ASTM F1160-05(2011)e1

(Test Method)Standard Test Method for Shear and Bending Fatigue Testing of Calcium Phosphate and Metallic Medical and Composite Calcium Phosphate/Metallic Coatings

Standard Test Method for Shear and Bending Fatigue Testing of Calcium Phosphate and Metallic Medical and Composite Calcium Phosphate/Metallic Coatings

SIGNIFICANCE AND USE

The shear and bending fatigue tests are used to determine the effect of variations in material, geometry, surface condition, stress, and so forth, on the fatigue resistance of coated metallic materials subjected to direct stress for up to 107 cycles. These tests may be used as a relative guide to the selection of coated materials for service under condition of repeated stress.

In order that such basic fatigue data be comparable, reproducible, and can be correlated among laboratories, it is essential that uniform fatigue practices be established.

The results of the fatigue test may be used for basic material property design. Actual components should not be tested using these test methods.

SCOPE

1.1 This test method covers the procedure for determining the shear and bending fatigue performance of calcium phosphate coatings and of porous and nonporous metallic coatings and for determining the bending fatigue performance of metallic coatings oversprayed with calcium phosphate. This test method has been established based on plasma-sprayed titanium and plasma-sprayed hydroxylapatite coatings. The efficacy of this test method for other coatings has not been established. In the shear fatigue mode, this test method evaluates the adhesive and cohesive properties of the coating on a metallic substrate. In the bending fatigue mode, this test method evaluates both the adhesion of the coating as well as the effects that the coating may have on the substrate material. These methods are limited to testing in air at ambient temperature. These test methods are not intended for application in fatigue tests of components or devices; however, the test method which most closely replicates the actual loading configuration is preferred.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: F1160 − 05(Reapproved 2011)

Standard Test Method for

Shear and Bending Fatigue Testing of Calcium Phosphate

and Metallic Medical and Composite Calcium Phosphate/

Metallic Coatings

This standard is issued under the fixed designation F1160; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—Units information was editorially corrected in January 2012.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 This test method covers the procedure for determining

E6 Terminology Relating to Methods of Mechanical Testing

the shear and bending fatigue performance of calcium phos-

E206 Definitions of Terms Relating to Fatigue Testing and

phate coatings and of porous and nonporous metallic coatings

the Statistical Analysis of Fatigue Data; Replaced by

and for determining the bending fatigue performance of

E 1150 (Withdrawn 1988)

metallic coatings oversprayed with calcium phosphate. This

E466 Practice for Conducting Force Controlled Constant

test method has been established based on plasma-sprayed

Amplitude Axial Fatigue Tests of Metallic Materials

titanium and plasma-sprayed hydroxylapatite coatings. The

E467 Practice for Verification of Constant Amplitude Dy-

efficacy of this test method for other coatings has not been

namic Forces in an Axial Fatigue Testing System

established. In the shear fatigue mode, this test method

E468 Practice for Presentation of Constant Amplitude Fa-

evaluates the adhesive and cohesive properties of the coating

tigue Test Results for Metallic Materials

on a metallic substrate. In the bending fatigue mode, this test

E1012 Practice for Verification of Testing Frame and Speci-

method evaluates both the adhesion of the coating as well as

men Alignment Under Tensile and Compressive Axial

the effects that the coating may have on the substrate material.

Force Application

These methods are limited to testing in air at ambient tempera-

ture. These test methods are not intended for application in

3. Definitions

fatigue tests of components or devices; however, the test

3.1 The definitions of terms relating to shear and fatigue

method which most closely replicates the actual loading

testing appearing in Terminology E6 shall be considered as

configuration is preferred.

applying to the terms used in this test method.

1.2 The values stated in either SI units or inch-pound units

4. Summary of Test Method

are to be regarded separately as standard. The values stated in

each system may not be exact equivalents; therefore, each 4.1 Shear Fatigue Testing:

4.1.1 The intent of the shear fatigue test is to determine the

system shall be used independently of the other. Combining

adhesive or cohesive strength, or both, of the coating.

values from the two systems may result in non-conformance

4.1.2 This test method is designed to allow the coating to

with the standard.

fail at either the coating/substrate interface, within the coating,

1.3 This standard does not purport to address all of the

or at the glue/coating interface between the coating and the

safety concerns, if any, associated with its use. It is the

adhesivebondingagentusedtotransmittheloadtothecoating.

responsibility of the user of this standard to establish appro-

4.2 Bending Fatigue Testing:

priate safety and health practices and determine the applica-

4.2.1 The primary intent of the bending fatigue test is to

bility of regulatory limitations prior to use.

quantify the effect that the coating has on the substrate it is

1 2

This test method is under the jurisdiction ofASTM Committee F04 on Medical For referenced ASTM standards, visit the ASTM website, www.astm.org, or

and Surgical Materials and Devices and is the direct responsibility of Subcommittee contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

F04.15 on Material Test Methods. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Oct. 1, 2011. Published January 2012. Originally the ASTM website.

approved in 1991. Last previous edition approved in 2005 as F1160 – 05. DOI: The last approved version of this historical standard is referenced on

10.1520/F1160-05R11E01. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

F1160 − 05 (2011)

applied to. Secondarily, it may be used to provide a subjective

evaluation of coating adhesion, (that is, spalling resistance,

cracking resistance, and so forth).

4.2.2 Thistestmethodisdesignedtofirstprovideasubstrate

fatiguestrengthtoserveasabaselinetoassesstheeffectsofthe

coating on the resulting fatigue strength of the system.

5. Significance and Use

5.1 The shear and bending fatigue tests are used to deter-

mine the effect of variations in material, geometry, surface

condition, stress, and so forth, on the fatigue resistance of

coatedmetallicmaterialssubjectedtodirectstressforupto10

cycles. These tests may be used as a relative guide to the

selection of coated materials for service under condition of

repeated stress.

5.2 In order that such basic fatigue data be comparable,

reproducible, and can be correlated among laboratories, it is

essential that uniform fatigue practices be established.

5.3 The results of the fatigue test may be used for basic

material property design. Actual components should not be

tested using these test methods.

FIG. 2 Adaptor to Mate the Gripping Device to the Tensile Ma-

chine

6. Equipment Characteristics

6.1 Equipment characteristics shall be in accordance with

Practice E466, Section 7. See also Practices E467 and E1012

and Definitions E206.

6.2 Shear Fatigue Test Grips:

6.2.1 General—Various types of grips may be used to

transmit the load to the specimens by the testing machine. To

ensure axial shear stress, it is important that the specimen axis

coincide with the centerline of the heads of the testing machine

and that the coating test plane be parallel to the axial load.Any

departure from this requirement (that is, any eccentric loading)

FIG. 3 Schematic of the Shear Test Setup

will introduce bending stresses that are not included in the

usual stress calculation (force/cross-sectional area).

6.2.2 A drawing of a typical gripping device for the test

assembly is shown in Fig. 1.

6.3 Bending Fatigue Test Grips—There are a variety of

6.2.3 Fig. 2 shows a drawing of the adaptor to mate the

testing machines that may be employed for this test (that is,

shear fixture to the tensile machine

rotating beam fatigue machines and axial fatigue machines).

6.2.4 Figs. 3 and 4 show a schematics of the test setup.

The gripping method for each type of equipment shall be

determined by either the manufacturer of that equipment

(rotating beam machines) or the user.

7. Adhesive Bonding Materials

7.1 Adhesive Bonding Agent—A polymeric adhesive bond-

ing agent in film form, or filled viscous adhesive cement, shall

be identified and shall meet the following requirements.

7.1.1 The bonding agent shall be capable of bonding the

coating on the test specimen components with an adhesive

shear strength that is at least 34.5 MPa [5000 psi] or as great as

the minimum required adhesion or cohesion strength of the

coating, whichever is greater.

7.1.2 In instances where coating porosity extends to the

coating/substrate interface, the bonding agent shall be suffi-

ciently viscous and application to the coating sufficiently

FIG. 1 Gripping Device for Shear Testing detailed, to ensure that it will not penetrate through the coating

´1

F1160 − 05 (2011)

equipment capacity, and the form in which the material is

available. However, the design must meet certain general

criteria as follows:

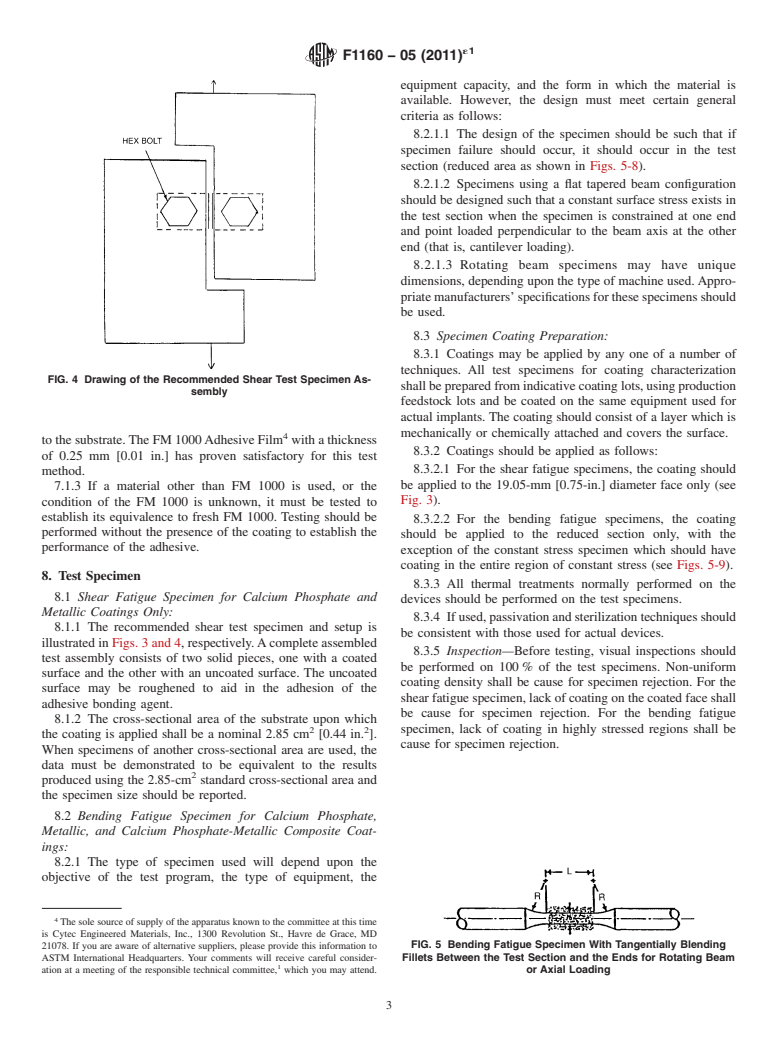

8.2.1.1 The design of the specimen should be such that if

specimen failure should occur, it should occur in the test

section (reduced area as shown in Figs. 5-8).

8.2.1.2 Specimens using a flat tapered beam configuration

should be designed such that a constant surface stress exists in

the test section when the specimen is constrained at one end

and point loaded perpendicular to the beam axis at the other

end (that is, cantilever loading).

8.2.1.3 Rotating beam specimens may have unique

dimensions, depending upon the type of machine used.Appro-

priatemanufacturers’specificationsforthesespecimensshould

be used.

8.3 Specimen Coating Preparation:

8.3.1 Coatings may be applied by any one of a number of

techniques. All test specimens for coating characterization

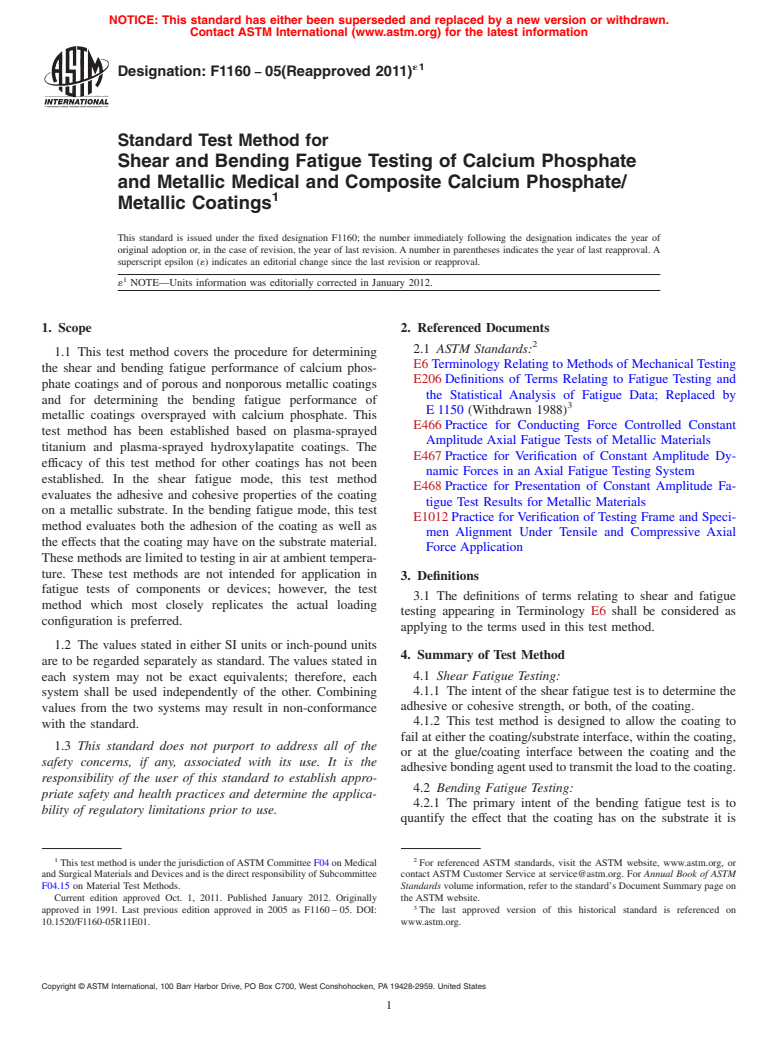

FIG. 4 Drawing of the Recommended Shear Test Specimen As-

shallbepreparedfromindicativecoatinglots,usingproduction

sembly

feedstock lots and be coated on the same equipment used for

actual implants. The coating should consist of a layer which is

mechanically or chemically attached and covers the surface.

to the substrate.The FM 1000Adhesive Film with a thickness

8.3.2 Coatings should be applied as follows:

of 0.25 mm [0.01 in.] has proven satisfactory for this test

8.3.2.1 For the shear fatigue specimens, the coating should

method.

be applied to the 19.05-mm [0.75-in.] diameter face only (see

7.1.3 If a material other than FM 1000 is used, or the

Fig. 3).

condition of the FM 1000 is unknown, it must be tested to

establish its equivalence to fresh FM 1000. Testing should be

8.3.2.2 For the bending fatigue specimens, the coating

performed without the presence of the coating to establish the

should be applied to the reduced section only, with the

performance of the adhesive.

exception of the constant stress specimen which should have

coating in the entire region of constant stress (see Figs. 5-9).

8. Test Specimen

8.3.3 All thermal treatments normally performed on the

8.1 Shear Fatigue Specimen for Calcium Phosphate and

devices should be performed on the test specimens.

Metallic Coatings Only:

8.3.4 Ifused,passivationandsterilizationtechniquesshould

8.1.1 The recommended shear test specimen and setup is

be consistent with those used for actual devices.

illustrated in Figs. 3 and 4, respectively.Acomplete assembled

8.3.5 Inspection—Before testing, visual inspections should

test assembly consists of two solid pieces, one with a coated

be performed on 100 % of the test specimens. Non-uniform

surface and the other with an uncoated surface. The uncoated

coating density shall be cause for specimen rejection. For the

surface may be roughened to aid in the adhesion of the

shear fatigue specimen, lack of coating on the coated face shall

adhesive bonding agent.

be cause for specimen rejection. For the bending fatigue

8.1.2 The cross-sectional area of the substrate upon which

2 2 specimen, lack of coating in highly stressed regions shall be

the coating is applied shall be a nominal 2.85 cm [0.44 in. ].

cause for specimen rejection.

When specimens of another cross-sectional area are used, the

data must be demonstrated to be equivalent to the results

produced using the 2.85-cm standard cross-sectional area and

the specimen size should be reported.

8.2 Bending Fatigue Specimen for Calcium Phosphate,

Metallic, and Calcium Phosphate-Metallic Composite Coat-

ings:

8.2.1 The type of specimen used will depend upon the

objective of the test program, the type of equipment, the

The sole source of supply of the apparatus known to the committee at this time

is Cytec Engineered Materials, Inc., 1300 Revolution St., Havre de Grace, MD

FIG. 5 Bending Fatigue Specimen With Tangentially Blending

21078. If you are aware of alternative suppliers, please provide this information to

ASTM International Headquarters. Your comments will receive careful consider- Fillets Between the Test Section and the Ends for Rotating Beam

ation at a meeting of the responsible technical committee, which you may attend. or Axial Loading

´1

F1160 − 05 (2011)

9.4.1.2 Apply a constant force using a calibrated high

temperature spring, resulting in a stress of 0.138 MPa [20 psi]

between the coating and the opposing device that will test the

coating.

FIG. 6 Specimens With a Continuous Radius Between the Ends 9.4.1.2.1

for Rotating Beam or Axial loading

Care must be taken to maintain alignment of the coating and

the matching counterface during the test.

9.4.1.3 Place the assembly in an oven and heat at 176°C for

2–3 h.

9.4.1.3.1

The exact amount of time necessary to cure the adhesive will

need to be determined by each user, as oven temperature may

FIG. 7 Specimens With Tangentially Blending Fillets Between the

vary with load size and oven type. It is suggested that the

Uniform Test Section and the Ends for Axial Loading

curing cycle be optimized first without the coating present.

9.4.1.4 Remove the cured assembly from the oven and

allow it to cool to room temperature.

9.4.1.5 Remove all excess adhesive which has protruded

fromthecoatedsurface.Thisprocessmustnotcompromisethe

integrity of the sample.

9.4.2 Place the specimen assembly in the grips so that the

FIG. 8 Specimens With a Continuous Radius Between the Ends

for Axial Loading long axis of the specimen is perpendicular to the direction of

the applied shear load through the centerline of the grip

assembly (see Fig. 3).

9.4.3 Specimens for which the adhesive has penetrated to

the substrate shall be discarded and the results not included in

the analysis and report.

9.5 Bending Fatigue Specimens:

9.5.1 Appropriate testing of the uncoated substrate material,

uponwhichthecoatingwillbeapplied,shouldbeperformedto

establish a baseline from which to assess the effect of the

FIG. 9 Tapered Beam Configuration for Bend Testing

coating.

9.5.1.1 The baseline test specimens may or may not be

9. Procedure

grit-blasted depending upon the objective of the test. In either

9.1 Thenumberofspecimensrequiredfortesting,aswellas

event, the surface roughness should be reported.

the test methods in which the fatigue data may be interpreted,

9.5.1.2 For composite calcium phosphate-metallic coatings,

can vary. Several test methods are referenced in this test

additional baseline testing of specimens with only the metallic

5,6,7

method.

coating should also be preformed to allow an assessment of the

effects of each coating.

9.2 The type of specimen used will depend upon the

9.5.2 When mounting the specimen, alignment is crucial.

objective of the test program, the type of equipment available,

Factors such as poorly machined specimens and misalignment

the equipment capacity, and the form in which the material is

of machine parts might result in excessive vibration leading to

available. The specimen chosen should come as close to

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.