ASTM B1005-17

(Specification)Standard Specification for Copper-Clad Aluminum Bar for Electrical Purposes (Bus Bar)

Standard Specification for Copper-Clad Aluminum Bar for Electrical Purposes (Bus Bar)

ABSTRACT

This specification covers the manufacturing and testing requirements for copper clad aluminum rectangular bar for electrical (bus) applications. Six classes of copper-clad aluminum bar are covered:

Class 20A—Nominal 20 volume % copper, annealed.

Class 25A—Nominal 25 volume % copper, annealed.

Class 30A—Nominal 30 volume % copper, annealed.

Class 20H—Nominal 20 volume % copper, hard-worked.

Class 25H—Nominal 25 volume % copper, hard-worked.

Class 30H—Nominal 30 volume % copper, hard-worked.

The products covered by this specification shall consist of a solid core of aluminum with a continuous outer copper layer bonded to the core throughout. This specification also covers information that shall be included in orders for materials, the responsibility of the producer for inspection and tests, tensile properties, bend properties, interface bonding, density, electrical properties, edge contours, dimensional tolerances, source inspection, retest, certification, and packaging and package marking.

SCOPE

1.1 This specification covers copper clad aluminum rectangular bar for electrical (bus) applications.

1.2 Six classes of copper-clad aluminum bar are covered as follows:

Class 20A—Nominal 20 volume % copper, annealed.

Class 25A—Nominal 25 volume % copper, annealed.

Class 30A—Nominal 30 volume % copper, annealed.

Class 20H—Nominal 20 volume % copper, hard-worked.

Class 25H—Nominal 25 volume % copper, hard-worked.

Class 30H—Nominal 30 volume % copper, hard-worked

1.3 The values stated in inch-pound units are to be regarded as the standard, except for resistivity and density, where the SI units are the standard. The values given in parentheses are for information only.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:B1005 −17

Standard Specification for

Copper-Clad Aluminum Bar for Electrical Purposes (Bus

1

Bar)

This standard is issued under the fixed designation B1005; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E8/E8M Test Methods for Tension Testing of Metallic Ma-

terials

1.1 This specification covers copper clad aluminum rectan-

E29 Practice for Using Significant Digits in Test Data to

gular bar for electrical (bus) applications.

Determine Conformance with Specifications

1.2 Six classes of copper-clad aluminum bar are covered as

E290 Test Methods for Bend Testing of Material for Ductil-

follows:

ity

Class 20A—Nominal 20 volume % copper, annealed.

Class 25A—Nominal 25 volume % copper, annealed.

3. Terminology

Class 30A—Nominal 30 volume % copper, annealed.

3.1 Definitions—Refer to Terminology B354 for definition

Class 20H—Nominal 20 volume % copper, hard-worked.

of product terms used in this specification.

Class 25H—Nominal 25 volume % copper, hard-worked.

Class 30H—Nominal 30 volume % copper, hard-worked

4. Ordering Information

1.3 The values stated in inch-pound units are to be regarded

4.1 Orders for materials to this specification shall include

as the standard, except for resistivity and density, where the SI

the following information:

units are the standard. The values given in parentheses are for

4.1.1 This specification designation (which includes the

information only.

number, the year, and the revision letter, if applicable),

1.4 This international standard was developed in accor- 4.1.2 Quantity in weight or pieces,

4.1.3 Classes, (see 1.2),

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the 4.1.4 Edge contour (Section 12),

4.1.5 Cross-Sectional Dimensions: Thickness and Width

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical (Section 13),

Barriers to Trade (TBT) Committee.

4.2 Additionally, orders for material to this specification

shall include the following information when required by the

2. Referenced Documents

purchaser:

2.1 The following documents of the issue in effect on date

4.2.1 Whether witness of inspection by the purchaser’s

of material purchase form a part of this specification to the

representative is required prior to material shipment (Section

extent referenced herein:

15),

2

4.2.2 Whether certification is required (Section 17),

2.2 ASTM Standards:

4.2.3 Whether an alternative tensile sampling selection

B193 Test Method for Resistivity of Electrical Conductor

procedure is acceptable (Section 7).

Materials

B354 Terminology Relating to Uninsulated Metallic Electri-

5. Manufacture

cal Conductors

5.1 The products covered by this specification shall consist

E3 Guide for Preparation of Metallographic Specimens

of a solid core of aluminum with a continuous outer copper

layerbondedtothecorethroughoutandshallbeofsuchquality

1

This specification is under the jurisdiction of ASTM Committee B01 on

thattheresultingproductscomplywiththerequirementsinthis

Electrical Conductors and is the direct responsibility of Subcommittee B01.06 on

specification.

Bi-Metallic Conductors.

Current edition approved April 1, 2017. Published May 2017. DOI: 10.1520/

6. Quality Assurance

B1005-17.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

6.1 Responsibility for Inspection and Tests—Unless other-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

wise specified in the contract or purchase order, the producer is

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. responsible for the performance of all inspection and test

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B1005−17

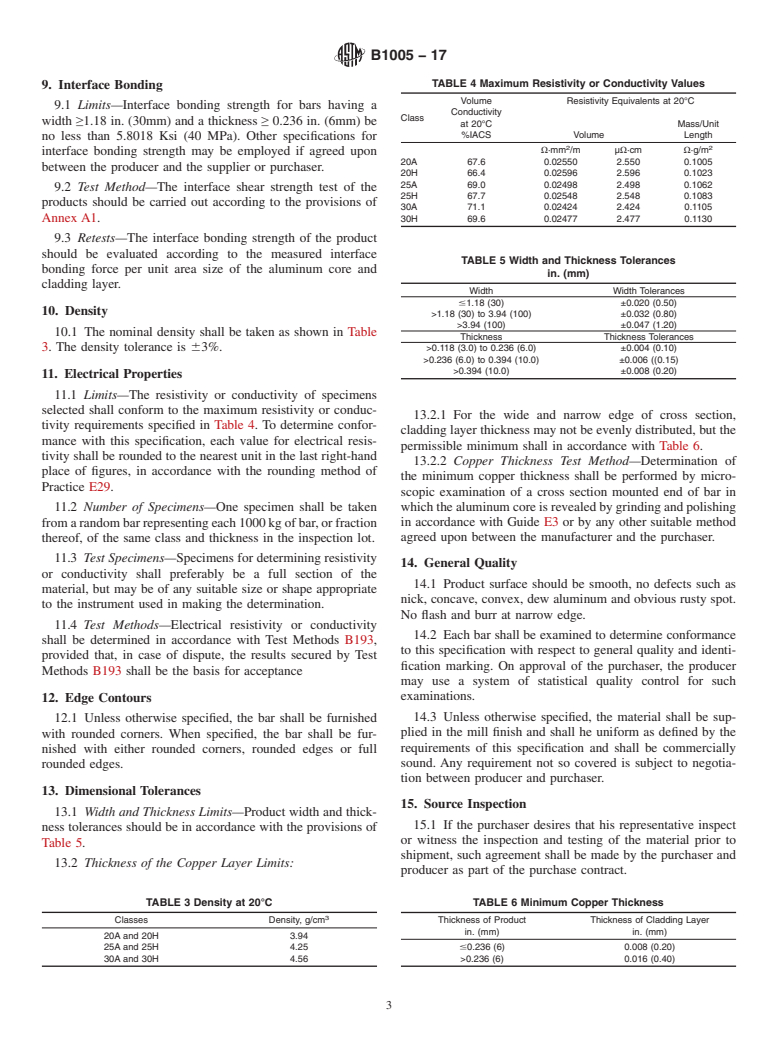

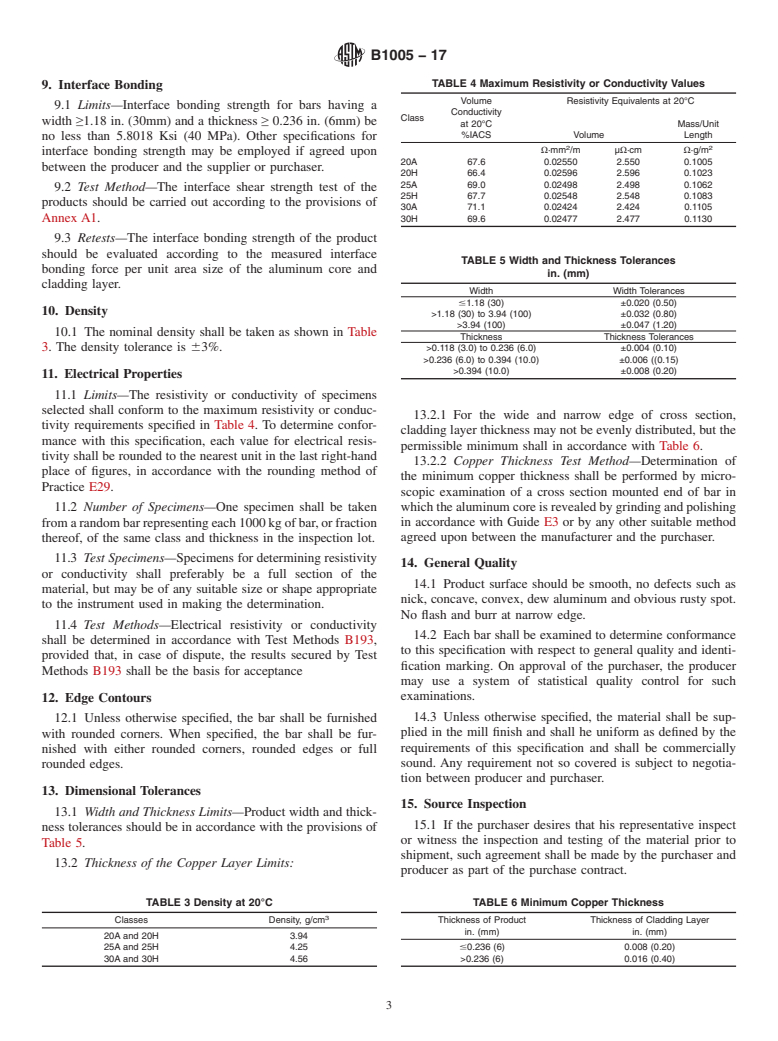

TABLE 2 The Diameter of the Bending Cylinder

requirements specified herein. The producer may use his own

or any other suitable facilities for the performance of the Thickness, Bending Diameter

in. (mm) in. (mm)

inspection and test requirements specified herein, unless dis-

<0.394 (10.0) 0.623 (16)

approvedbythepurchaserintheorderoratthetimeofcontract

$0.394 (10.0) 1.260 (32)

signing. The purchaser shall have the right to perform any of

the inspections and tests set forth in this specification where

such inspections are deemed n

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B1005 − 17

Standard Specification for

Copper-Clad Aluminum Bar for Electrical Purposes (Bus

1

Bar)

This standard is issued under the fixed designation B1005; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E8/E8M Test Methods for Tension Testing of Metallic Ma-

terials

1.1 This specification covers copper clad aluminum rectan-

E29 Practice for Using Significant Digits in Test Data to

gular bar for electrical (bus) applications.

Determine Conformance with Specifications

1.2 Six classes of copper-clad aluminum bar are covered as

E290 Test Methods for Bend Testing of Material for Ductil-

follows:

ity

Class 20A—Nominal 20 volume % copper, annealed.

Class 25A—Nominal 25 volume % copper, annealed.

3. Terminology

Class 30A—Nominal 30 volume % copper, annealed.

3.1 Definitions—Refer to Terminology B354 for definition

Class 20H—Nominal 20 volume % copper, hard-worked.

of product terms used in this specification.

Class 25H—Nominal 25 volume % copper, hard-worked.

Class 30H—Nominal 30 volume % copper, hard-worked

4. Ordering Information

1.3 The values stated in inch-pound units are to be regarded

4.1 Orders for materials to this specification shall include

as the standard, except for resistivity and density, where the SI

the following information:

units are the standard. The values given in parentheses are for

4.1.1 This specification designation (which includes the

information only.

number, the year, and the revision letter, if applicable),

4.1.2 Quantity in weight or pieces,

1.4 This international standard was developed in accor-

dance with internationally recognized principles on standard- 4.1.3 Classes, (see 1.2),

4.1.4 Edge contour (Section 12),

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom- 4.1.5 Cross-Sectional Dimensions: Thickness and Width

mendations issued by the World Trade Organization Technical (Section 13),

Barriers to Trade (TBT) Committee.

4.2 Additionally, orders for material to this specification

shall include the following information when required by the

2. Referenced Documents

purchaser:

2.1 The following documents of the issue in effect on date

4.2.1 Whether witness of inspection by the purchaser’s

of material purchase form a part of this specification to the

representative is required prior to material shipment (Section

extent referenced herein:

15),

2

4.2.2 Whether certification is required (Section 17),

2.2 ASTM Standards:

4.2.3 Whether an alternative tensile sampling selection

B193 Test Method for Resistivity of Electrical Conductor

procedure is acceptable (Section 7).

Materials

B354 Terminology Relating to Uninsulated Metallic Electri-

5. Manufacture

cal Conductors

E3 Guide for Preparation of Metallographic Specimens 5.1 The products covered by this specification shall consist

of a solid core of aluminum with a continuous outer copper

layer bonded to the core throughout and shall be of such quality

1

This specification is under the jurisdiction of ASTM Committee B01 on

that the resulting products comply with the requirements in this

Electrical Conductors and is the direct responsibility of Subcommittee B01.06 on

specification.

Bi-Metallic Conductors.

Current edition approved April 1, 2017. Published May 2017. DOI: 10.1520/

6. Quality Assurance

B1005-17.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

6.1 Responsibility for Inspection and Tests—Unless other-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

wise specified in the contract or purchase order, the producer is

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. responsible for the performance of all inspection and test

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B1005 − 17

TABLE 2 The Diameter of the Bending Cylinder

requirements specified herein. The producer may use his own

or any other suitable facilities for the performance of the Thickness, Bending Diameter

in. (mm) in. (mm)

inspection and test requirements specified herein, unless dis-

<0.394 (10.0) 0.623 (16)

approved by the purchaser in the order or at the time of contract

$0.394 (10.0) 1.260 (32)

signing. The purchaser shall have the right to perform any of

the inspections and tests set forth in this specification where

such inspections are deemed necessary to assure that material

phenomenon inside the bending width. In macrostructure, near

conform

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.