ASTM F568M-02

(Specification)Standard Specification for Carbon and Alloy Steel Externally Threaded Metric Fasteners

Standard Specification for Carbon and Alloy Steel Externally Threaded Metric Fasteners

SCOPE

1.1 This specification covers chemical and mechanical requirements for nine property classes of carbon and alloy steel externally threaded metric fasteners in nominal thread diameters M1.6 through M100 suited for use in general engineering applications.

1.2 This specification does not cover dimensional requirements for fasteners of any property class. When referencing this specification for procurement purposes, it is mandatory that size, type, style, and any special dimensions of the product be additionally specified.

1.2.1 In case of any conflict in requirements, the requirements of the individual product specification shall take precedence over those of this general specification.

1.2.2 The purchaser may specify additional requirements which do not negate any of the provisions of this general specification or of the individual product specification. Such additional requirements, the acceptance of which are subject to negotiation with the supplier, must be included in the order information (see Section ).

1.3 Requirements for seven of the nine property classes, 4.6, 4.8, 5.8, 8.8, 9.8, 10.9, and 12.9, are essentially identical with requirements given for these classes in ISO 898-1. The other two, 8.8.3 and 10.9.3, are not recognized in ISO standards.

1.4 Classes 8.8.3 and 10.9.3 bolts, screws, and studs have atmospheric corrosion resistance and weathering characteristics comparable to those of the steels covered in Specification A 588. The atmospheric corrosion resistance of these steels is substantially better than that of carbon steel with or without copper addition. See . When properly exposed to the atmosphere, these steels can be used bare (uncoated) for many applications.

1.5 When agreed on by the purchaser, Class 5.8 fasteners may be supplied when either Classes 4.6 or 4.8 are ordered; Class 4.8 may be supplied when Class 4.6 is ordered; Class 8.8.3 may be supplied when Class 8.8 is ordered; and Class 10.9.3 may be supplied when Class 10.9 is ordered.

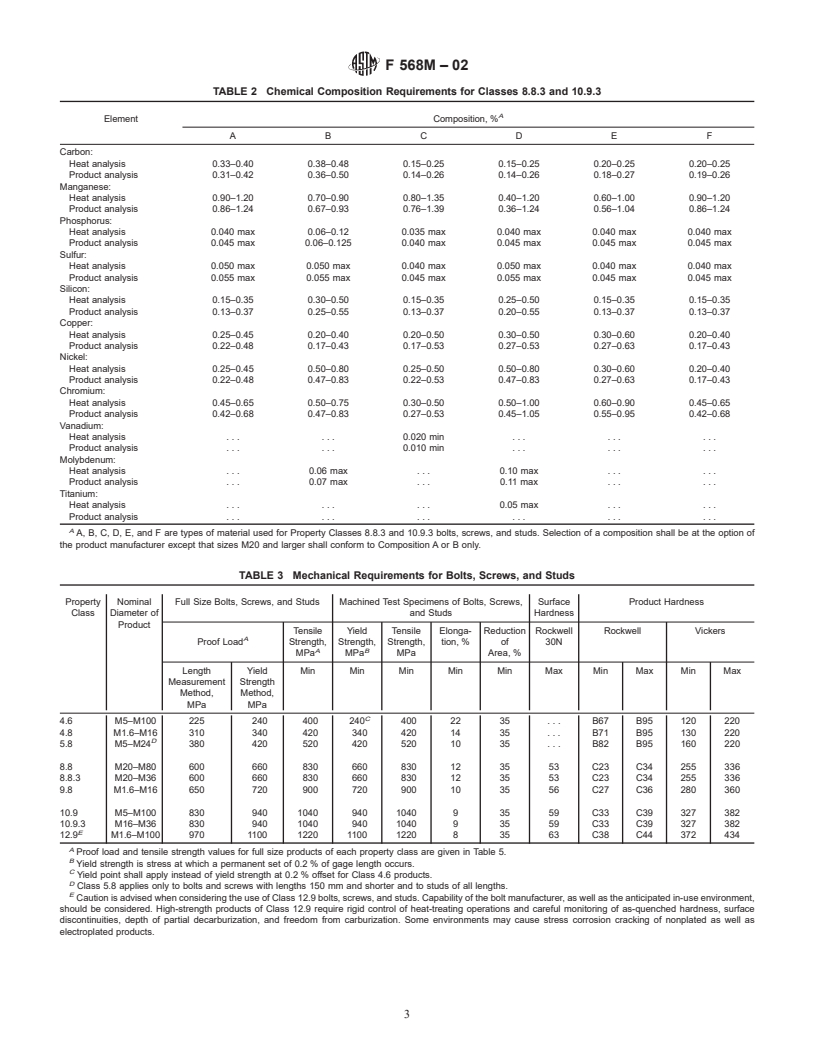

1.6 The product size range for which each property class is applicable is given in Table 1 and Table 2 on chemical composition requirements, and the mechanical requirements table (see Table 3).

1.7 Appendix X1 gives conversion guidance to assist designers and purchasers in the selection of a suitable property class.

1.8 Appendix X2 explains the significance of the property class designation numerals.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F 568M – 02

METRIC

Standard Specification for

Carbon and Alloy Steel Externally Threaded Metric

1

Fasteners

This standard is issued under the fixed designation F 568M; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* Class 4.8 may be supplied when Class 4.6 is ordered; Class

8.8.3 may be supplied when Class 8.8 is ordered; and Class

1.1 This specification covers chemical and mechanical re-

10.9.3 may be supplied when Class 10.9 is ordered.

quirements for nine property classes of carbon and alloy steel

1.6 The product size range for which each property class is

externally threaded metric fasteners in nominal thread diam-

applicable is given in Table 1 and Table 2 on chemical

eters M1.6 through M100 suited for use in general engineering

composition requirements, and the mechanical requirements

applications.

table (see Table 3).

1.2 This specification does not cover dimensional require-

1.7 Appendix X1 gives conversion guidance to assist de-

ments for fasteners of any property class. When referencing

signers and purchasers in the selection of a suitable property

this specification for procurement purposes, it is mandatory

class.

that size, type, style, and any special dimensions of the product

1.8 Appendix X2 explains the significance of the property

be additionally specified.

class designation numerals.

1.2.1 In case of any conflict in requirements, the require-

ments of the individual product specification shall take prece-

2. Referenced Documents

dence over those of this general specification.

2.1 ASTM Standards:

1.2.2 The purchaser may specify additional requirements

A 153 Specification for Zinc Coating (Hot-Dip) on Iron and

which do not negate any of the provisions of this general

2

Steel Hardware

specification or of the individual product specification. Such

A 307 Specification for Carbon Steel Bolts and Studs,

additional requirements, the acceptance of which are subject to

3

60 000 psi Tensile Strength

negotiation with the supplier, must be included in the order

A 325 Specification for Structural Bolts, Steel, Heat

information (see Section 3).

3

Treated, 120/105 ksi Minimum Tensile Strength

1.3 Requirements for seven of the nine property classes, 4.6,

A 325M Specification for High-Strength Bolts for Struc-

4.8, 5.8, 8.8, 9.8, 10.9, and 12.9, are essentially identical with

3

tural Steel Joints [Metric]

requirements given for these classes in ISO 898-1. The other

A 354 Specification for Quenched and Tempered Alloy

two, 8.8.3 and 10.9.3, are not recognized in ISO standards.

Steel Bolts, Studs, and Other Externally Threaded Fasten-

1.4 Classes 8.8.3 and 10.9.3 bolts, screws, and studs have

3

ers

atmospheric corrosion resistance and weathering characteris-

A 449 Specification for Quenched and Tempered Steel

tics comparable to those of the steels covered in Specification

3

Bolts and Studs

A 588. The atmospheric corrosion resistance of these steels is

A 490 Specification for Heat-Treated Steel Structural Bolts,

substantially better than that of carbon steel with or without

3

150 ksi Minimum Tensile Strength

copper addition. See 5.2. When properly exposed to the

A 490M Specification for High-Strength Steel Bolts,

atmosphere, these steels can be used bare (uncoated) for many

Classes 10.9 and 10.9.3, for Structural Steel Joints [Met-

applications.

3

ric]

1.5 When agreed on by the purchaser, Class 5.8 fasteners

A 574 Specification for Alloy Steel Socket-Head Cap

may be supplied when either Classes 4.6 or 4.8 are ordered;

3

Screws

A 588/A588M Specification for High-Strength Low-Alloy

1

This specification is under the jurisdiction of ASTM Committee F16 on

Fasteners and is the direct responsibility of Subcommittee F16.02 on Steel Bolts,

Nuts, Rivets and Washers.

2

Current edition approved Oct. 10, 2002. Published November 2002. Originally Annual Book of ASTM Standards, Vol 01.06.

3

published as F 568 – 79. Last previous edition F 568 – 98. Annual Book of ASTM Standards, Vol 01.08.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F 568M – 02

TABLE 1 Chemical Composition Requirements

Property Nominal Product Product Analysis Element (% by weight) Tempering

Class Diameter, mm Temperature, °C

Material and Treatment CMn B P S

Min Max Min Min Max Max Min

4.6 M5–M100 low or medium carbon steel . . . 0.55 . . . . . . 0.048 0.058 . . .

4.8 M1.6–M

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.