ASTM C872-10

(Test Method)Standard Test Method for Lead and Cadmium Release from Porcelain Enamel Surfaces

Standard Test Method for Lead and Cadmium Release from Porcelain Enamel Surfaces

SIGNIFICANCE AND USE

The determination of lead and cadmium release from porcelain enamel surfaces was formerly of interest only to manufacturers of porcelain enamel cookware and similar food service products. Food contact surfaces of these container-type products have been evaluated using a test procedure similar to Test Method C738. Recently, however, there has been a need to measure lead and cadmium release from flat or curved porcelain enamel surfaces that are not capable of being evaluated by a test similar to Test Method C738.

SCOPE

1.1 This test method covers the precise determination of lead and cadmium extracted by acetic acid from porcelain enamel surfaces.

1.2 Values stated in SI units are to be regarded as the standard. Inch-pound units are given for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C872 − 10

StandardTest Method for

Lead and Cadmium Release from Porcelain Enamel

1

Surfaces

This standard is issued under the fixed designation C872; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

This test method covers the precise determination of lead or cadmium extracted by acetic acid from

porcelain enamel surfaces. The procedure of extraction may be expected to accelerate the release of

lead or cadmium and to serve, therefore, as a severe test that is unlikely to be matched under actual

conditions of usage.

1. Scope 4. Significance and Use

1.1 This test method covers the precise determination of 4.1 The determination of lead and cadmium release from

lead and cadmium extracted by acetic acid from porcelain porcelain enamel surfaces was formerly of interest only to

enamel surfaces. manufacturers of porcelain enamel cookware and similar food

service products. Food contact surfaces of these container-type

1.2 Values stated in SI units are to be regarded as the

products have been evaluated using a test procedure similar to

standard. Inch-pound units are given for information only.

TestMethodC738.Recently,however,therehasbeenaneedto

1.3 This standard does not purport to address all of the

measure lead and cadmium release from flat or curved porce-

safety concerns, if any, associated with its use. It is the

lain enamel surfaces that are not capable of being evaluated by

responsibility of the user of this standard to establish appro-

a test similar to Test Method C738.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

5. Interferences

5.1 Since a specific hollow cathode lamp for lead and

2. Referenced Documents

cadmium is used, there are no interferences.

2

2.1 ASTM Standards:

6. Apparatus

C738 Test Method for Lead and Cadmium Extracted from

Glazed Ceramic Surfaces

6.1 Atomic Absorption Spectrophotometer , equipped with a

D1193 Specification for Reagent Water

102-mm (4-in.) single slot or Boling burner head and digital

3

concentration readout attachment (DCR) if available. This

3. Summary of Test Method

instrument should have a sensitivity of about 0.5 mg/L of lead

for 1 % absorption and a sensitivity of about 0.03 mg/L of

3.1 The lead and cadmium extracted from the article under

cadmium for 1 % absorption. The operating conditions as

test by acetic acid at 20 to 24°C (68 to 75°F) after 24 h of

specified in the instrument manufacturer’s analytical methods

leachingaremeasuredbyatomicabsorptionspectrophotometry

manual shall be used.

using a specific hollow cathode lamp for lead and cadmium

respectively.

NOTE 1—ppm, mg/L, and µg/mL are equivalent units.

6.2 Hollow Cathode Lead Lamp, with wavelength set at

283.3 or 217.0 nm.

1

ThistestmethodisunderthejurisdictionofASTMCommitteeB08onMetallic

6.3 Hollow Cathode Cadmium Lamp, with wavelength set

and Inorganic Coatings and is the direct responsibility of Subcommittee B08.12 on

Materials for Porcelain Enamel and Ceramic-Metal Systems. at 228.8 nm.

Current edition approved April 1, 2010. Published May 2010. Originally

6.4 Glassware of chemically resistant borosilicate glass, to

approvedin1977.Lastpreviouseditionapprovedin2005asC872 – 89(2005).DOI:

10.1520/C0872-10. make reagents and solutions.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Perkin-Elmer model 303 and Jarrell-Ash model 82-546 have been found

the ASTM website. suitable for this determination.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C872 − 10

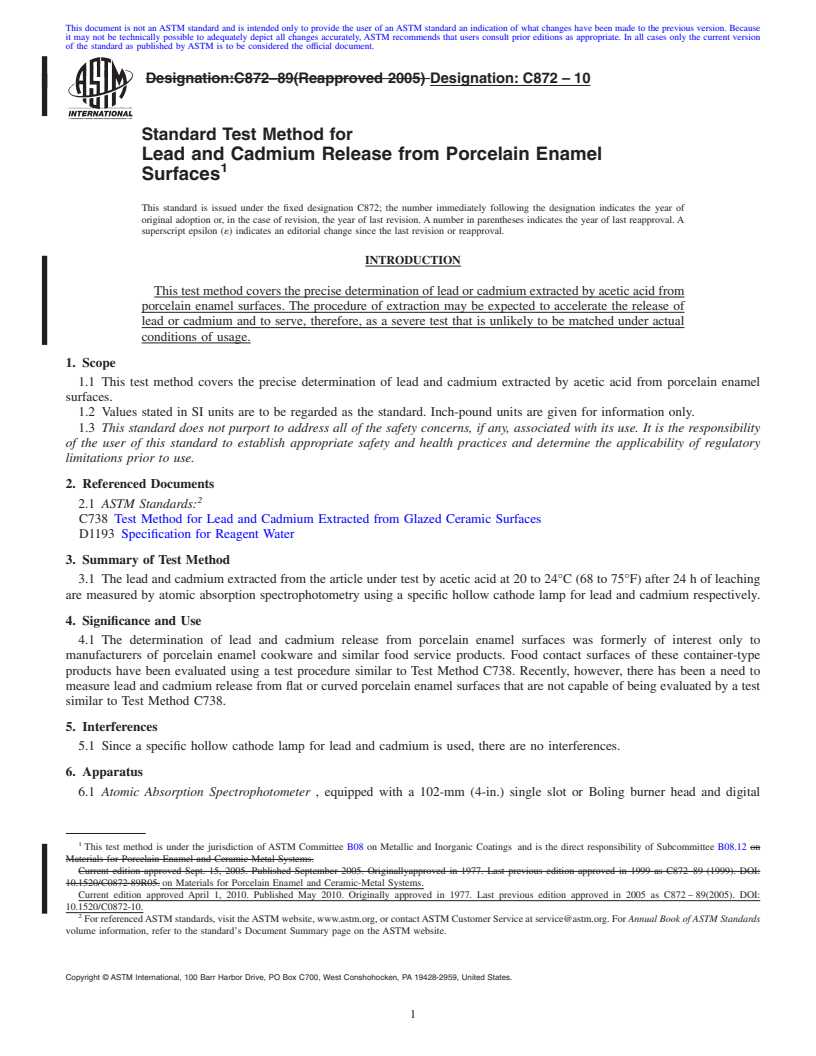

Metric Equivalents for Apparatus

Dimensions (Fig. 1)

in. mm

1

⁄8 3.2

1

⁄4 6.4

3

⁄8 9.5

1

1 ⁄4 31.8

25

1 ⁄32 45.2

1

2 ⁄4 57.2

2.31 58.7

2.5 63.5

4 101.6

1

4 ⁄16 103.2

1

4 ⁄8 104.8

1

5 ⁄2 139.7

FIG. 1 Suitable Test Cell

4

6.5 Test Cell, suitable for the containment of the leaching where such specifications are available. Other grades may be

solution on a flat porcelain enamel surface. A cell that has used provided it is first ascertained that the reagent is of

proved suitable for this purpose is shown in Fig. 1. sufficiently high purity to permit its use without lessening the

accuracy of the determination.

7. Reagents

7.2 Purity of Water—Unless otherwise indicated, references

7.1 Purity of Reagents—Reagent grade chemicals shall be

to water shall be understood to mean disti

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:C872–89(Reapproved 2005) Designation: C872 – 10

Standard Test Method for

Lead and Cadmium Release from Porcelain Enamel

1

Surfaces

This standard is issued under the fixed designation C872; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

This test method covers the precise determination of lead or cadmium extracted by acetic acid from

porcelain enamel surfaces. The procedure of extraction may be expected to accelerate the release of

lead or cadmium and to serve, therefore, as a severe test that is unlikely to be matched under actual

conditions of usage.

1. Scope

1.1 This test method covers the precise determination of lead and cadmium extracted by acetic acid from porcelain enamel

surfaces.

1.2 Values stated in SI units are to be regarded as the standard. Inch-pound units are given for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

C738 Test Method for Lead and Cadmium Extracted from Glazed Ceramic Surfaces

D1193 Specification for Reagent Water

3. Summary of Test Method

3.1 The lead and cadmium extracted from the article under test by acetic acid at 20 to 24°C (68 to 75°F) after 24 h of leaching

are measured by atomic absorption spectrophotometry using a specific hollow cathode lamp for lead and cadmium respectively.

4. Significance and Use

4.1 The determination of lead and cadmium release from porcelain enamel surfaces was formerly of interest only to

manufacturers of porcelain enamel cookware and similar food service products. Food contact surfaces of these container-type

products have been evaluated using a test procedure similar to Test Method C738. Recently, however, there has been a need to

measure lead and cadmium release from flat or curved porcelain enamel surfaces that are not capable of being evaluated by a test

similar to Test Method C738.

5. Interferences

5.1 Since a specific hollow cathode lamp for lead and cadmium is used, there are no interferences.

6. Apparatus

6.1 Atomic Absorption Spectrophotometer , equipped with a 102-mm (4-in.) single slot or Boling burner head and digital

1

This test method is under the jurisdiction of ASTM Committee B08 on Metallic and Inorganic Coatings and is the direct responsibility of Subcommittee B08.12 on

Materials for Porcelain Enamel and Ceramic-Metal Systems.

Current edition approved Sept. 15, 2005. Published September 2005. Originallyapproved in 1977. Last previous edition approved in 1999 as C872–89 (1999). DOI:

10.1520/C0872-89R05. on Materials for Porcelain Enamel and Ceramic-Metal Systems.

Current edition approved April 1, 2010. Published May 2010. Originally approved in 1977. Last previous edition approved in 2005 as C872 – 89(2005). DOI:

10.1520/C0872-10.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

C872 – 10

3

concentration readout attachment (DCR) if available. This instrument should have a sensitivity of about 0.5 mg/Lof lead for 1 %

absorption and a sensitivity of about 0.03 mg/L of cadmium for 1 % absorption. The operating conditions as specified in the

instrument manufacturer’s analytical methods manual shall be used.

NOTE 1—ppm, mg/L, and µg/mL are equivalent units.

6.2 Hollow Cathode Lead Lamp, with wavelength set at 283.3 or 217.0 nm.

6.3 Hollow Cathode Cadmium Lamp, with wavelength set at 228.8 nm.

6.4 Glassware of chemically resistant borosilicate glass, to make reagents and solutions.

6.5 Test Cell, suitable for the containment of the leaching solution on a flat porcelain enamel surface. A cell that has proved

suitable for this purpose is shown in Fig. 1.

7. Reagents

7.1 Purity of Reagents—Reagent grade chemicals shall be used in all tests. Unless otherwise indicated, it is in

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.