ASTM D7272-06(2018)

(Test Method)Standard Test Method for Determining the Integrity of Seams Used in Joining Geomembranes by Premanufactured Taped Methods

Standard Test Method for Determining the Integrity of Seams Used in Joining Geomembranes by Premanufactured Taped Methods

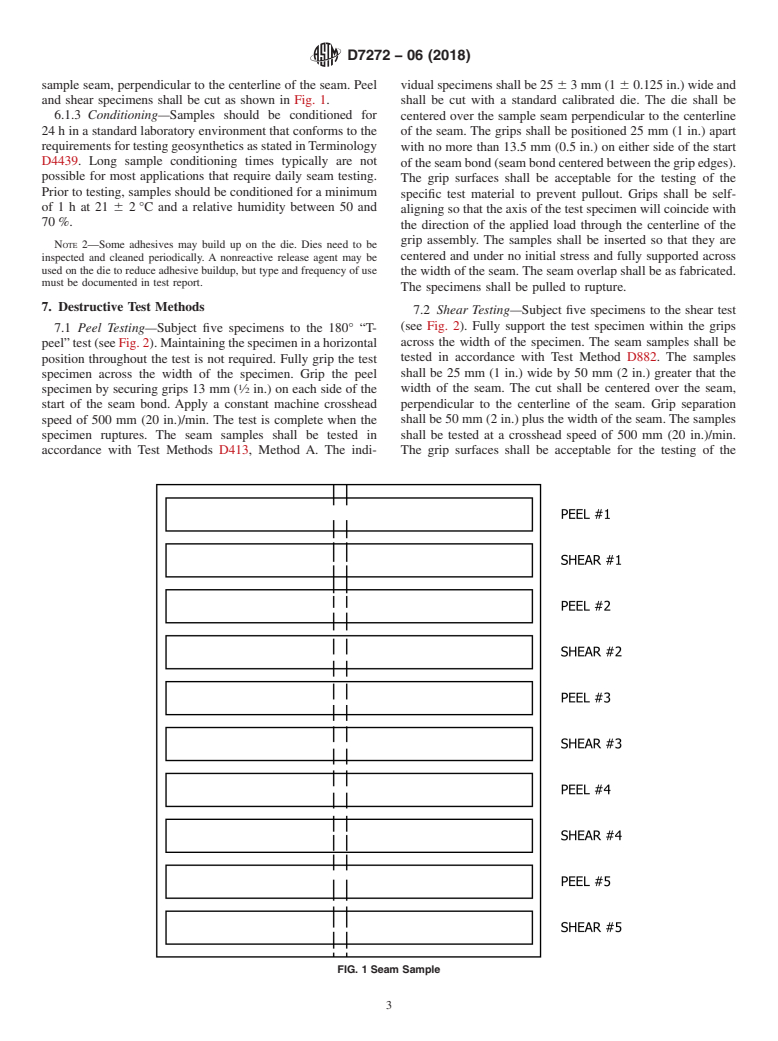

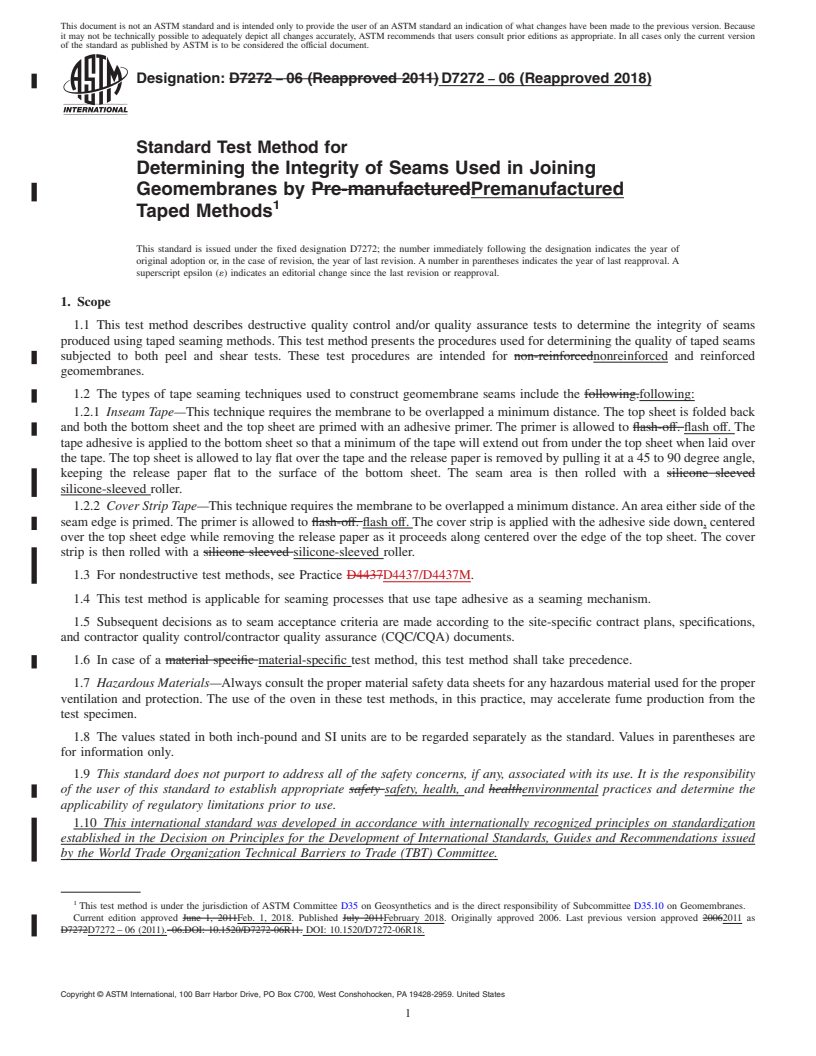

SIGNIFICANCE AND USE

4.1 Significance—With the increased use of geomembranes as a barrier material to restrict liquid migration from one location to another, a need has been created for a standard test method to evaluate the quality of geomembrane seams produced by tape methods. In the case of geomembranes, it has become evident that geomembrane seams can exhibit separation in the field under certain conditions. This is an index-type test method used for quality assurance and quality control purposes; it is also intended to provide the quality engineer with sufficient seam peel and shear data to evaluate seam quality.

4.2 Use—Recording and reporting data, such as separation that occurs during the peel test and elongation during the shear test, will allow the quality assurance engineer to take measures necessary to ensure the repair of inferior seams during construction, and therefore, minimize the potential for seam separation while in service. The acceptable value of adhesion measured will, of course, vary from product to product as a result of different formulations and types of products. However, once a product is established, minimum values of separation force can be determined and agreed to by producer and consumer, and both can monitor the installation to ensure maintenance of the agreed-upon minimum value.

SCOPE

1.1 This test method describes destructive quality control and/or quality assurance tests to determine the integrity of seams produced using taped seaming methods. This test method presents the procedures used for determining the quality of taped seams subjected to both peel and shear tests. These test procedures are intended for nonreinforced and reinforced geomembranes.

1.2 The types of tape seaming techniques used to construct geomembrane seams include the following:

1.2.1 Inseam Tape—This technique requires the membrane to be overlapped a minimum distance. The top sheet is folded back and both the bottom sheet and the top sheet are primed with an adhesive primer. The primer is allowed to flash off. The tape adhesive is applied to the bottom sheet so that a minimum of the tape will extend out from under the top sheet when laid over the tape. The top sheet is allowed to lay flat over the tape and the release paper is removed by pulling it at a 45 to 90 degree angle, keeping the release paper flat to the surface of the bottom sheet. The seam area is then rolled with a silicone-sleeved roller.

1.2.2 Cover Strip Tape—This technique requires the membrane to be overlapped a minimum distance. An area either side of the seam edge is primed. The primer is allowed to flash off. The cover strip is applied with the adhesive side down, centered over the top sheet edge while removing the release paper as it proceeds along centered over the edge of the top sheet. The cover strip is then rolled with a silicone-sleeved roller.

1.3 For nondestructive test methods, see Practice D4437/D4437M.

1.4 This test method is applicable for seaming processes that use tape adhesive as a seaming mechanism.

1.5 Subsequent decisions as to seam acceptance criteria are made according to the site-specific contract plans, specifications, and contractor quality control/contractor quality assurance (CQC/CQA) documents.

1.6 In case of a material-specific test method, this test method shall take precedence.

1.7 Hazardous Materials—Always consult the proper material safety data sheets for any hazardous material used for the proper ventilation and protection. The use of the oven in these test methods, in this practice, may accelerate fume production from the test specimen.

1.8 The values stated in both inch-pound and SI units are to be regarded separately as the standard. Values in parentheses are for information only.

1.9 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate saf...

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7272 − 06 (Reapproved 2018)

Standard Test Method for

Determining the Integrity of Seams Used in Joining

1

Geomembranes by Premanufactured Taped Methods

This standard is issued under the fixed designation D7272; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope specifications, and contractor quality control/contractor quality

assurance (CQC/CQA) documents.

1.1 This test method describes destructive quality control

and/or quality assurance tests to determine the integrity of 1.6 In case of a material-specific test method, this test

seams produced using taped seaming methods. This test method shall take precedence.

method presents the procedures used for determining the

1.7 Hazardous Materials—Always consult the proper mate-

quality of taped seams subjected to both peel and shear tests.

rial safety data sheets for any hazardous material used for the

These test procedures are intended for nonreinforced and

proper ventilation and protection. The use of the oven in these

reinforced geomembranes.

test methods, in this practice, may accelerate fume production

1.2 The types of tape seaming techniques used to construct from the test specimen.

geomembrane seams include the following:

1.8 The values stated in both inch-pound and SI units are to

1.2.1 Inseam Tape—This technique requires the membrane

be regarded separately as the standard. Values in parentheses

to be overlapped a minimum distance. The top sheet is folded

are for information only.

back and both the bottom sheet and the top sheet are primed

1.9 This standard does not purport to address all of the

with an adhesive primer. The primer is allowed to flash off. The

safety concerns, if any, associated with its use. It is the

tape adhesive is applied to the bottom sheet so that a minimum

responsibility of the user of this standard to establish appro-

of the tape will extend out from under the top sheet when laid

priate safety, health, and environmental practices and deter-

over the tape. The top sheet is allowed to lay flat over the tape

mine the applicability of regulatory limitations prior to use.

and the release paper is removed by pulling it at a 45 to 90

1.10 This international standard was developed in accor-

degree angle, keeping the release paper flat to the surface of the

dance with internationally recognized principles on standard-

bottom sheet. The seam area is then rolled with a silicone-

ization established in the Decision on Principles for the

sleeved roller.

Development of International Standards, Guides and Recom-

1.2.2 Cover Strip Tape—This technique requires the mem-

mendations issued by the World Trade Organization Technical

brane to be overlapped a minimum distance. An area either side

Barriers to Trade (TBT) Committee.

of the seam edge is primed. The primer is allowed to flash off.

The cover strip is applied with the adhesive side down,

2. Referenced Documents

centered over the top sheet edge while removing the release

2

2.1 ASTM Standards:

paper as it proceeds along centered over the edge of the top

D413 Test Methods for Rubber Property—Adhesion to Flex-

sheet. The cover strip is then rolled with a silicone-sleeved

ible Substrate

roller.

D638 Test Method for Tensile Properties of Plastics

1.3 For nondestructive test methods, see Practice D4437/

D653 Terminology Relating to Soil, Rock, and Contained

D4437M.

Fluids

1.4 This test method is applicable for seaming processes

D882 Test Method for Tensile Properties of Thin Plastic

that use tape adhesive as a seaming mechanism.

Sheeting

D4437/D4437M Practice for Nondestructive Testing (NDT)

1.5 Subsequent decisions as to seam acceptance criteria are

for Determining the Integrity of Seams Used in Joining

made according to the site-specific contract plans,

Flexible Polymeric Sheet Geomembranes

1

This test method is under the jurisdiction of ASTM Committee D35 on

Geosynthetics and is the direct responsibility of Subcommittee D35.10 on Geomem-

2

branes. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Feb. 1, 2018. Published February 2018. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved 2006. Last previous version approved 2011 as D7272 – 06 (2011). DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D7272-06R18. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7272 − 06 (2018)

D4439 Terminology f

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7272 − 06 (Reapproved 2011) D7272 − 06 (Reapproved 2018)

Standard Test Method for

Determining the Integrity of Seams Used in Joining

Geomembranes by Pre-manufacturedPremanufactured

1

Taped Methods

This standard is issued under the fixed designation D7272; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method describes destructive quality control and/or quality assurance tests to determine the integrity of seams

produced using taped seaming methods. This test method presents the procedures used for determining the quality of taped seams

subjected to both peel and shear tests. These test procedures are intended for non-reinforcednonreinforced and reinforced

geomembranes.

1.2 The types of tape seaming techniques used to construct geomembrane seams include the following.following:

1.2.1 Inseam Tape—This technique requires the membrane to be overlapped a minimum distance. The top sheet is folded back

and both the bottom sheet and the top sheet are primed with an adhesive primer. The primer is allowed to flash-off. flash off. The

tape adhesive is applied to the bottom sheet so that a minimum of the tape will extend out from under the top sheet when laid over

the tape. The top sheet is allowed to lay flat over the tape and the release paper is removed by pulling it at a 45 to 90 degree angle,

keeping the release paper flat to the surface of the bottom sheet. The seam area is then rolled with a silicone sleeved

silicone-sleeved roller.

1.2.2 Cover Strip Tape—This technique requires the membrane to be overlapped a minimum distance. An area either side of the

seam edge is primed. The primer is allowed to flash-off. flash off. The cover strip is applied with the adhesive side down, centered

over the top sheet edge while removing the release paper as it proceeds along centered over the edge of the top sheet. The cover

strip is then rolled with a silicone sleeved silicone-sleeved roller.

1.3 For nondestructive test methods, see Practice D4437D4437/D4437M.

1.4 This test method is applicable for seaming processes that use tape adhesive as a seaming mechanism.

1.5 Subsequent decisions as to seam acceptance criteria are made according to the site-specific contract plans, specifications,

and contractor quality control/contractor quality assurance (CQC/CQA) documents.

1.6 In case of a material specific material-specific test method, this test method shall take precedence.

1.7 Hazardous Materials—Always consult the proper material safety data sheets for any hazardous material used for the proper

ventilation and protection. The use of the oven in these test methods, in this practice, may accelerate fume production from the

test specimen.

1.8 The values stated in both inch-pound and SI units are to be regarded separately as the standard. Values in parentheses are

for information only.

1.9 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.10 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

1

This test method is under the jurisdiction of ASTM Committee D35 on Geosynthetics and is the direct responsibility of Subcommittee D35.10 on Geomembranes.

Current edition approved June 1, 2011Feb. 1, 2018. Published July 2011February 2018. Originally approved 2006. Last previous version approved 20062011 as

D7272D7272 – 06 (2011).–06.DOI: 10.1520/D7272-06R11. DOI: 10.1520/D7272-06R18.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7272 − 06 (2018)

2. Referenced Documents

2

2.1 ASTM Standards:

D413 Test Methods for Rubber Property—Adhesion to Flexible Substrate

D638 Test Method for Tensile Properties of Plastics

D653 Terminology Relating to Soil, Rock, and Contained Fluids

D882 Test

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.