ASTM D7754-11e1

(Test Method)Standard Test Method for Determination of Trace Oxygenates in Automotive Spark-Ignition Engine Fuel by Multidimensional Gas Chromatography

Standard Test Method for Determination of Trace Oxygenates in Automotive Spark-Ignition Engine Fuel by Multidimensional Gas Chromatography

SIGNIFICANCE AND USE

5.1 The analysis of trace oxygenates in automotive spark-ignition engine fuel has become routine in certain areas to ensure compliance whenever oxygenated fuels are used. In addition, test methods to measure trace levels of oxygenates in automotive spark-ignition fuel are necessary to assess product quality.

SCOPE

1.1 This test method covers the determination of trace oxygenates in automotive spark-ignition engine fuel. The method used is a multidimensional gas chromatographic method using 1,2-dimethoxy ethane as the internal standard. The oxygenates that are analyzed are: methyl-tertiary butyl ether (MTBE), ethyl-tertiary butyl ether (ETBE), diisopropyl ether (DIPE), methanol, tertiary-amyl methyl ether (TAME), n-propanol, i-propanol, n-butanol, i-butanol, tert-butyl alcohol, sec-butyl alcohol, and tert-pentanol. Ethanol is usually not measured as a trace oxygenate since ethanol can be used as the main oxygenate compound in finished automotive spark-ignition fuels such as reformulated automotive spark-ignition fuels. The concentration range of the oxygenates covered in the ILS study was from 10 µg/Kg to 2000 µg/Kg. In addition this method is also suitable for the measurement of the C5 isomeric alcohols (2-methyl-1-butanol, 2-methyl-2-butanol) present from the fermentation of ethanol.

1.2 The ethanol blending concentration for which this test method applies ranges from 1 to 15% by volume. Higher concentrations of ethanol coelute with methanol in the analytical column. Lower levels of ethanol, similar to the other oxygenate, can be calibrated and analyzed also. If higher ethanol concentrations are expected, the window cutting technique can be used to avoid ethanol from entering the analytical column and interfere with the determination of the other oxygenates of interest. Refer to Appendix X1 for details.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3.1 Alternate units, in common usage, are also provided to increase clarity and aid the users of this test method.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: D7754 − 11

StandardTest Method for

Determination of Trace Oxygenates in Automotive Spark-

Ignition Engine Fuel by Multidimensional Gas

1

Chromatography

This standard is issued under the fixed designation D7754; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Research report information was added editorially to Section 14 in November 2015.

1. Scope 1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This test method covers the determination of trace

responsibility of the user of this standard to establish appro-

oxygenates in automotive spark-ignition engine fuel. The

priate safety and health practices and determine the applica-

method used is a multidimensional gas chromatographic

bility of regulatory limitations prior to use.

method using 1,2-dimethoxy ethane as the internal standard.

The oxygenates that are analyzed are: methyl-tertiary butyl

2. Referenced Documents

ether (MTBE), ethyl-tertiary butyl ether (ETBE), diisopropyl

2

ether (DIPE), methanol, tertiary-amyl methyl ether (TAME),

2.1 ASTM Standards:

n-propanol, i-propanol, n-butanol, i-butanol, tert-butyl alcohol,

D4057 Practice for Manual Sampling of Petroleum and

sec-butyl alcohol, and tert-pentanol. Ethanol is usually not

Petroleum Products

measured as a trace oxygenate since ethanol can be used as the

D4307 Practice for Preparation of Liquid Blends for Use as

main oxygenate compound in finished automotive spark-

Analytical Standards

ignition fuels such as reformulated automotive spark-ignition

D4815 Test Method for Determination of MTBE, ETBE,

fuels.Theconcentrationrangeoftheoxygenatescoveredinthe

TAME, DIPE, tertiary-Amyl Alcohol and C to C Alco-

1 4

ILS study was from 10 µg/Kg to 2000 µg/Kg. In addition this

hols in Gasoline by Gas Chromatography

method is also suitable for the measurement of the C5 isomeric

D6304 Test Method for Determination of Water in Petro-

alcohols (2-methyl-1-butanol, 2-methyl-2-butanol) present

leum Products, Lubricating Oils, and Additives by Cou-

from the fermentation of ethanol.

lometric Karl Fischer Titration

1.2 The ethanol blending concentration for which this test

3. Terminology

method applies ranges from 1 to 15% by volume. Higher

concentrations of ethanol coelute with methanol in the analyti- 3.1 Definitions of Terms Specific to This Standard:

cal column. Lower levels of ethanol, similar to the other

3.1.1 electronic pressure control, n—electronic pneumatic

oxygenate, can be calibrated and analyzed also. If higher

control of carrier gas flows. Can be flow or pressure pro-

ethanol concentrations are expected, the window cutting tech-

grammed to speed up elution of components.

nique can be used to avoid ethanol from entering the analytical

3.1.2 flame ionization detector (FID), n—detector used to

column and interfere with the determination of the other

analyze the components eluting from the column.

oxygenates of interest. Refer to Appendix X1 for details.

3.1.3 fluidic switch, n—device that reverses the directional

1.3 The values stated in SI units are to be regarded as

flow in a union T altering the pressure at the midpoint. In its

standard. No other units of measurement are included in this

simplest design it is also known as a Dean Switch.

standard.

3.1.4 inlet, n—capillary split/splitless inlet system operated

1.3.1 Alternateunits,incommonusage,arealsoprovidedto

in the split mode is recommended. Operate the inlet within its

increase clarity and aid the users of this test method.

linear range.

1

This test method is under the jurisdiction of ASTM Committee D02 on

2

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Subcommittee D02.04.0L on Gas Chromatography Methods. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

CurrenteditionapprovedOct.1,2011.PublishedNovember2011.DOI:10.1520/ Standards volume information, refer to the standard’s Document Summary page on

D7754-11E01. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

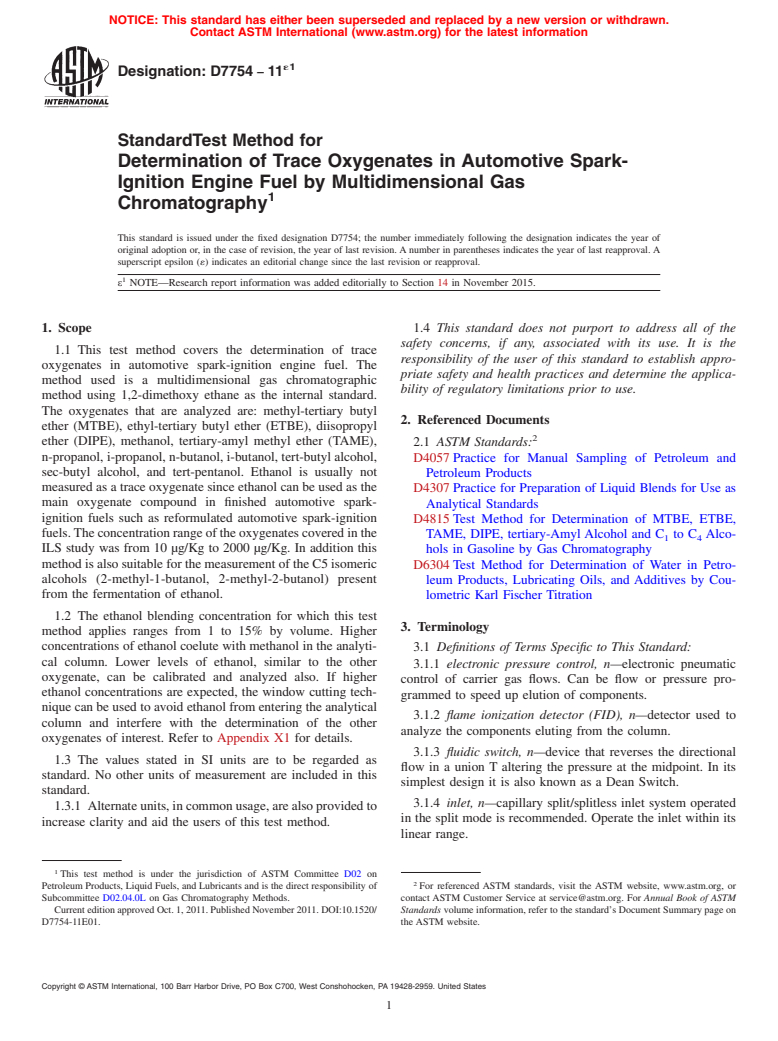

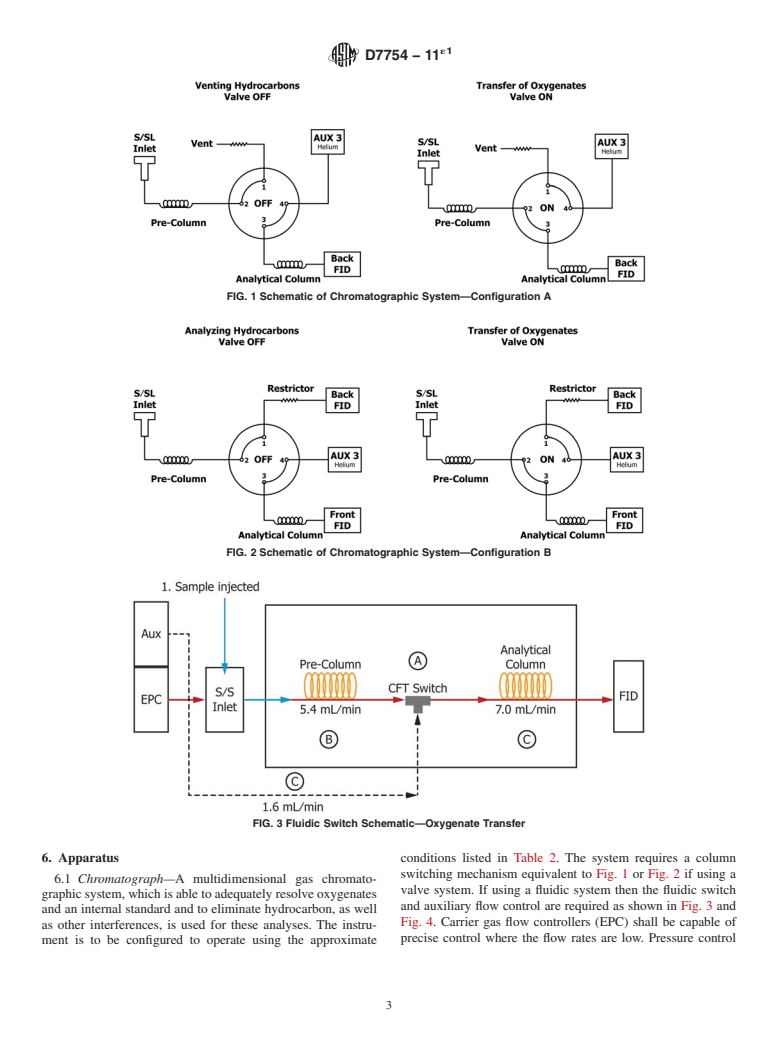

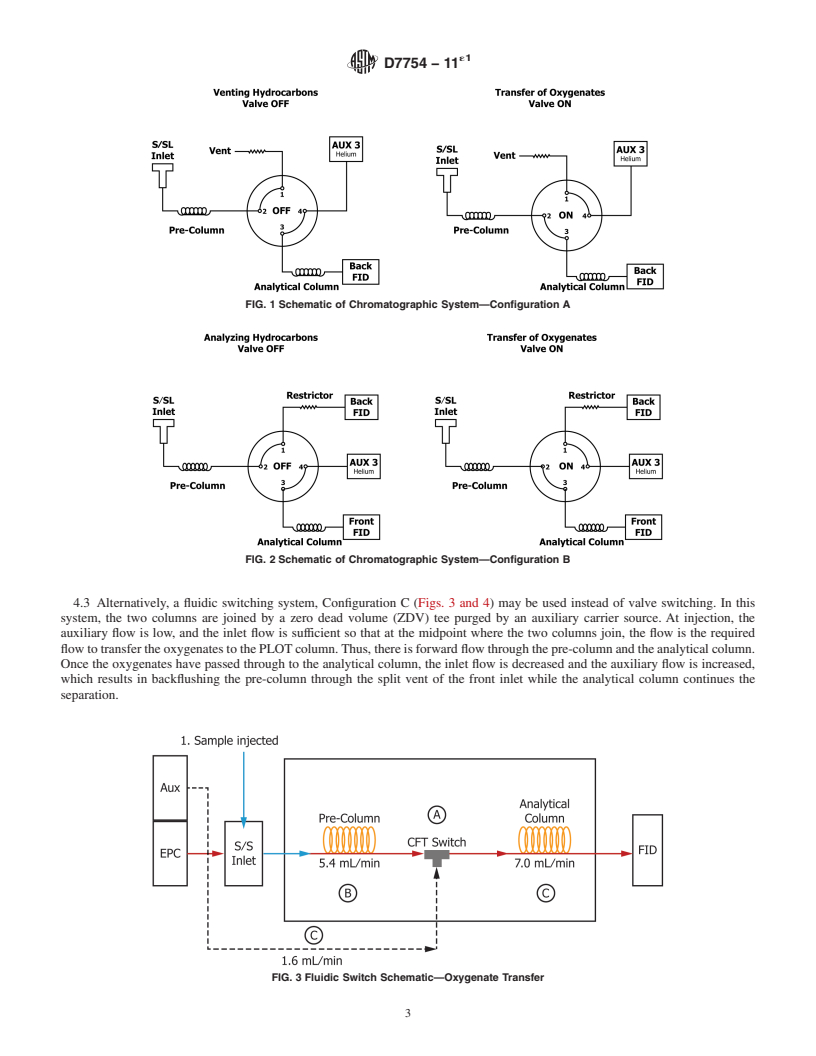

---------------------- Page: 1 ----------------------

´1

D7754 − 11

3.1.4.1 split ratio, n— in capillary gas chromatography, the and the DME are transferred to the analytical oxygen selective

ratio of the total flow of carrier gas to the sample inlet versus column by the switching valve. While the oxygenates and the

the flow of the carrier gas to the capillary column is expressed DM

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: D7754 − 11 D7754 − 11

Standard Test Method for

Determination of Trace Oxygenates in Automotive Spark-

Ignition Engine Fuel by Multidimensional Gas

1

Chromatography

This standard is issued under the fixed designation D7754; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Research report information was added editorially to Section 14 in November 2015.

1. Scope

1.1 This test method covers the determination of trace oxygenates in automotive spark-ignition engine fuel. The method used

is a multidimensional gas chromatographic method using 1,2-dimethoxy ethane as the internal standard. The oxygenates that are

analyzed are: methyl-tertiary butyl ether (MTBE), ethyl-tertiary butyl ether (ETBE), diisopropyl ether (DIPE), methanol,

tertiary-amyl methyl ether (TAME), n-propanol, i-propanol, n-butanol, i-butanol, tert-butyl alcohol, sec-butyl alcohol, and

tert-pentanol. Ethanol is usually not measured as a trace oxygenate since ethanol can be used as the main oxygenate compound

in finished automotive spark-ignition fuels such as reformulated automotive spark-ignition fuels. The concentration range of the

oxygenates covered in the ILS study was from 10 μg/Kg to 2000 μg/Kg. In addition this method is also suitable for the

measurement of the C5 isomeric alcohols (2-methyl-1-butanol, 2-methyl-2-butanol) present from the fermentation of ethanol.

1.2 The ethanol blending concentration for which this test method applies ranges from 1 to 15% by volume. Higher

concentrations of ethanol coelute with methanol in the analytical column. Lower levels of ethanol, similar to the other oxygenate,

can be calibrated and analyzed also. If higher ethanol concentrations are expected, the window cutting technique can be used to

avoid ethanol from entering the analytical column and interfere with the determination of the other oxygenates of interest. Refer

to Appendix X1 for details.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3.1 Alternate units, in common usage, are also provided to increase clarity and aid the users of this test method.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D4057 Practice for Manual Sampling of Petroleum and Petroleum Products

D4307 Practice for Preparation of Liquid Blends for Use as Analytical Standards

D4815 Test Method for Determination of MTBE, ETBE, TAME, DIPE, tertiary-Amyl Alcohol and C to C Alcohols in

1 4

Gasoline by Gas Chromatography

D6304 Test Method for Determination of Water in Petroleum Products, Lubricating Oils, and Additives by Coulometric Karl

Fischer Titration

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 electronic pressure control, n—electronic pneumatic control of carrier gas flows. Can be flow or pressure programmed to

speed up elution of components.

1

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcommittee

D02.04.0L on Gas Chromatography Methods.

Current edition approved Oct. 1, 2011. Published November 2011. DOI:10.1520/D7754–11DOI:10.1520/D7754-11E01.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

´1

D7754 − 11

3.1.2 flame ionization detector (FID), n—detector used to analyze the components eluting from the column.

3.1.3 fluidic switch, n—device that reverses the directional flow in a union T altering the pressure at the midpoint. In its simplest

design it is also known as a Dean Switch.

3.1.4 inlet, n—capillary split/splitless inlet system operated in the split mode is recommended. Operate the inlet within its linear

ran

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.