ASTM E2160-01

(Test Method)Standard Test Method for Heat of Reaction of Thermally Reactive Materials by Differential Scanning Calorimetry

Standard Test Method for Heat of Reaction of Thermally Reactive Materials by Differential Scanning Calorimetry

SCOPE

1.1 This test method determines the exothermic heat of reaction of thermally reactive chemicals or chemical mixtures, using milligram specimen sizes, by differential scanning calorimetry. Such reactive materials may include thermally unstable or thermoset materials.

1.2 This test method also determines the extrapolated onset temperature and peak heat flow temperature for the exothermic reaction.

1.3 This test method may be performed on solids, liquids or slurries.

1.4 The applicable temperature range of this method is 25 to 600°C.

1.5 SI units are to be regarded as the standard.

1.6 There is no ISO method equivalent to this standard.

1.7 This standard is related to Test Method E 537 and to NAS 1613, but provides additional information.

1.8 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E 2160 – 01

Standard Test Method for

Heat of Reaction of Thermally Reactive Materials by

Differential Scanning Calorimetry

This standard is issued under the fixed designation E 2160; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope E 1231 Practice for Hazard Potential Figures-of-Merit for

Thermally Unstable Materials

1.1 This test method determines the exothermic heat of

E 1860 Test Method for Elapsed Time Calibration of Ther-

reaction of thermally reactive chemicals or chemical mixtures,

mal Analyzers

using milligram specimen sizes, by differential scanning calo-

2.2 Other Standard:

rimetry. Such reactive materials may include thermally un-

NAS 1613 Seal Element, Packing, Preformed, Ethylene

stable or thermoset materials.

Propylene Rubber, National Aerospace Standard, Aero-

1.2 This test method also determines the extrapolated onset

space Industries Association of America, 1725 DeSales

temperature and peak heat flow temperature for the exothermic

St., NM, Washington, DC 20036

reaction.

1.3 This test method may be performed on solids, liquids or

3. Terminology

slurries.

3.1 Specific technical terms used in this standard are defined

1.4 The applicable temperature range of this method is 25 to

in Terminologies E 473 and E 1142.

600°C.

1.5 SI units are to be regarded as the standard.

4. Summary of Test Method

1.6 There is no ISO method equivalent to this standard.

4.1 A small (milligram) quantity of the reactive material is

1.7 This standard is related to Test Method E 537 and to

heated at 10°C/min through a temperature region where a

NAS 1613, but provides additional information.

chemical reaction takes place. The exothermic heat flow

1.8 This standard may involve hazardous materials, opera-

produced by the reaction is recorded as a function of tempera-

tions, and equipment. This standard does not purport to

ture and time by a differential scanning calorimeter. Integration

address all of the safety concerns, if any, associated with its

of the exothermic heat flow over time yields the heat of

use. It is the responsibility of the user of this standard to

reaction. If the heat flow is endothermic, then this test method

establish appropriate safety and health practices and deter-

is not to be used.

mine the applicability of regulatory limitations prior to use.

4.2 The test method can be used to determine the fraction of

a reaction that has occurred in a partially reacted sample. The

2. Referenced Documents

heat of reaction is determined for a specimen that is known to

2.1 ASTM Standards:

2 be 100 % unreacted and is compared to the heat of reaction

E 473 Terminology Relating to Thermal Analysis

determined for the partially reacted sample. Appropriate cal-

E 537 Test Method for Assessing the Thermal Stability of

2 culation yields the fraction of the latter sample that was

Chemicals by Methods of Thermal Analysis

unreacted.

E 967 Practice for Temperature Calibration of Differential

4.3 Subtracting the reaction fraction remaining from unity

Scanning Calorimeters and Differential Thermal Analyz-

(1) yields the fraction reacted. The fraction reacted may be

ers

expressed as percent. If the sample tested is a thermoset resin,

E 968 Practice of Heat Flow Calibration of Differential

the percent reacted is often called the percent of cure.

Scanning Calorimeters

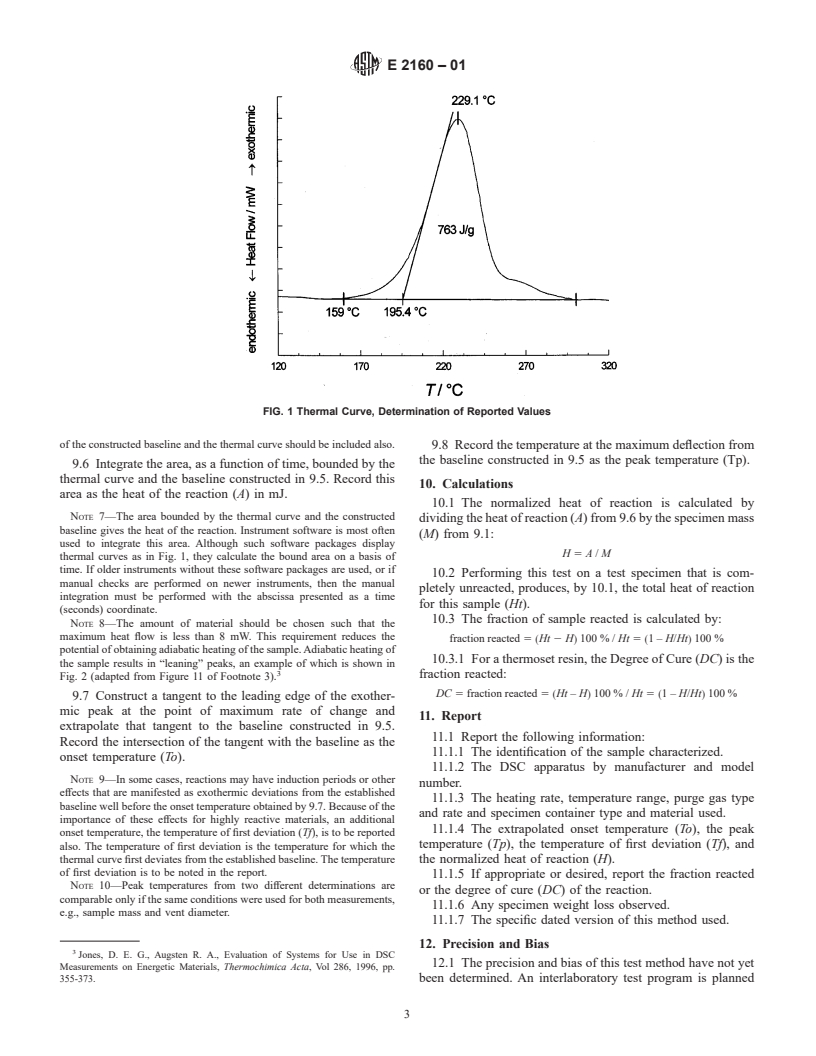

4.4 The extrapolated onset temperature and peak heat flow

E 1142 Terminology Relating to Thermophysical Proper-

temperature are determined for the exothermic heat flow

ties

thermal curve from 4.1.

5. Significance and Use

This test method is under the jurisdiction of ASTM Committee E37 on Thermal

Measurements and is the direct responsibility of Subcommittee E37.01 on Thermal

5.1 This method is useful in determining the extrapolated

Analysis Test Methods.

onset temperature, the peak heat flow temperature and the heat

Current edition approved Sept. 10, 2001. Published December 2001.

of reaction of a material. Any onset temperature determined by

Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E2160–01

this method is not valid for use as the sole information used for personnel or the apparatus. Use of an exhaust system to remove

determination of storage or processing conditions. such effluents is recommended.

5.2 This test method is useful in determining the fraction of

8. Calibration

a reaction that has been completed in a sample prior to testing.

This fraction of reaction that has been completed can be a 8.1 Perform any calibration procedures recommended by

the apparatus manufacturer as described in the Operations

measure of the degree of cure of a thermally reactive polymer

or can be a measure of decomposition of a thermally reactive Manual.

8.2 Calibrate the temperature signal to within 6 2 °C using

material upon aging.

5.3 The heat of reaction values may be used in Practice Practice E 967.

8.3 Calibrate the heat flow signal to within 6 0.5 % using

E 1231 to determine hazard potential figures-of-merit Explo-

sion Potential and Shock Sensitivity. Practice E 968.

8.4 Calibrate the elapsed time signal, or ascertain its accu-

5.4 This test method may be used in research, process

control, quality assurance, and specification acceptance. racy, to within 6 0.5 % using Test Method E 1860.

9. Procedure

6. Apparatus

9.1 Into a tared sample container, weigh to within 6 1μg, 1

6.1 Differential Scanning Calorimeter (DSC), capable of

to 2 mg of the test specimen. Record this mass as M in mg.

measuring and recording heat flow as a function of temperature

Close the sample container but provide a vent to ensure that the

and time. Such a DSC is composed of:

internal pressure is in equilibrium with the ambient pressure.

6.1.1 Test Chamber, composed of:

Weigh the sealed container to within 6 1 μg and recorded this

6.1.1.1 Furnace(s), to provide uniform controlled heating of

mass as N in mg.

a specimen and reference to a constant temperature or at a

constant rate within the temperature range of 25 to 600°C.

NOTE 2—Because of the reactive nature of the materials examined by

6.1.1.2 Temperature Sensor, to provide an indication of the this method, small specimen sizes shall be used unless the approximate

reactivity of the test specimen is known. Other specimen sizes may be

specimen or furnace temperature to within 6 0.5°C.

used but shall be reported. Make sure that the specimen is homogenous

6.1.1.3 Differential Sensor, to detect a heat flow difference

and represents the sample.

between the specimen and reference equivalent to 0.2 mW.

NOTE 3—Some substances may have non-reactive components mixed

6.1.1.4 Means of Sustaining a Test Chamber Environment,

with the thermally reactive material. An example would be reinforcing

of inert (for example, nitrogen, helium or argon) or reactive

fibers mixed with a thermally-curing polymer. A specification of the

(for example, air) gas at a purge rate of 50 6 5 mL/min.

fraction of inert material in the mixture may accompany these materials.

The user should be aware that such specifications involve tolerances so

NOTE 1—Typically, at least 99 % pure nitrogen, helium or argon is

that the actual fraction of inert material may vary within these tolerances

employed when oxidation in air is a concern. Unless effects of moisture

from lot to lot. In such cases, the actual fraction of inert material must be

are to be studied, use of dry purge gas is recommended.

taken into account.

6.1.1.5 Temperature Controller, capable of executing a NOTE 4—For highly reactive materials, the selection of sample con-

tainers can be particularly important. The material from which the

specific temperature program by operating the furnace(s)

container is constructed may catalyze the reaction or react with the sample

between selected temperature limits (ambient temperature to

material. Sealed containers may cause an autocatalytic effect or possibly

600°C) at a heating rate between 2 and 20°C/min constant to

a pressure effect. In open containers loss of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.