ASTM D6849-02(2012)

(Practice)Standard Practice for Storage and Use of Liquefied Petroleum Gases (LPG) in Sample Cylinders for LPG Test Methods

Standard Practice for Storage and Use of Liquefied Petroleum Gases (LPG) in Sample Cylinders for LPG Test Methods

SIGNIFICANCE AND USE

5.1 LPG samples can change composition during storage and use from preferential vaporization of lighter (lower molecular weight) hydrocarbon components, dissolved inert gases (N2, Ar, He, and so forth) and other dissolved gases/liquids (NH3, CO2, H2S, H2O, etc.). Careful selection of cylinder type, cylinder volume, and use of inert gas for pressurizing cylinders is required to ensure that composition changes are small enough to maintain the integrity of LPG when used as a QC reference material for various LPG test methods.

5.2 Monitoring of ongoing precision and bias on QC materials using control chart techniques in accordance with Practice D6299 can be used to establish the need for calibration or maintenance.

SCOPE

1.1 This practice covers information for the storage and use of LPG samples in standard cylinders of the type used in sampling method, Practice D1265 and floating piston cylinders used in sampling method, Practice D3700.

1.2 This practice is especially applicable when the LPG sample is used as a quality control (QC) reference material for LPG test methods, such as gas chromatography (GC) analysis (Test Method D2163) or vapor pressure (Test Method D6897) that use only a few mL per test, since relatively small portable Department of Transportation (DOT) cylinders (for example, 20 lb common barbecue cylinders) can be used. This practice can be applied to other test methods. However, test methods that require a large amount of sample per test (for example, manual vapor pressure Test Method D1267) will require QC volumes in excess of 1000 L if stored in standard DOT cylinders or American Society of Mechanical Engineers (ASME) vessels.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6849 −02(Reapproved 2012)

Standard Practice for

Storage and Use of Liquefied Petroleum Gases (LPG) in

Sample Cylinders for LPG Test Methods

This standard is issued under the fixed designation D6849; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Measurement System Performance

D6897 Test Method for Vapor Pressure of Liquefied Petro-

1.1 This practice covers information for the storage and use

leum Gases (LPG) (Expansion Method)

of LPG samples in standard cylinders of the type used in

sampling method, Practice D1265 and floating piston cylinders

3. Terminology

used in sampling method, Practice D3700.

3.1 Definitions of Terms Specific to This Standard:

1.2 This practice is especially applicable when the LPG

3.1.1 floating piston cylinder (FPC)—a high-pressure

sample is used as a quality control (QC) reference material for

sample container with a free floating internal piston(s) that

LPG test methods, such as gas chromatography (GC) analysis

effectively divides the container into two or more separate

(Test Method D2163) or vapor pressure (Test Method D6897)

compartments. The sample is contained on one side of the

that use only a few mL per test, since relatively small portable

piston (the sample or product side). The chamber on the other

Department of Transportation (DOT) cylinders (for example,

side of the piston (the charge or pre-charge side) is maintained

20 lb common barbecue cylinders) can be used. This practice

at a higher pressure than the vapor pressure of the sample with

can be applied to other test methods. However, test methods

an inert gas. This allows collection of a sample with no loss of

that require a large amount of sample per test (for example,

volatile components and no formation of a gaseous phase that

manual vapor pressure Test Method D1267) will require QC

may alter the composition of the sample. The cylinder is

volumes in excess of 1000 L if stored in standard DOT

equipped with a piston follower or indicating rod or other

cylinders or American Society of Mechanical Engineers

indicating device to show the position of the floating piston.

(ASME) vessels.

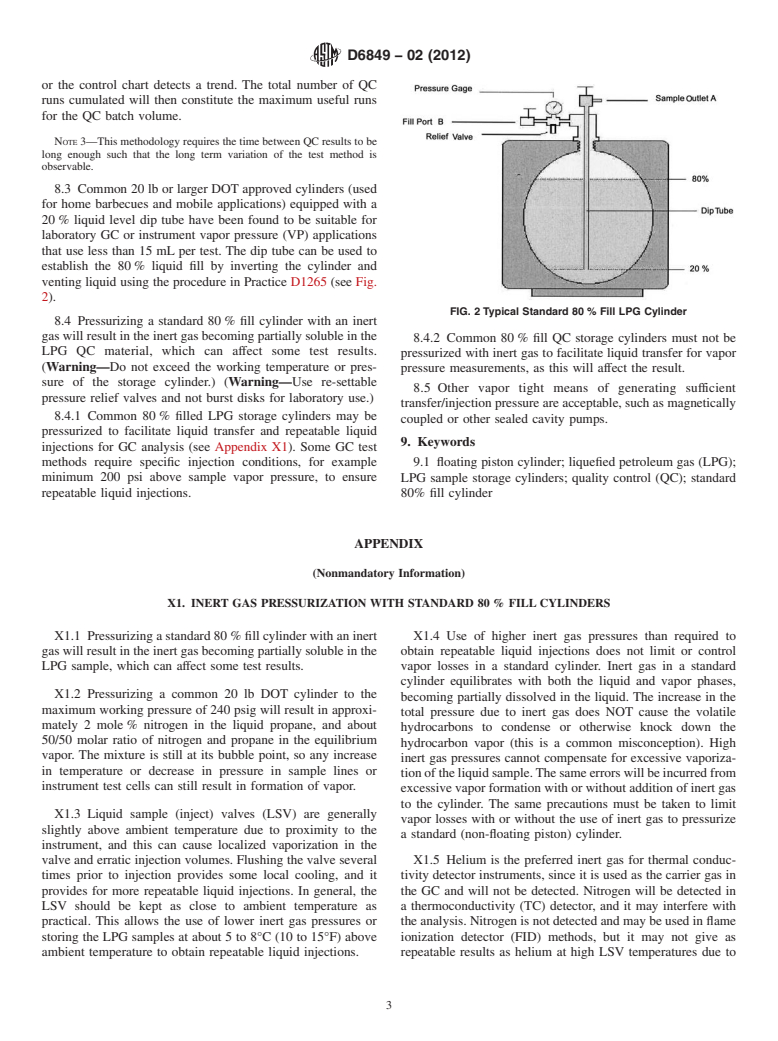

3.1.2 standard 80 % fill cylinder—a pressure rated cylinder

2. Referenced Documents

or vessel such as described in Practice D1265, or conforming

to DOT or ASME cylinder standards. These cylinders are not

2.1 ASTM Standards:

equipped with a floating piston, and have both an equilibrium

D1265 Practice for Sampling Liquefied Petroleum (LP)

liquid and vapor phase when used for LPG.

Gases, Manual Method

D1267 Test Method for Gage Vapor Pressure of Liquefied

4. Summary of Practice

Petroleum (LP) Gases (LP-Gas Method)

D2163 Test Method for Analysis of Liquefied Petroleum

4.1 This practice provides information for the design and

(LP) Gases and Propene Concentrates by Gas Chromatog-

operation of LPG sample storage cylinders taking into account

raphy

properties of LPG and types of cylinders in common use for

D3700 Practice for Obtaining LPG Samples Using a Float-

storage of LPG.

ing Piston Cylinder

4.2 This practice provides additional guidelines to Practice

D6299 Practice for Applying Statistical Quality Assurance

D6299 to determine the minimum volume of LPG sample

and Control Charting Techniques to Evaluate Analytical

material required, when used as a QC reference material.

5. Significance and Use

This practice is under the jurisdiction of ASTM Committee D02 on Petroleum

Products and Lubricants and is the direct responsibility of Subcommittee D02.08 on

5.1 LPG samples can change composition during storage

Volatility.

and use from preferential vaporization of lighter (lower mo-

Current edition approved Nov. 1, 2012. Published November 2012. Originally

lecular weight) hydrocarbon components, dissolved inert gases

approved in 2002. Last previous edition approved in 2007 as D6849–02 (2007).

DOI: 10.1520/D6849-02R12.

(N , Ar, He, and so forth) and other dissolved gases/liquids

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

(NH ,CO ,H S, H O, etc.). Careful selection of cylinder type,

3 2 2 2

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

cylinder volume, and use of inert gas for pressurizing cylinders

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. is required to ensure that composition changes are small

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6849−02 (2012)

enough to maintain the integrity of LPG when used as a QC

reference material for various LPG test methods.

5.2 Monitoring of ongoing precision and bias on QC mate-

rials using control chart techniques in accordance with Practice

D6299 can be used to establish the need for calibration or

maintenance.

6. Reference Materials

6.1 The LPG QC reference material should have a vapor

pressure and composition in the range of the samples regularly

tested by the equipment. This is particularly important for

LPG/natural gas liquid (NGL) mixtures near the critical

temperature, as these liquids have large thermal and pressure

expansion coefficients.

6.2 LPG QC reference materials should be stored in an

environment suitable for long term storage without significant

sample degradation for the test(s) being performed.

NOTE 1—As an example, evidence of a long term shift or bias in the

LPG QC reference material results obtained relative to the established

statistical control limits and average value determined for the test initially,

may indicate that the composition of the LPG QC reference material has

significantly degraded or changed over time. An investigation should be

conducted to determine if the long term stability of the QC reference

material is the cause for the out-of-control situation.

7. Use of Floating Piston Cylinders for LPG Samples

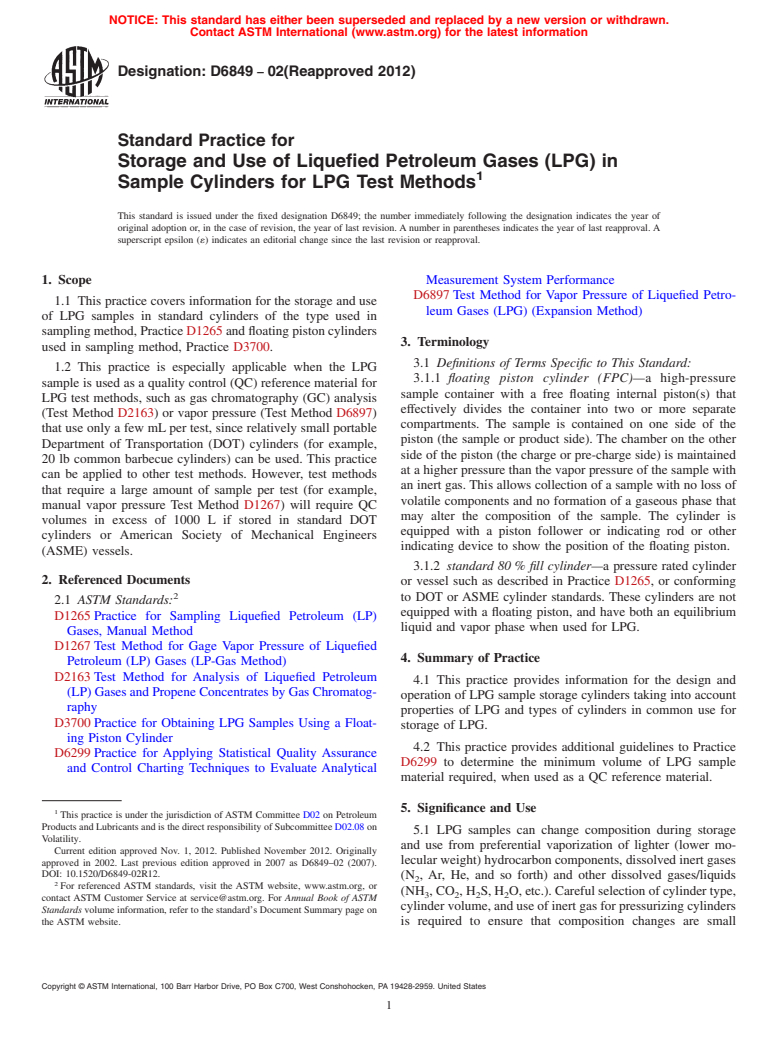

FIG. 1Typical Floating Piston Cylinder (FPC)

7.1 Minimum LPG sample volume can be determined in

accordance with Practice D6299.

matelylinearatlowvaportoliquid(V/L)ratios.Thesechanges

NOTE 2—Estimating the minimum LPG sample volume needed in-

accelerate and become more significant as the remaining

cludes such things as the sample volume needed to conduct the appropri-

ate test(s) and the number of analytical measurements that are expected to

volume of liquid decreases and the cylinder approaches empty.

be made over the intended period of use.

However, if the initial volume is sufficiently large, and the final

7.2 Floating piston cylinders (see Fig. 1) are preferred for

V/L ratio is limited, the change will occur very slowly over

LPG sample materials for tests involving accurate determina- time,andthematerialisstillsuitableasaQC.Intheshortterm,

tion of light gases.

the composition is essentially constant relative to the precision

of the method.

7.3 Excessive inert gas pressure should be avoided for long

8.2.2 In the long run, the control limits can be periodically

term storage of vapor pressure QC or calibrant materials in

adjusted to compensate for any long-term trend, or the charted

floating piston cylinders. Leakage of inert gas past worn or

response can be compensated for the long-term trend using

damaged floating piston seals can cause an increase in dis-

historical data, or equation of state calculations based on

solved gas concentration and vapor pressure of the QC sample

cylinder weight or volume. Consult a statistician for appropri-

material.

ate techniques to develop a prediction model for the long-term

trend.

8. Use of Standard 80 %

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.