ASTM C1199-00(2008)

(Test Method)Standard Test Method for Measuring the Steady-State Thermal Transmittance of Fenestration Systems Using Hot Box Methods

Standard Test Method for Measuring the Steady-State Thermal Transmittance of Fenestration Systems Using Hot Box Methods

SIGNIFICANCE AND USE

This test method details the calibration and testing procedures and necessary additional temperature instrumentation required in applying Test Methods C 236, C 976, or C 1363 to measure the thermal transmittance of fenestration systems mounted vertically in the thermal chamber.

Since both temperature and surface heat transfer coefficient conditions affect results, use of recommended conditions will assist in reducing confusion caused by comparing results of tests performed under dissimilar conditions. Standardized test conditions for determining the thermal transmittance of fenestration systems are specified in Practice E 1423 and Section 5.3. However, this procedure can be used with other conditions for research purposes or product development.

It should be recognized that the only true experimental measurement is the thermal transmittance, US, value determined in Section 7. The “standardized” thermal transmittance value, UST, obtained by either the Calibration Transfer Standard (CTS) or area weighting (AW) methods described in Section 8 include adjustments to the US value that are made because the current computer calculation methods (NFRC 100-97) for determining the thermal transmittance are not capable of applying the actual surface heat transfer coefficients that exist on the test specimen while testing at standardized conditions. The current computer calculation methods assume that uniform standardized surface heat transfer coefficients exist on the indoor and outdoor fenestration product surfaces, which is not the case. Until such a time that the computer calculation methods are upgraded to have the actual surface heat transfer coefficients applied to the actual fenestration product geometry, the modification of the true tested thermal transmittance value, US, to a standardized value UST, is necessary for rating and comparison (measured with calculated) purposes.

It should be noted that the standardized surface heat transfer coefficients, hh and hs,...

SCOPE

1.1 This test method covers requirements and guidelines and specifies calibration procedures required for the measurement of the steady-state thermal transmittance of fenestration systems installed vertically in the test chamber. This test method specifies the necessary measurements to be made using measurement systems conforming to either Test Methods C 236, C 976, or C 1363 for determination of fenestration system thermal transmittance.

Note 1—This test method allows the testing of projecting fenestration products (that is, garden windows, skylights, and roof windows) installed vertically in a surround panel. Current research on skylights, roof windows, and projecting products hopefully will provide additional information that can be added to the next version of this test method so that skylight and roof windows can be tested horizontally or at some angle typical of a sloping roof.

1.2 This test method refers to the thermal transmittance, U, and the corresponding thermal resistance, R, of a fenestration system installed vertically in the absence of solar and air leakage effects.

Note 2—The methods described in this document may also be adapted for use in determining the thermal transmittance of sections of building wall, and roof and floor assemblies containing thermal anomalies, which are smaller than the hot box metering area.

1.3 This test method describes how to determine a fenestration product's (also called test specimen) thermal transmittance, US, at well-defined environmental conditions. The thermal transmittance, which is sometimes called the air-to-air U-factor, is also a reported test result from Test Methods C 236, C 976, and C 1363. If only the thermal transmittance is reported using this test method, the test report must also include a detailed description of the environmental conditions in the thermal chamber during the test as outlined in 10.3.

1.4 For rating purposes, this test method al...

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C1199–00 (Reapproved 2008)

Standard Test Method for

Measuring the Steady-State Thermal Transmittance of

Fenestration Systems Using Hot Box Methods

This standard is issued under the fixed designation C 1199; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.4 For rating purposes, this test method also describes how

to calculate a standardized thermal transmittance, U , which

1.1 This test method covers requirements and guidelines ST

can be used to compare test results from laboratories with

and specifies calibration procedures required for the measure-

different weather side wind directions and thermal chamber

ment of the steady-state thermal transmittance of fenestration

configurations, and can also be used to directly compare to

systems installed vertically in the test chamber. This test

calculated results from current computer programs for deter-

methodspecifiesthenecessarymeasurementstobemadeusing

mining the thermal transmittance of fenestration products.

measurement systems conforming to either Test Methods

Although this test method specifies two methods of calculating

C 236, C 976,or C 1363 for determination of fenestration

the standardized thermal transmittance, only the standardized

system thermal transmittance.

thermal transmittance result from one method is reported for

NOTE 1—This test method allows the testing of projecting fenestration

each test. One standardized thermal transmittance calculation

products (that is, garden windows, skylights, and roof windows) installed

procedure is the Calibration Transfer Standard (CTS) method

vertically in a surround panel. Current research on skylights, roof

and another is the area weighting (AW) method (see 4.3 and

windows, and projecting products hopefully will provide additional

Section 8 for further descriptions of these two methods). The

information that can be added to the next version of this test method so

that skylight and roof windows can be tested horizontally or at some angle area weighting method requires that the surface temperatures

typical of a sloping roof.

on both sides of the test specimen be directly measured as

specified in Practice E 1423 in order to determine the surface

1.2 This test method refers to the thermal transmittance, U,

heat transfer coefficients on the fenestration product during the

and the corresponding thermal resistance, R, of a fenestration

test. The CTS method does not use the measured surface

system installed vertically in the absence of solar and air

temperatures on the test specimen and instead utilizes the

leakage effects.

calculation of equivalent surface temperatures from calibration

NOTE 2—The methods described in this document may also be adapted

data to determine the test specimen surface heat transfer

for use in determining the thermal transmittance of sections of building

coefficients. The area weighting (AW) method shall be used

wall, and roof and floor assemblies containing thermal anomalies, which

whenever the thermal transmittance, U , is greater than 3.4

S

are smaller than the hot box metering area.

2 2

W/(m •K) {0.6 Btu/(hr•Ft •°F)}, or when the ratio of test

1.3 This test method describes how to determine a fenestra-

specimen projected surface area to wetted (that is, total heat

tion product’s (also called test specimen) thermal transmit-

transfer or developed) surface area on either side of the test

tance, U , at well-defined environmental conditions. The ther-

S

specimen is less than 0.80. Otherwise the CTS method shall be

mal transmittance, which is sometimes called the air-to-air

used to standardize the thermal transmittance results.

U-factor,isalsoareportedtestresultfromTestMethodsC 236,

1.5 Adiscussionoftheterminologyandunderlyingassump-

C 976, and C 1363. If only the thermal transmittance is

tions for measuring the thermal transmittance are included.

reported using this test method, the test report must also

1.6 The values stated in SI units are to be regarded as the

include a detailed description of the environmental conditions

standard. The values given in parentheses are provided for

in the thermal chamber during the test as outlined in 10.3.

information purposes only.

1.7 This standard does not purport to address all of the

ThistestmethodisunderthejurisdictionofASTMCommitteeC16onThermal

safety concerns, if any, associated with its use. It is the

Insulation and is the direct responsibility of Subcommittee C16.30 on Thermal

responsibility of the user of this standard to establish appro-

Measurement.

priate safety and health practices and determine the applica-

Current edition approved Oct. 15, 2008. Published July 2009. Originally

bility of regulatory limitations prior to use.

approved in 1991. Last previous edition approved in 2000 as C 1199 – 00.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C1199–00 (2008)

2. Referenced Documents 3. Terminology

2.1 ASTM Standards: 3.1 Definitions—Definitions and terms are in accordance

C 168 Terminology Relating to Thermal Insulation withdefinitionsinTerminologiesE 631andC 168,fromwhich

C 177 Test Method for Steady-State Heat Flux Measure- the following have been selected and modified to apply to

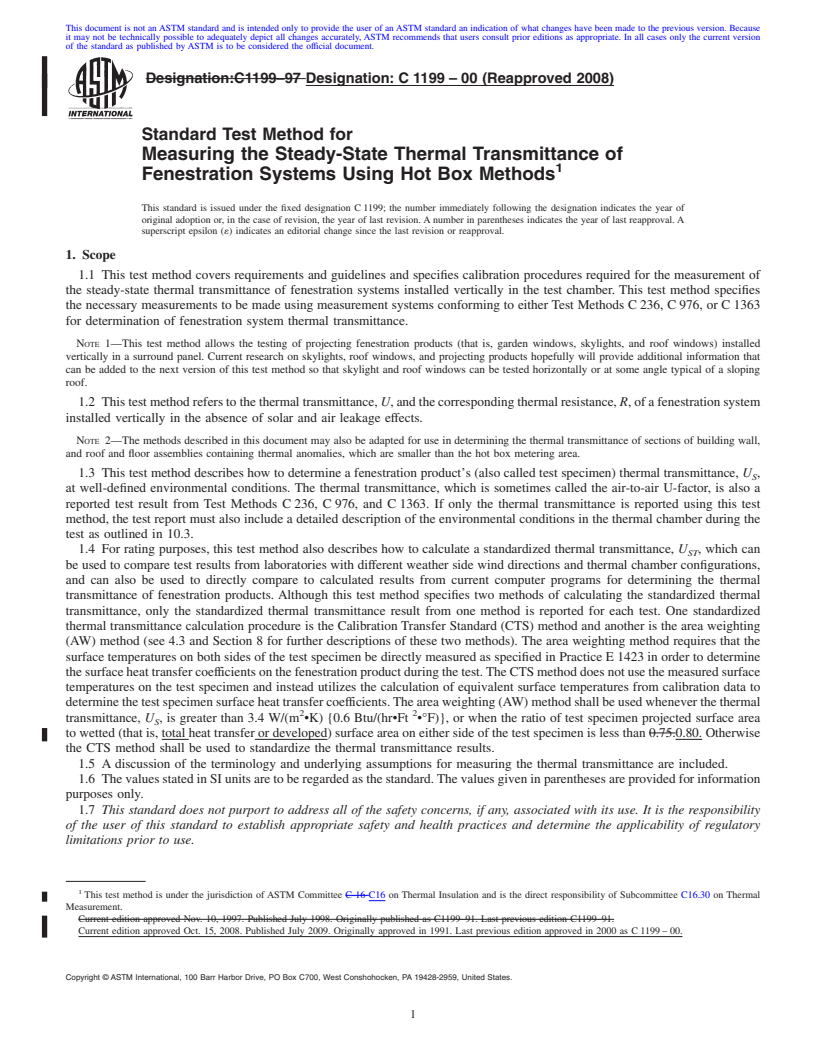

fenestration systems. See Fig. 1 for temperature locations.

ments and Thermal Transmission Properties by Means of

the Guarded-Hot-Plate Apparatus 3.2 Definitions of Terms Specific to This Standard:

3.2.1 calibration transfer standard, n— an insulation board

C 236 Test Method for Steady-State Thermal Performance

of Building Assemblies by Means of a Guarded Hot Box that is faced with glazing, and instrumented with temperature

sensors between the glazing and the insulation board core,

C 518 Test Method for Steady-State Thermal Transmission

Properties by Means of the Heat Flow Meter Apparatus which is used to calibrate the surface resistances and the

surround panel (see Annex A1 for design guidelines for

C 976 Test Method for Thermal Performance of Building

Assemblies by Means of a Calibrated Hot Box calibration transfer standards).

3.2.2 overall thermal resistance, R , n—the temperature

C 1045 Practice for Calculating Thermal Transmission

S

Properties Under Steady-State Conditions differencebetweentheenvironmentsonthetwosidesofabody

or assembly when a unit heat flow per unit area is established

C 1114 TestMethodforSteady-StateThermalTransmission

through the body or assembly under steady-state conditions. It

Properties by Means of the Thin-Heater Apparatus

is defined as follows:

C 1363 Test Method for Thermal Performance of Building

Materials and Envelope Assemblies by Means of a Hot

R 5 1/U (1)

S S

Box Apparatus

3.2.3 standardized thermal transmittance, U , n—the heat

ST

E 283 Test Method for Determining Rate of Air Leakage

transmission in unit time through unit area of a test specimen

Through Exterior Windows, Curtain Walls, and Doors

and standardized boundary air films, induced by unit tempera-

Under Specified Pressure DifferencesAcross the Specimen

ture difference between the environments on each side. It is

E 631 Terminology of Building Constructions

calculated using the CTS method as follows:

E 783 Test Method for Field Measurement of Air Leakage

1/U 5 1/U 1~1/h –1/h !1~1/h –1/h ! (2)

ST[CTS] S STh h STc c

Through Installed Exterior Windows and Doors

E 1423 Practice for Determining Steady State Thermal and using the area weighting (AW) method:

Transmittance of Fenestration Systems

1/U 51/U 1~A /A !~1/h –1/h !1~A /A !~1/h –1/h !

ST[AW] S S h STh h S c STc c

2.2 ISO Standards:

(3)

ISO 8990 Thermal Insulation-Determination of Steady-

whereh andh arethestandardizedsurfaceheattransfer

STh STc

State Thermal Transmission Properties—Calibrated and

coefficients on the room side and weather side, respectively.

Guarded Hot Box

Their numerical values are specified in 8.2.9.1.

ISO12567–1:2000 Thermal Insulation—Determination of

3.2.3.1 Discussion—The calculation of the standardized

Thermal Resistance of Components—Hot Box Method

thermal transmittance, U , assumes that only the surface heat

ST

for Windows and Doors

transfer coefficients change from the calibrated standardized

2.3 Other Standards:

values for the conditions of the test. This assumption may not

be valid if the surface temperature differentials for the stan-

NFRC 100-97 Procedure for Determining Fenestration

Product Thermal U-factors dardized calibration conditions are different from the surface

temperaturedifferentialthatexistedforthefenestrationproduct

BS874 Part 3, Section 3.1, 1987, British Standard Methods

during the test procedure. Therefore, the standardized thermal

for Determining Thermal Insulation Properties, (Part 3,

transmittance should only be considered as an approximation

Tests for Thermal Transmittance and Conductance, Sec-

for use in comparing with calculated thermal transmittance

tion 3.1) Guarded Hot Box Method

values with standardized surface heat transfer coefficients.

BS874 Part 3, Section 3.2, 1990, British Standard Methods

for Determining Thermal Insulation Properties, Part 3,

Tests for Thermal Transmittance and Conductance, Sec-

tion 3.2 Calibrated Hot Box Method

ASHRAE Fundamentals Handbook, 1997

Withdrawn. The last approved version of this historical standard is referenced

on www.astm.org.

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

4th Floor, New York, NY 10036, http://www.ansi.org.

Available from National Fenestration Rating Council, 1300 Spring Street, Suite

120, Silver Spring, MD 20910.

Available from British Standards Institute (BSI), 389 Chiswick High Rd.,

London W4 4AL, U.K., http://www.bsi-global.com.

Available from American Society of Heating, Refrigerating, and Air-

Conditioning Engineers, Inc. (ASHRAE), 1791 Tullie Circle, NE, Atlanta, GA FIG. 1 Schematic Representation of Various Temperatures for

30329, http://www.ashrae.org. Fenestration Systems

C1199–00 (2008)

3.2.4 surface resistance, n—the temperature difference be- measured.Forinhomogeneoustestspecimens,onlythethermal

tween an isothermal surface and its surroundings when a unit transmittance, U , can be defined and measured. It is therefore

S

heat flow per unit area is established between the surface and essential to calibrate with surface heat transfer coefficients on

the surroundings under steady-state conditions by the com- the Calibration Transfer Standard (CTS) which are as close as

bined effects of convection and radiation. Subscripts h and c possible to the conventionally accepted values for building

are used to differentiate between room side and weather side design. Likewise, it would be desirable to have a surround

surface resistances, respectively. Surface resistances are calcu- panel that closely duplicates the actual wall where the fenes-

lated as follows: tration system would be installed. However, due to the wide

variety of fenestration opening designs and constructions, this

r 5 1/h (4)

h h

is not feasible. Furthermore, for high resistance fenestration

systems installed in fenestration opening designs and construc-

r 5 1/h (5)

c c

tions that are thermal bridges, the large relative amount of heat

3.2.5 surface heat transfer coeffıcient, h, n—the time rate of

transfer through the thermal bridge will cause the relatively

heat flow from a unit area of a surface to its surroundings,

small amount of heat transfer through the fenestration system

induced by a unit temperature difference between the surface

to have a larger than desirable error. As a result of the points

and the environment. (This is sometimes called surface con-

stated above, the calculation of a specimen thermal conduc-

ductance or film coeffıcient.)

tance or resistance (surface to surface) from a measured

3.2.5.1 Discussion—Subscripts are used to differentiate be-

thermal transmittance and the calculated surface heat transfer

tween room side (1 or h) and weather side (2 or c) surface

coefficients is not part of the basic measurement procedure.

conditions (see Fig. 1). It should be recognized that due to

However, by using the CTS method or the area weighting

radiation effects, the room side or weather side temperature (t

h

(AW) method described in Section 8 it is possible to obtain a

and t , respectively), may differ from the respective room side

c

standardized thermal transmittance, U , which is a rather

ST

or weather side baffle temperatures (t and t , respectively).

b1 b2

useful tool for the evaluation and comparison of experimental

If there is a difference of more than 61°C(62.0 °F), either on

results for fenestration systems with computer calculations of

the room side or weather side, the radiation effects shall be

the thermal transmittance.

accounted for to maintain accuracy in the calculated surface

3.2.6 surround panel (sometimes called the mask, mask

heat transfer coefficients. The areas used to calculate the

wall, or homogeneous wall), n—a homogeneous panel with an

surface heat transfer coefficients (Eq 6 and 8) are different

opening where the test specimen is installed (see 5.1.2 for a

depending on which method of standardization is used. When

description of a surround panel.)

the CTS Method is used to standardize the thermal transmit-

3.2.7 test specimen, n—the fenestration system or product

tance, the projected area, A , is used to calculate the surface

S

being tested.

heat transfer coefficients, whereas when using the area weight-

3.2.8 test specimen thermal transmittance, U (sometimes

ing method, the actual “wetted or heat transfer” surface area, S

called the overall coefficient of heat transfer or air-to-air

A or A , is used to determine the surface heat transfer

c

h

U-factor),n—theheattransferinunittimethroughunitareaof

coefficients.

a test specimen and its boundary air films, induced by unit

The room side and weather side surface heat transfer coefficients are

temperature difference between the environments on each side.

calculated as follows:

It is determined as follows:

when:

U 5 Q /[A •~t – t !# (10)

S S S h c

t 5 t 61°C!, (6)

~

h b1

3.3 Symbols—The symbols, terms, and units used in this

h 5 Q /[~A !~t – t !#

h S Sorh h 1

test method are as follows:

when:

t fi t ~61° C!, (7)

h b1

h 5 ~q 1 q !/~t – t ! A = total heat transfer (or developed) surface area

h r1 c1 h 1 h

when:

of test specimen on room side, m ,

A = total heat transfer (or developed) surface area

t 5 t ~61°C!, c

c b2

of test specimen on weather side, m ,

h 5 Q /[~A ! ~t – t !#

c S Sorc 2 c

A = area of room si

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:C1199–97 Designation:C1199–00 (Reapproved 2008)

Standard Test Method for

Measuring the Steady-State Thermal Transmittance of

Fenestration Systems Using Hot Box Methods

This standard is issued under the fixed designation C 1199; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers requirements and guidelines and specifies calibration procedures required for the measurement of

the steady-state thermal transmittance of fenestration systems installed vertically in the test chamber. This test method specifies

the necessary measurements to be made using measurement systems conforming to either Test Methods C 236, C 976, or C 1363

for determination of fenestration system thermal transmittance.

NOTE 1—This test method allows the testing of projecting fenestration products (that is, garden windows, skylights, and roof windows) installed

vertically in a surround panel. Current research on skylights, roof windows, and projecting products hopefully will provide additional information that

can be added to the next version of this test method so that skylight and roof windows can be tested horizontally or at some angle typical of a sloping

roof.

1.2 Thistestmethodreferstothethermaltransmittance,U,andthecorrespondingthermalresistance,R,ofafenestrationsystem

installed vertically in the absence of solar and air leakage effects.

NOTE 2—The methods described in this document may also be adapted for use in determining the thermal transmittance of sections of building wall,

and roof and floor assemblies containing thermal anomalies, which are smaller than the hot box metering area.

1.3 This test method describes how to determine a fenestration product’s (also called test specimen) thermal transmittance, U ,

S

at well-defined environmental conditions. The thermal transmittance, which is sometimes called the air-to-air U-factor, is also a

reported test result from Test Methods C 236, C 976, and C 1363. If only the thermal transmittance is reported using this test

method, the test report must also include a detailed description of the environmental conditions in the thermal chamber during the

test as outlined in 10.3.

1.4 For rating purposes, this test method also describes how to calculate a standardized thermal transmittance, U , which can

ST

be used to compare test results from laboratories with different weather side wind directions and thermal chamber configurations,

and can also be used to directly compare to calculated results from current computer programs for determining the thermal

transmittance of fenestration products. Although this test method specifies two methods of calculating the standardized thermal

transmittance, only the standardized thermal transmittance result from one method is reported for each test. One standardized

thermal transmittance calculation procedure is the Calibration Transfer Standard (CTS) method and another is the area weighting

(AW) method (see 4.3 and Section 8 for further descriptions of these two methods). The area weighting method requires that the

surface temperatures on both sides of the test specimen be directly measured as specified in Practice E 1423 in order to determine

thesurfaceheattransfercoefficientsonthefenestrationproductduringthetest.TheCTSmethoddoesnotusethemeasuredsurface

temperatures on the test specimen and instead utilizes the calculation of equivalent surface temperatures from calibration data to

determinethetestspecimensurfaceheattransfercoefficients.Theareaweighting(AW)methodshallbeusedwheneverthethermal

2 2

transmittance, U , is greater than 3.4 W/(m •K) {0.6 Btu/(hr•Ft •°F)}, or when the ratio of test specimen projected surface area

S

to wetted (that is, total heat transfer or developed) surface area on either side of the test specimen is less than 0.75.0.80. Otherwise

the CTS method shall be used to standardize the thermal transmittance results.

1.5 A discussion of the terminology and underlying assumptions for measuring the thermal transmittance are included.

1.6 ThevaluesstatedinSIunitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareprovidedforinformation

purposes only.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

This test method is under the jurisdiction of ASTM Committee C-16 C16 on Thermal Insulation and is the direct responsibility of Subcommittee C16.30 on Thermal

Measurement.

Current edition approved Nov. 10, 1997. Published July 1998. Originally published as C1199–91. Last previous edition C1199–91.

Current edition approved Oct. 15, 2008. Published July 2009. Originally approved in 1991. Last previous edition approved in 2000 as C 1199 – 00.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C1199–00 (2008)

2. Referenced Documents

2.1 ASTM Standards:

C 168 Terminology Relating to Thermal Insulating Materials Terminology Relating to Thermal Insulation

C 177 Test Method for Steady-State Heat Flux Measurements and Thermal Transmission Properties by Means of the

Guarded-Hot-Plate Apparatus

C 236 Test Method for Steady-State Thermal Performance of Building Assemblies by Means of a Guarded Hot Box

C 518 Test Method for Steady-StateThermal Heat Flux Measurements andTransmission Properties by Means of the Heat Flow

Meter Apparatus

C 976 Test Method for Thermal Performance of Building Assemblies by Means of a Calibrated Hot Box

C 1045 Practice for Calculated Thermal Transmission Properties from Steady-State Heat Flux Measurements Practice for

Calculating Thermal Transmission Properties Under Steady-State Conditions

C 1114 Test Method for Steady-State Thermal Transmission Properties by Means of the Thin-Heater Apparatus

C 1363 Test Method for Thermal Performance of Building Materials and Envelope Assemblies by Means of a Hot Box

Apparatus

E 283 TestMethodforRateofAirLeakageThroughExteriorWindows,CurtainWalls,andDoorsTestMethodforDetermining

Rate of Air Leakage Through Exterior Windows, Curtain Walls, and Doors Under Specified Pressure Differences Across the

Specimen

E 631 Terminology of Building Constructions

E 783 Test Method for Field Measurement of Air Leakage Through Installed Exterior Windows and Doors

E 1423 Practice for Determining the Steady-StateSteady State Thermal Transmittance of Fenestration Systems

2.2 ISO Standards:

ISO 8990 Thermal Insulation-Determination of Steady-State Thermal Transmission Properties—Calibrated and Guarded Hot

Box

ISO/DIS 12567ThermalISO12567–1:2000 Thermal Insulation—Determination of Thermal Resistance of Components—Hot

Box Method for Windows and Doors

2.3 Other Standards:

NFRC 100-97 Procedure for Determining Fenestration Product Thermal U-factors

BS874 Part 3, Section 3.1, 1987, British Standard Methods for Determining Thermal Insulation Properties, (Part 3, Tests for

Thermal Transmittance and Conductance, Section 3.1) Guarded Hot Box Method

BS874 Part 3, Section 3.2, 1990, British Standard Methods for Determining Thermal Insulation Properties, Part 3, Tests for

Thermal Transmittance and Conductance, Section 3.2 Calibrated Hot Box Method

ASHRAE Fundamentals Handbook, 1997

3. Terminology

3.1 Definitions— Definitions and terms are in accordance with definitions in Terminologies E 631 and C 168, from which the

following have been selected and modified to apply to fenestration systems. See Fig. 1 for temperature locations.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 calibration transfer standard, n— an insulation board that is faced with glazing, and instrumented with temperature

sensors between the glazing and the insulation board core, which is used to calibrate the surface resistances and the surround panel

(see Annex A1 for design guidelines for calibration transfer standards).

3.2.2 overall thermal resistance, R , n—the temperature difference between the environments on the two sides of a body or

S

assemblywhenaunitheatflowperunitareaisestablishedthroughthebodyorassemblyundersteady-stateconditions.Itisdefined

as follows:

R 5 1/U (1)

S S

3.2.3 standardized thermal transmittance, U , n—the heat transmission in unit time through unit area of a test specimen and

ST

standardized boundary air films, induced by unit temperature difference between the environments on each side. It is calculated

using the CTS method as follows:

1/U 5 1/U 1 1/h –1/h !1 1/h –1/h ! (2)

~ ~

ST[CTS] S STh h STc c

Annual Book of ASTM Standards, Vol 04.06.

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

Annual Book of ASTM Standards, Vol 04.07.

Available from National Fenestration Rating Council, 1300 Spring Street, Suite 120, Silver Spring, MD 20910.

4 nd th

Available from American National Standards Institute, 11 West 42 St., 13 Floor, New York, NY 10036.

Available from British Standards Institute (BSI), 389 Chiswick High Rd., London W4 4AL, U.K., http://www.bsi-global.com.

Available from National Fenestration Rating Council, 1300 Spring Street, Suite 120, Silver Spring, MD 20910.

Available from American Society of Heating, Refrigerating, and Air-Conditioning Engineers, Inc. (ASHRAE), 1791 Tullie Circle, NE, Atlanta, GA 30329,

http://www.ashrae.org.

C1199–00 (2008)

FIG. 1 Schematic Representation of Various Temperatures for

Fenestration Systems

and using the area weighting (AW) method:

1/U 51/U 1~A /A !~1/h –1/h !1~A /A !~1/h –1/h ! (3)

ST[AW] S S h STh h S c STc c

where h and h are the standardized surface heat transfer coefficients on the room side and weather side, respectively. Their

STh STc

numerical values are specified in 8.2.9.1.

3.2.3.1 Discussion—The calculation of the standardized thermal transmittance, U , assumes that only the surface heat transfer

ST

coefficients change from the calibrated standardized values for the conditions of the test. This assumption may not be valid if the

surface temperature differentials for the standardized calibration conditions are different from the surface temperature differential

that existed for the fenestration product during the test procedure. Therefore, the standardized thermal transmittance should only

be considered as an approximation for use in comparing with calculated thermal transmittance values with standardized surface

heat transfer coefficients.

3.2.4 surface resistance, n—the temperature difference between an isothermal surface and its surroundings when a unit heat

flow per unit area is established between the surface and the surroundings under steady-state conditions by the combined effects

of convection and radiation. Subscripts h and c are used to differentiate between room side and weather side surface resistances,

respectively. Surface resistances are calculated as follows:

r 5 1/h (4)

h h

r 5 1/h (5)

c c

3.2.5 surface heat transfer coeffıcient, h, n—the time rate of heat flow from a unit area of a surface to its surroundings, induced

by a unit temperature difference between the surface and the environment. (This is sometimes called surface conductance or film

coeffıcient.)

3.2.5.1 Discussion—Subscripts are used to differentiate between room side (1 or h) and weather side (2 or c) surface conditions

(seeFig.1).Itshouldberecognizedthatduetoradiationeffects,theroomsideorweathersidetemperature(t and t ,respectively),

h c

may differ from the respective room side or weather side baffle temperatures (t and t , respectively). If there is a difference of

b1 b2

more than 61°C(62.0 °F), either on the room side or weather side, the radiation effects mustshall be accounted for to maintain

accuracy in the calculated surface heat transfer coefficients. The areas used to calculate the surface heat transfer coefficients (Eq

6 and 8) are different depending on which method of standardization is used. When the CTS Method is used to standardize the

thermaltransmittance,theprojectedarea, A ,isusedtocalculatethesurfaceheattransfercoefficients,whereaswhenusingthearea

S

weighting method, the actual “wetted or heat transfer” surface area, A or A , is used to determine the surface heat transfer

h c

coefficients.

The room side and weather side surface heat transfer coefficients are calculated as follows:

when:

t 5 t ~61°C!, (6)

h b1

h 5 Q /[~A !~t – t !#

h S Sorh h 1

when:

t fi t ~61° C!, (7)

h b1

h 5 ~q 1 q !/~t – t !

h r1 c1 h 1

when:

t 5 t ~61°C!,

c b2

h 5 Q /[~A ! ~t – t !#

c S Sorc 2 c

when: !#

C1199–00 (2008)

when:

t fi t ~6 1°C!, (8)

c b2

h 5 q 1 q !/ t – t ! (9)

~ ~

c r2 c2 2 c

3.2.5.2 Discussion—When testing inhomogeneous test specimens, the test specimen surface temperatures and surface heat

transfer coefficients will not be exactly the same as those obtained using the calibration transfer standard. As a consequence, the

surface heat transfer coefficients obtained using the calibration transfer standard cannot be unambiguously defined and hence a test

specimen conductance cannot be defined and measured. For inhomogeneous test specimens, only the thermal transmittance, U ,

S

can be defined and measured. It is therefore essential to calibrate with surface heat transfer coefficients on the Calibration Transfer

Standard (CTS) which are as close as possible to the conventionally accepted values for building design. Likewise, it would be

desirable to have a surround panel that closely duplicates the actual wall where the fenestration system would be installed.

However, due to the wide variety of fenestration opening designs and constructions, this is not feasible. Furthermore, for high

resistance fenestration systems installed in fenestration opening designs and constructions that are thermal bridges, the large

relative amount of heat transfer through the thermal bridge will cause the relatively small amount of heat transfer through the

fenestrationsystemtohavealargerthandesirableerror.Asaresultofthepointsstatedabove,thecalculationofaspecimenthermal

conductance or resistance (surface to surface) from a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.