ASTM D5181-09

(Test Method)Standard Test Method for Abrasion Resistance of Printed Matter by the GA-CAT Comprehensive Abrasion Tester

Standard Test Method for Abrasion Resistance of Printed Matter by the GA-CAT Comprehensive Abrasion Tester

SIGNIFICANCE AND USE

Abrasion resistance during transport and storage is essential to prevent marring of type matter, designs, or protective coatings on the exterior of labels and other printed materials. Recognizing that the actual amount of abrasion occurring in the field depends on relative humidity, temperature, tightness of packing, and a host of other variables, this test method provides a rapid means for comparing the abrasion resistance of test surfaces under laboratory conditions. It is useful for specification acceptance between the supplier and the customer.

This test method can also be used to evaluate the relative abrasion resistance of printed inks, varnishes, laminates and substrates, and the abrasiveness of inks.

SCOPE

1.1 This test method covers the procedure for determining the abrasion resistance of printed matter using a GA-CAT Comprehensive Abrasion Tester.

1.2 This test method is applicable to packaging labels, book, catalog, and magazine covers, bar codes, corrugated boxes, and other containers having applied graphics on any flat substrate. It is not recommended for powder coatings.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5181 − 09

Standard Test Method for

Abrasion Resistance of Printed Matter by the GA-CAT

1

Comprehensive Abrasion Tester

This standard is issued under the fixed designation D5181; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 4. Summary of Test Method

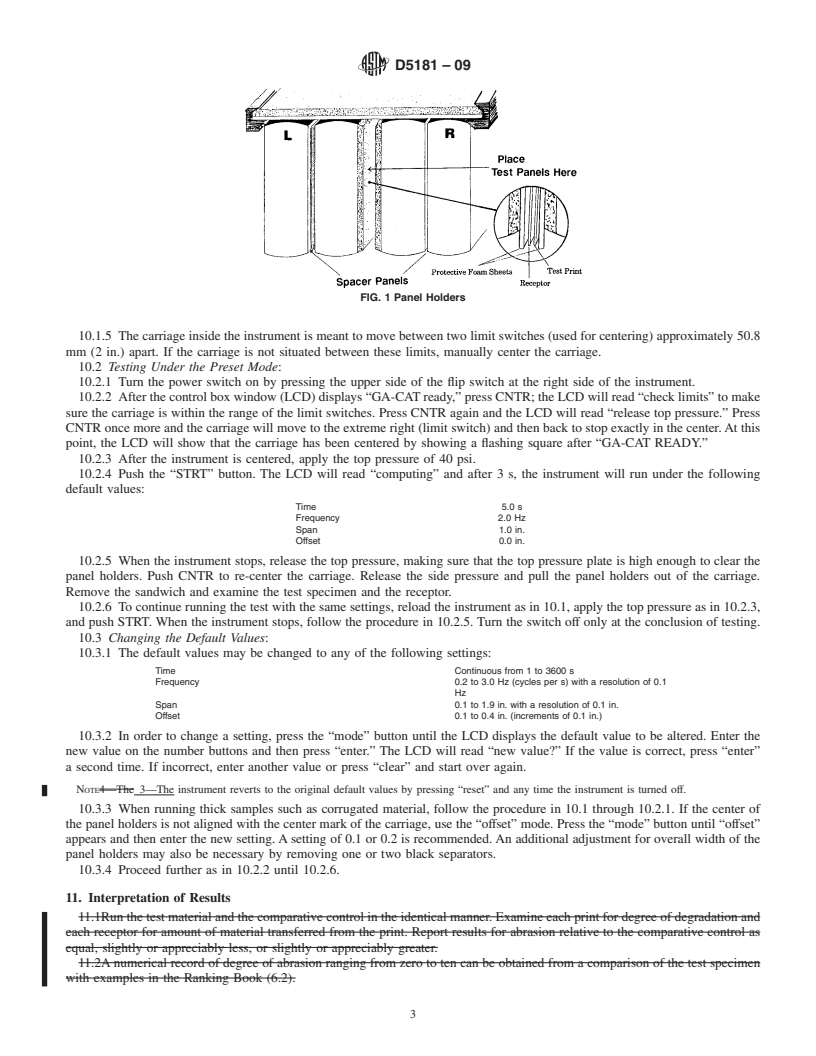

1.1 This test method covers the procedure for determining 4.1 The test print and a receptor are sandwiched in the panel

the abrasion resistance of printed matter using a GA-CAT holder of the GA-CAT Comprehensive Abrasion Tester,

Comprehensive Abrasion Tester. clamped together with a known force, and made to slide over

each other at a known frequency and over a known distance for

1.2 Thistestmethodisapplicabletopackaginglabels,book,

a predetermined time period.

catalog,andmagazinecovers,barcodes,corrugatedboxes,and

other containers having applied graphics on any flat substrate. 4.2 The test specimen is examined for degree of print

It is not recommended for powder coatings. degradation and the receptor for amount of ink or other

material transferred from the specimen surface.

1.3 The values stated in SI units are to be regarded as the

standard. The values given in parentheses are for information

5. Significance and Use

only.

5.1 Abrasion resistance during transport and storage is

1.4 This standard does not purport to address all of the

essential to prevent marring of type matter, designs, or protec-

safety concerns, if any, associated with its use. It is the

tive coatings on the exterior of labels and other printed

responsibility of the user of this standard to establish appro-

materials. Recognizing that the actual amount of abrasion

priate safety and health practices and determine the applica-

occurring in the field depends on relative humidity,

bility of regulatory limitations prior to use.

temperature,tightnessofpacking,andahostofothervariables,

this test method provides a rapid means for comparing the

2. Referenced Documents

abrasionresistanceoftestsurfacesunderlaboratoryconditions.

2

2.1 ASTM Standards:

It is useful for specification acceptance between the supplier

E171 Practice for Conditioning and Testing Flexible Barrier

and the customer.

Packaging

5.2 Thistestmethodcanalsobeusedtoevaluatetherelative

abrasion resistance of printed inks, varnishes, laminates and

3. Terminology

substrates, and the abrasiveness of inks.

3.1 Definitions of Terms Specific to This Standard:

3.1.1 abrasion resistance, n—resistance against the act of

6. Apparatus

scraping, smudging, or rubbing off.

6.1 GA-CAT Comprehensive Abrasion Tester.

3.1.2 abrasiveness, n—the degree to which a product tends

to cause abrasion by the act of rubbing or scraping.

7. Materials

3.1.3 receptor, n—film or paper of standard abrasiveness

7.1 Receptors, can be an unprinted sheet of the same

onto which material removed from the specimen is deposited

substrate or a printed sheet of the identical substrate for

during the abrasion testing process.

face-to-face testing cut to approximately 102 by 114 mm (4 by

1

4 ⁄2 in.).

1

7.2 Foam Sheeting, 2 pieces, each approximately 2 mm in

This test method is under the jurisdiction of ASTM Committee D01 on Paint

1

and Related Coatings, Materials, andApplications and is the direct responsibility of

thickness and cut to 102 by 114 mm (4 by 4 ⁄2 in.).

Subcommittee D01.56 on Printing Inks.

Current edition approved Dec. 1, 2009. Published January 2010. Originally NOTE 1—Use of foam sheeting as a backing for the test specimen and

approved in 1991. Last previous edition approved in 2004 as D5181 – 04. DOI: the receptor is recommended to provide uniform pressure over the test

10.1520/D5181-09.

surfaces and to prevent ink, varnish, or other particles from becoming

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

imbedded in the sensitive surface of the panel holders.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

7.3 Comparative Control, a production or laboratory print

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. preferably having known abrasion resistance. The comparative

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5181 − 09

control must have the same substrate, color(s), and subject direction of the specimen is vertical. Take care that the

matter as the test print. sandwich does not extend below the bottom of the panel

holders.

8. Test Specimen an

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D5181–04 Designation:D5181–09

Standard Test Method for

Abrasion Resistance of Printed Matter by the GA-CAT

1

Comprehensive Abrasion Tester

This standard is issued under the fixed designation D5181; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method covers the procedure for determining the abrasion resistance of printed matter using a GA-CAT

Comprehensive Abrasion Tester.

1.2This1.2 This test method is applicable to packaging labels, book, catalog, and magazine covers, bar codes, corrugated boxes,

and other containers having applied graphics on any flat substrate. It is not recommended for powder coatings.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

E171 Specification for Atmospheres for Conditioning and Testing Flexible Barrier Materials

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 abrasion resistance, n—resistance against the act of scraping, smudging, or rubbing off.

3.1.2 abrasiveness, n—the degree to which a product tends to cause abrasion by the act of rubbing or scraping.

3.1.3 receptor, n—film or paper of standard abrasiveness onto which material removed from the specimen is deposited during

the abrasion testing process. Alternatively, printed paper from which material is removed onto the specimen that has a higher

degree of abrasiveness than the receptor (in case of testing abrasiveness). —film or paper of standard abrasiveness onto which

material removed from the specimen is deposited during the abrasion testing process.

4. Summary of Test Method

4.1 The test print and a receptor are sandwiched in the panel holder of the GA-CAT Comprehensive Abrasion Tester, clamped

together with a known force, and made to slide over each other at a known frequency and over a known distance for a

predetermined time period.

4.2The test specimen is examined for degree of print degradation and the receptor for amount of ink or other material transferred

from the specimen surface. Results may be rated relative to a comparative control run in the identical manner, or they may be

quantified by comparison to a ranking scale numbered from zero to ten (zero being the most abrasion resistant and ten the least

abrasion resistant).

4.2 The test specimen is examined for degree of print degradation and the receptor for amount of ink or other material

transferred from the specimen surface.

5. Significance and Use

5.1 Abrasion resistance during transport and storage is essential to prevent marring of type matter, designs, or protective

coatings on the exterior of labels and other printed materials. Recognizing that the actual amount of abrasion occurring in the field

1

This test method is under the jurisdiction of ASTM Committee D01 on Paint and Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.56 on Printing Inks.

´1

Current edition approved July 1, 2004. Published July 2004. Originally approved in 1991. Last previous edition approved in 1997 as D5181–91(1997) . DOI:

10.1520/D5181-04.

Current edition approved Dec. 1, 2009. Published January 2010. Originally approved in 1991. Last previous edition approved in 2004 as D5181 – 04. DOI:

10.1520/D5181-09.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D5181–09

depends on relative humidity, temperature, tightness of packing, and a host of other variables, this test method provides a rapid

means for comparing the abrasion resistance of test surfaces under lab

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.