconds to hours for the indicated leak rate to stabilize.

tothetestsystem.Thepressureinthetestsystemwillnaturally

Stabilization criteria should be based on point to point varia-

decayduetoanumberoffactors(pressureequilibratingwithin

tions in the measured leak rate with a target of less than three

the test system, gas temperature equilibrating, and so forth).

The settling time will be dependent on the geometry of the test times the calculated test resolution. The test data used in the

system, the test pressures, filling times, type of gas used, and leak calculation in Section 16 will utilize data collected after

other environmental factors.

stabilization.

The leak rate should be calculated from the individual

measurements with the following equations:

N 5 ∆ PV ⁄ RT ∆ t ,mol/s (1)

~ ! ~ ~ !!

FIG. 2 Illustration of Pressure Decay Test Data

E2930 − 13 (2021)

15.7 Theleakratecalculationcanbecalculatedusingoneof 16.4 It is important to perform multiple tests if possible to

two methods. Method A is preferred as it also allows for understand the stability of the measurements. Leak rate mea-

estimation of the precision of the test from the standard surementscanbeaffectedbyenvironmentalvariablesandthese

deviation of the measurements. effects can be significant; particularly when testing large

15.7.1 Method A—The average of the calculated leak rates volumes (greater than 100 L).

determined from successive pressure measurements after sta-

bilization.

17. Report

15.7.2 Method B—The leak rate is calculated from a single

17.1 Report of Test—The report of the test should have the

pressurereadingobtainedafterstabilizationandthepressureat

following information:

the end of the test.

17.1.1 Test Date

15.8 Once the stabilization time has been determined for a

17.1.2 Test Time

particular test system, it is not required to perform multiple

17.1.3 Test Technician

pressure measurements when utilizing Method A. The initial

17.1.4 Test Accuracy

pressure after stabilization and the final pressure are sufficient.

17.1.5 Beginning vessel test pressure

16. Calculation or Interpretation of Results

17.1.6 Ending vessel test pressure

16.1 The leak rates should be calculated with equation 4 in

17.1.7 Average reference test pressure (pressure outside of

15.5. The significance of the measured leak rates should be

vessel)

interpretedfromthecomputedtestresolutionandtestaccuracy.

17.1.8 Average test temperature

Measured leak rates which are less than or equal to either the

17.1.9 Duration of test

test accuracy or test resolution are not significant.

17.1.10 Test gas

16.2 MethodA—TheleakrateshouldbecalculatedusingEq

17.1.11 Average test leak rate in standard units

1 and 2 in 15.5 with the pressure change,�P, calculated as the

difference between the pressure after stabilization from the

18. Precision and Bias

pressure at the end of the test. The change in time, �t, is the

18.1 Precision and Bias—The bias should be calculated

differenceine

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.