ASTM F2165-02(2008)

(Specification)Standard Specification for Flexible Pre-Insulated Piping

Standard Specification for Flexible Pre-Insulated Piping

ABSTRACT

This specification establishes the materials and performance requirements for flexible, pre-insulated piping intended for hot and chilled water applications. Piping system may include one or more carrier pipes within a common outer jacket and shall be supplied in coil form. Carrier-pipe, thermal-insulation, and protective-jacket material shall be continuous and uniform throughout the coil while connections and joints in the carrier pipe and the protective jacket shall not be allowed within the coil. The pipe assembly shall be subjected to end seal and bending force tests for water infiltration inspection and to ensure the flexibility of the piping system, respectively.

SCOPE

1.1 This specification covers flexible, pre-insulated piping commonly used to convey hot and cold fluids.

1.2 This specification establishes materials and performance requirements for flexible, pre-insulated piping intended for hot and chilled water applications.

1.3 Piping systems may include one or more carrier pipes within a common outer jacket.

1.4 The text of this specification references notes and footnotes that provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered part of this standard.

1.5 Units—The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.6 The following safety hazards caveat pertains to the test methods portion, Section 7, of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F2165 −02(Reapproved 2008) An American National Standard

Standard Specification for

Flexible Pre-Insulated Piping

This standard is issued under the fixed designation F2165; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

This specification covers materials and test methods for flexible, pre-insulated piping with

non-bonded insulation. For the purpose of this standard, flexible pre-insulated piping system shall

refertoapipingsystemthatissuppliedcompletewithcarrierpipe,thermalinsulation,andouterjacket

manufactured as an integrated system, and is supplied in a coil. This specification covers the

requirements, material specifications, and test methods of piping systems intended to convey hot and

cold fluids. Piping systems may include one or more carrier pipes within a common outer jacket.

1. Scope 2. Referenced Documents

1.1 This specification covers flexible, pre-insulated piping 2.1 ASTM Standards:

commonly used to convey hot and cold fluids. C168Terminology Relating to Thermal Insulation

C177Test Method for Steady-State Heat Flux Measure-

1.2 Thisspecificationestablishesmaterialsandperformance

ments and Thermal Transmission Properties by Means of

requirements for flexible, pre-insulated piping intended for hot

the Guarded-Hot-Plate Apparatus

and chilled water applications.

D1600TerminologyforAbbreviatedTermsRelatingtoPlas-

1.3 Piping systems may include one or more carrier pipes

tics

within a common outer jacket.

D2104Specification for Polyethylene (PE) Plastic Pipe,

1.4 The text of this specification references notes and Schedule 40 (Withdrawn 2010)

D2239Specification for Polyethylene (PE) Plastic Pipe

footnotes that provide explanatory material. These notes and

footnotes (excluding those in tables and figures) shall not be (SIDR-PR) Based on Controlled Inside Diameter

D3035SpecificationforPolyethylene(PE)PlasticPipe(DR-

considered part of this standard.

PR) Based on Controlled Outside Diameter

1.5 Units—The values stated in inch-pound units are to be

F412Terminology Relating to Plastic Piping Systems

regarded as standard. The values given in parentheses are

F714Specification for Polyethylene (PE) Plastic Pipe (DR-

mathematical conversions to SI units that are provided for

PR) Based on Outside Diameter

information only and are not considered standard.

F876SpecificationforCrosslinkedPolyethylene(PEX)Tub-

1.6 The following safety hazards caveat pertains to the test

ing

methods portion, Section 7, of this specification. This standard

F877SpecificationforCrosslinkedPolyethylene(PEX)Hot-

does not purport to address all of the safety concerns, if any,

and Cold-Water Distribution Systems

associated with its use. It is the responsibility of the user of this

F1281 Specification for Crosslinked Polyethylene/

standard to establish appropriate safety and health practices

Aluminum/Crosslinked Polyethylene (PEX-AL-PEX)

and determine the applicability of regulatory requirements

Pressure Pipe

prior to use.

F1282 Specification for Polyethylene/Aluminum/

1 2

This specification is under the jurisdiction ofASTM Committee F17 on Plastic For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Piping Systems and is the direct responsibility of Subcommittee F17.11 on contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Composite. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved May 1, 2008. Published November 2008. Originally the ASTM website.

approved in 2002. Last previous edition approved in 2002 as F2165–02. DOI: The last approved version of this historical standard is referenced on

10.1520/F2165-02R08. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2165−02 (2008)

Polyethylene (PE-AL-PE) Composite Pressure Pipe 4. Significance and Use

2.2 NSF Standards:

4.1 Thisspecificationestablishesmaterialsandperformance

ANSI/NSF 14Plastics and Plumbing System Components

requirements for flexible, pre-insulated piping intended for hot

ANSI/NSF61DrinkingWaterSystemComponents—Health

and chilled water applications.

Effects

4.2 The bending force test ensures that the installer will

2.3 DIN Standards :

obtain materials that will be suitable for installation as flexible

DIN 8074Polyethylene (PE) Pipes, PE 63, PE 80, PE-100,

piping.

PE-HD—General Quality Requirements and Testing

DIN 8075Polyethylene (PE) Pipes, PE 63, PE 80, PE-100,

5. Materials

PE-HD—Dimensions

5.1 Carrier Pipe(s):

DIN16892 CrosslinkedPolyethylenePipes—GeneralQual-

5.1.1 PEX carrier pipe shall conform to one or more of the

ity Requirements and Testing

following: Specifications F876, F877; DIN 16892 or DIN

DIN 16893 Crosslinked Polyethylene Pipes—Dimensions

16893.

5.1.2 PE carrier pipe shall conform to one or more of the

3. Terminology

following: Specifications D2104, D2239, D3035, F714; DIN

3.1 Definitions are in accordance with Terminology F412

8075 or DIN 8074.

for plastic piping systems and C168 for thermal insulating

5.1.3 Composite carrier pipe shall confirm to Specifications

materials; abbreviations are in accordance with Terminology

F1281 or F1282.

D1600 unless otherwise indicated.

5.1.4 Otherpipingmaterialsasspecifiedbycustomerspeci-

3.2 Definitions of Terms Specific to This Standard:

fications.

3.2.1 bonded insulation system, n—a product that is the

5.2 Thermal Insulation:

result of applying thermal insulation to a carrier pipe where a

5.2.1 Insulationshallhaveamaximumthermalconductivity

bond forms between the insulation and the carrier pipe that

of 0.30 BTU·in./h·ft ·°F (0.04 W/(m·K) when measured in

exceeds the modulus of elasticity of the carrier pipe.

accordance with Test Method C177.

3.2.2 carrier pipe, n—thepipe(s)thatareusedtoconveythe

5.2.2 All seams of the insulation shall be sealed.

medium.

5.2.3 Insulation shall be visually inspected for voids and

3.2.3 crosslinked polyethylene (PEX) plastic, n— plastic otherdefectspriortotheapplicationofthejacket.Anyvoidsor

prepared by crosslinking (curing) polyethylene compounds. variance in thickness greater than 0.1 in. shall be reason for

rejection. Manufacturer shall repair or replace defective insu-

3.2.4 end seal, n—a device that provides a seal between the

lation before product is shipped to the customer. Channels for

outer jacket and carrier pipe, providing a moisture barrier for

heattrace,controlwiring,ororientationmarkingsareexcluded

the insulation.

from this requirement.

3.2.5 flexible pre-insulated pipe system, n—afactorymanu-

5.2.4 Insulation shall not be bonded to the carrier pipe.

facturedpre-insulatedpipesystemconsistingofcarrierpipe(s),

5.3 Outer Jacket:

thermalinsulatingmaterial,andprotectivejacket.Thisproduct

5.3.1 The outer jacket shall be constructed of a watertight,

is supplied in coils.

corrugated material.

3.2.6 jacket, n—the outer covering of the flexible pre-

5.3.2 Theouterjacketshallcontain2weightpercentcarbon

insulated pipe system. The jacket provides mechanical and

black, finely divided and thoroughly dispersed to provide

moisture protection for the insulation.

protection from UV degradation.

3.2.7 non-bonded insulation system, n—aproductthatisthe

5.4 Materials to join sections of the carrier pipe or to

result of applying thermal insulation to a carrier pipe without

transition to other piping materials shall be supplied by the

bonding the insulation to the carrier pipe, allowing the carrier

system supplier and shall be one of the following types:

pipe to move freely within the insulation.

5.4.1 Compression Fittings, or

3.2.8 pipe joint, n—a connection between two sections of

5.4.2 Heat-Fusion Welding.

piping material. The pipe joint shall include the connection of

5.5 The system supplier shall supply insulation and cover

the carrier pipe, insulation of the bare section carrier pipe, and

for any joints.

protective outer jacket.

3.2.9 thermal insulation, n—a general term used to describe

6. Requirements

any material that reduces heat transfer.

6.1 The system shall be supplied in c

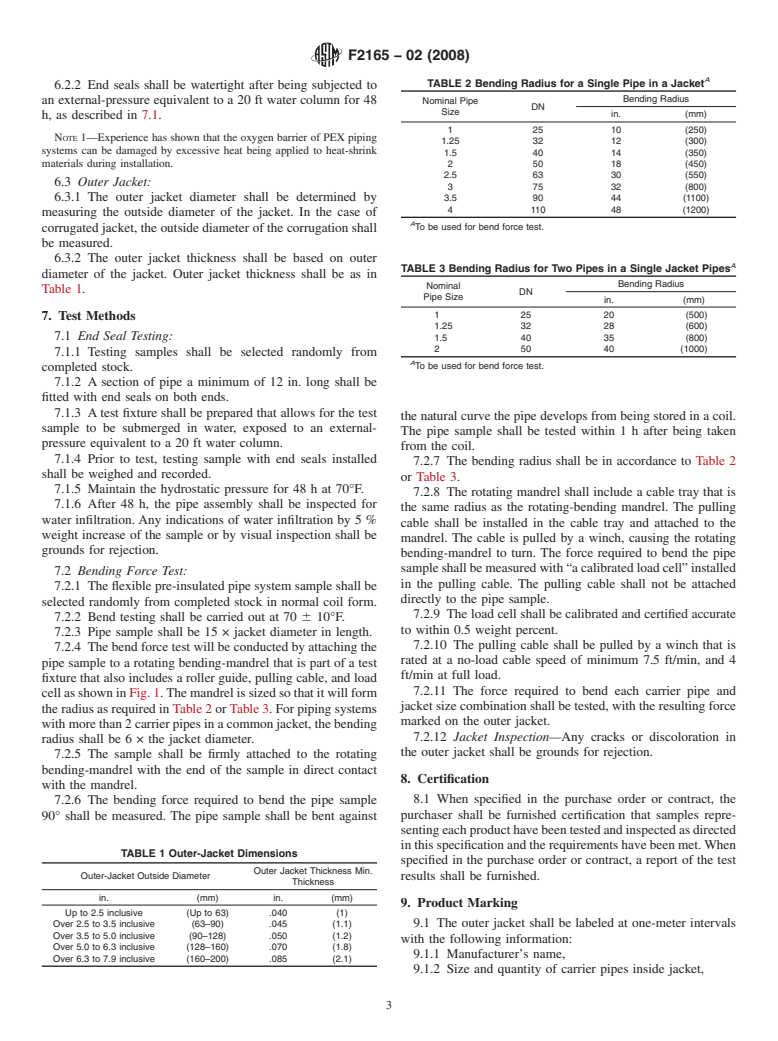

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.