ASTM D5368-93(2001)

(Test Method)Standard Test Methods for Gravimetric Determination of Total Solvent Extractable Content (TSEC) of Solid Waste Samples

Standard Test Methods for Gravimetric Determination of Total Solvent Extractable Content (TSEC) of Solid Waste Samples

SCOPE

1.1 These test methods describe standard procedures for gravimetrically determining the total nonvolatile and semi-volatile organic content of solvent extracts from soils or solid wastes. The following methods are included: SectionMethod A--Micro-Determination of TSEC11-13Method B--Evaporating Dish Procedure14-16Method C--Boiling Flask Procedure17-19

1.2 These methods are used after a solvent extract is obtained from a soil or solid waste. For these methods to be applicable, the extraction solvent must have a boiling point less than that of water at ambient pressure.

1.3 The total solvent extractable content (TSEC) of a soil, sediment, sludge, or solid waste depends upon the solvent and method used for the extraction procedure.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D5368–93 (Reapproved 2001)

Standard Test Methods for

Gravimetric Determination of Total Solvent Extractable

Content (TSEC) of Solid Waste Samples

This standard is issued under the fixed designation D 5368; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1 total solvent extractable content (TSEC)— the total

concentration by weight (w/w) of organic materials that is

1.1 These test methods describe standard procedures for

extractable from a soil or solid waste by the selected solvent.

gravimetrically determining the total nonvolatile and semi-

volatile organic content of solvent extracts from soils or solid

4. Summary of Methods

wastes. The following methods are included:

4.1 The sample is extracted with an organic solvent using a

Section

procedure such as described in Practices D 5369 (Soxhlet

Method A—Micro-Determination of TSEC 11-13

Method B—Evaporating Dish Procedure 14-16

Extraction) or Test Method D 4281. The quantity of material

Method C—Boiling Flask Procedure 17-19

extracted into the solvent is determined as the residue weight

1.2 These methods are used after a solvent extract is after solvent evaporation. Similar ASTM methods are Test

obtained from a soil or solid waste. For these methods to be Methods D 2109 and D 3445, and Practice D 2910.

applicable,theextractionsolventmusthaveaboilingpointless 4.1.1 Method A, Micro-Determination Method—The resi-

than that of water at ambient pressure. due weight after solvent evaporation is determined for 200 µL

1.3 The total solvent extractable content (TSEC) of a soil, ofsolventextractevaporatedonanaluminumweighingdish.A

sediment, sludge, or solid waste depends upon the solvent and heat lamp is used to effect evaporation.

method used for the extraction procedure. 4.1.2 Method B, Evaporating Dish Procedure—The residue

weight after solvent evaporation is determined for 1.0 to 75.0

2. Referenced Documents

mL of solvent extract. Solvent is evaporated in an evaporating

2.1 ASTM Standards: dish by heating at 5°C below the solvent boiling point. A

D 2109 Test Methods for Nonvolatile Matter in Haloge-

stream of nitrogen over the surface of the solvent is used to

nated Organic Solvents and Their Admixtures accelerate evaporation.

D 2910 PracticeforConcentrationandRecoveryofOrganic

4.1.3 Method C, Boiling Flask Method—Theresidueweight

Matter from Water by Activated Carbon

after solvent evaporation is determined for 100 to 300 mL of

D 3086 TestMethodforOrganochlorinePesticidesinWater solvent evaporated in a boiling flask. Solvent is evaporated in

D 3445 Test Method for Nonvolatile Matter in Trichlorot-

a water bath at the solvent boiling point.

rifluoroethane

5. Significance and Use

D 3694 Practices for Preparation of Sample Containers and

for Preservation of Organic Constituents 5.1 The TSEC provides a quantitative measure of the total

D 4281 Test Method for Oil and Grease (Fluorocarbon solvent extractable organic content of the solid waste in

Extractable Substances) by Gravimetric Determination question.BasedupontheTSEC,theextractmaybeanalyzedor

D 5369 Practice for the Extraction of Solid Waste Samples further processed (that is, further cleanup or solvent concen-

for Chemical Analysis Using Soxhlet Extraction tration) in preparation for analysis. Thus, the TSEC provides a

quantitative measure for optimizing the extractable organic

3. Terminology

concentration prior to chemical analysis.

3.1 Definition: 5.2 The TSEC of soil or waste material may be used as a

quantitativemeasureforthescreeningandselectionofsamples

for chemical analysis.

These test methods are under the jurisdiction of ASTM Committee D34 on

5.3 The TSEC may be useful as a simple and relatively

Waste Management and are the direct responsibility of Subcommittee D34.01.06 on

Analytical Methods. inexpensive quantitative indicator of changes occurring in the

Current edition approved Feb. 15, 1993. Published April 1993.

total extractable organic content of soil or waste materials.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5.4 The detection limit of the TSEC depends upon the

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

specific procedures employed. Typical detection limits in

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

solvent extracts (that is, without solvent pre-concentration) for

Withdrawn.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D5368–93 (2001)

Method A are more than 1000 µg/g. For Method B typical 6.4 Inorganic constituents extractable from the waste by the

detection limits are 20 to 100 µg/g in the solvent extract. For solvent selected will result in a positive interference in the

Method C the typical detection limits are 3 to 20 µg/g for determination of TSEC, unless removed prior to TSEC deter-

solutes in the solvent extract. mination.Thispotentialforinterferencemustbedeterminedby

5.5 The sensitivity of the methods can be adjusted by the analyst on a case by case basis using existing data and best

varying the volume of solvent extract prior to gravimetric judgment.

residue determination.

7. Selection of the Extraction Solvent

6. Interferences

7.1 The selection of solvent for extraction and TSEC

6.1 Solvents,reagents,glassware,andothersampleprocess-

determination will depend upon many factors, including the

inghardwaremayyieldanunacceptablebackgroundrelativeto

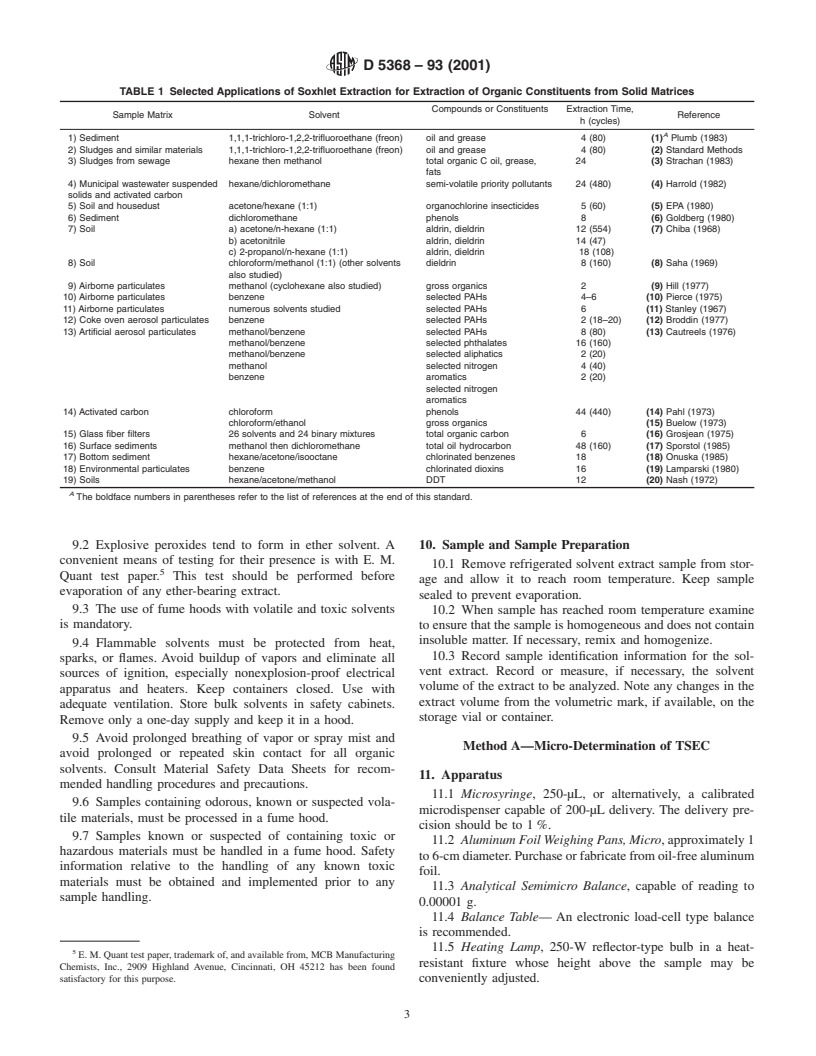

following (see Table 1 for selected applications):

the limit of detection required for the TSEC measurement. A

7.1.1 Boiling point of the solvent,

method blank must be performed in order to demonstrate the

7.1.2 Boilingpointofthecompoundsorclassofcompounds

viability of the solvent and equipment used. Specific selection

of interest,

of reagents and the purification of solvents by distillation in

7.1.3 Tendencyofthesolventandmatrixtoformemulsions,

all-glass systems may be required when low levels (that is,

7.1.4 Solvent strength (that is, polarity, solubility of com-

<100 µg/g) of TSEC are of interest.

pounds of interest),

6.1.1 Glassware should be cleaned by washing with deter-

7.1.5 Safety of solvent use (that is, toxicity, flammability),

gent or non-chromate cleaning solution, rinsing first with tap

7.1.6 Purity of solvent, and

water, then reagent water, then redistilled acetone, and finally

7.1.7 Solvent compatibility with analysis instrumentation.

with pesticide quality solvent (that is, the solvent used for

7.2 The analyst should demonstrate a recovery using a

extraction). For additional information, see Practices D 3694.

spiking procedure in the matrix of interest before using this

If the type and size of glassware permits, it may be cleaned by

procedure.

heating in a muffle furnace at 400°C for 15 to 30 min.

7.3 The extract is exposed to temperatures approaching the

Alternatively, glassware may be oven dried at 103°C for at

boiling point of the solvent during the evaporation procedure.

least 1 h, after solvent rinsing and draining. Volumetric

Consequently, one must ensure that heat-labile and more

glassware should not be heated in a muffle furnace.

volatile solutes that may be of interest are stable and recover-

6.1.2 Plastics,exceptPTFE-fluorocarbon,canbeasourceof

able by the method and the solvent of choice. Because

serious interference, especially when specific organic constitu-

low-boiling fractions are lost in solvent removal, reproducible

ents are of analytical interest. Their use must be avoided.

results can only be obtained by strict adherence to method

Extracted samples should be stored in glass bottles with

details.

PTFE-fluorocarbon-lined caps. Extraction solvent volumes

8. Reagents and Materials

should be recorded and containers sealed to prevent solvent

evaporation or cross contamination. Extracts should be refrig-

8.1 Purity of Reagents—Reagent grade chemicals shall be

erated above the freezing point of the solvent. used in all tests. Unless otherwise indicated, all reagents must

6.1.3 If required, rinse glassware and utensils with extrac-

conform to the specifications of the Committee on Analytical

tion solvent prior to use in order to remove interferences. The Reagents of the American Chemical Society where such

method blank should be less than 20 % of the minimum

specifications are available. Other grades may be used, pro-

reportable concentration. vided it is first determined that the reagent is of sufficiently

6.1.4 Impurities in the extracting solvent can be a source of

high purity to permit its use without lessening the accuracy of

interferences or TSEC background. Solvent blanks should be the determination.

analyzed with each new bottle of solvent. Whenever a high

8.2 When low concentrations of TSEC are to be determined

TSEC background, or interfering compounds are traced to the (that is, <100 µg/g in the waste) pesticide-grade solvents (that

solvent, a new source of solvent should be obtained. Alterna-

is, distilled in glass) are recommended. The solvent blank for

tively, impurities can often be removed by distillation in glass. TSEC and the specific constituents of interest must be below

6.2 Arelatively highTSEC background can also result from

20 % of the reportable lower limit for the analysis.

inorganic drying agents (that is, Na SO , MgSO , CuSO ,

8.3 Acetone ((CH ) CO), technical grade.

2 4 4 4 3 2

CaCl , CaSO ,K CO , KOH, BaO, CaO, H SO ,P O )inthe 8.4 Explosion-Proof Oven or Furnace.

2 4 2 3 2 4 2 5

extracting solvent.Arelatively high background of any drying

8.5 Heating Mantles.

agent used (>20 % of the minimum TSEC concentration of

9. Precautions

interest) in the solvent will preclude the application of the

method for TSEC determinations in those cases. Residue 9.1 Some solvents (for example, benzene, chloroform, and

ignition and inorganic analysis are suggested to evaluate this carbon tetrachloride) are suspected human carcinogens and

potential background. must be handled by approved methods.

6.3 Organic interferences can arise from the extraction of

impurities from inorganic drying agents. If this is suspected,

“Reagent Chemicals, American Chemical Society Specifications,” Am. Chem.

the interference may be removed by rinsing the drying agent

Soc., Washington, DC. For suggestions on the testing of reagents not listed by the

with pure extraction solvent followed by oven drying of the

American Chemical Society, see “Analar Standards for Laboratory U.K. Chemical,”

inorganic drying agent. BDH Ltd., Poole, Dorset, and the “United States Pharmacopeia.”

D5368–93 (2001)

TABLE 1 Selected Applications of Soxhlet Extraction for Extraction of Organic Constituents from Solid Matrices

Compounds or Constituents Extraction Time,

Sample Matrix Solvent Reference

h (cycles)

A

1) Sediment 1,1,1-trichloro-1,2,2-trifluoroethane (freon) oil and grease 4 (80) (1) Plumb (1983)

2) Sludges and similar materials 1,1,1-trichloro-1,2,2-trifluoroethane (freon) oil and grease 4 (80) (2) Standard Methods

3) Sludges from sewage hexane then methanol total organic C oil, grease, 24 (3) Strachan (1983)

fats

4) Municipal wastewater suspended hexane/dichloromethane semi-volatile priority pollutants 24 (480) (4) Harrold (1982)

solids and activated carbon

5) Soil and housedust acetone/hexane (1:1) organochlorine insecticides 5 (60) (5) EPA (1980)

6) Sediment dichloromethane phenols 8 (6) Goldberg (1980)

7) Soil a) acetone/n-hexane (1:1) aldrin, dieldrin 12 (554) (7) Chiba (1968)

b) acetonitrile aldrin, dieldrin 14 (47)

c) 2-propanol/n-hexane (1:1) aldrin, dieldrin 18 (108)

8) Soil chloroform/methanol (1:1) (other solvents dieldrin 8 (160) (8) Saha (1969)

also studied)

9) Airborne particulates methanol (cyclohexane also studied) gross organics 2 (9) Hill (1977)

10) Airborne particulates benzene selected PAHs 4–6 (10) Pierce (1975)

11) Airborne particulates numerous solvents studied selected PAHs 6 (11) Stanley (1967)

12) Coke oven aerosol particulates benzene selected PAHs 2 (18–20) (12) Broddin (1977)

13) Artificial aerosol particulates methanol/benzene selected PAHs 8 (80) (13) Cautreels (1976)

methanol/benzene selected phthalates 16 (160)

methanol/benzene selected aliphatics 2 (20)

methanol selected nitrogen 4 (40)

benzene aromatics 2 (20)

selected nitrogen

aromatics

14) Activated carbon chloroform phenols 44 (440) (14) Pahl (1973)

chloroform/ethanol gross organics (15) Buelow (1973)

15) Glass fiber filters 26 solvents and 24 binary mixtures total organic carbon 6 (16) Grosjean (1975)

16) Surface sediments methanol then dichloromethane total oil hydrocarbon 48 (160) (17) Sporstol (1985)

17) Bottom sediment hexane/acetone/isooctane chlorinated benzenes 18 (18) Onuska (1985)

18) Environmental particulates benzene chlorinated dioxins 16 (19) Lamparski (1980)

19) Soils hexane/acetone/methanol DDT 12 (20) Nash (1972)

A

The boldface numbers in parentheses refer to the list of references at the end of this standard.

9.2 Explosive peroxides tend to form in ether solvent. A 10. Sample and Sample Preparation

convenient means of testing for their presence is with E. M.

10.1 Remove refrigerated solvent extract sample from stor-

Quant test paper. This test should be performed before

age and allow it to reach room temperature. Keep sample

evaporation of any ether-bearing extract.

sealed to prevent evaporation.

9.3 The use of fume hoods with volatile and toxic solvents

10.2 When sample has reached room temperature examine

is mandatory. to ensure that the sample is homogeneous and does not contain

insoluble matter. If necessary, remix and homogenize.

9.4 Flammable solvents must be protected from heat,

10.3 Record sample identification information for the sol-

sparks, or flames. Avoid buildup of vapors and eliminate all

vent extract. Record or measure, if necessary, the solvent

sources of ignition, especially nonexplosion-proof electrical

volume of the extract to be analyzed. Note any changes in the

apparatus and heaters. Keep containers closed. Use with

extract volume from the volumetric mark, if available, on the

adequate ventilation. Store bulk solvents in safety cabinets.

storage vial or container.

Remove only a one-day supply and keep it in a hood.

9.5 Avoid prolonged breathing of vapor or spray mist and

Method A—Micro-Determination of TSEC

avoid prolonged or repeated skin contact for all organic

solvents. Consult Material Safety Data Sheets for recom-

11. Apparatus

mended handling procedures and precautions.

11.1 Microsyringe, 250-

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.