ASTM B976-11(2015)

(Specification)Standard Specification for Fiber Reinforced Aluminum Matrix Composite (AMC) Core Wire for Aluminum Conductors, Composite Reinforced (ACCR)

Standard Specification for Fiber Reinforced Aluminum Matrix Composite (AMC) Core Wire for Aluminum Conductors, Composite Reinforced (ACCR)

ABSTRACT

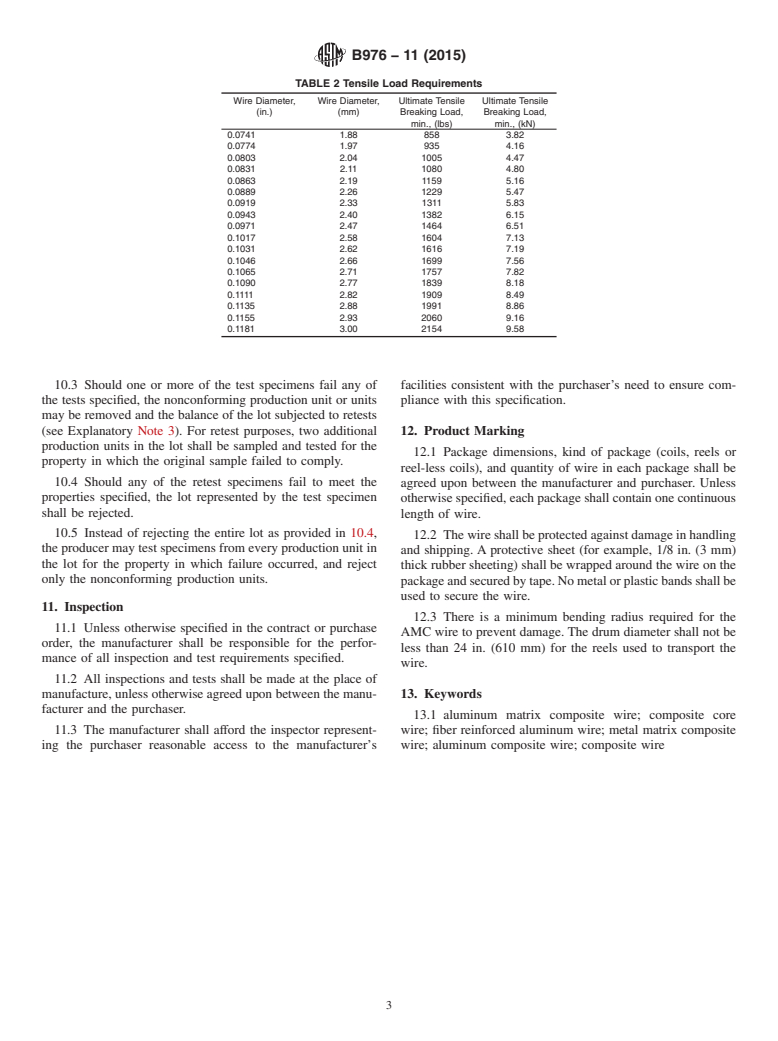

This specification covers fiber reinforced, aluminum matrix composite wire used for mechanical reinforcement in the manufacture of aluminum conductor, composite reinforced (ACCR). This wire consists of continuous filament fibers of aluminum oxide in a matrix of aluminum. The fiber reinforcement shall be continuous tows of aluminum oxide. Before stranding, the composite core wire of any diameter shall conform to the tensile breaking load requirements.

SCOPE

1.1 This specification covers fiber reinforced, aluminum matrix composite core wire used for mechanical reinforcement in the manufacture of aluminum conductor, composite reinforced (ACCR). This wire consists of continuous filament fibers of aluminum oxide in a matrix of aluminum.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.2.1 Exception—Some non-standard SI units provided for information only do not appear in brackets.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B976 −11 (Reapproved 2015)

Standard Specification for

Fiber Reinforced Aluminum Matrix Composite (AMC) Core

Wire for Aluminum Conductors, Composite Reinforced

1

(ACCR)

This standard is issued under the fixed designation B976; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

3.1 Definitions of Terms Specific to This Standard:

1.1 This specification covers fiber reinforced, aluminum

3.1.1 fiber reinforced aluminum matrix composite wire, n—a

matrix composite core wire used for mechanical reinforcement

wire consisting of two constituents: the first a number of

in the manufacture of aluminum conductor, composite rein-

continuousfibersofaluminumoxidealongtheaxisofthewire,

forced (ACCR). This wire consists of continuous filament

which is embedded in the second constituent of aluminum

fibers of aluminum oxide in a matrix of aluminum.

metal, as shown in Fig. 1.

1.2 The values stated in inch-pound units are to be regarded

3.1.2 lot, n—unless otherwise specified in the contract or

as standard. The values given in parentheses are mathematical

order, a lot shall consist of all coils of wire of the same

conversions to SI units that are provided for information only

diameter submitted for inspection at the same time.

and are not considered standard.

3.1.3 production unit, n—a reel, spool, or other package of

1.2.1 Exception—Some non-standard SI units provided for

wire that represents a single usable length.

information only do not appear in brackets.

3.1.4 sample, n—the production unit(s) from which a test

1.3 This standard does not purport to address all of the

specimen(s) has been removed, and which is considered to

safety concerns, if any, associated with its use. It is the

have properties representative of the lot.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- 3.1.5 specimen, n—a length of wire removed for test pur-

bility of regulatory limitations prior to use. poses.

3.1.6 tow, n—a bundle, containing multiple fibers.

2. Referenced Documents

3.1.7 AMC, n—Aluminum Matrix Composite, a material

2.1 The following documents of the issue in effect on date

consisting of two constituents: the first a series of continuous

of material purchase form a part of this specification to the fibers of aluminum oxide which is embedded in the second

extent referenced herein.

constituent of aluminum metal.

2

3.1.8 ACCR, n—Aluminum Conductor Composite

2.2 ASTM Standards:

Reinforced, a concentric-lay-stranded conductor made up of

B193 Test Method for Resistivity of Electrical Conductor

outer aluminum strands of hard, heat resistant aluminum wires

Materials

and a core of round, aluminum matrix composite wire(s), for

B830 Specification for Uniform Test Methods and Fre-

use as overhead electrical conductors.

quency

D3552 Test Method for Tensile Properties of Fiber Rein-

4. Ordering Information

forced Metal Matrix Composites

4.1 Orders for material under this specification shall include

the following information:

4.1.1 Quantity of each size,

1

This specification is under the jurisdiction of ASTM Committee B01 on

4.1.2 Wire size (see 8.1),

Electrical Conductors and is the direct responsibility of Subcommittee B01.07 on

4.1.3 Place of inspection (see 11.1),

Conductors of Light Metals.

4.1.4 Package size and type (see 12.1),

Current edition approved Oct. 1, 2015. Published October 2015. Originally

approved in 2011. Last previous edition approved in 2011 as B976 – 11. DOI:

4.1.5 Special package marking.

10.1520/B0976-11R15.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5. Materials and Manufacture

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.1 The fiber reinforcement shall be continuous tows of

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. aluminum oxide.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B976−11 (2015)

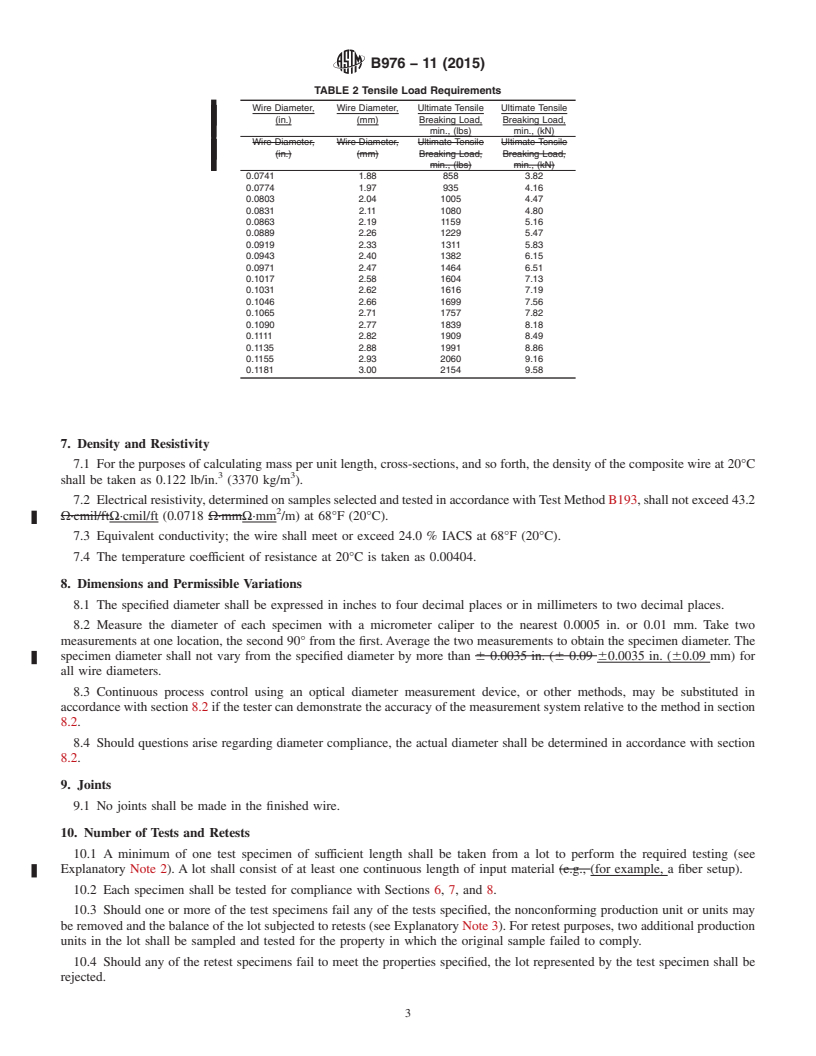

NOTE 1—Dark Phases are fiber viewed end-on and the light phase is aluminum matrix. The equivalent diameter of the fibers is approximately 470 µin.

(12 µm).

FIG. 1Polished Cross-section of an Aluminum Matrix Composite Wire

5.2 The core wires shall be of such quality and purity that 7. Density and Resistivity

the finished product shall have the approximate properties and

7.1 For the purposes of calculating mass per unit length,

characteristics prescribed in this specification, including break-

cross-sec

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B976 − 11 B976 − 11 (Reapproved 2015)

Standard Specification for

Fiber Reinforced Aluminum Matrix Composite (AMC) Core

Wire for Aluminum Conductors, Composite Reinforced

1

(ACCR)

This standard is issued under the fixed designation B976; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers fiber reinforced, aluminum matrix composite core wire used for mechanical reinforcement in the

manufacture of aluminum conductor, composite reinforced (ACCR). This wire consists of continuous filament fibers of aluminum

oxide in a matrix of aluminum.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.2.1 Exception—Some non-standard SI units provided for information only do not appear in brackets.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 The following documents of the issue in effect on date of material purchase form a part of this specification to the extent

referenced herein.

2

2.2 ASTM Standards:

B193 Test Method for Resistivity of Electrical Conductor Materials

B830 Specification for Uniform Test Methods and Frequency

D3552 Test Method for Tensile Properties of Fiber Reinforced Metal Matrix Composites

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 fiber reinforced aluminum matrix composite wire, n—a wire consisting of two constituents: the first a number of

continuous fibers of aluminum oxide along the axis of the wire, which is embedded in the second constituent of aluminum metal,

as shown in Fig. 1.

3.1.2 lot, n—unless otherwise specified in the contract or order, a lot shall consist of all coils of wire of the same diameter

submitted for inspection at the same time.

3.1.3 production unit, n—a reel, spool, or other package of wire that represents a single usable length.

3.1.4 sample, n—the production unit(s) from which a test specimen(s) has been removed, and which is considered to have

properties representative of the lot.

3.1.5 specimen, n—a length of wire removed for test purposes.

3.1.6 tow, n—a bundle, containing multiple fibers.

3.1.7 AMC, n—Aluminum Matrix Composite, a material consisting of two constituents: the first a series of continuous fibers

of aluminum oxide which is embedded in the second constituent of aluminum metal.

1

This specification is under the jurisdiction of ASTM Committee B01 on Electrical Conductors and is the direct responsibility of Subcommittee B01.07 on Conductors

of Light Metals.

Current edition approved April 1, 2011Oct. 1, 2015. Published May 2011October 2015. Originally approved in 2011. Last previous edition approved in 2011 as B976 –

11. DOI: 10.1520/B0976-11.10.1520/B0976-11R15.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’sstandard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B976 − 11 (2015)

NOTE 1—Dark Phases are fiber viewed end-on and the light phase is aluminum matrix. The equivalent diameter of the fibers is approximately 470 μin.

(12 μm).

FIG. 1 Polished Cross-section of an Aluminum Matrix Composite Wire.Wire

3.1.8 ACCR, n—Aluminum Conductor Composite Reinforced, a concentric-lay-stranded conductor made up of outer aluminum

strands of hard, heat resistant aluminum wires and a core of round, aluminum matrix composite wire(s), for use as overhead

electrical conductors.

4. Ordering Information

4.1 Orders for material under this specification shall include the following information:

4.1.1 Quantity of each size,

4.1.2 Wire size (see 8.1),

4.1.3 Place of inspection (see 11.1),

4.1.4 Package size and type (see 12.1) ),

4.1.5 Special package markingmarking.

5. Materials and Manufacture

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.