ASTM F1245-89(2006)

(Specification)Standard Specification for Faucets, Single and Double, Compression and Self-Closing Type, Shipboard

Standard Specification for Faucets, Single and Double, Compression and Self-Closing Type, Shipboard

ABSTRACT

This specification covers single- and double compression and self-closing faucets for shipboard plumbing installations. Faucets may be classified into nine types: Type I is the standard (bibb) with three classes namely Class A (compression, plain end), Class B (compression, hose end), and Class C (self-closing); Type II is a lavatory, self-closing, low spout faucet with two classes which are Class A (fast-closing) and Class B (slow-closing, depression type); Type III is a folding lavatory,self-closing faucet; Type IV is an elbow operated faucet, Type V is a faucet with lavatory, combination water supply and drain fixture; Type VI is a faucet with combination supply fixture swing spout for use on galley sinks; Type VII is a faucet with single supply fixture swing spout for use with steam kettles and urns and this type has two classes namely Class A which has spout for overhead supply and Class B which has spout for riser supply; Type VIII is a faucet with supply fixture for pressed metal and shock mounted china lavatories; and Type IX which is a faucet with lavatory and combination of water supply and drain fixtures. Faucet bodies shall be made of bronze and handles shall be of commercial grade cast or forged brass or bronze. Bonnets, handwheels, and nuts shall be of commercial quality brass or bronze; machine screws shall be made of commercial brass. Seat washers shall be of a rubber or fiber material and suitable for a certain water temperature range without deterioration of material. Springs for self-closing faucets shall be of corrosionresisting steel, phosphor bronze, or nickel copper. All samples shall be subjected to a hydrostatic test.

SCOPE

1.1 This specification covers single and double compression and self-closing faucets for shipboard plumbing installations.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 The following precautionary caveat pertains only to the test methods portion, Section 10, of this standard. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: F1245 – 89 (Reapproved 2006)

Standard Specification for

Faucets, Single and Double, Compression and Self-Closing

Type, Shipboard

This standard is issued under the fixed designation F1245; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope PPP-B-585 Boxes, Wood, Wirebound

PPP-B-591 Boxes, Shipping, Fiberboard, Wood-Cleated

1.1 This specification covers single- and double-

PPP-B-601 Boxes, Wood, Cleated-Plywood

compression and self-closing faucets for shipboard plumbing

PPP-B-621 Boxes, Wood, Nailed and Lock-Corner

installations.

PPP-B-636 Box, Shipping, Fiberboard

1.2 Thevaluesstatedininch-poundunitsaretoberegarded

PPP-B-676 Boxes, Setup

as the standard. The values given in parentheses are for

QQ-N-290 Nickel Plating (Electrodeposited)

information only.

QQ-C-320 Chromium Plating (Electrodeposited)

1.3 The following precautionary caveat pertains only to the

2.4 Military Specification:

test methods portion, Section 10, of this standard. This stan-

MIL-P-116 Preservation, Methods of

dard does not purport to address all of the safety concerns, if

2.5 Military Standards:

any, associated with its use. It is the responsibility of the user

MIL-STD-105 Sampling Procedures and Tables for Inspec-

of this standard to establish appropriate safety and health

tion by Attributes

practices and determine the applicability of regulatory limita-

MIL-STD-129 Marking for Shipment and Storage

tions prior to use.

2.6 Naval Sea Systems Command (NAVSEA):

2. Referenced Documents NAVSEA Drawing 803-5959206 Faucet, Metering

NAVSEA Drawing 805-1623970 Unit, Lavatory for Offi-

2.1 ASTM Standards:

cers Station

B62 Specification for Composition Bronze or Ounce Metal

Castings

3. Classification

B584 Specification for Copper Alloy Sand Castings for

3.1 Faucets shall be of the following types and classes as

General Applications

3 specified (see 4.1):

2.2 American National Standards Institute Standard:

3.1.1 Type I—Standard (bibb):

B1.1 Unified Inch Screw Threads (UN and UNR Thread

3.1.1.1 Class A—Compression, plain end.

Form)

3.1.1.2 Class B—Compression, hose end.

2.3 Federal Specifications:

3.1.1.3 Class C—Self-closing.

PPP-B-566 Boxes, Folding, Paperboard

3.1.2 Type II—Lavatory, self-closing, low spout.

3.1.2.1 Class A—Fast-closing.

This specification is under the jurisdiction ofASTM Committee F25 on Ships

3.1.2.2 Class B—Slow-closing, depression type.

and Marine Technology and is the direct responsibility of Subcommittee F25.11 on

3.1.3 Type III—Folding lavatory, self-closing.

Machinery and Piping Systems.

3.1.4 Type IV—Elbow operated.

Current edition approved Feb. 1, 2006. Published February 2006. Originally

approved in 1989. Last previous edition approved in 2001 as F1245–89 (2001).

3.1.5 Type V—Lavatory, combination water supply and

DOI: 10.1520/F1245-89R06.

drain fixture.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3.1.6 Type VI—Combination supply fixture swing spout for

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on use on galley sinks.

the ASTM website.

3.1.7 Type VII—Single supply fixture swing spout for use

Available from American National Standards Institute, 25 W. 43rd St., 4th

with steam kettles and urns.

Floor, New York, NY 10036.

3.1.7.1 Class A—Spout for overhead supply.

AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F1245 – 89 (2006)

3.1.7.2 Class B—Spout for riser supply.

3.1.8 Type VIII—Supplyfixtureforpressedmetalandshock

mounted china lavatories.

3.1.9 Type IX—Lavatory, combination water supply and

drain fixtures, depression type.

4. Ordering Information

4.1 Orders for equipment under this specification shall

include the following information, as required, to describe the

FIG. 1 Type I Standard Faucet, Classes A, B, and C

equipment adequately:

4.1.1 ASTM designation and year of issue,

4.1.2 Type and class of faucet required (see 3.1),

6.2.1.1 The shank of the faucet and one end of the tailpiece

4.1.3 Type of handle required (see 6.11),

shall be arranged as a ground joint union; the other end of the

4.1.4 Marking required for handles (see 13.1),

tailpiece shall be provided with outside threads ⁄4-in. NPS.

4.1.5 Size and weight of Type I faucet required (see 7.1),

6.2.2 Class A lavatory faucets shall be in accordance with

4.1.6 Overall dimensions for Type II faucets (see 7.2),

Fig. 2.

4.1.7 ShankdesignforTypeII,ClassBfaucets(see6.2.3.2),

6.2.2.1 They shall operate on a cam, ball, or roller bearings.

4.1.8 Overall dimensions and position of inlet (side or

6.2.2.2 Faucetswithrenewableoperatingunitsmaybeused.

bottom) for Type III faucets (see 7.3),

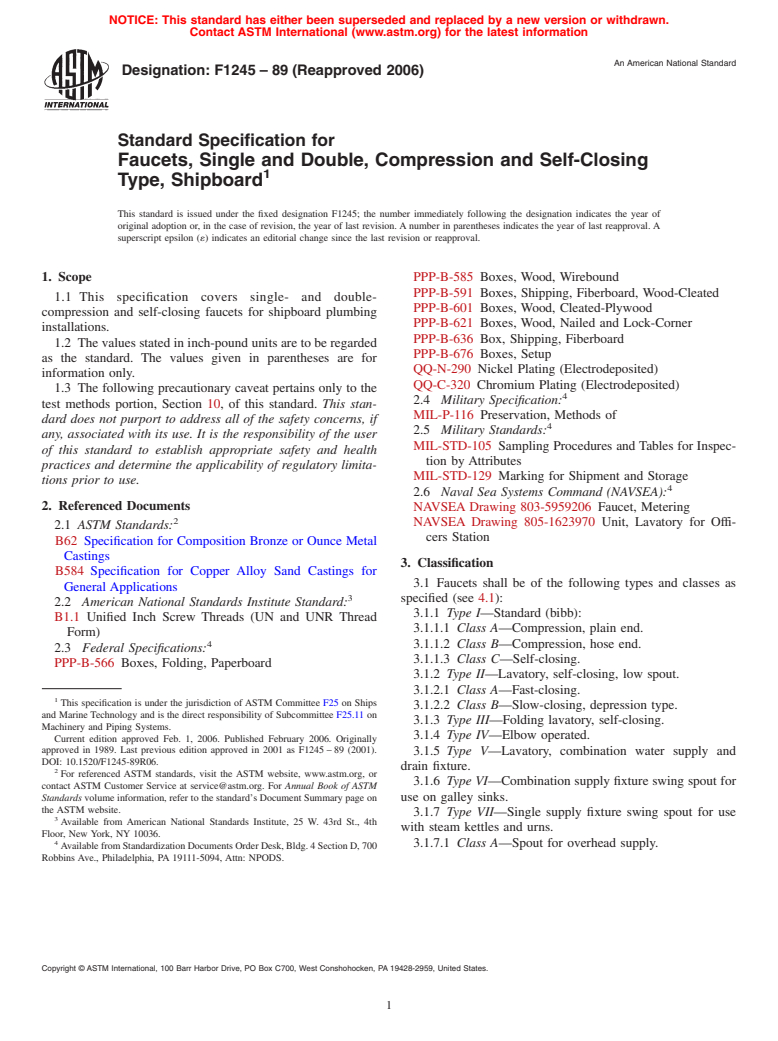

6.2.3 Class B lavatory faucets shall be in accordance with

4.1.9 Overall dimensions and whether spray is required for

Fig. 3.

Type IV faucets (see 6.4.1.3 and 7.4),

6.2.3.1 They shall be fitted with an adjusting device, which

4.1.10 Length of spout for Type VI fixtures (see 7.6.1),

cannot be tampered with, for regulating the closing from 3 to

4.1.11 Whether escutcheon plates are provided for Type VI

20 s in accordance with NAVSEA Drawing 803-5959206.

faucets (see 6.6.3),

6.2.3.2 Shank design shall be as specified (see 4.1.7).

4.1.12 Whether connections are other than ⁄4-in. nominal 6.3 Type III, folding lavatory self-closing.

pipe size (NPS) (see 6.8.2.1), 6.3.1 Faucets shall be in accordance with Fig. 4.

4.1.13 Sample size for examination and testing (see 10.1, 6.3.1.1 They shall be of the cam, ball or roller bearing

self-closing type.

10.2, and 11.1), and

4.1.14 Optional requirements, if any (see Supplementary 6.3.1.2 The body shall be designed for back mounting.

6.4 Type IV, elbow operated.

Requirements S1 through S3).

6.4.1 Faucets shall be in accordance with Fig. 5 except that

a gooseneck spout is acceptable.

5. Materials

6.4.1.1 They shall have a double faucet with a rigid spout

5.1 Faucet bodies shall be made of bronze conforming to

with or without buttons, renewable seats, and sleeves or

Specification B62 or Specification B584.

renewable units and integral stops in shanks with union inlets.

5.2 Handles shall be of commercial grade cast or forged

6.4.1.2 Escutcheon plates shall be provided for the fixtures.

brass or bronze.

6.4.1.3 Spray shall be provided when specified (see 4.1.9).

5.3 Bonnets, handwheels, and nuts shall be of commercial

6.5 Type V, lavatory, combination water supply and drain

quality brass or bronze; machine screws shall be made of

fixtures.

commercial brass.

6.5.1 Fixtures shall be in accordance with Fig. 6.

5.4 Seat washers shall be of a rubber or fiber material

6.5.1.1 The trunion lugs shall be designed so that the

capable of withstanding the hydrostatic test of 10.1 and

trunions will be held in place by spring clips or other device.

suitable for water temperature from 30 to 190°F (−1 to 88°C)

without deterioration of material.

5.5 Springs for self-closing faucets shall be of corrosion-

resisting steel, phosphor bronze, or nickel copper.

6. Requirements

6.1 Type I, standard.

6.1.1 Type I faucets shall be in accordance with Fig. 1.

6.1.1.1 Faucets shall have hexagon shoulders and a male

threaded inlet.

6.1.2 Class A faucets shall be plain; Class B shall have

⁄4-in. (19-mm) hose thread. Class C shall be the same as Class

A except they shall be self-closing.

6.2 Type II, lavatory, self-closing, low spout.

6.2.1 Faucets shall be provided with a shank, fitted with a

NOTE 1—All dimensions are in inches. 1 in. = 25.4 mm.

metal washer and locknut and with a ⁄4-in. NPS tailpiece. FIG. 2 Type II Class A Lavatory, Self-Closing, Low Spout Faucet

F1245 – 89 (2006)

NOTE 1—All dimensions are in inches. 1 in. = 25.4 mm.

FIG. 3 Type II Class B Faucet

NOTE 1—All dimensions are in inches. 1 in. = 25.4 mm.

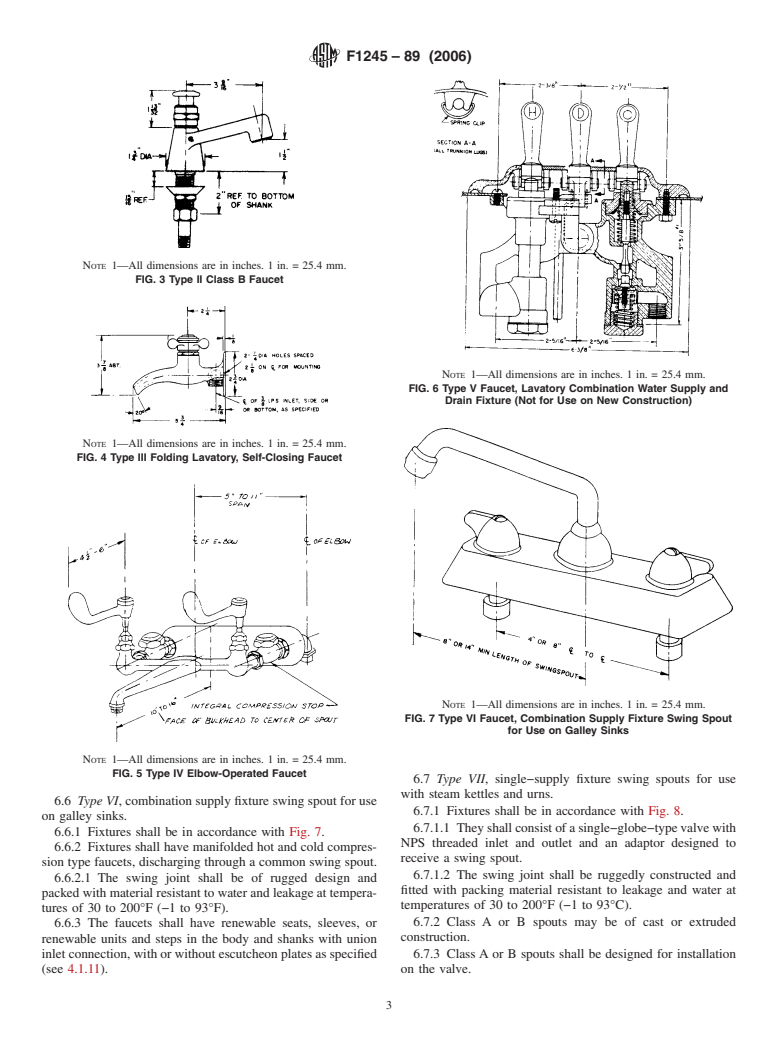

FIG. 6 Type V Faucet, Lavatory Combination Water Supply and

Drain Fixture (Not for Use on New Construction)

NOTE 1—All dimensions are in inches. 1 in. = 25.4 mm.

FIG. 4 Type III Folding Lavatory, Self-Closing Faucet

NOTE 1—All dimensions are in inches. 1 in. = 25.4 mm.

FIG. 7 Type VI Faucet, Combination Supply Fixture Swing Spout

for Use on Galley Sinks

NOTE 1—All dimensions are in inches. 1 in. = 25.4 mm.

FIG. 5 Type IV Elbow-Operated Faucet

6.7 Type VII, single−supply fixture swing spouts for use

with steam kettles and urns.

6.6 Type VI, combination supply fixture swing spout for use

6.7.1 Fixtures shall be in accordance with Fig. 8.

on galley sinks.

6.7.1.1 Theyshallconsistofasingle−globe−typevalvewith

6.6.1 Fixtures shall be in accordance with Fig. 7.

NPS threaded inlet and outlet and an adaptor designed to

6.6.2 Fixtures shall have manifolded hot and cold compres-

receive a swing spout.

sion type faucets, discharging through a common swing spout.

6.7.1.2 The swing joint shall be ruggedly constructed and

6.6.2.1 The swing joint shall be of rugged design and

fitted with packing material resistant to leakage and water at

packedwithmaterialresistanttowaterandleakageattempera-

temperatures of 30 to 200°F (−1 to 93°C).

tures of 30 to 200°F (−1 to 93°F).

6.7.2 Class A or B spouts may be of cast or extruded

6.6.3 The faucets shall have renewable seats, sleeves, or

construction.

renewable units and steps in the body and shanks with union

inletconnection,withorwithoutescutcheonplatesasspecified 6.7.3 Class A or B spouts shall be designed for installation

(see 4.1.11). on the valve.

F1245 – 89 (2006)

6.8.4 The faucet may seat with or against the water supply

pressure.

6.8.5 Faucetswithrenewableoperatingunitswillbeaccept-

able.

6.9 Type IX, lavatory, combination water supply and drain

fixtures, depression type.

6.9.1 In addition to the requirements specified herein, Type

IXfixturesshallalsobeinaccordancewithNAVSEADrawing

803-5959206.

6.10 Threads for threaded parts shall conform to the appli-

cable requirements of ANSI B1.1.

6.11 Handles shall be four-ball, four-arm, star, T, loose-key

T, or lever type, as specified (see 4.1.3), with the exception

noted in 6.11.1.

6.11.1 Handles for Type II, Class B and Type IX faucets

shall be in accordance with NAVSEA Drawing 803-5959206.

6.11.2 Handwheels may be provided for Type VII faucets.

NOTE 1—All dimensions are in inches. 1 in. = 25.4 mm.

7. Dimensions, Mass, and Permissible Variations

FIG. 8 Type VII Faucet, Single-Supply Fixture Swing Spout for

7.1 TypeIfaucetsshallbeofthesizesandweightsspecified

Use with Steam Kettles and Urns

in Table 1.

7.2 Type II faucets shall be of the dimensions specified in

6.8 Type VIII, supply fixture for pressed metal and shock

4.1.6.

mounted china, lavatories.

7.2.1 Dimensions shown on Fig. 3 are approximate.

6.8.1 Fixtures shall be in accordance with Fig. 9.

7.2.2 Faucets shall have a minimum weight, including the

6.8.2 Fixtures shall consist of a manifold incorporating hot

tailpiece, of 1.5 lb (0.7 kg) 65%.

and cold water NPS female threaded inlet connections to

7.3 ForType III faucets, overall dimensions and position of

permit connection from top or bottom of the manifold and

the inlet (side or bottom) shall be as specified (see 4.1.8). The

common outlet (through direct compression type or inverted

dimensions shown on Fig. 4 are approximate.

compression type) faucets.

7.4 For Type IV faucets, overall dimensions shall be as

6.8.2.1 Unless otherwise specified (see 4.1.12), the connec-

specified (see 4.1.9). The dimensions shown on Fig. 5 are

tions shall be ⁄4-in. NPS.

approximate.

6.8.3 Faucets shall be of the self-closing type operating on

7.5 Type V fixtures shall conform to the dimensions shown

a cam, ball, or roller bearing.

on Fig. 6.

7.6 TypeVIfixturesshallconformtothedimensionsshown

on Fig. 7.

7.6.1 The swing spout shall be 8- or 14-in. (203- to

356-mm) minimum length, as specified (see 4.1.10).

7.7 Type VII fixtures shall conform to the dimensions

shown on Fig. 8.

7.8 Type VIII fixtures shall conform to the dimensions

shown on Fig. 9.

7.9 TypeIXfixturesshallconformtothedimensionsshown

on NAVSEA Drawing 803-5959206.

8. Workmanship, Finish, and Appearance

8.1 Faucetsshallbetruetoformandfreefromalldefectsor

blemishes affecting the appearance or serviceability.

A

TABLE 1 Size and Weight of Type I Faucets

Nominal Pipe Size, in. Minimum Weight, lb

1 3

⁄2 ⁄4

3 7

⁄4 ⁄8

NOTE 1—All dimensions are in inches. 1 in. = 25.4 mm.

1 1

1 ⁄4 1 ⁄8

FIG. 9 Type VIII Faucet, Supply Fixture for Pressed Metal and

A

Shock-Mounted China Lavatories 1 in. = 25.4 mm; 1 lb = 0.45 kg.

F1245 – 89 (2006)

8.2 Before plating, faucets shall be thoroughly cleaned of facilitiessuitablefortheperformanceoftheinspectionrequire-

sand and scale by the acid-bath process (or a process satisfac- ments specified herein unless disapproved by the purchaser.

tory to the purchaser) and shall have all fins and roughness 11.2.2 The purchaser reserves the right to perform any of

removed and polished. the inspections set forth in the specification where such

8.3 Nickel chromium plating shall be applied to surfaces inspections are deemed necessary to ensure that supplies and

normally visible after installation including exposed bolts, services conform to prescribed requirements.

nuts, screws, or other fastenings. 11.2.3 The absence of any inspection requirements in the

8.3.1 Nickel plating on copper-base alloys shall be Class 1, specification shall not relieve the contractor of the responsibil-

Type VII (QC) in accordance with QQ-N-290. ity of ensuring that all products or supplies submitted to the

8.3.2 Chromium plating, over nickel, shall be Class 1,Type purchaser for acceptance comply with all requirements of the

I in accordance with QQ-C-320. contract.

12. Rejection and Rehearing

9. Sampling

12.1 Material that fails to conform to the requirements of

9.1 All faucets of the same type, class, and size offered for

thisspecificationmayberejected.Rejectionshouldbereported

delivery at one time shall be considered a lot for purposes of

to the producer or supplier promptly and in writing. In case of

examination and hydrostatic test.

dissatisfaction with the results of the test, the producer or

10. Test Methods

supplier may make claim for a rehearing.

10.1 Samples,asspecified(see4.1.13),shallbetestedunder

13. Product Marking

a hydrostatic pressure of 100 psi (690 kPa).

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.