ASTM F2716-08(2014)

(Practice)Standard Practice for Comparison of Nonmetallic Flat Gaskets in High Pressure Saturated Steam

Standard Practice for Comparison of Nonmetallic Flat Gaskets in High Pressure Saturated Steam

SIGNIFICANCE AND USE

3.1 This practice may be used to evaluate Classification F104 gasket materials using saturated steam and standard ASME RF (raised face) flanges. This practice is intended for use as quality control or material comparison tool and should not be used to predict performance.

SCOPE

1.1 This practice provides a means of comparing various nonmetallic flat gasket materials, Classification F104, in saturated steam service under controlled conditions. While the practice is designed primarily for flat gaskets, it also can be applied to various form-in-place gasket materials upon modification. The practice may be used for quality control or material comparison purposes as agreed upon between producer and user. This practice is consistent with Fluid Sealing Association test method, FSA-NMG-204-02, with regard to fixtures used and procedure.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F2716 − 08 (Reapproved 2014)

Standard Practice for

Comparison of Nonmetallic Flat Gaskets in High Pressure

Saturated Steam

This standard is issued under the fixed designation F2716; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 ASME Standards:

ASME B16.21 Nonmetallic Flat Gaskets for Pipe Flanges

1.1 This practice provides a means of comparing various

ASME PCC-1 Guidelines for Pressure Boundary Bolted

nonmetallic flat gasket materials, Classification F104, in satu-

Flange Joint Assembly

rated steam service under controlled conditions. While the

2.3 ESA/FSA Standards:

practice is designed primarily for flat gaskets, it also can be

ESA/FSA Publication No. 009/98 Guidelines for Safe Seal

applied to various form-in-place gasket materials upon modi-

Usage - Flanges and Gaskets

fication. The practice may be used for quality control or

FSA-NMG-204-02 Standard Test Method for Performance

material comparison purposes as agreed upon between pro-

of Non-Asbestos Gaskets in High Pressure, Saturated

ducer and user. This practice is consistent with Fluid Sealing

Steam

Association test method, FSA-NMG-204-02, with regard to

fixtures used and procedure.

3. Significance and Use

1.2 The values stated in inch-pound units are to be regarded

3.1 This practice may be used to evaluate Classification

as standard. The values given in parentheses are mathematical

F104 gasket materials using saturated steam and standard

conversions to SI units that are provided for information only

ASME RF (raised face) flanges. This practice is intended for

and are not considered standard.

use as quality control or material comparison tool and should

not be used to predict performance.

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

4. Apparatus

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

4.1 The test equipment shall consist of the following com-

bility of regulatory limitations prior to use.

ponents:

4.1.1 Hot Air Circulating Oven, equipped with temperature

2. Referenced Documents

controls and capable of maintaining temperatures up to 570 6

5°F (299 6 3°C).

2.1 ASTM Standards:

4.1.2 Scales, capable of maintaining an accuracy of 60.1 g

A193/A193M Specification for Alloy-Steel and Stainless

with a nominal capacity of 12 kg.

Steel Bolting for High Temperature or High Pressure

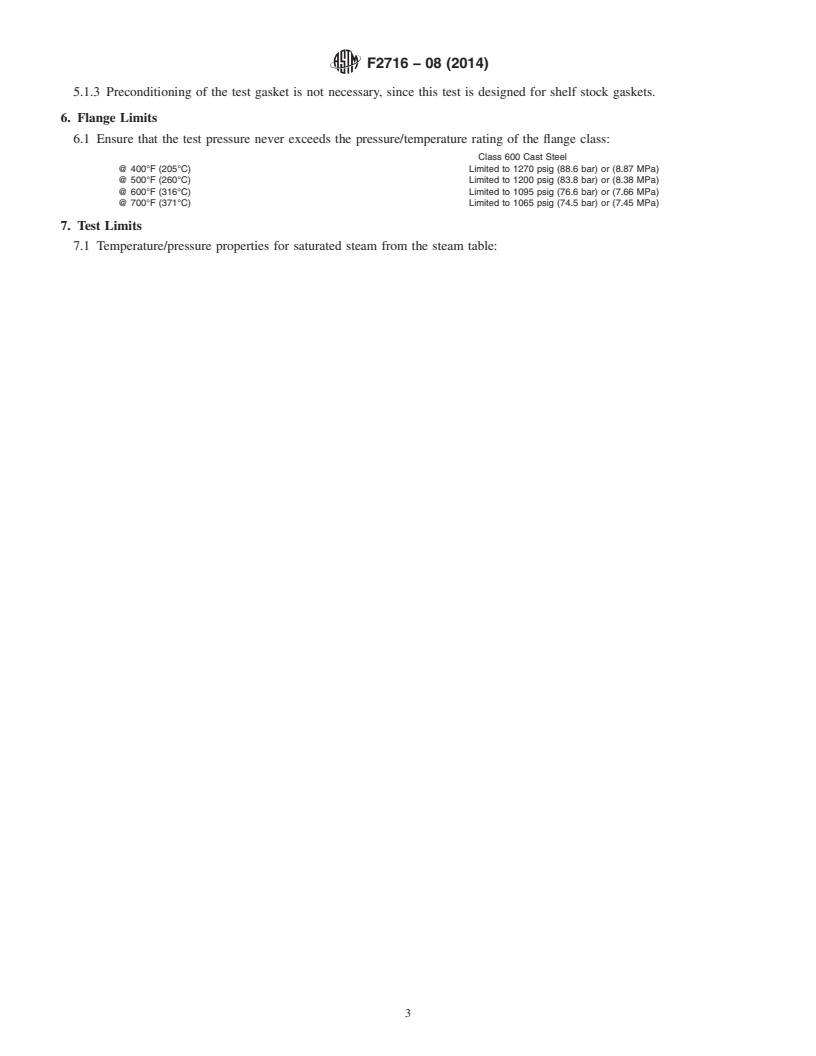

4.1.3 Flange Fixture—A2 in. cast steel Class 600 fixture

Service and Other Special Purpose Applications

made from one weld neck flange capped by welding to boiler

A194/A194M Specification for Carbon Steel, Alloy Steel,

code and one blind flange (see Fig. 1). Flange surfaces are 275

and Stainless Steel Nuts for Bolts for High Pressure or

to 325 RMS µin. (7.0 to 8.3 µmm), flatness range 0.002 in.

High Temperature Service, or Both

(0.05 mm). Each fixture shall have an identification number.

F104 Classification System for Nonmetallic Gasket Materi-

4.1.4 FlangeProtectors—To help ensure safe operation, use

als

standard metal flange protectors.

4.1.5 Fasteners:

4.1.5.1 Seven ⁄8-in. bolts, 4 in. long, per Specification

This practice is under the jurisdiction ofASTM Committee F03 on Gaskets and

A193/A193M, Grade B7.

is the direct responsibility of Subcommittee F03.10 on Composite Gaskets.

Current edition approved July 1, 2014. Published November 2014. Originally

approved in 2008. Last previous edition approved in 2008 as F2716 – 08. DOI:

10.1520/F2716-08R14. Available from American Society of Mechanical Engineers (ASME), ASME

For referenced ASTM standards, visit the ASTM website, www.astm.org, or International Headquarters, Three Park Ave., New York, NY 10016-5990, http://

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM www.asme.org.

Standards volume information, refer to the standard’s Document Summary page on Available from Fluid Sealing Association (FSA), 994 Old Eagle School Road,

the ASTM website. Suite 1019, Wayne, PA 19087–1866.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2716 − 08 (2014)

FIG. 1 FSA Steam Test Fixture

4.1.5.2 One calibrated bolt modified by the insertion of a 4.2.3 Follow the steps in Section 9 for one cycle of a

calibration pin as detailed in Fig. 1. minimum of 24 h. Ensure that the gasket is acceptable for that

4.1.5.3 Eight ⁄8-in. hexagonal nuts per Specification A194/

temperature/pressure.

A194M, Grade 4, coarse thread.

4.1.5.4 Sixteen ⁄8-in. hardened steel washers (38-45 HRC),

5. Test Specimen

Grade 8.

5.1 The test specimen shall be a Class 600 2-in. (50-mm)

4.1.6 Calibrated Dial Indicator, graduated to 0.0001 in.

ring gasket. It is recommended that a ⁄16-in. (1.5-mm) thick

(0.0025 mm) and equipped with a 90° conical contact point to

gasket be used. However, other thicknesses can be used if

be used in conjunction with the adapter shown in Fig. 1.

agreed to by the producer and user.

4.1.7 Torque Wrench—One calibrated torque wrench with a

5.1.1 See ASME B16.21, Table 8, for gasket dimensions.

minimum capacity of 70 ft·lbf (95 N·m).

5.1.2 See Classification F104 for thickness tolerance.

4.1.8 Torque Wrench—One calibrated torque wrench with a

range of 0 to 200 in.·lbf (0 to 23 N·m).

5.1.3 Preconditioning of the test gasket is not necessary,

4.1.9 Bolt Lubricant—High temperature-resistant molybde-

since this test is designed for shelf stock gaskets.

num disulfide grease.

6. Flange Limits

4.2 Preparation of Apparatus:

4.2.1 Priortorunninganytestsinanewfixture,theintegrity

6.1 Ensure that the test pressure never exceeds the pressure/

of the assembled test fixture should be checked by running a

temperature rating of the flange class:

test at a temperature at least 100°F (38°C) higher than the test

Class 600 Cast Steel

temperature,withoutexceedingthetemperature/pressurerating

@ 400°F (205°C) Limited to 1270 psig (88.6 bar) or (8.87 MPa)

for the flange. A standard gasket material approved for these @ 500°F (260°C) Limited to 1200 psig (83.8 bar) or (8.38 MPa)

@ 600°F (316°C) Limited to 1095 psig (76.6 bar) or (7.66 MPa)

service conditions shall be used with water as the test fluid.

@ 700°F (371°C) Limited to 1065 psig (74.5 bar) or (7.45 MPa)

4.2.2 The maximum use temperature for the fixture with

saturated steam is 563°F (295°C). Therefore, if a test tempera-

7. Test Limits

ture is not specified, this maximum shall be used as the default.

However, any temperature that does not exceed this limit may 7.1 Temperature/pressure properties for saturated steam

be used if agreed upon by the producer and user. from the steam table:

F2716 − 08 (2014)

9.6.6 Using a calibrated torque wrench, torque the bolt

400°F (205°C) Generates 235 psig (16.2 bar) or (1.62 MPa)

450°F (232°C) Generates 405 psig (27.9 bar) or (2.79 MPa)

according to the FSA recommended cross pattern in 3 incre-

500°F (260°C) Generates 665 psig (45.8 bar) or (4.58 MPa)

ments of 20 6 5 ft·lbf (27 6 7 N·m) and finally one cycle at

540°F (282°C) Generates 945 psig (65.1 bar) or (6.51 MPa)

65 6 5 ft·lbf (886 7 N·m) (see ESA/FSA Publication No.

550°F (288°C) Generates 1035 psig (71.3 bar) or (7.13 MPa)

563°F (295°C) Generates 1145 psig (78.9 bar) or (7.89 MPa)

009/98 or ASME PCC-1, or both). Then torque each bolt

consecutively in a counterclockwise pattern at 65 ft·lbf (88

8. Bolt Torque Guidelines

N·m), doing the first bolt a second time. The final torque may

8.1 The recommended assembly torque is 65 6 5 ft·lbf (88 be adjusted as agreed upon between producer and user, but

6 7 N·m), which produces a gasket stress of approximately 11 must be clearly stated in the report. The default torque setting

000 psi (75.8 MPa). This calculation is based on the use of shal

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F2716 − 08 F2716 − 08 (Reapproved 2014)

Standard Practice for

Comparison of Nonmetallic Flat Gaskets in High Pressure

Saturated Steam

This standard is issued under the fixed designation F2716; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice provides a means of comparing various nonmetallic flat gasket materials, Classification F104, in saturated

steam service under controlled conditions. While the practice is designed primarily for flat gaskets, it also can be applied to various

form-in-place gasket materials upon modification. The practice may be used for quality control or material comparison purposes

as agreed upon between producer and user. This practice is consistent with Fluid Sealing Association test method, FSA-NMG-

204-02, with regard to fixtures used and procedure.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

A193/A193M Specification for Alloy-Steel and Stainless Steel Bolting for High Temperature or High Pressure Service and Other

Special Purpose Applications

A194/A194M Specification for Carbon and Alloy Steel Nuts for Bolts for High Pressure or High Temperature Service, or Both

F104 Classification System for Nonmetallic Gasket Materials

2.2 ASME Standards:

ASME B16.21 Nonmetallic Flat Gaskets for Pipe Flanges

ASME PCC-1 Guidelines for Pressure Boundary Bolted Flange Joint Assembly

2.3 ESA/FSA Standards:

ESA/FSA Publication No. 009/98 Guidelines for Safe Seal Usage - Flanges and Gaskets

FSA-NMG-204-02 Standard Test Method for Performance of Non-Asbestos Gaskets in High Pressure, Saturated Steam

3. Significance and Use

3.1 This practice may be used to evaluate Classification F104 gasket materials using saturated steam and standard ASME RF

(raised face) flanges. This practice is intended for use as quality control or material comparison tool and should not be used to

predict performance.

4. Apparatus

4.1 The test equipment shall consist of the following components:

4.1.1 Hot Air Circulating Oven, equipped with temperature controls and capable of maintaining temperatures up to 570 6 5°F

(299 6 3°C).

4.1.2 Scales, capable of maintaining an accuracy of 60.1 g with a nominal capacity of 12 kg.

This practice is under the jurisdiction of ASTM Committee F03 on Gaskets and is the direct responsibility of Subcommittee F03.10 on Composite Gaskets.

Current edition approved May 1, 2008July 1, 2014. Published May 2008November 2014. Originally approved in 2008. Last previous edition approved in 2008 as

F2716 – 08. DOI: 10.1520/F2716-08.10.1520/F2716-08R14.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from American Society of Mechanical Engineers (ASME), ASME International Headquarters, Three Park Ave., New York, NY 10016-5990, http://

www.asme.org.

Available from Fluid Sealing Association (FSA), 994 Old Eagle School Road, Suite 1019, Wayne, PA 19087–1866.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2716 − 08 (2014)

4.1.3 Flange Fixture—A2 in. cast steel Class 600 fixture made from one weld neck flange capped by welding to boiler code and

one blind flange (see Fig. 1). Flange surfaces are 275 to 325 RMS μin. (7.0 to 8.3 μmm), flatness range 0.002 in. (0.05 mm). Each

fixture shall have an identification number.

4.1.4 Flange Protectors—To help ensure safe operation, use standard metal flange protectors.

4.1.5 Fasteners:

4.1.5.1 Seven ⁄8-in. bolts, 4 in. long, per Specification A193/A193M, Grade B7.

4.1.5.2 One calibrated bolt modified by the insertion of a calibration pin as detailed in Fig. 1.

4.1.5.3 Eight ⁄8-in. hexagonal nuts per Specification A194/A194M, Grade 4, coarse thread.

4.1.5.4 Sixteen ⁄8-in. hardened steel washers (38-45 HRC), Grade 8.

4.1.6 Calibrated Dial Indicator, graduated to 0.0001 in. (0.0025 mm) and equipped with a 90° conical contact point to be used

in conjunction with the adapter shown in Fig. 1.

4.1.7 Torque Wrench—One calibrated torque wrench with a minimum capacity of 70 ft·lbf (95 N·m).

4.1.8 Torque Wrench—One calibrated torque wrench with a range of 0 to 200 in.·lbf (0 to 23 N·m).

4.1.9 Bolt Lubricant—High temperature-resistant molybdenum disulfide grease.

4.2 Preparation of Apparatus:

4.2.1 Prior to running any tests in a new fixture, the integrity of the assembled test fixture should be checked by running a test

at a temperature at least 100°F (38°C) higher than the test temperature, without exceeding the temperature/pressure rating for the

flange. A standard gasket material approved for these service conditions shall be used with water as the test fluid.

4.2.2 The maximum use temperature for the fixture with saturated steam is 563°F (295°C). Therefore, if a test temperature is

not specified, this maximum shall be used as the default. However, any temperature that does not exceed this limit may be used

if agreed upon by the producer and user.

4.2.3 Follow the steps in Section 9 for one cycle of a minimum of 24 h. Ensure that the gasket is acceptable for that

temperature/pressure.

5. Test Specimen

5.1 The test specimen shall be a Class 600 2-in. (50-mm) ring gasket. It is recommended that a ⁄16-in. (1.5-mm) thick gasket

be used. However, other thicknesses can be used if agreed to by the producer and user.

5.1.1 See ASME B16.21, Table 8, for gasket dimensions.

5.1.2 See Classification F104 for thickness tolerance.

FIG. 1 FSA Steam Test Fixture

F2716 − 08 (2014)

5.1.3 Preconditioning of the test gasket is not necessary, since this test is designed for shelf stock gaskets.

6. Flange Limits

6.1 Ensure that the test pressure never exceeds the pressure/temperature rating of the flange class:

Class 600 Cast Steel

@ 400°F (205°C) Limited to 1270 psig (88.6 bar) or (8.87 MPa)

@ 500°F (260°C) Limited to 1200 psig (83.8 bar) or (8.38 MPa)

@ 600°F (316°C) Limited to 1095 psig (76.6 bar) or (7.66 MPa)

@ 700°F (371°C) Limited to 1065 psig (74.5 bar) or (7.45 MPa)

7. Test Limits

7.1 Temperature/pressure properties for saturated steam from the steam table:

F2716 − 08 (2014)

400°F (205°C) Generates 235 psig (16.2 bar) or (1.62 MPa)

450°F (232°C) Generates 405 psig (27.9 bar) or (2.79 MPa)

500°F (260°C) Generates 665 psig (45.8 bar) or (4.58 MPa)

540°F (282°C) Generates 945 psig (65.1 bar) or (6.51 MPa)

550°F (288°C) Generates 1035 psig (71.3 bar) or (7.13 MPa)

563°F (295°C) Generates 1145 psig (78.9 bar) or (7.89 MPa)

8. Bolt Torque Guidelines

8.1 The recommended assembly torque is 65 6 5 ft·lbf (88 6 7 N·m), which produces a gasket stress of approximately 11 000

psi (75.8 MPa). This calculation is based on the use of molybdenum disulfide grease as the bolt lubricant (4.1.9).

8.2 A recommended article is “Torque - Tensioning Part II” by Dr. H. E. Trucks. Also see ASME PCC-1.

8.3 Various assembly torques may be used, as agreed upon by producer and user, and provided the gasket stress is never less

than 4350 psi (30 MPa).

9. Procedure

9.1 A minimum of two test assemblies is recommended per gasket type tested.

9.2 En

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.