ASTM D6052-97(2023)

(Test Method)Standard Test Method for Preparation and Elemental Analysis of Liquid Hazardous Waste by Energy-Dispersive X-Ray Fluorescence

Standard Test Method for Preparation and Elemental Analysis of Liquid Hazardous Waste by Energy-Dispersive X-Ray Fluorescence

SIGNIFICANCE AND USE

4.1 The elemental analysis of liquid hazardous waste is often important for regulatory and process-specific requirements. This test method provides the user an accurate, rapid method for trace and major element determinations.

SCOPE

1.1 This test method covers the determination of trace and major element concentrations by energy-dispersive X-ray fluorescence spectrometry (EDXRF) in liquid hazardous waste (LHW).

1.2 This test method has been used successfully on numerous samples of aqueous and organic-based LHW for the determination of the following elements: Ag, As, Ba, Br, Cd, Cl, Cr, Cu, Fe, Hg, I, K, Ni, P, Pb, S, Sb, Se, Sn, Tl, V, and Zn.

1.3 This test method is applicable for other elements (Si-U) not listed in 1.2.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D6052 − 97 (Reapproved 2023)

Standard Test Method for

Preparation and Elemental Analysis of Liquid Hazardous

Waste by Energy-Dispersive X-Ray Fluorescence

This standard is issued under the fixed designation D6052; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 Other ASTM Documents:

ASTM Data Series DS 46 X-ray Emission Wavelengths and

1.1 This test method covers the determination of trace and

KeV Tables for Nondiffractive Analysis

major element concentrations by energy-dispersive X-ray fluo-

rescence spectrometry (EDXRF) in liquid hazardous waste

3. Summary of Test Method

(LHW).

3.1 A weighed portion of activated alumina and sample are

1.2 This test method has been used successfully on numer-

combined in a mixing vessel and shaken until well mixed. The

ous samples of aqueous and organic-based LHW for the

sample mixture is transferred into a disposable sample cup and

determination of the following elements: Ag, As, Ba, Br, Cd,

placed in the spectrometer for analysis.

Cl, Cr, Cu, Fe, Hg, I, K, Ni, P, Pb, S, Sb, Se, Sn, Tl, V, and Zn.

3.2 The K spectral emission lines are used for elements

1.3 This test method is applicable for other elements (Si-U)

Si-Ba.

not listed in 1.2.

3.3 The L spectral emission lines are used for elements with

1.4 This standard does not purport to address all of the

atomic numbers greater than Ba.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

4. Significance and Use

priate safety, health, and environmental practices and deter-

4.1 The elemental analysis of liquid hazardous waste is

mine the applicability of regulatory limitations prior to use.

often important for regulatory and process-specific require-

1.5 This international standard was developed in accor-

ments. This test method provides the user an accurate, rapid

dance with internationally recognized principles on standard-

method for trace and major element determinations.

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

5. Interferences

mendations issued by the World Trade Organization Technical

5.1 Spectral Overlaps (Deconvolution):

Barriers to Trade (TBT) Committee.

5.1.1 Samples containing a mixture of elements often ex-

hibit X-ray emission line overlap. Modern Si (Li) detectors

2. Referenced Documents

generally provide adequate resolution to minimize the effects

2.1 ASTM Standards:

of spectral overlap. In cases where emission line overlap exists,

C982 Guide for Selecting Components for Energy-

techniques of peak fitting exist for extracting corrected analyte

Dispersive X-Ray Fluorescence (XRF) Systems (With-

emission line intensities. For example, the PbLα “line overlaps

drawn 2008)

with the AsKα.” The PbLβ line can be used to avoid this

D1193 Specification for Reagent Water

overlap and the AsK lines can then be resolved from the PbLα

overlap. The actual lines used for any particular element should

be such that overlaps are minimized. Follow the EDXRF

manufacturer’s recommendation concerning spectral deconvo-

This test method is under the jurisdiction of ASTM Committee D34 on Waste

lution. Reference should be made to ASTM Data Series DS 46

Management and is the direct responsibility of Subcommittee D34.01.06 on

Analytical Methods.

for detailed information on potential line overlaps.

Current edition approved Nov. 1, 2023. Published November 2023. Originally

5.2 Matrix Interferences (Regression):

approved in 1997. Last previous edition approved in 2016 as D6052 – 97 (2016).

DOI: 10.1520/D6052-97R23.

5.2.1 Matrix interference in the measurement of “as re-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

ceived” LHW samples using EDXRF has been the principle

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

limitation in the development and expanding use of this

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

The last approved version of this historical standard is referenced on

www.astm.org. Available from ASTM Headquarters, Customer Service.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6052 − 97 (2023)

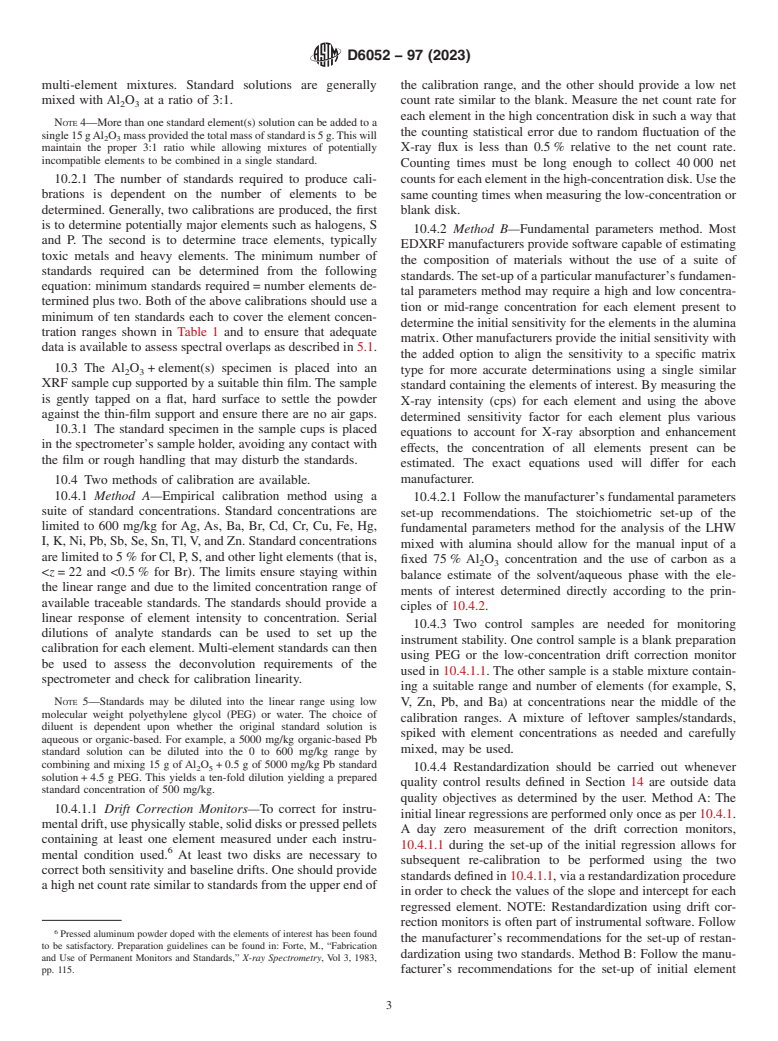

TABLE 1 Recommended Standards Ranges

instrumental technique. Using well-understood XRF principles

for controlling matrix effects, for example, dilution and matrix Low Con- High Con- High Con-

Low Con-

centration centration centration

modification using lithium borate fusion and addition of heavy

Analyte Analyte centration

Range, Range, Range,

Range, mg/kg

absorbers, a matrix can be stabilized. Using calcined alumina

mg/kg mg/kg mg/kg

and the above principles, matrices are stabilized for quantita-

Ag 5 600 Zn 5 600

Ba 5 600 As 5 600

tive EDXRF analysis.

P 0.1 % 5 % Se 5 600

5.2.2 The response range of this test method should be

S 0.05 % 5 % Br 10 5000

linear with respect to the elements of interest and their

Cl 0.05 % 5 % Cd 5 600

regulatory or process control, or both, action thresholds. Large K 0.1 % 5 % Sb 5 600

V 5 600 Sn 5 600

concentration variations of element or matrix, or both, compo-

Cr 5 600 I 5 600

nents in LHW samples can result in nonlinear X-ray intensity

Fe 5 600 Hg 5 600

Ni 5 600 Tl 5 600

response at increasing element concentrations.

Cu 5 600 Pb 5 600

6. Apparatus

6.1 Energy-Dispersive X-ray Fluorescence Spectrometer,

capable of measuring the wavelengths of the elements listed in

7.8 Mixing Balls, approximately 1 cm diameter, stainless

1.2. Refer to Guide C982 for system specifications.

steel or equivalent.

6.2 Analytical Balance, capable of weighing to 0.001 g. 1

NOTE 2—Potential low level Cr, Fe or Ni (<20 mg/kg ) contamination

due to the use of stainless steel may exist. Other suitable materials would

7. Reagents and Materials be tungsten carbide, Zr or Ta.

7.9 Thin-Film Support.

7.1 Purity of Reagents—Reagent grade chemicals shall be

used in all tests. Unless otherwise indicated, it is intended that

NOTE 3—The user should select a thin-film support that provides for

all reagents conform to the specifications of the Committee on

maximum transmittance and is resistant to typical components in LHW.

Analytical Reagents of the American Chemical Society, where The thin-film supports used in the development of this test method were

a polypropylene base and a high-purity 4 μm polyester film.

such specifications are available. Other grades may be used,

provided it is first ascertained that the reagent is of sufficiently

7.10 Sample Cups, vented.

high purity to permit its use without lessening the accuracy of

7.11 Helium, He—Minimum 99.99 purity for use as a

the determination.

chamber purge gas for the analysis of Cl, P, and S. This

7.2 Purity of Water—Unless otherwise indicated, references

numerical purity is intended to specify a general grade of

to water shall be understood to mean meeting the numerical

helium. Ultra-high purity helium is not required for this test

requirements of Type II water as defined by Specification

method.

D1193.

8. Sample

7.3 Aluminum Oxide, Al O , pre-calcined at 1500 °C, ap-

2 3

8.1 Because of the potential heterogeneous nature of LHW,

proximately 100 to 125 mesh.

all possible efforts should be made to ensure that representative

7.4 Aqueous or Organic-Based Atomic Absorption Stan-

samples are taken.

dards (AAS), 1000 mg/L for the elements Ag, As, Ba, Cd, Cr,

Cu, Fe, Hg, K, Ni, Pb, Sb, Se, Sn, Tl, V, and Zn. Standard

9. Preparation of Apparatus

solutions for elements not listed are also available.

9.1 Follow the manufacturer’s instructions for set-up,

NOTE 1—AAS standards are typically presented in mass/vol units. The

conditioning, preparation, and maintenance of the XRF spec-

density of these solutions can be considered as unity (that is, 1) thus they

trometer.

can be considered as % mass/mass (m/m).

9.2 When required, reference spectra should be obtained

7.5 1-bromonaphthalene, trichlorobenzene, iodobenzoic

from pure element standards for all deconvoluted elements.

acid, triethyl phosphate, and dithiodiglycol are the recom-

mended standards for the elements Br, Cl, I, P and S,

9.3 Spectral and matrix interferences as listed in the Inter-

respectively.

ferences section must be addressed per the manufacturer’s

recommendations.

7.6 Low Molecular Weight Polyethylene Glycol (PEG 400,

or equivalent) or Water is used for producing method blank.

10. Calibration and Standardization

7.7 High-Density Polyethylene (HDPE) Wide Mouth,

10.1 The spectrometer must be calibrated using an appro-

Round, Screw-Cap Bottles, 50 to 60 mL capacity.

priate reference element(s) at a minimum frequency as recom-

mended by the manufacturer.

10.2 Analytical standards should be prepared gravimetri-

Reagent Chemicals, American Chemical Society Specifications, American

Chemical Society, Washington, DC. For suggestions on the testing of reagents not

cally by blending the solution or pure element standards with

listed by the American Chemical Society, see Analar Standards for Laboratory

Al O to suitable standard concentrations as determined by the

2 3

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

user’s analytical requirements. Table 1 gives recommended

and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

MD. concentration ranges for regression. Standards can be single or

D6052 − 97 (2023)

multi-element mixtures. Standard solutions are generally the calibration range, and the other should provide a low net

mixed with Al O at a ratio of 3:1. count rate similar to the blank. Measure the net count rate for

2 3

each element in the high concentration disk in such a way that

NOTE 4—More than one standard element(s) solution can be added to a

the counting statistical error due to random fluctuation of the

single 15 g Al O mass provided the total mass of standard is 5 g. This will

2 3

maintain the proper 3:1 ratio while allowing mixtures of potentially X-ray flux is less than 0.5 % relative to the net count rate.

incompatible elements to be combined in a single standard.

Counting times must be long enough to collect 40 000 net

10.2.1 The number of standards required to produce cali- counts for each element in the high-concentration disk. Use the

brations is dependent on the number of elements to be same counting times when measuring the low-concentration or

determined. Generally, two calibrations are produced, the first

blank disk.

is to determine potentially major elements such as halogens, S

10.4.2 Method B—Fundamental parameters method. Most

and P. The second is to determine trace elements, typically

EDXRF manufacturers provide software capable of estimating

toxic metals and heavy elements. The minimum number of

the composition of materials without the use of a suite of

standards required can be determined from the following

standards. The set-up of a particular manufacturer’s fundamen-

equation: minimum standards required = number elements de-

tal parameters method may require a high and low concentra-

termined plus two. Both of the above calibrations should use a

tion or mid-range concentration for each element present to

minimum of ten standards each to cover the element concen-

determine the initial sensitivity for the elements in the alumina

tration ranges shown in Table 1 and to ensure that adequate

matrix. Other manufacturers provide the initial sensitivity with

data is available to assess spectral overlaps as described in 5.1.

the added option to align the sensitivity to a specific matrix

10.3 The Al O + element(s) specimen is placed into an

type for more accurate determinations using a single similar

2 3

XRF sample cup supported by a suitable thin film. The sample

standard containing the elements of interest. By measuring the

is gently tapped on a flat, hard surface to settle the powder

X-ray intensity (cps) for each element and using the above

against the thin-film support and ensure there are no air gaps.

determined sensitivity factor for each element plus various

10.3.1 The standard specimen in the sample cups is placed

equations to account for X-ray absorption and enhancement

in the spectrometer’s sample holder, avoiding any contact with

effects, the concentration of all elements present can be

the film or rough handling that may disturb the standards.

estimated. The exact equations used will differ for each

manufacturer.

10.4 Two methods of calibration are available.

10.4.1 Method A—Empirical calibration method using a

10.4.2.1 Follow the manufacturer’s fundamental parameters

suite of standard concentrations. Standard concentrations are

set-up recommendations. The stoichiometric set-up of the

limited to 600 mg/kg for Ag, As, Ba, Br, Cd, Cr, Cu, Fe, Hg,

fundamental parameters method for the analysis of the LHW

I, K, Ni, Pb, Sb, Se, Sn, Tl, V, and Zn. Standard concentrations

mixed with alumina should allow for the manual input of a

are limited to 5 % for Cl, P, S, and other light elements (that is,

fixed 75 % Al O concentration and the use of carbon as a

2 3

balance estimate of the solvent/aqueous phase with the ele-

the linear range and due to the limited concentration range of

ments of interest determined directly according to the prin-

available traceable standards. The standards should provide a

ciples of 10.4.2.

linear response of element intensity to concentration. Serial

10.4.3 Two control samples are needed for monitoring

dilutions of analyte standards can be used to set up the

instrument stability. One control sample is a blank preparation

calibration for each element. Multi-element standards can then

using PEG or the low-concentration drift correction monitor

be used to assess the deconvolution requirements of the

used in 10.4.1.1. The other sample is a stable mixture contain-

spectrometer and check for calibration linearity.

ing a suitable range and number of elements (for example, S,

NOTE 5—Standards may be diluted into the linear range using low

V, Zn, Pb, and Ba) at concentrations near the middle of the

molecular weight polyethylene glycol (PEG) or water. The choice of

calibration ranges. A mixture of leftover samples/standards,

diluent is dependent upon whether the original stan

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.