ASTM D732-10

(Test Method)Standard Test Method for Shear Strength of Plastics by Punch Tool

Standard Test Method for Shear Strength of Plastics by Punch Tool

SIGNIFICANCE AND USE

Shear strength obtained by the use of punch-type tooling is one of the recognized methods of comparing materials, or obtaining data for engineering design purposes, or both. However, it must be recognized that for end-use applications there are likely to be many factors not taken into account in this test method, such as stress-concentrating geometries and rates of shear, which can profoundly affect the measured shear strength. Moreover, the fact that the shear strength is calculated by dividing the load by the area of the sheared edge (punch circumference X specimen thickness) does not interpret as indicating the shear strength value so obtained is solely a material property, independent of thickness.

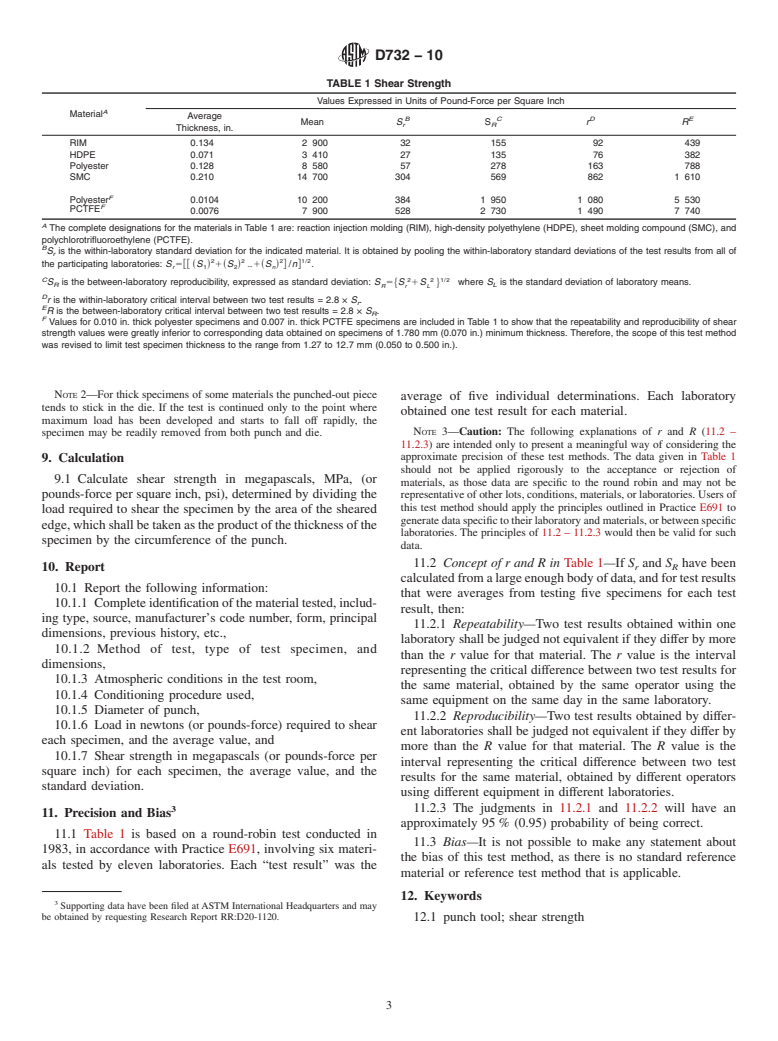

For many materials, it is possible that there is a specification that requires the use of this test method, but with some procedural modifications that take precedence when adhering to the specification. Therefore, it is advisable to refer to that material specification before using this test method. Table 1 of Classification System D4000 lists the ASTM materials standards that currently exist.

SCOPE

1.1 This test method covers the procedure for determining the shear strength of composite materials in the form of sheets, plates, and molded shapes in thicknesses from 1.27 to 12.7 mm (0.050 to 0.500 in.).

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1—There is no known ISO equivalent to this standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D732 − 10

Standard Test Method for

1

Shear Strength of Plastics by Punch Tool

This standard is issued under the fixed designation D732; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* 4. Significance and Use

1.1 This test method covers the procedure for determining 4.1 Shearstrengthobtainedbytheuseofpunch-typetooling

is one of the recognized methods of comparing materials, or

the shear strength of composite materials in the form of sheets,

plates, and molded shapes in thicknesses from 1.27 to 12.7 mm obtaining data for engineering design purposes, or both.

However, it must be recognized that for end-use applications

(0.050 to 0.500 in.).

therearelikelytobemanyfactorsnottakenintoaccountinthis

1.2 The values stated in SI units are to be regarded as the

test method, such as stress-concentrating geometries and rates

standard. The values given in parentheses are for information

of shear, which can profoundly affect the measured shear

only.

strength.Moreover,thefactthattheshearstrengthiscalculated

1.3 This standard does not purport to address all of the

by dividing the load by the area of the sheared edge (punch

safety concerns, if any, associated with its use. It is the

circumference X specimen thickness) does not interpret as

responsibility of the user of this standard to establish appro-

indicating the shear strength value so obtained is solely a

priate safety and health practices and determine the applica-

material property, independent of thickness.

bility of regulatory limitations prior to use.

4.2 For many materials, it is possible that there is a

NOTE 1—There is no known ISO equivalent to this standard.

specification that requires the use of this test method, but with

some procedural modifications that take precedence when

2. Referenced Documents

adhering to the specification. Therefore, it is advisable to refer

2

2.1 ASTM Standards:

to that material specification before using this test method.

D618 Practice for Conditioning Plastics for Testing

Table 1 of Classification System D4000 lists the ASTM

D4000 Classification System for Specifying Plastic Materi-

materials standards that currently exist.

als

5. Apparatus

E4 Practices for Force Verification of Testing Machines

5.1 Testing Machine—Any suitable testing machine of the

E691 Practice for Conducting an Interlaboratory Study to

constant-rate-of-crosshead movement type. The testing ma-

Determine the Precision of a Test Method

chine shall be equipped with the necessary drive mechanism

3. Terminology for imparting to the crosshead a uniform, controlled velocity

with respect to the base. The testing machine shall also be

3.1 Definitions:

equipped with a load-indicating mechanism capable of show-

3.1.1 shear strength—the maximum load required to shear

ing the total compressive load carried by the test specimen.

the specimen in such a manner that the moving portion of the

This mechanism shall be essentially free from inertia-lag at the

load fixture has completely cleared the stationary portion,

specified rate of testing and shall indicate the load with an

divided by the sheared area. It is expressed in megapascals (or

accuracy of 61 % of the indicated value or better. The

pounds-force per square inch) based on the area of the sheared

accuracy of the testing machine shall be verified in accordance

edge or edges.

with Practices E4.

5.2 Shear Tool—A shear tool of the punch type which is so

1

This test method is under the jurisdiction ofASTM Committee D20 on Plastics constructed that the specimen is rigidly clamped both to the

and is the direct responsibility of Subcommittee D20.10 on Mechanical Properties.

stationary block and movable block so that it cannot be

Current edition approved April 1, 2010. Published April 2010. Originally

deflected during the test.Asuitable form of shear tool is shown

approved in 1943. Last previous edition approved in 2009 as D732 – 09. DOI:

in Fig. 1.

10.1520/D0732-10.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5.3 Micrometers—Suitable micrometers for measuring the

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

thickness of the test specimen to an incremental discrimination

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. of at least 0.025 mm (0.001 in.).

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. Uni

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D732–09 Designation: D732 – 10

Standard Test Method for

1

Shear Strength of Plastics by Punch Tool

This standard is issued under the fixed designation D732; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

1.1 Thistestmethodcoverstheprocedurefordeterminingtheshearstrengthofcompositematerialsintheformofsheets,plates,

and molded shapes in thicknesses from 1.27 to 12.7 mm (0.050 to 0.500 in.).

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

NOTE 1—There is no known ISO equivalent to this standard.

2. Referenced Documents

2

2.1 ASTM Standards:

D618 Practice for Conditioning Plastics for Testing

D4000 Classification System for Specifying Plastic Materials

D4066Classification System for Nylon Injection and Extrusion Materials (PA)

E4 Practices for Force Verification of Testing Machines

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3. Terminology

3.1 Definition:

3.1.1 shear strength—the maximum load required to shear the specimen in such a manner that the moving portion of the load

fixture has completely cleared the stationary portion, divided by the sheared area. It is expressed in megapascals (or pounds-force

per square inch) based on the area of the sheared edge or edges.

4. Significance and Use

4.1 Shear strength obtained by the use of punch-type tooling is one of the recognized methods of comparing materials, or

obtaining data for engineering design purposes, or both. However, it must be recognized that for end-use applications there are

likely to be many factors not taken into account in this test method, such as stress-concentrating geometries and rates of shear,

which can profoundly affect the measured shear strength. Moreover, the fact that the shear strength is calculated by dividing the

load by the area of the sheared edge (punch circumference X specimen thickness) does not interpret as indicating the shear strength

value so obtained is solely a material property, independent of thickness.

4.2 For many materials, it is possible that there is a specification that requires the use of this test method, but with some

procedural modifications that take precedence when adhering to the specification.Therefore, it is advisable to refer to that material

specification before using this test method. Table 1 of Classification System D4000 lists the ASTM materials standards that

currently exist.

5. Apparatus

5.1 Testing Machine—Anysuitabletestingmachineoftheconstant-rate-of-crossheadmovementtype.Thetestingmachineshall

be equipped with the necessary drive mechanism for imparting to the crosshead a uniform, controlled velocity with respect to the

1

This test method is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.10 on Mechanical Properties.

Current edition approved Oct. 15, 2009. Published November 2009. Originally approved in 1943. Last previous edition approved in 2002 as D732–02. DOI:

10.1520/D0732-09.

CurrenteditionapprovedApril1,2010.PublishedApril2010.Originallyapprovedin1943.Lastpreviouseditionapprovedin2009asD732 – 09.DOI:10.1520/D0732-10.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D732 – 10

base. The testing machine shall also be equipped with a load-indicating mechanism capable of showing the total compressive load

carried by the test specimen. This mechanism shall be essentially free from inertia-lag at the specified rate of t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.