ASTM D4696-92(2000)

(Guide)Standard Guide for Pore-Liquid Sampling from the Vadose Zone

Standard Guide for Pore-Liquid Sampling from the Vadose Zone

SIGNIFICANCE AND USE

Sampling from the vadose zone may be an important component of some ground water monitoring strategies. It can provide information regarding contaminant transport and attenuation in the vadose zone. This information can be used for mitigating potential problems prior to degradation of a ground water resource (1).6

The choice of appropriate sampling devices for a particular location is dependent on various criteria. Specific guidelines for designing vadose zone monitoring programs have been discussed by Morrison (1), Wilson (2), Wilson (3), Everett (4), Wilson (5), Everett et al (6), Wilson (7), Everett et al (8), Everett et al (9), Robbins et al (10), Merry and Palmer (11), U.S. EPA (12), Ball (13), and Wilson (14). In general, it is prudent to combine various unsaturated and free drainage samplers into a program, so that the different flow regimes may be monitored.

This guide does not attempt to present details of installation and use of the equipment discussed. However, an effort has been made to present those references in which the specific techniques may be found.

SCOPE

1.1 This guide discusses equipment and procedures used for sampling pore-liquid from the vadose zone (unsaturated zone). The guide is limited to in-situ techniques and does not include soil core collection and extraction methods for obtaining samples.

1.2 The term "pore-liquid" is applicable to any liquid from aqueous pore-liquid to oil. However, all of the samplers described in this guide were designed, and are used to sample aqueous pore-liquids only. The abilities of these samplers to collect other pore-liquids may be quite different than those described.

1.3 Some of the samplers described in this guide are not currently commercially available. These samplers are presented because they may have been available in the past, and may be encountered at sites with established vadose zone monitoring programs. In addition, some of these designs are particularly suited to specific situations. If needed, these samplers could be fabricated.

1.4 The values stated in SI units are to be regarded as the standard.

1.5 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.5 This guide offers an organized collection of information or a series of options and does not recommend a specific course of action. This document cannot replace education or experience and should be used in conjunction with professional judgment. Not all aspects of this guide may be applicable in all circumstances. This ASTM standard is not intended to represent or replace the standard of care by which the adequacy of a given professional service must be judged, nor should this document be applied without consideration of a project's many unique aspects. The word "Standard" in the title of this document means only that the document has been approved through the ASTM consensus process.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 4696 – 92 (Reapproved 2000)

Standard Guide for

Pore-Liquid Sampling from the Vadose Zone

This standard is issued under the fixed designation D4696; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 Thisguidediscussesequipmentandproceduresusedfor 2.1 ASTM Standards:

sampling pore-liquid from the vadose zone (unsaturated zone). D653 Terminology Relating to Soil, Rock, and Contained

The guide is limited to in-situ techniques and does not include Fluids

soil core collection and extraction methods for obtaining

3. Terminology

samples.

3.1 Definitions:

1.2 The term “pore-liquid” is applicable to any liquid from

aqueous pore-liquid to oil. However, all of the samplers 3.1.1 Wherereasonable,precisetermsandnameshavebeen

usedwithinthisguide.However,certaintermsandnameswith

described in this guide were designed, and are used to sample

aqueous pore-liquids only. The abilities of these samplers to varying definitions are ubiquitous within the literature and

industry of vadose zone monitoring. For purposes of recogni-

collect other pore-liquids may be quite different than those

described. tion, these terms and names have been included in the guide

withtheirmostcommonusage.Intheseinstances,thecommon

1.3 Some of the samplers described in this guide are not

currently commercially available. These samplers are pre- definitions have been included in Appendix X1. Examples of

such terms are soil, lysimeter, vacuum and pore-liquid tension.

sented because they may have been available in the past, and

may be encountered at sites with established vadose zone 3.2 Definitions of Terms Specific to This Standard:

3.2.1 Appendix X1 is a compilation of those terms used in

monitoring programs. In addition, some of these designs are

particularly suited to specific situations. If needed, these this guide. More comprehensive compilations, that were used

as sources for Appendix X1, are (in decreasing order of their

samplers could be fabricated.

1.4 The values stated in SI units are to be regarded as the usage):

3.2.1.1 Terminology D653,

standard.

3.2.1.2 Compilation of ASTM Terminology,

1.5 This standard does not purport to address all of the

safety problems, if any, associated with its use. It is the 3.2.1.3 Glossary of Soil Science Terms,SoilScienceSociety

of America, and,

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- 3.2.1.4 Webster’s New Collegiate Dictionary,

bility of regulatory limitations prior to use.

4. Summary of Guide

1.6 This guide offers an organized collection of information

4.1 Poresinthevadosezonecanbesaturatedorunsaturated.

or a series of options and does not recommend a specific

Somesamplersaredesignedtoextractliquidsfromunsaturated

course of action. This document cannot replace education or

pores; others are designed to obtain samples from saturated

experienceandshouldbeusedinconjunctionwithprofessional

pores (for example, perched ground water) or saturated

judgment. Not all aspects of this guide may be applicable in all

macropores (for example, fissures, cracks, and burrows). This

circumstances. This ASTM standard is not intended to repre-

guide addresses these categories. The sampler types discussed

sent or replace the standard of care by which the adequacy of

are:

a given professional service must be judged, nor should this

4.1.1 Suction samplers (unsaturated sampling), (see Section

document be applied without consideration of a project’s many

7),

unique aspects. The word “Standard” in the title of this

4.1.2 Free drainage samplers (saturated sampling), (see

document means only that the document has been approved

Section 8),

through the ASTM consensus process.

Annual Book of ASTM Standards, Vol 04.08.

1 3

ThisguideisunderthejurisdictionofASTMCommitteeD18onSoilandRock Compilation of ASTM Terminology, Sixth edition, ASTM, 1916 Race Street,

and is the direct responsibility of Subcommittee D18.21 on Ground Water Vadose

Philadelphia, PA 19103, 1986.

Zone Investigations. Glossary of Soil Science Terms, Soil Science Society of America, 1987.

Current edition approved April 15, 1992. Published June 1992. Webster’s New Collegiate Dictionary, Fifth edition, 1977.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 4696

4.1.3 Perched ground water samplers (saturated sampling), al (8), Everett et al (9), Robbins et al (10), Merry and Palmer

(see Section 9), and (11), U.S. EPA (12), Ball (13), and Wilson (14). In general, it

4.1.4 Experimental absorption samplers (unsaturated sam- is prudent to combine various unsaturated and free drainage

pling), (see Section 10). samplersintoaprogram,sothatthedifferentflowregimesmay

4.2 Most samplers designed for sampling liquid from un- be monitored.

saturated pores may also be used to sample from saturated

5.3 This guide does not attempt to present details of

pores. This is useful in areas where the water table fluctuates,

installation and use of the equipment discussed. However, an

so that both saturated and unsaturated conditions occur at effort has been made to present those references in which the

differenttimes.However,samplersdesignedforsamplingfrom

specific techniques may be found.

saturated pores cannot be used in unsaturated conditions. This

is because the liquid in unsaturated pores is held at less than

6. Criteria for Selecting Pore-Liquid Samplers

atmospheric pressures (see Richard’s outflow principle,in

6.1 Decisions on the types of samplers to use in a monitor-

Appendix X1).

ing program should be based on consideration of a variety of

4.3 The discussion of each sampler is divided into specific

criteria that include the following:

topics that include:

6.1.1 Required sampling depths,

4.3.1 Operating principles,

6.1.2 Required sample volumes,

4.3.2 Description,

6.1.3 Soil characteristics,

4.3.3 Installation,

6.1.4 Chemistry and biology of the liquids to be sampled,

4.3.4 Operation, and

6.1.5 Moisture flow regimes,

4.3.5 Limitations.

6.1.6 Required durability of the samplers,

5. Significance and Use

6.1.7 Required reliability of the samplers,

5.1 Sampling from the vadose zone may be an important 6.1.8 Climate,

component of some ground water monitoring strategies. It can

6.1.9 Installation requirements of the samplers,

provide information regarding contaminant transport and at-

6.1.10 Operational requirements of the samplers,

tenuation in the vadose zone.This information can be used for

6.1.11 Commercial availability, and

mitigating potential problems prior to degradation of a ground

6.1.12 Costs.

water resource (1).

6.2 Some of these criteria are discussed in this guide.

5.2 The choice of appropriate sampling devices for a par-

However, the ability to balance many of these factors against

ticular location is dependent on various criteria. Specific

one another can only be obtained through field experience.

guidelines for designing vadose zone monitoring programs

have been discussed by Morrison (1), Wilson (2), Wilson (3),

7. Suction Samplers

Everett (4),Wilson (5), Everett et al (6),Wilson (7), Everett et

7.1 Table 1 presents the various types of suction samplers.

The range of operating depths is the major criterion by which

suctionsamplersaredifferentiated.Accordingly,thecategories

Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof

of suction samplers are as follows:

this standard.

TABLE 1 Suction Sampler Summary

A

Porous Section Maximum Pore Air Entry Operational Suction Maximum Operation

Sampler Type

Material Size (µm) Value (cbar) Range (cbar) Depth (m)

A

Vacuum lysimeters Ceramic 1.2 to 3.0 (1) >100 <60 to 80 <7.5

A

PTFE 15 to 30 (2) 10 to 21 <10 to 21 <7.5

B

Stainless steel NA 49 to 5 49 to 5 <7.5

A

Pressure-vacuum lysimeters Ceramic 1.2 to 3.0 (1) >100 <60 to 80 <15

A

PTFE 15 to 30 (2) 10 to 21 <10 to 21 <15

A

High pressure-vacuum lysimeters Ceramic 1.2 to 3.0 (1) >100 <60 to 80 <91

A

PTFE 15 to 30 (2) 10 to 21 <10 to 21 <91

B B B

Filter tip samplers Polyethylene NA NA NA None

Ceramic 2to3(1) >100 <60 to 80 <7.5

B B B

Stainless steel NA NA NA none

Cellulose-acetate hollow-fiber samplers Cellulose <2.8 >100 <60 to 80 <7.5

Acetate

Non cellulosic

Polymer <2.8 >100 <60 to 80 <7.5

Membrane filter samplers Cellulose <2.8 >100 <60 to 80 <7.5

Acetate

B B

PTFE 2to5 NA NA <7.5

B B B

Vacuum plate samplers Alundum NA NA NA <7.5

Ceramic 1.2 to 3.0 >100 60 to 80 <7.5

B B

Fritted glass 4 to 5.5 NA NA <7.5

B

Stainless steel NA 49 to 5 49 to 5 <7.5

A

Pore size determined by bubbling pressure (1) or mercury intrusion (2).

B

NA = Not available.

D 4696

7.1.1 Vacuum Lysimeters—These samplers are theoretically meniscuses of the liquid in the porous segment are able to

operational at depths less than about 7.5 m. The practical withstand the applied suction (depending on the maximum

operational depth is 6 m under ideal conditions. pore sizes and hydrophobicity/hydrophilicity), liquid moves

7.1.2 Pressure-Vacuum Lysimeters—Thesesamplersareop- into the sampler. The ability of the meniscuses to withstand a

erational at depths less than about 15 m. suction decreases with increasing pore size and also with

7.1.3 High Pressure-Vacuum Lysimeters— (Also known as increasing hydrophobicity of the porous segment (see 7.6). If

pressure-vacuum lysimeters with transfer vessels.) These sam- the maximum pore sizes are too large and hydrophobicity too

plers are normally operational down to about 46 m, although great, the meniscuses are not able to withstand the applied

installations as deep as 91 m have been reported (15). suction.As a result, they break down, hydraulic contact is lost,

7.1.4 Suction Lysimeters With Low Bubbling Pressures and only air enters the sampler. As described in 7.6, ceramic

(Samplers With PTFE Porous Sections)—These samplers are porous segments are hydrophilic and the maximum pore sizes

available in numerous designs that can be used to maximum are small enough to allow meniscuses to withstand the entire

depths varying from about 7.5 to 46 m. range of sampling suctions. Presently available polytetrafluo-

roethylene (PTFE) porous segments are hydrophobic, the

NOTE 1—The samplers of 7.1.1, 7.1.2, 7.1.3, and 7.1.4 are referred to

maximum pore sizes are larger, and only a very limited range

collectively as suction lysimeters. Within this standard, lysimeter is

of sampling suction can be applied before meniscuses break

defined as a device used to collect percolating water for analyses (16).

down and sampling ends (see 7.6.1.3). Therefore, samplers

7.1.5 Filter Tip Samplers—These samplers theoretically

made with PTFE porous segments may be used only for

have no maximum sampling depth.

sampling soils with low pore-liquid tensions (12, 17).

7.1.6 Experimental Suction Samplers— The samplers have

7.2.1.3 The ability of a sampler to withstand applied suc-

limited field applications at the present time. They include

tions can be directly measured by its bubbling pressure. The

cellulose-acetate hollow-fiber samplers, membrane filter sam-

bubbling pressure is measured by saturating the porous seg-

plers,andvacuumplatesamplers.Theyaregenerallylimitedto

ment, immersing it in water, and pressurizing the inside of the

depths less than about 7.5 m.

porous segment with air. The pressure at which air starts

7.2 Operating Principles:

bubbling through the porous segment into the surrounding

7.2.1 General:

water is the bubbling pressure. The magnitude of the bubbling

7.2.1.1 Suction lysimeters consist of a hollow, porous sec-

pressureisequaltothemagnitudeofthemaximumsuctionthat

tion attached to a sample vessel or a body tube. Samples are

can be applied to the sampler before air entry occurs (air entry

obtained by applying suction to the sampler and collecting

value). Because the bubbling pressure is a direct measure of

pore-liquidinthebodytube.Samplesareretrievedbyavariety

how a sampler will perform, it is more useful than measure-

of methods.

ment of pore size distributions.

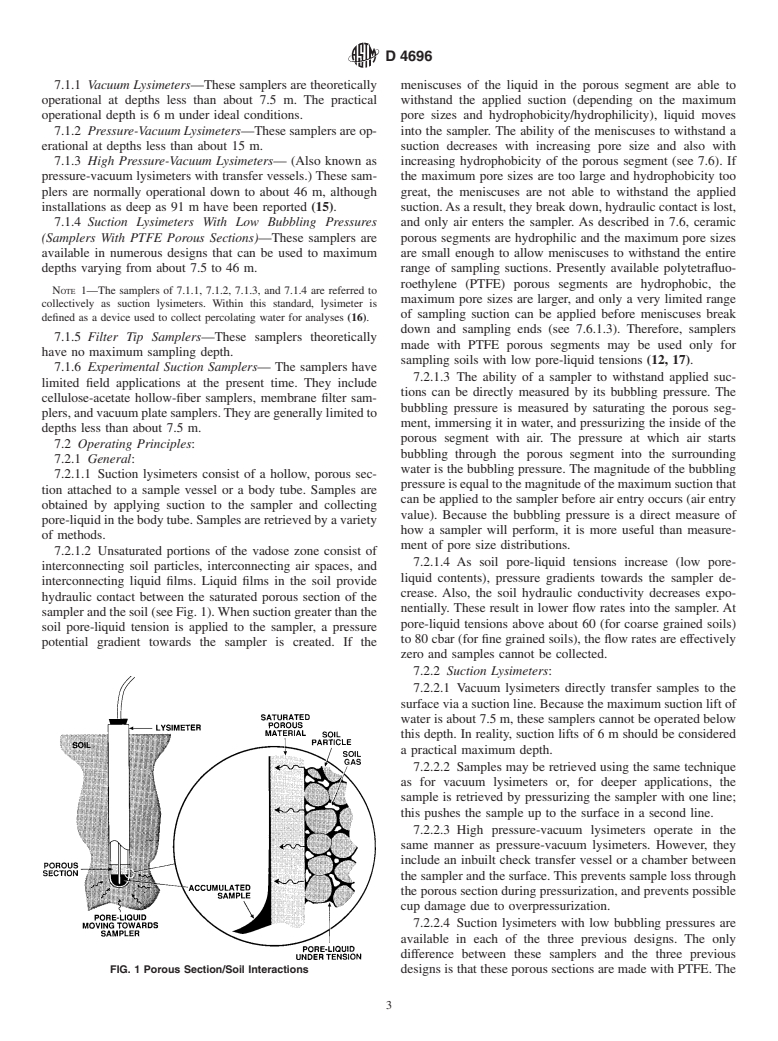

7.2.1.2 Unsaturated portions of the vadose zone consist of

7.2.1.4 As soil pore-liquid tensions increase (low pore-

interconnecting soil particles, interconnecting air spaces, and

liquid contents), pressure gradients towards the sampler de-

interconnecting liquid films. Liquid films in the soil provide

crease. Also, the soil hydraulic conductivity decreases expo-

hydraulic contact between the saturated porous section of the

nentially. These result in lower flow rates into the sampler.At

samplerandthesoil(seeFig.1).Whensuctiongreaterthanthe

pore-liquid tensions above about 60 (for coarse grained soils)

soil pore-liquid tension is applied to the sampler, a pressure

to 80 cbar (for fine grained soils), the flow rates are effectively

potential gradient towards the sampler is created. If the

zero and samples cannot be collected.

7.2.2 Suction Lysimeters:

7.2.2.1 Vacuum lysimeters directly transfer samples to the

surfaceviaasuctionline.Becausethemaximumsuctionliftof

water is about 7.5 m, these samplers cannot be operated below

this depth. In reality, suction lifts of 6 m should be considered

a practical maximum depth.

7.2.2.2 Samples may be retrieved using the same technique

as for vacuum lysimeters or, for deeper applications, the

sample is retrieved by pressurizing the sampler with one line;

this pushes the sample up to the surface in a second line.

7.2.2.3 High pressure-vacuum lysimeters operate in the

same manner as pressure-vacuum lysimeters. However, they

include an inbuilt check transfer vessel or a chamber between

the sampler and the surface.This prevents sample loss through

the porous section during pressurization, and prevents possible

cup damage due to overpressurization.

7.2.2.4 Suction lysimeters with low bubbling pressures are

available in each of the three previous designs. The only

difference between these samplers and the three previous

FIG. 1 Porous Section/Soil Interactions designs is that these porous sections are made with PTFE.The

D 4696

low bubbling pressure (and hence large pore size or hydropho-

bicity, or both) of PTFE constrains these samplers to soils that

are nearly saturated (see 7.2.1.2 and 7.6.1.3).

7.2.3 Filter Tip Samplers—Samples are collected from a

filter tip sampler by lowering an evacuated sample vial down

an access tube to a permanently emplaced porous tip. The vial

is connected to the porous tip and sample flows through the

poroussectio

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.