ASTM F2408-09

(Specification)Standard Specification for Ornamental Fences Employing Galvanized Steel Tubular Pickets

Standard Specification for Ornamental Fences Employing Galvanized Steel Tubular Pickets

ABSTRACT

This specification establishes the minimum requirements for coated tubular picket ornamental fence systems fabricated from galvanized steel components. Steel material for tubular picket ornamental fence system structural components shall be galvanized by the hot-dip process, either after forming, or prior to forming. Powder coatings applied to the exterior surface of fence components shall be polymer material: polyester or epoxy and polyester combinations. Wet coating applied to the exterior surface of fence components shall be a two-coat paint application system (one coat of epoxy, polyester or polyurethane primer; one coat of polyester, polyurethane, or acrylic liquid). Fittings, fasteners, and decorative accessories for ornamental steel fence systems shall be manufactured with a material and finish coating that meets the same protective coating performance requirements as required for panels and posts. Four structural test methods shall be conducted: Method A which is application of horizontal concentrated load, Method B which is application of vertical concentrated load, Method C which is application of horizontal thrust load to infill areas, and Method D which is application of horizontal cone penetration load. Different tests shall also be performed in order to determine the following properties of the fence system coatings: adhesion, corrosion resistance, impact resistance, and weathering resistance.

SCOPE

1.1 This specification establishes the minimum requirements for coated tubular picket ornamental fence systems fabricated from galvanized steel components.

1.2 The requirements of this specification do not apply to vertical bar fence systems utilizing solid bar or wrought iron materials.

1.3 The values stated with in-pound units are to be regarded as standard. The SI values in parentheses are provided for information.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F2408 – 09

Standard Specification for

Ornamental Fences Employing Galvanized Steel Tubular

1

Pickets

This standard is issued under the fixed designation F2408; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D822 Practice for Filtered Open-Flame Carbon-Arc Expo-

sures of Paint and Related Coatings

1.1 This specification establishes the minimum require-

D1654 Test Method for Evaluation of Painted or Coated

ments for coated tubular picket ornamental fence systems

Specimens Subjected to Corrosive Environments

fabricated from galvanized steel components.

D2244 Practice for Calculation of Color Tolerances and

1.2 The requirements of this specification do not apply to

Color Differences from Instrumentally Measured Color

vertical bar fence systems utilizing solid bar or wrought iron

Coordinates

materials.

D2794 Test Method for Resistance of Organic Coatings to

1.3 The values stated with in-pound units are to be regarded

the Effects of Rapid Deformation (Impact)

as standard. The SI values in parentheses are provided for

D3359 Test Methods for Measuring Adhesion by Tape Test

information.

E4 Practices for Force Verification of Testing Machines

2. Referenced Documents

3. Terminology

2

2.1 ASTM Standards:

3.1 Definitions of Terms Specific to This Standard:

A239 Practice for Locating the Thinnest Spot in a Zinc

,

3.1.1 tubular picket ornamental metal fence system—an

(Galvanized) Coating on Iron or Steel Articles

architectural metal fence system that combines ornamental

A653/A653M Specification for Steel Sheet, Zinc-Coated

fence structural components (that is, tubular pickets, rails, and

(Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed)

posts) with ornamental accessories and fasteners, assembled

by the Hot-Dip Process

and evaluated as a complete installed structure.

A1008/A1008M Specification for Steel, Sheet, Cold-

3.1.2 fence panel—fabricated unit consisting of rails and

Rolled, Carbon, Structural, High-Strength Low-Alloy,

pickets. Also referred to as a fence section.

High-Strength Low-Alloy with Improved Formability, So-

3.1.3 rail—horizontal structural component of a fence

lution Hardened, and Bake Hardenable

panel.

A1011/A1011M Specification for Steel, Sheet and Strip,

3.1.4 tubular picket—hollow vertical ornamental compo-

Hot-Rolled, Carbon, Structural, High-Strength Low-Alloy,

nent of a fence panel.

High-Strength Low-Alloy with Improved Formability, and

3.1.5 post—vertical fence structural component that sup-

Ultra-High Strength

ports the panel in the ornamental metal fence system.

B117 Practice for Operating Salt Spray (Fog) Apparatus

3.1.6 ornamental accessory—any fitting that adds further

D523 Test Method for Specular Gloss

decoration to an ornamental metal fence system including

D714 Test Method for Evaluating Degree of Blistering of

itemssuchasfinials,caps,picketcollars,rings,scrolls,orother

Paints

ornamental panel inserts.

3.1.7 adhesion—the bonding integrity of an organic coating

1

This specification is under the jurisdiction ofASTM Committee F14 on Fences

to the base metal substrate.

and is the direct responsibility of Subcommittee F14.35 on Architectural Metal

3.1.8 corrosion resistance—the ability of an organically

Fence Systems.

coated metal product to resist attack due to the base metal

Current edition approved Sept. 1, 2009. Published September 2009. Originally

attempting to return to a more passive oxidized state.

approved in 2004. Last previous edition approved in 2007 as F2408 - 07. DOI:

10.1520/F2408-09.

3.1.9 impact resistance—the measure of an organically

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

coatedmetalproducttoresistindention;theabilityofacoating

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

toresistcrackingorlossofadhesionduetoreformingthemetal

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. during bending or a shape change from abuse.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

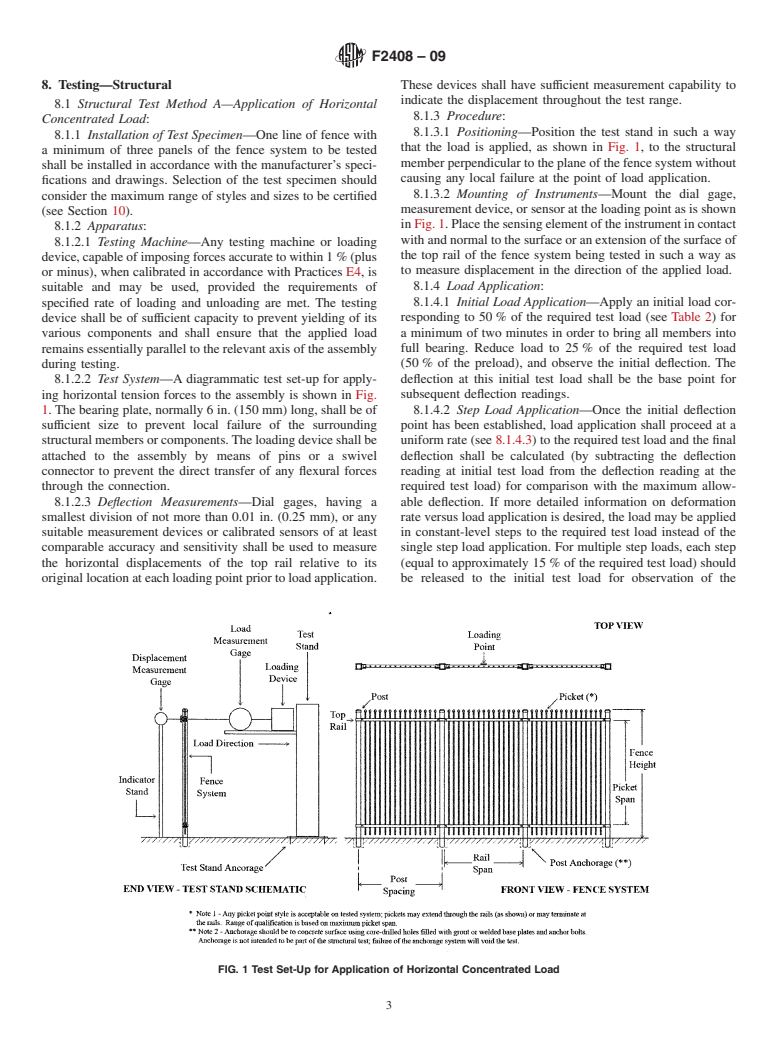

---------------------- Page: 1 ----------------------

F2408 – 09

3.1.10 weathering resistance—the ability of an organically 5.2.1 Powder coatings applied to the exterior surface of

coated metal product to resist loss of coating gloss or color fence components shall be polymer material: polyester or

change due to excessive humidity or ultra-violet (UV) sunlight epoxy and polyester combinations having a minimum thick-

exposure. ness of 3 mils; polyolefin elastomer having a minimum

thickness of 7 mils; or PVC

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:F2408–07 Designation: F 2408 – 09

Standard Specification for

Ornamental Fences Employing Galvanized Steel Tubular

1

Pickets

This standard is issued under the fixed designation F 2408; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 Thisspecificationestablishestheminimumrequirementsforcoatedtubularpicketornamentalfencesystemsfabricatedfrom

galvanized steel components.

1.2 Therequirementsofthisspecificationdonotapplytoverticalbarfencesystemsutilizingsolidbarorwroughtironmaterials.

1.3 The values stated with in-pound units are to be regarded as standard. The SI values in bracketsparentheses are provided for

information.

2. Referenced Documents

2

2.1 ASTM Standards:

,

A 239 Practice for Locating the Thinnest Spot in a Zinc (Galvanized) Coating on Iron or Steel Articles

A 653/A 653M Specification for Steel Sheet, Zinc-Coated (Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed) by the

Hot-Dip Process

A 1008/A 1008M Specification for Steel, Sheet, Cold-Rolled, Carbon, Structural, High-Strength Low-Alloy, High-Strength

Low-Alloy with Improved Formability, Solution Hardened, and Bake Hardenable

A 1011/A 1011M Specification for Steel, Sheet and Strip, Hot-Rolled, Carbon, Structural, High-Strength Low-Alloy, High-

Strength Low-Alloy with Improved Formability, and Ultra-High Strength

B117 Practice for Operating Salt Spray (Fog) Apparatus

D 523 Test Method for Specular Gloss

D 714 Test Method for Evaluating Degree of Blistering of Paints

D 822 Practice for Filtered Open-Flame Carbon-Arc Exposures of Paint and Related Coatings

D 1654 Test Method for Evaluation of Painted or Coated Specimens Subjected to Corrosive Environments

D 2244 Practice for Calculation of Color Tolerances and Color Differences from Instrumentally Measured Color Coordinates

D 2794 Test Method for Resistance of Organic Coatings to the Effects of Rapid Deformation (Impact)

D 3359 Test Methods for Measuring Adhesion by Tape Test

E4 Practices for Force Verification of Testing Machines

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 tubular picket ornamental metal fence system—an architectural metal fence system that combines ornamental fence

structuralcomponents(thatis,tubularpickets,rails,andposts)withornamentalaccessoriesandfasteners,assembledandevaluated

as a complete installed structure.

3.1.2 fence panel—fabricated unit consisting of rails and pickets. Also referred to as a fence section.

3.1.3 rail—horizontal structural component of a fence panel.

3.1.4 tubular picket—hollow vertical ornamental component of a fence panel.

3.1.5 post—vertical fence structural component that supports the panel in the ornamental metal fence system.

3.1.6 ornamental accessory—any fitting that adds further decoration to an ornamental metal fence system including items such

as finials, caps, picket collars, rings, scrolls, or other ornamental panel inserts.

3.1.7 adhesion—the bonding integrity of an organic coating to the base metal substrate.

1

This specification is under the jurisdiction of ASTM Committee F14 on Fences and is the direct responsibility of Subcommittee F14.35 on Architectural Metal Fence

Systems.

Current edition approved JulySept. 1, 2007.2009. Published July 2007.September 2009. Originally approved in 2004. Last previous edition approved in 20062007 as

F 2408 - 067.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

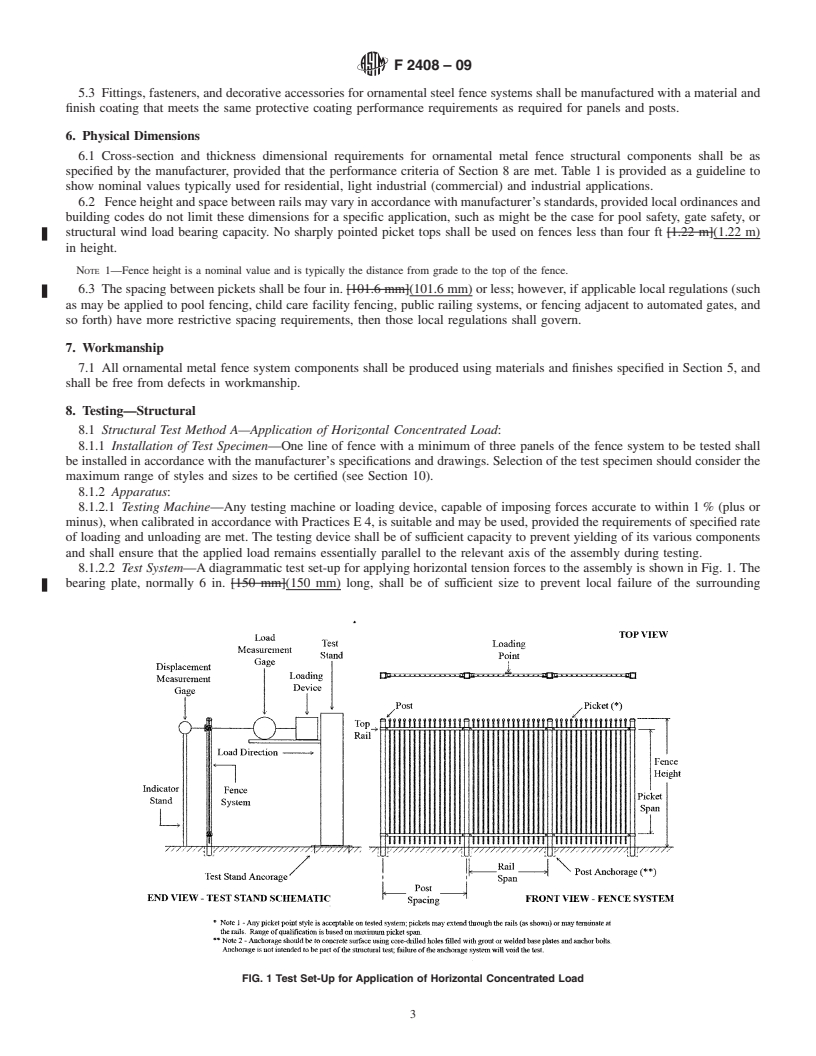

F2408–09

3.1.8 corrosion resistance—the ability of an organically coated metal product to resist attack due to the base metal attempting

to return to a more passive oxidized state.

3.1.9 impact resistance—the measure of an organically coated metal product to resist indention; the ability of a coating to resist

cracking or loss of adhesion due to reforming the metal during bending or a shape change from abuse.

3.1.10 weathering resistance—the ability of an organically coated metal product to resist loss of coating gloss or color change

due to excessive humidit

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.