ASTM A716-03

(Specification)Standard Specification for Ductile Iron Culvert Pipe

Standard Specification for Ductile Iron Culvert Pipe

ABSTRACT

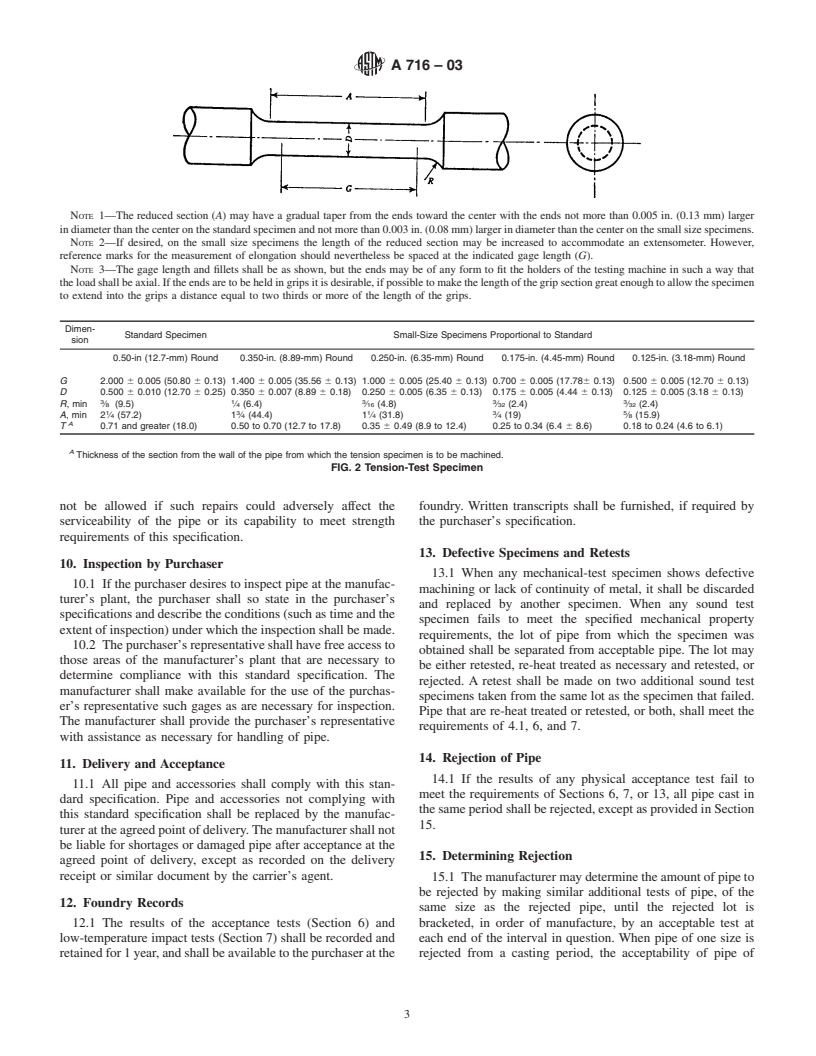

This specification covers ductile-iron culvert pipe centrifugally cast. The pipe shall be manufactured of ductile iron that meets the mechanical requirements such as tensile strength, yield strength, elongation, and impact value. The pipe shall be provided with suitable joints, such as push-on or other types of joints that prevent lateral displacement, but plain-end pipe for use with suitable couplings may be furnished. Standard wall thickness and weight values of push-on joint pipe are given. Pressure Class ductile iron pipe in Type 5 trench is illustrated. All pipe shall be coated inside and outside with an asphaltic material. Acceptance tests by tension and Charpy impact testing shall be performed. The standard test specimens for these testing methods are detailed.

SCOPE

1.1 This specification covers 14 to 64-in. ductile-iron culvert pipe centrifugally cast.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 The following safety hazards caveat pertains only to the test methods portions, Sections 6 and 7, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A 716 – 03

Standard Specification for

1

Ductile Iron Culvert Pipe

This standard is issued under the fixed designation A 716; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

A

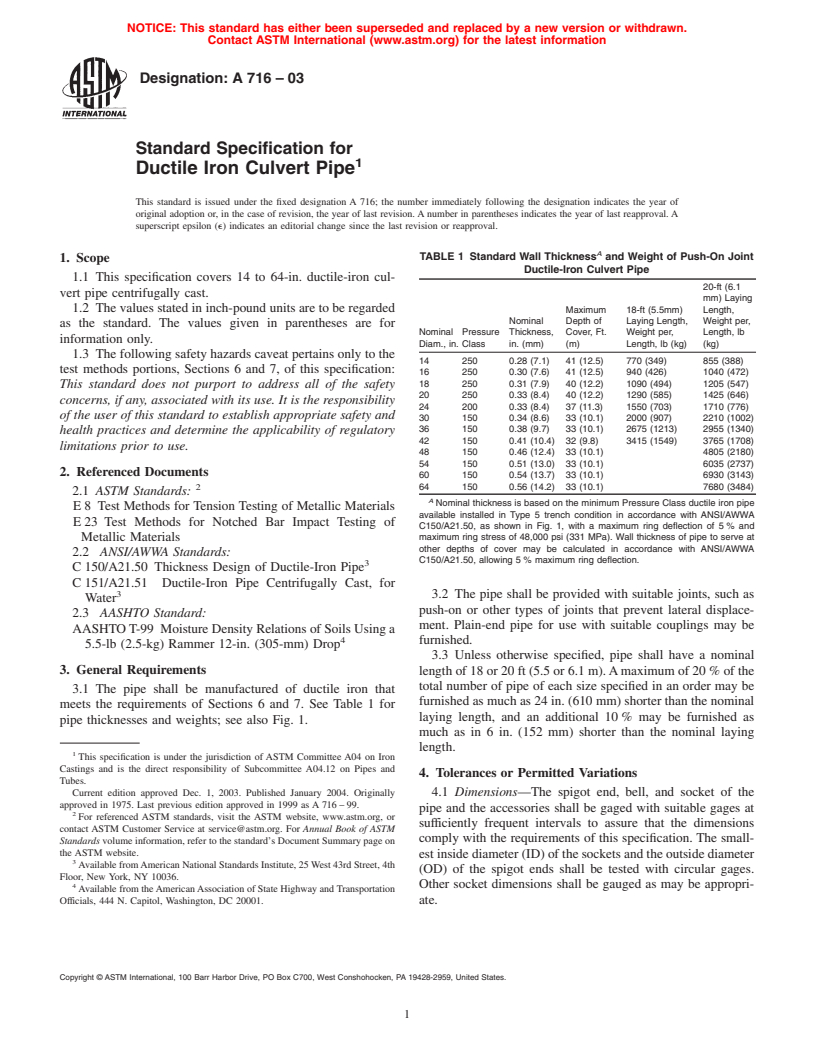

TABLE 1 Standard Wall Thickness and Weight of Push-On Joint

1. Scope

Ductile-Iron Culvert Pipe

1.1 This specification covers 14 to 64-in. ductile-iron cul-

20-ft (6.1

vert pipe centrifugally cast.

mm) Laying

1.2 The values stated in inch-pound units are to be regarded

Maximum 18-ft (5.5mm) Length,

Nominal Depth of Laying Length, Weight per,

as the standard. The values given in parentheses are for

Nominal Pressure Thickness, Cover, Ft. Weight per, Length, lb

information only.

Diam., in. Class in. (mm) (m) Length, lb (kg) (kg)

1.3 The following safety hazards caveat pertains only to the

14 250 0.28 (7.1) 41 (12.5) 770 (349) 855 (388)

test methods portions, Sections 6 and 7, of this specification:

16 250 0.30 (7.6) 41 (12.5) 940 (426) 1040 (472)

18 250 0.31 (7.9) 40 (12.2) 1090 (494) 1205 (547)

This standard does not purport to address all of the safety

20 250 0.33 (8.4) 40 (12.2) 1290 (585) 1425 (646)

concerns, if any, associated with its use. It is the responsibility

24 200 0.33 (8.4) 37 (11.3) 1550 (703) 1710 (776)

of the user of this standard to establish appropriate safety and

30 150 0.34 (8.6) 33 (10.1) 2000 (907) 2210 (1002)

36 150 0.38 (9.7) 33 (10.1) 2675 (1213) 2955 (1340)

health practices and determine the applicability of regulatory

42 150 0.41 (10.4) 32 (9.8) 3415 (1549) 3765 (1708)

limitations prior to use.

48 150 0.46 (12.4) 33 (10.1) 4805 (2180)

54 150 0.51 (13.0) 33 (10.1) 6035 (2737)

2. Referenced Documents

60 150 0.54 (13.7) 33 (10.1) 6930 (3143)

2 64 150 0.56 (14.2) 33 (10.1) 7680 (3484)

2.1 ASTM Standards:

A

Nominal thickness is based on the minimum Pressure Class ductile iron pipe

E8 Test Methods for Tension Testing of Metallic Materials

available installed in Type 5 trench condition in accordance with ANSI/AWWA

E23 Test Methods for Notched Bar Impact Testing of

C150/A21.50, as shown in Fig. 1, with a maximum ring deflection of 5 % and

Metallic Materials maximum ring stress of 48,000 psi (331 MPa). Wall thickness of pipe to serve at

other depths of cover may be calculated in accordance with ANSI/AWWA

2.2 ANSI/AWWA Standards:

C150/A21.50, allowing 5 % maximum ring deflection.

3

C150/A21.50 Thickness Design of Ductile-Iron Pipe

C151/A21.51 Ductile-Iron Pipe Centrifugally Cast, for

3

3.2 The pipe shall be provided with suitable joints, such as

Water

push-on or other types of joints that prevent lateral displace-

2.3 AASHTO Standard:

ment. Plain-end pipe for use with suitable couplings may be

AASHTOT-99 MoistureDensityRelationsofSoilsUsinga

4

furnished.

5.5-lb (2.5-kg) Rammer 12-in. (305-mm) Drop

3.3 Unless otherwise specified, pipe shall have a nominal

3. General Requirements

lengthof18or20ft(5.5or6.1m).Amaximumof20%ofthe

total number of pipe of each size specified in an order may be

3.1 The pipe shall be manufactured of ductile iron that

furnishedasmuchas24in.(610mm)shorterthanthenominal

meets the requirements of Sections 6 and 7. See Table 1 for

laying length, and an additional 10% may be furnished as

pipe thicknesses and weights; see also Fig. 1.

much as in 6 in. (152 mm) shorter than the nominal laying

length.

1

This specification is under the jurisdiction of ASTM Committee A04 on Iron

Castings and is the direct responsibility of Subcommittee A04.12 on Pipes and

4. Tolerances or Permitted Variations

Tubes.

Current edition approved Dec. 1, 2003. Published January 2004. Originally

4.1 Dimensions—The spigot end, bell, and socket of the

approved in 1975. Last previous edition approved in 1999 as A716–99.

pipe and the accessories shall be gaged with suitable gages at

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

sufficiently frequent intervals to assure that the dimensions

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

comply with the requirements of this specification. The small-

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

estinsidediameter(ID)ofthesocketsandtheoutsidediameter

3

AvailablefromAmericanNationalStandardsInstitute,25West43rdStreet,4th

(OD) of the spigot ends shall be tested with circular gages.

Floor, New York, NY 10036.

4

Other socket dimensions shall be gauged as may be appropri-

Available from theAmericanAssociation of State Highway andTransportation

Officials, 444 N. Capitol, Washington, DC 20001. ate.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.