ASTM A646/A646M-06(2016)

(Specification)Standard Specification for Premium Quality Alloy Steel Blooms and Billets for Aircraft and Aerospace Forgings

Standard Specification for Premium Quality Alloy Steel Blooms and Billets for Aircraft and Aerospace Forgings

ABSTRACT

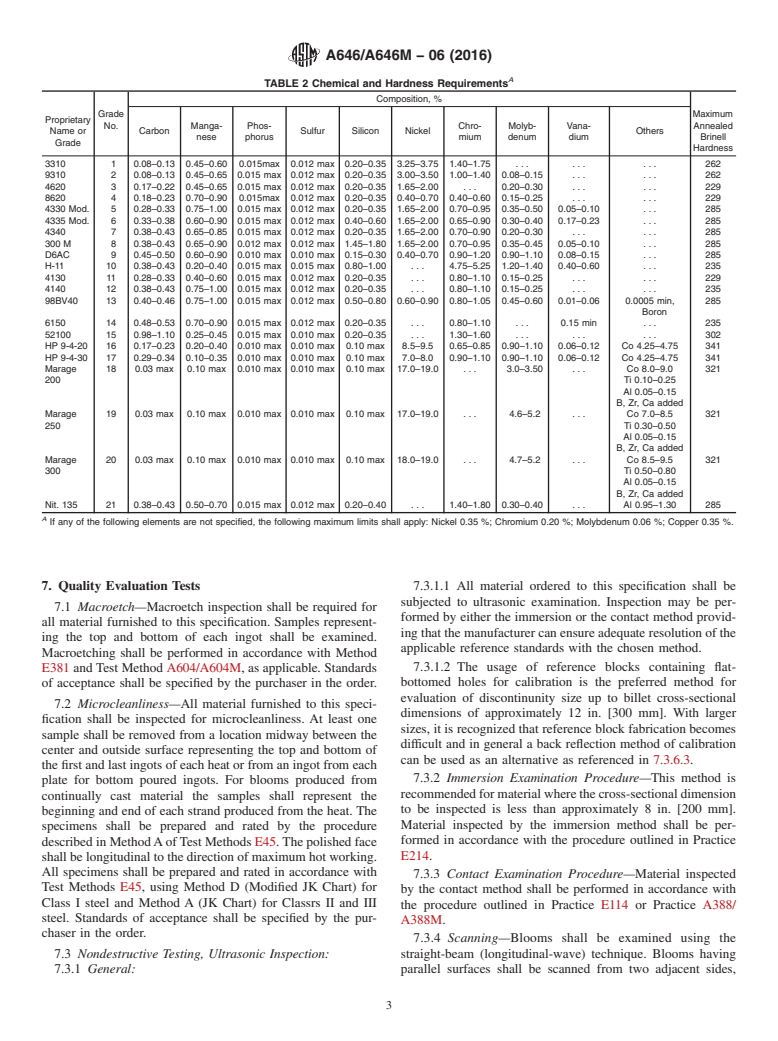

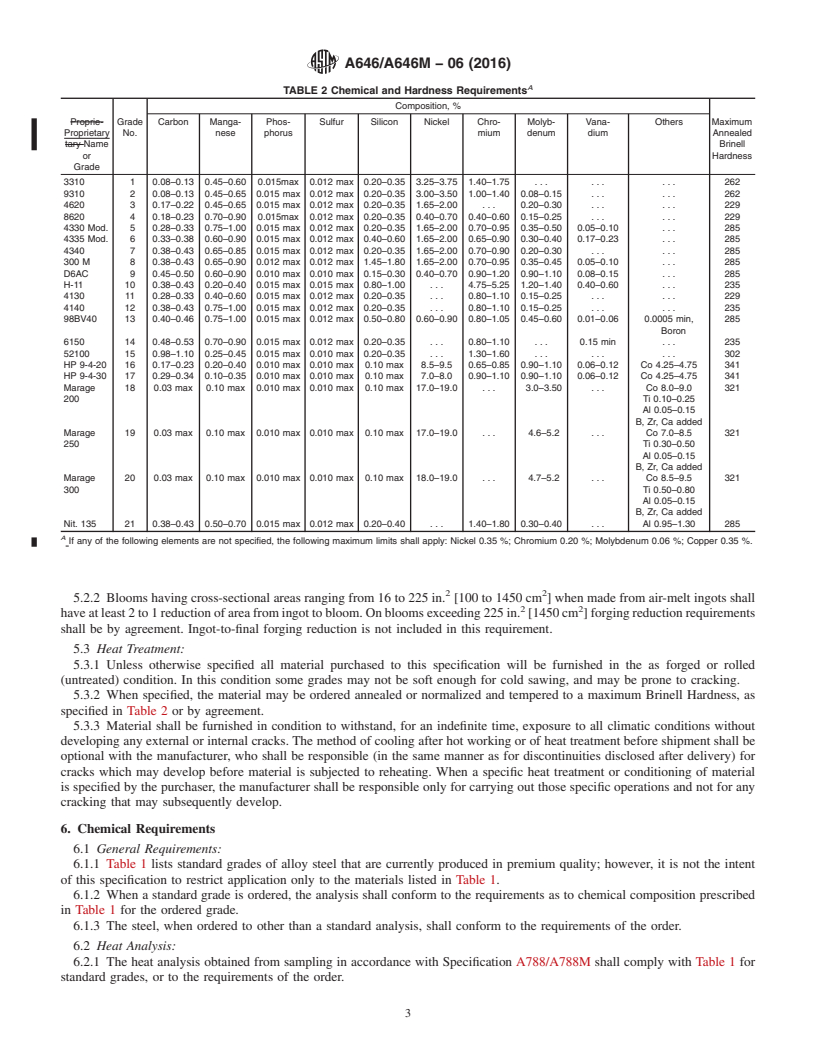

This specification deals with the standard requirements for premium quality alloy steel semifinished rolled or forged blooms and billets for reforging into aircraft and aerospace critical parts such as landing-gear forgings. Covered here are three basic classifications of steel, namely: Class I, steel manufactured by vacuum-induction melting or consumable-electrode vacuum melting process; Class II, air-melted steel manufactured by electric-furnace vacuum degassing process; Class III, air-melted steel manufactured by electric-furnace ladle refining and vacuum degassing processes. Steel materials shall be heat-treated and hot-worked by either hot rolling or forging. Alloy steels shall be examined by heat and product analyses and hardenability tests, and shall conform to chemical composition and maximum annealed Brinell hardness requirements. Quality evaluation tests, such as macrotech, microcleanliness, and nondestructive ultrasonic (both immersion and contact examination) inspection, shall be performed as well.

SCOPE

1.1 This specification covers premium quality alloy steel semifinished rolled or forged blooms and billets for reforging into critical parts such as aircraft landing-gear forgings.

1.2 Blooms and billets, hereinafter referred to as blooms, are semifinished steel products, hot rolled or forged to approximate cross-sectional dimensions. Blooms may be square, round, hexagonal, octagonal, or rectangular in section. For the purposes of this specification, minimum bloom section size will be 16 in.2 [103 cm2].

1.3 This specification covers two basic classifications of steel:

1.3.1 Class I—Vacuum-induction melted or consumable-electrode vacuum melted, or other suitable processes which will satisfy the quality requirements of this specification.

1.3.2 Class II—Air-melted vacuum degassed.

1.3.3 Class III—Air melted electric furnace ladle refined and vacuum degassed.

1.4 The values stated in either inch-pound or SI (metric) units are to be regarded separately as standards. Within the text and tables, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

1.5 Unless the order specifies the applicable “M” specification the material shall be furnished to the inch-pound units.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A646/A646M −06 (Reapproved 2016)

Standard Specification for

Premium Quality Alloy Steel Blooms and Billets for Aircraft

1

and Aerospace Forgings

This standard is issued under the fixed designationA646/A646M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* A388/A388M Practice for Ultrasonic Examination of Steel

Forgings

1.1 This specification covers premium quality alloy steel

A788/A788M Specification for Steel Forgings, General Re-

semifinished rolled or forged blooms and billets for reforging

quirements

into critical parts such as aircraft landing-gear forgings.

A604/A604M Practice for Macroetch Testing of Consum-

1.2 Blooms and billets, hereinafter referred to as blooms,

able Electrode Remelted Steel Bars and Billets

are semifinished steel products, hot rolled or forged to approxi-

E45 Test Methods for Determining the Inclusion Content of

mate cross-sectional dimensions. Blooms may be square,

Steel

round, hexagonal, octagonal, or rectangular in section. For the

E114 Practice for Ultrasonic Pulse-Echo Straight-Beam

purposes of this specification, minimum bloom section size

Contact Testing

2 2

will be 16 in. [103 cm ].

E127 Practice for Fabrication and Control of Aluminum

Alloy Ultrasonic Standard Reference Blocks

1.3 This specification covers two basic classifications of

steel: E214 Practice for Immersed Ultrasonic Testing by the Re-

flection Method Using Pulsed Longitudinal Waves (With-

1.3.1 Class I—Vacuum-induction melted or consumable-

3

electrode vacuum melted, or other suitable processes which drawn 2007)

E381 Method of Macroetch Testing Steel Bars, Billets,

will satisfy the quality requirements of this specification.

1.3.2 Class II—Air-melted vacuum degassed. Blooms, and Forgings

4

1.3.3 Class III—Air melted electric furnace ladle refined

2.2 AMS Standards:

and vacuum degassed.

AMS 2300 Steel Cleanliness, Premium-Quality

AMS 2301 Steel Cleanliness, Aircraft-Quality

1.4 The values stated in either inch-pound or SI (metric)

AMS 2304 Steel Cleanliness, Special Aircraft-Quality

units are to be regarded separately as standards.Within the text

andtables,theSIunitsareshowninbrackets.Thevaluesstated

3. Terminology

in each system are not exact equivalents; therefore, each

system shall be used independently of the other. Combining

3.1 In addition to the terminology requirements of Specifi-

values from the two systems may result in nonconformance

cation A788/A788M, the following terms that are specific to

with the specification.

this specification apply:

1.5 Unless the order specifies the applicable “M” specifica-

3.2 Definitions:

tion the material shall be furnished to the inch-pound units.

3.2.1 air-melted vacuum-degassed steel—arc- or induction-

furnace-melted steel that is vacuum treated immediately prior

2. Referenced Documents

to or during the operation of pouring the ingot.

2

2.1 ASTM Standards:

3.2.2 consumable-electrode vacuum-remelted steel—metal

A255 Test Methods for Determining Hardenability of Steel

that has been remelted into a crucible in vacuum from single or

multiple electrodes.

3.2.3 electroslag-melted steel—metal that has been remelted

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

into a crucible from single or multiple electrodes utilizing an

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

A01.06 on Steel Forgings and Billets. electrical discharge through molten slag as a source of heat.

Current edition approved March 1, 2016. Published April 2016. Originally

approved in 1971. Last previous edition approved in 2011 as A646/A646M – 06

(2011). DOI: 10.1520/A0646_A0646M-06R16.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or The last approved version of this historical standard is referenced on

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM www.astm.org.

4

Standards volume information, refer to the standard’s Document Summary page on Available from SAE International (SAE), 400 Commonwealth Dr.,Warrendale,

the ASTM website. PA 15096, http://www.sae.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A646/A646M−06 (2016)

3.2.3.1 Discussion—For the purposes of this specification processes such as electroslag or electron-beam melting may be

the parent heat from which any electrode for remelting by the considered acceptable.

electroslag process has been produced shall have b

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: A646/A646M − 06 (Reapproved 2011) A646/A646M − 06 (Reapproved 2016)

Standard Specification for

Premium Quality Alloy Steel Blooms and Billets for Aircraft

1

and Aerospace Forgings

This standard is issued under the fixed designation A646/A646M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This specification covers premium quality alloy steel semifinished rolled or forged blooms and billets for reforging into

critical parts such as aircraft landing-gear forgings.

1.2 Blooms and billets, hereinafter referred to as blooms, are semifinished steel products, hot rolled or forged to approximate

cross-sectional dimensions. Blooms may be square, round, hexagonal, octagonal, or rectangular in section. For the purposes of this

2 2

specification, minimum bloom section size will be 16 in. [103 cm ].

1.3 This specification covers two basic classifications of steel:

1.3.1 Class I—Vacuum-induction melted or consumable-electrode vacuum melted, or other suitable processes which will satisfy

the quality requirements of this specification.

1.3.2 Class II—Air-melted vacuum degassed.

1.3.3 Class III—Air melted electric furnace ladle refined and vacuum degassed degassed.

1.4 The values stated in either inch-pound or SI (metric) units are to be regarded separately as standards. Within the text and

tables, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system shall

be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

1.5 Unless the order specifies the applicable “M” specification the material shall be furnished to the inch-pound units.

2. Referenced Documents

2

2.1 ASTM Standards:

A255 Test Methods for Determining Hardenability of Steel

A388/A388M Practice for Ultrasonic Examination of Steel Forgings

A788/A788M Specification for Steel Forgings, General Requirements

A604A604/A604M Test Method Practice for Macroetch Testing of Consumable Electrode Remelted Steel Bars and Billets

E45 Test Methods for Determining the Inclusion Content of Steel

E114 Practice for Ultrasonic Pulse-Echo Straight-Beam Contact Testing

E127 Practice for Fabrication and Control of Aluminum Alloy Ultrasonic Standard Reference Blocks

3

E214 Practice for Immersed Ultrasonic Testing by the Reflection Method Using Pulsed Longitudinal Waves (Withdrawn 2007)

E381 Method of Macroetch Testing Steel Bars, Billets, Blooms, and Forgings

4

2.2 AMS Standards:

AMS 2300 Steel Cleanliness, Premium-Quality

AMS 2301 Steel Cleanliness, Aircraft-Quality

AMS 2304 Steel Cleanliness, Special Aircraft-Quality

3. Terminology

3.1 In addition to the terminology requirements of Specification A788/A788M, the following terms that are specific to this

specification apply:

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel, Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee A01.06

on Steel Forgings and Billets.

Current edition approved April 1, 2011March 1, 2016. Published June 2011April 2016. Originally approved in 1971. Last previous edition approved in 20062011 as

A646/A646M – 06.A646/A646M – 06 (2011). DOI: 10.1520/A0646_A0646M-06R11. 10.1520/A0646_A0646M-06R16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

4

Available from SAE International (SAE), 400 Commonwealth Dr., Warrendale, PA 15096-0001,15096, http://www.sae.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A646/A646M − 06 (2016)

3.2 Definitions:

3.2.1 air-melted vacuum-degassed steel—arc- or induction-furnace-melted steel that is vacuum treated immediately prior to or

during the operation of pouring the ingot.

3.2.2 consumable-electrode vacuum-remelted steel—metal that has been remelted into a crucible in vacuum from single or

multiple electrodes.

3.2.3 electroslag-m

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.