ASTM E956-83(2023)

(Classification)Standard Classification for Municipal Mixed Nonferrous Metals (MNM)

Standard Classification for Municipal Mixed Nonferrous Metals (MNM)

SIGNIFICANCE AND USE

4.1 This classification is intended for use in the marketing of mixed nonferrous metals.

4.2 Mixed nonferrous metals covered by this classification are suitable for use by one or more of the following industries:

4.2.1 Secondary aluminum smelters,

4.2.2 Primary aluminum producers,

4.2.3 Scrap dealers and processors,

4.2.4 Zinc refiners, and

4.2.5 Copper refiners.

SCOPE

1.1 This classification covers municipal mixed nonferrous metals (MNM), not source-separated, that are recovered from municipal waste destined for disposal.

1.2 The mixed nonferrous metals (MNM) have been subdivided according to processing history, nonferrous metal content, size, and moisture content.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E956 − 83 (Reapproved 2023)

Standard Classification for

Municipal Mixed Nonferrous Metals (MNM)

This standard is issued under the fixed designation E956; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 4.75 mm (No. 4) Sieve and Finer for Metal-Bearing Ores

and Related Materials

1.1 This classification covers municipal mixed nonferrous

E753 Specification for Municipal Aluminum Scrap (MAS)

metals (MNM), not source-separated, that are recovered from

(Discontinued 2001) (Withdrawn 2001)

municipal waste destined for disposal.

1.2 The mixed nonferrous metals (MNM) have been subdi-

3. Terminology

vided according to processing history, nonferrous metal

3.1 Definitions of Terms Specific to This Standard:

content, size, and moisture content.

3.1.1 loose combustible material (organic)—loose combus-

1.3 The values stated in inch-pound units are to be regarded

tible organics (LCO) that consist of, but are not limited to,

as standard. The values given in parentheses are mathematical

nonmetallic materials such as paper, rags, plastic, rubber,

conversions to SI units that are provided for information only

wood, food wastes, and yard or lawn wastes, etc., which are not

and are not considered standard.

permanently attached to noncombustible objects. The LCOs

are defined as material larger than No. 12 Mesh (U.S. Standard

1.4 This standard does not purport to address all of the

Sieve) as stated in Specification E11. A determination of LCOs

safety concerns, if any, associated with its use. It is the

is best done by sampling the material and handpicking, hand

responsibility of the user of this standard to establish appro-

cleaning, and visually identifying the materials described

priate safety, health, and environmental practices and deter-

previously.

mine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accor-

3.1.2 mixed nonferrous metal content—mixed nonferrous

dance with internationally recognized principles on standard-

metals remaining after removal of magnetics, combustibles,

ization established in the Decision on Principles for the

and other nonmetals (for example, glass, rock, etc.). Further

Development of International Standards, Guides and Recom-

methods of separation and identification may be agreed upon

mendations issued by the World Trade Organization Technical

between purchaser and seller and can include picking or

Barriers to Trade (TBT) Committee.

dense-media separation.

3.1.3 moisture percent—liquid content, as determined by

2. Referenced Documents

weight loss when sample material is dried to a constant weight

2.1 ASTM Standards:

at 110 6 5 °C.

D2013/D2013M Practice for Preparing Coal Samples for

3.1.4 total combustibles—materials that include paints,

Analysis

lacquers, coatings, plastics, etc., associated with the original

E11 Specification for Woven Wire Test Sieve Cloth and Test

nonferrous products, as well as combustible materials (paper,

Sieves

plastic, textile, etc.) which become associated with the nonfer-

E122 Practice for Calculating Sample Size to Estimate, With

rous product after it is manufactured.

Specified Precision, the Average for a Characteristic of a

Lot or Process

4. Significance and Use

E276 Test Method for Particle Size or Screen Analysis at

4.1 This classification is intended for use in the marketing of

mixed nonferrous metals.

This classification is under the jurisdiction of ASTM Committee D34 on Waste

4.2 Mixed nonferrous metals covered by this classification

Management and is the direct responsibility of Subcommittee D34.03 on Treatment,

are suitable for use by one or more of the following industries:

Recovery and Reuse.

Current edition approved June 1, 2023. Published June 2023. Originally 4.2.1 Secondary aluminum smelters,

approved in 1983. Last previous edition approved in 2015 as E956 – 83 (2015).

4.2.2 Primary aluminum producers,

DOI: 10.1520/E0956-83R23.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E956 − 83 (2023)

4.2.3 Scrap dealers and processors, 6.3 Mixed nonferrous metals shall be considered to be of a

4.2.4 Zinc refiners, and particular classification if the value for each component

4.2.5 Copper refiners. specified, as obtained by the test method agreed upon between

the purchaser and seller, shall not exceed any of the limits for

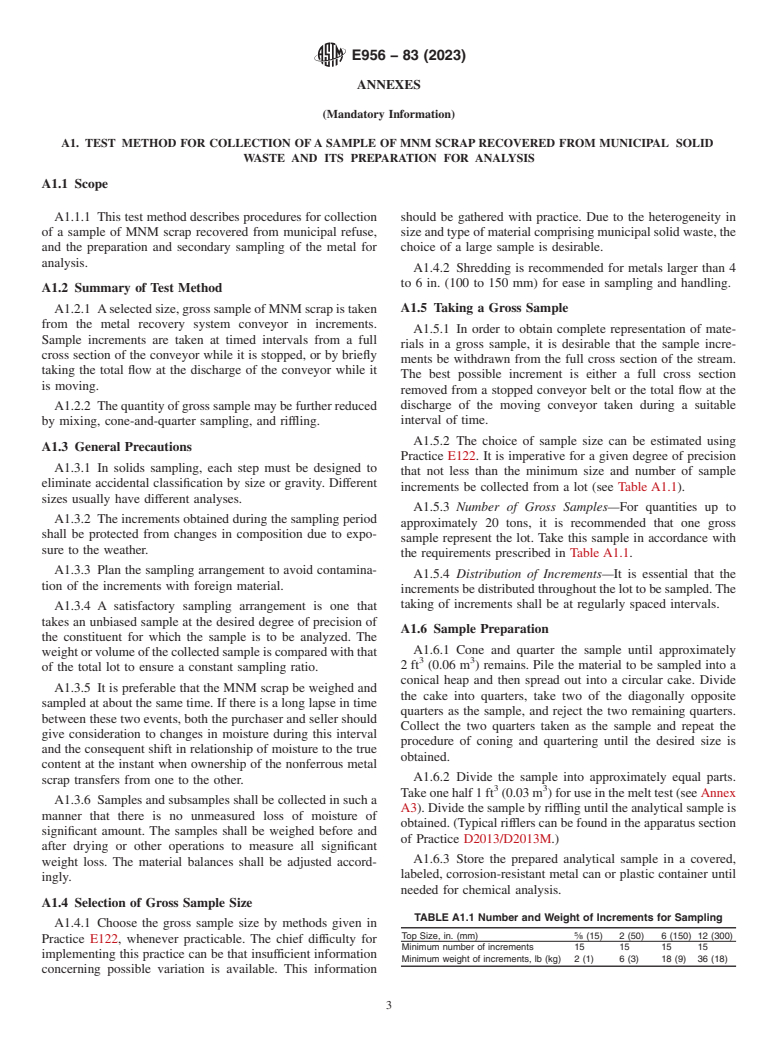

5. Basis of Classification (refer to Table 1)

that grade.

5.1 This classification covers material either processed to

7. Physical Requirements

recover aluminum or not processed to recover aluminum.

7.1 In addition to Table 1, the MNM physical requirements

5.2 This classification consists of four types of MNM, based

include the following:

on nonferrous metal content. The four types of MNM are

7.1.1 Bulk Density—The density for MNM is not specified

further subdivided into three grades, based on size. The three

and shall be agreed upon between the purchaser and the seller.

grades of MNM are further subdivided into two classes, based

7.1.2 Fineness—Acceptability of contained fines shall be

on moisture content.

determined by the purchaser and seller.

7.1.3 Loose Combustibles—As agreed upon between pur-

6. Ordering Information

chaser and seller.

6.1 Mixed nonferrous metals may be identified using the

7.1.4 Magnetics—The presence of free magnetic material is

criteria in Table 1. This is an unusual material, and the table is

not specified and shall be as agreed upon between the pur-

included for information purposes rather than to establish

chaser and seller as part of the purchase contract.

limits. The unit operations used to recover MNM may aid the

8. Sampling

purchaser and seller in establishing a classification. Some of

the more common unit operations used to recover MNM 8.1 Sampling shall be in accordance with the procedures

described in Annex A1 or Annex A2. Either procedure may be

include the following:

6.1.1 Wet Processing—Water elutriators, dense media, and used, as determined by agreement between the purchaser and

the seller.

mineral jig.

6.1.2 Dry Processing—Air classifier, air knife, gravity or 8.1.1 Annex A1 covers sampling at the point of origin.

concentrating table, Humphrey spiral, eddy-current separator, 8.1.2 Annex A2 covers sampling at the point of receipt.

electrostatic separator, and handpicking.

9. Test Methods

6.2 It is recognized that variations in the MNM may occur

9.1 Determine the properties of fineness, moisture, and

due to the heterogeneous nature of the solid waste stream. The

metal recovery in accordance with the procedures described in

criteria indicated are intended as a means for the purchaser and

Annex A3.

the seller to establish the value and quality of the MNM.

10. Rejection and Rehearing

10.1 Material that fails to conform to the requirements of

TABLE 1 Classification of Municipal Mixed Nonferrous Metals

A this classification may be rejected. Rejection should be re-

(MNM)

ported to the seller promptly and in writing. In case of

Type I Type II Type III Type IV

Classification Over 90 % 50 to 90 % 30 to 50 % Less Than dissatisfaction with the results of the test, the seller may make

MNM MNM MNM 30 % MNM

claim for a rehearing.

Grades 1 2 3

over 6 in. 2 to 6 in. under 2 in.

11. Shipping

(150 mm) (50 to 150 mm) incl (50 mm)

Class A B

11.1 Mixed nonferrous metals shall be shipped in rail cars,

high (5 % moisture and over) low (under 5 % moisture)

trailers, or other containers as agreed upon between the

A

It is important for both purchaser and seller to note whether material had been

purchaser and the seller. The shipping equipment shall be

processed to recover aluminum or whether it had not been processed to recover

sufficiently watertight to prevent the MNM from becoming wet

aluminum and what, if any, procedures where used.

during shipment.

E956 − 83 (2023)

ANNEXES

(Mandatory Information)

A1. TEST METHOD FOR COLLECTION OF A SAMPLE OF MNM SCRAP RECOVERED FROM MUNICIPAL SOLID

WASTE AND ITS PREPARATION FOR ANALYSIS

A1.1 Scope

A1.1.1 This test method describes procedures for collection should be gathered with practice. Due to the heterogeneity in

of a sample of MNM scrap recovered from municipal refuse, size and type of material comprising municipal solid waste, the

and the preparation and secondary sampling of the metal for choice of a large sample is desirable.

analysis.

A1.4.2 Shredding is recommended for metals larger than 4

to 6 in. (100 to 150 mm) for ease in sampling and handling.

A1.2 Summary of Test Method

A1.5 Taking a Gross Sample

A1.2.1 A selected size, gross sample of MNM scrap is taken

from the metal recovery system conveyor in increments.

A1.5.1 In order to obtain complete representation of mate-

Sample increments are taken at timed intervals from a full

rials in a gross sample, it is desirable that the sample incre-

cross section of the conveyor while it is stopped, or by briefly

ments be withdrawn from the full cross section of the stream.

taking the total flow at the discharge of the conveyor while it

The best possible increment is either a full cross section

is moving.

removed from a stopped conveyor belt or the total flow at the

discharge of the moving conveyor taken during a suitable

A1.2.2 The quantity of gross sample may be further reduced

interval of time.

by mixing, cone-and-quarter sampling, and riffling.

A1.5.2 The choice of sample size can be estimated using

A1.3 General Precautions

Practice E122. It is imperative for a given degree of precision

A1.3.1 In solids sampling, each step must be designed to

that not le

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.