ASTM D6079-11

(Test Method)Standard Test Method for Evaluating Lubricity of Diesel Fuels by the High-Frequency Reciprocating Rig (HFRR)

Standard Test Method for Evaluating Lubricity of Diesel Fuels by the High-Frequency Reciprocating Rig (HFRR)

SIGNIFICANCE AND USE

Diesel fuel injection equipment has some reliance on lubricating properties of the diesel fuel. Shortened life of engine components, such as diesel fuel injection pumps and injectors, has sometimes been ascribed to lack of lubricity in a diesel fuel.

The trend of HFRR test results to diesel injection system pump component distress due to wear has been demonstrated in pump rig tests for some fuel/hardware combinations where boundary lubrication is believed to be a factor in the operation of the component.

The wear scar generated in the HFRR test is sensitive to contamination of the fluids and test materials, the temperature of the test fuel, and the ambient relative humidity. Lubricity evaluations are also sensitive to trace contaminants acquired during test fuel sampling and storage.

The HFRR and Scuffing Load Ball on Cylinder Lubricity Evaluator (SLBOCLE, Test Method D6078) are two methods for evaluating diesel fuel lubricity. No absolute correlation has been developed between the two test methods.

The HFRR may be used to evaluate the relative effectiveness of diesel fuels for preventing wear under the prescribed test conditions. Correlation of HFRR test results with field performance of diesel fuel injection systems has not yet been determined.

This test method is designed to evaluate boundary lubrication properties. While viscosity effects on lubricity in this test method are not totally eliminated, they are minimized.

SCOPE

1.1 This test method covers the evaluation of the lubricity of diesel fuels using a high-frequency reciprocating rig (HFRR).

1.2 This test method is applicable to middle distillate fuels, such as Grades No. 1-D S15, S500, and S5000, and Grades No. 2-D S15, S500, and S5000 diesel fuels, in accordance with Specification D975; and other similar petroleum-based fuels which can be used in diesel engines. This test method is applicable to biodiesel blends. B5 was included in the round robin program that determined the precision statement.

Note 1—It is not known that this test method will predict the performance of all additive/fuel combinations. Additional work is underway to establish this correlation and future revisions of this test method may be necessary once this work is complete.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicable regulatory limitations prior to use. Specific warning statements are given in Section 7.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6079 − 11

StandardTest Method for

Evaluating Lubricity of Diesel Fuels by the High-Frequency

1

Reciprocating Rig (HFRR)

This standard is issued under the fixed designation D6079; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* D4177Practice for Automatic Sampling of Petroleum and

Petroleum Products

1.1 Thistestmethodcoverstheevaluationofthelubricityof

D4306Practice for Aviation Fuel Sample Containers for

diesel fuels using a high-frequency reciprocating rig (HFRR).

Tests Affected by Trace Contamination

1.2 This test method is applicable to middle distillate fuels,

D6078TestMethodforEvaluatingLubricityofDieselFuels

suchasGradesNo.1-DS15,S500,andS5000,andGradesNo.

by the Scuffing Load Ball-on-Cylinder Lubricity Evalua-

2-D S15, S500, and S5000 diesel fuels, in accordance with

tor (SLBOCLE)

Specification D975; and other similar petroleum-based fuels

E18Test Methods for Rockwell Hardness of Metallic Ma-

which can be used in diesel engines. This test method is

terials

applicable to biodiesel blends. B5 was included in the round

E92TestMethodforVickersHardnessofMetallicMaterials

robin program that determined the precision statement. 3

(Withdrawn 2010)

4

2.2 SAE Standard:

NOTE 1—It is not known that this test method will predict the

performance of all additive/fuel combinations.Additional work is under-

SAE-AMS 6440Steel, Bars, Forgings, and Tubing, 1.45 Cr

way to establish this correlation and future revisions of this test method

(0.93-1.05C) (SAE 52100), for Bearing Applications

may be necessary once this work is complete. 5

2.3 ISO Standard:

1.3 The values stated in SI units are to be regarded as

ISO 3290Roller Bearings, Balls – Dimensions and toler-

standard. No other units of measurement are included in this

ances

standard.

3. Terminology

1.4 This standard does not purport to address all of the

3.1 Definitions:

safety concerns, if any, associated with its use. It is the

3.1.1 boundary lubrication, n—a condition in which the

responsibility of the user of this standard to establish appro-

friction and wear between two surfaces in relative motion are

priate safety and health practices and determine the applicable

determined by the properties of the surfaces and the properties

regulatory limitations prior to use.Specificwarningstatements

of the contacting fluid, other than bulk viscosity.

are given in Section 7.

3.1.1.1 Discussion—Metal to metal contact occurs and the

chemistry of the system is involved. Physically adsorbed or

2. Referenced Documents

2 chemically reacted soft films (usually very thin) support

2.1 ASTM Standards:

contact loads. As a result, some wear is inevitable.

D975Specification for Diesel Fuel Oils

3.1.2 lubricity, n—a qualitative term describing the ability

D4057Practice for Manual Sampling of Petroleum and

of a fluid to affect friction between, and wear to, surfaces in

Petroleum Products

relative motion under load.

3.1.2.1 Discussion—In this test method, the lubricity of a

1 fluid is evaluated by the wear scar, in microns, produced on an

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of oscillatingballfromcontactwithastationarydiskimmersedin

Subcommittee D02.E0 on Burner, Diesel, Non-Aviation Gas Turbine, and Marine

the fluid operating under defined and controlled conditions.

Fuels.

Current edition approved March 1, 2011. Published April 2011. Originally 3.2 Abbreviations:

ε1

approved in 1999. Last previous edition approved in 2004 as D6079–04 . DOI:

10.1520/D6079-11.

3

This test method was developed by ISO/TC22/SC7/WG6 and is a part of ISO The last approved version of this historical standard is referenced on

12156. www.astm.org.

2 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or AvailablefromSAEInternational(SAE),400CommonwealthDr.,Warrendale,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM PA 15096-0001, http://www.sae.org.

5

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D6079 − 11

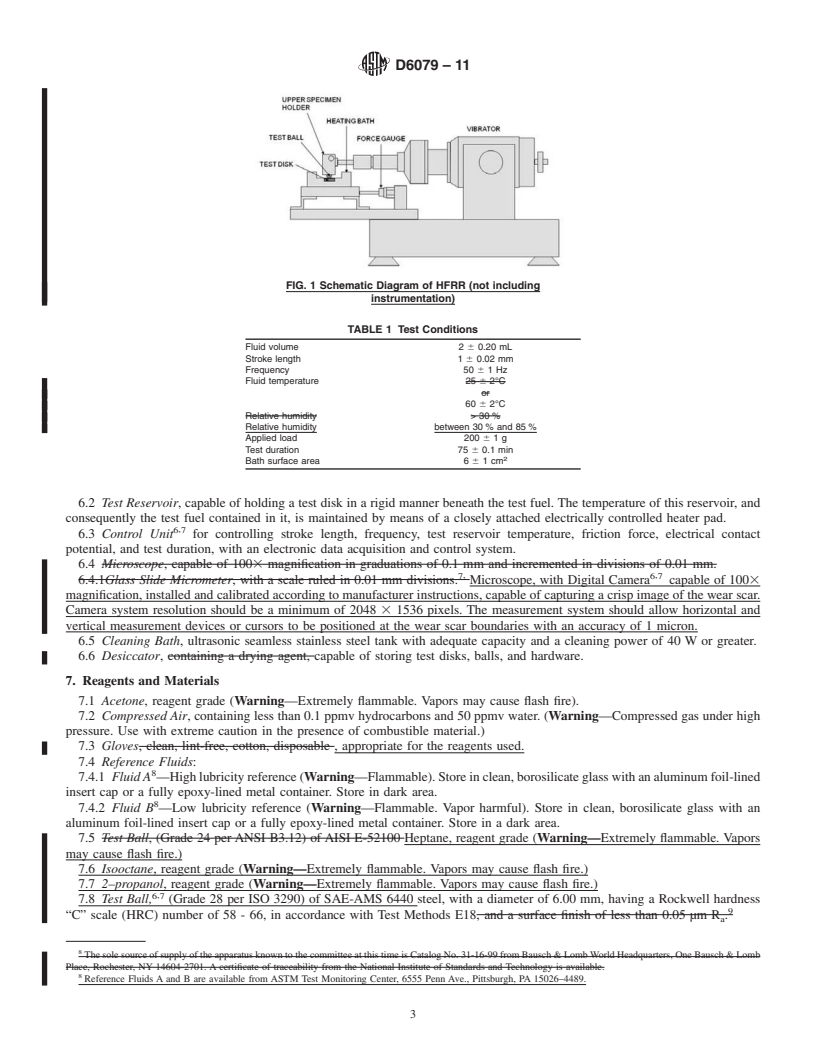

3.2.1 HFRR—high frequency reciprocating rig

3.2.2 WSD—wear scar diameter

4. Summary of Test Method

4.1 A 2-mL test specimen

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation:D6079–04 Designation:D6079–11

Standard Test Method for

Evaluating Lubricity of Diesel Fuels by the High-Frequency

1

Reciprocating Rig (HFRR)

This standard is issued under the fixed designation D6079; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

´ NOTE—Editorial changes were made throughout in April 2005.

1. Scope*

1.1 This test method covers the evaluation of the lubricity of diesel fuels using a high-frequency reciprocating rig (HFRR).

1.2This test method is applicable to middle distillate fuels, such as Grades Low Sulfur No. 1 D, Low Sulfur No. 2 D, No. 1 D,

and No. 2 D diesel fuels, in accordance with Specification

1.2 This test method is applicable to middle distillate fuels, such as Grades No. 1-D S15, S500, and S5000, and Grades No. 2-D

S15, S500, and S5000 diesel fuels, in accordance with Specification D975; and other similar petroleum-based fuels which can be

used in diesel engines ; and other similar petroleum-based fuels which can be used in diesel engines.This test method is applicable

to biodiesel blends. B5 was included in the round robin program that determined the precision statement.

NOTE 1—It is not known that this test method will predict the performance of all additive/fuel combinations. Additional work is underway to further

establish this correlation and future revisions of this test method may be necessary once this work is complete.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicable regulatory limitations

prior to use. Specific warning statements are given in Section 7.

2. Referenced Documents

2

2.1 ASTM Standards:

D975 Specification for Diesel Fuel Oils

D4057 Practice for Manual Sampling of Petroleum and Petroleum Products

D4177 Practice for Automatic Sampling of Petroleum and Petroleum Products

D4306 Practice for Aviation Fuel Sample Containers for Tests Affected by Trace Contamination

D6078 Test Method for Evaluating Lubricity of Diesel Fuels by the Scuffing Load Ball-on-Cylinder Lubricity Evaluator

(SLBOCLE)

E18 Test Methods for Rockwell Hardness of Metallic Materials

E92 Test Method for Vickers Hardness of Metallic Materials

3

2.2 American Iron and Steel Institute Standard:SAE Standard:

AISI E-52100Chromium Alloy Steel

SAE-AMS 6440 Steel, Bars, Forgings, and Tubing, 1.45 Cr (0.93-1.05C) (SAE 52100), for Bearing Applications

4

2.3 American National Standards Institute Standard:ISO Standard:

ANSI B3.12Metal Balls

ISO 3290 Roller Bearings, Balls – Dimensions and tolerances

1

This test method is under the jurisdiction ofASTM Committee D02 on Petroleum Products and Lubricants and is the direct responsibility of Subcommittee D02.E0 on

Burner, Diesel, Non-Aviation Gas Turbine, and Marine Fuels.

Current edition approved Nov.March 1, 2004.2011. Published November 2004.April 2011. Originally approved in 1999. Last previous edition approved in 20022004 as

´1

D6079–04 . DOI: 10.1520/D6079-11.

This test method was developed by ISO/TC22/SC7/WG6 and is a part of ISO 12156. DOI: 10.1520/D6079-04E01.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American Iron and Steel Institute (AISI), 1140 Connecticut Ave., Suite 705, Washington, DC 20036.

3

Available from SAE International (SAE), 400 Commonwealth Dr., Warrendale, PA 15096-0001, http://www.sae.org.

4

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D6079–11

3. Terminology

3.1Definitions of Terms Specific to This Standard:

3.1 Definitions:

3.1.1 boundary lubrication, n—a condition in which the friction and wear

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.