ASTM D6459-99

(Test Method)Standard Test Method for Determination of Erosion Control Blanket (ECB) Performance in Protecting Hillslopes from Rainfall-Induced Erosion

Standard Test Method for Determination of Erosion Control Blanket (ECB) Performance in Protecting Hillslopes from Rainfall-Induced Erosion

SCOPE

1.1 This test method covers the guidelines, requirements and procedures for evaluating the ability of Erosion Control Blankets (ECBs) to protect hillslopes from rainfall-induced erosion. Critical elements of this protection are the ability of the ECB to:

1.1.1 Absorb the impact force raindrops, thereby reducing soil particle loosening through "splash" mechanisms;

1.1.2 Slow runoff and encourage infiltration, thereby reducing soil particle displacement and transport through "overland flow" mechanisms;

1.1.3 Absorb shear forces of overland flow; and,

1.1.4 Trap soil particles beneath.

1.2 This test method utilizes full-scale testing procedures, rather than reduced-scale (bench-scale) simulation, and is patterned after conditions typically found on construction sites at the conclusion of earthwork operations, but prior to the start of revegetation work. Therefore this considers only unvegetated conditions.

Note 1--Future revisions may consider partial or fully vegetated conditions.

1.3 This test method provides a comparative evaluation of an ECB to baseline bare soil conditions under controlled and documented conditions.

1.4 The values stated in SI units are to be regarded as standard. The inch-pound values given in parentheses are provided for information purposes only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Also, the user must comply with prevalent regulatory codes, such as OSHA (Occupational Health and Safety Administration) guidelines, while using the test method.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 6459 – 99

Standard Test Method for

Determination of Erosion Control Blanket (ECB)

Performance in Protecting Hillslopes from Rainfall-Induced

Erosion

This standard is issued under the fixed designation D 6459; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This test method covers the guidelines, requirements 2.1 ASTM Standards:

and procedures for evaluating the ability of Erosion Control C 136 Test Method for Sieve Analysis of Fine and Course

Blankets (ECBs) to protect hillslopes from rainfall-induced Aggregates

erosion. Critical elements of this protection are the ability of D 422 Test Method for Particle-Size Analysis of Soils

the ECB to: D 698 Test Method for Laboratory Characteristics of Soil

1.1.1 Absorb the impact force of raindrops, thereby reduc- Using Standard Effort

ing soil particle loosening through “splash” mechanisms; D 2974 Standard Test Methods for Moisture, Ash, and

1.1.2 Slow runoff and encourage infiltration, thereby reduc- Organic Matter of Peat and Other Organic Soils

ing soil particle displacement and transport through “overland D 4318 Standard Test Method for Liquid Limit, Plastic

flow” mechanisms; Limit, and Plasticity Index of Soils

1.1.3 Absorb shear forces of overland flow; and,

3. Terminology

1.1.4 Trap soil particles beneath.

1.2 This test method utilizes full-scale testing procedures, 3.1 Definitions of Terms Specific to This Standard:

3.1.1 erosion control blanket (ECB), n—a degradable ma-

rather than reduced-scale (bench-scale) simulation, and is

patterned after conditions typically found on construction sites terial, composed primarily of processed natural organic mate-

rials, manufactured or fabricated into rolls designed to reduce

at the conclusion of earthwork operations, but prior to the start

of revegetation work. Therefore this considers only unveg- soil erosion and assist in the growth, establishment and

etated conditions. protection of vegetation.

3.1.2 erosion control net (ECN), n—a planar woven natural

NOTE 1—Future revisions may consider partial or fully vegetated

fiber or extruded synthetic mesh used as a component in the

conditions.

manufacture of ECBs.

1.3 This test method provides a comparative evaluation of

3.1.3 index test, n—a test procedure which may contain a

an ECB to baseline bare soil conditions under controlled and

known bias, but which may be used to establish an order for a

documented conditions.

set of specimens with respect to the property of interest.

1.4 The values stated in SI units are to be regarded as

3.1.4 lot, n—a unit of production, or a group of other units

standard. The inch-pound values given in parentheses are

or packages, taken for sampling or statistical examination,

provided for information purposes only.

having one or more common properties and being readily

1.5 This standard does not purport to address all of the

separable from other similar units.

safety concerns, if any, associated with its use. It is the

3.1.5 natural, n—a class name of various fibers of animal,

responsibility of the user of this standard to establish appro-

mineral or vegetable origin.

priate safety and health practices and determine the applica-

3.1.6 openweavetextile(OWT),n—atemporarydegradable

bilityofregulatorylimitationspriortouse. Also, the user must

ECB composed of natural or polymer yarns woven into a

comply with prevalent regulatory codes, such as OSHA (Oc-

matrix used to provide erosion control and facilitate vegetation

cupational Health and SafetyAdministration) guidelines, while

establishment.

using the test method.

This test method is under the jurisdiction of ASTM Committee D-18 on Soil

andRock;SubcommitteeD18.25onErosionandSedimentControlTechnology;and Annual Book of ASTM Standards, Vol 04.02.

is the direct responsibility of Section .02 on Erosion Control Blankets (ECBs). Annual Book of ASTM Standards, Vol 04.08.

Current edition approved Oct. 10, 1999. Published January 2000. Annual Book of ASTM Standards, Vol 15.09.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 6459

3.1.7 polymer, n—a chemical compound or mixture of 5.1.1 Reduce soil loss and sediment concentrations in

compounds formed by polymerization and consisting essen- stormwaterrunoffunderconditionsofvaryingrainfallintensity

tially of repeating molecular structural units.

and soil type, and;

3.1.8 sample, n—a portion of material which is taken for

5.1.2 Improve water quality exiting the area disturbed by

testing or documentation and used in the laboratory as a source

earthwork activity by reducing suspended solids.

of individual specimens.

5.2 This test method models and examines conditions typi-

3.1.9 temporary degradable, adj—composed of biologi-

cally found on construction sites involving earthwork activities

cally, photochemically or otherwise degradable materials that

including:highwayandroads;airports;residential,commercial

temporarily reduce soil erosion and enhance the establishment

and industrial developments; pipelines, mines, and landfills;

of vegetation.

golf courses; etc.

5.3 This test method is a performance test, but can be used

4. Summary of Test Method

forqualitycontroltodetermineproductconformancetoproject

4.1 The performance of an erosion control blanket in

specifications. Caution is advised since information about

reducing rainfall-induced erosion is determined by subjecting

between-laboratory precision is incomplete. Unique project-

the material to simulated rainfall in a controlled and docu-

specific conditions should be taken into consideration.

mented environment.

4.2 Key elements of the testing process include:

6. Apparatus

4.2.1 Calibration of the rainfall simulation equipment;

4.2.2 Preparation of the test plot;

6.1 Rainfall Simulators—Rainfall simulators shall include

4.2.3 Documentation of the ECB to be tested;

sprinkler heads, sprinkler risers, valves and pressure gages.

4.2.4 Installation of the ECB;

Thesprinklerheadsshouldbeselectedontheirabilitytomodel

4.2.5 Performance of the test;

natural raindrop size and distribution (no more than 10 %

4.2.6 Collection of runoff and associated sediment yield

greater than 6 mm (0.24 in.) and no more than 10 % smaller

data;

than 1 mm (0.04 in.)). To approximate the kinetic energy of

4.2.7 Analysis of the resultant data, and;

natural rainfall, the sprinkler riser shall be constructed to

4.2.8 Reporting.

position the sprinkler heads to achieve a minimum fall height

(peak vertical trajectory) of 4.3 m (14 ft).Aflow control valve

5. Significance and Use

and a pressure gauge capable of maintaining a uniform

5.1 This test method evaluates ECBs and their means of operating pressure shall be located on each riser. Fig. 1 shows

installation to: an example of a rainfall simulator.

FIG. 1 Typical Rainfall Simulator

D 6459

6.2 Water Source—Any water source shall be suitable for water onto the test plot (“run-on”) occurs. The barrier shall be

this use provided that it does not contain deleterious materials continuous such that joints do not allow outside flow to enter

which could impair the operation of the rainfall simulators. the plot. Commercially available lawn edging is suitable for

6.3 RunoffandSedimentCollectionSystem—Therunoffand this purpose.

sediment collection system includes flashing, collection appa-

7.1.5 Loosen the soil veneer to a depth of approximately 10

ratus and a holding tank. Flashing shall be fabricated to direct cm (4 in.) using a tiller or other appropriate tools. Rake the

runoff from the plot into the collection apparatus. Once the tilled plot smooth with a steel hand rake and lightly compact

runoff is on the flashing, it may be desirable to divert the flow using a turf roller. Repair depressions, voids, soft, or uncom-

to a single collection point. The flashing shall be continuous pactedareasbeforetestingcommences.Also,freetheplotfrom

across the entire bottom edge of the plot. A holding tank(s) obstruction or protrusions, such as roots, large stones, or other

capable of temporarily containing all runoff shall be connected foreign material.

to the collection apparatus. 7.1.6 If the plots have been used for previous test series,

6.4 Miscellaneous—Other miscellaneous equipment in-

discard the soil carried of the plot and obliterate any rills and

cludes: rain gauges (20), pie pans (3), sieve set (standard US gullies. Spread new soil of the same type across the plot and

sieves), evaporating dishes, a drying oven or microwave oven,

blend(rakeortill)intothesurface.Ifthesoillossofthecontrol

balances, meteorological equipment (wind speed, temperature,

plot differs significantly from the base line calibration test

precipitation),asurveyor’srod,samplebottlesandbags,cooler

reevaluate the soil properties.

and camera or video recorder.

7.2 Calibration:

7.2.1 Calibration of the rainfall simulation equipment in-

7. Procedure

cludes:

7.1 Test Plot Preparation:

7.2.1.1 Rainfall intensity;

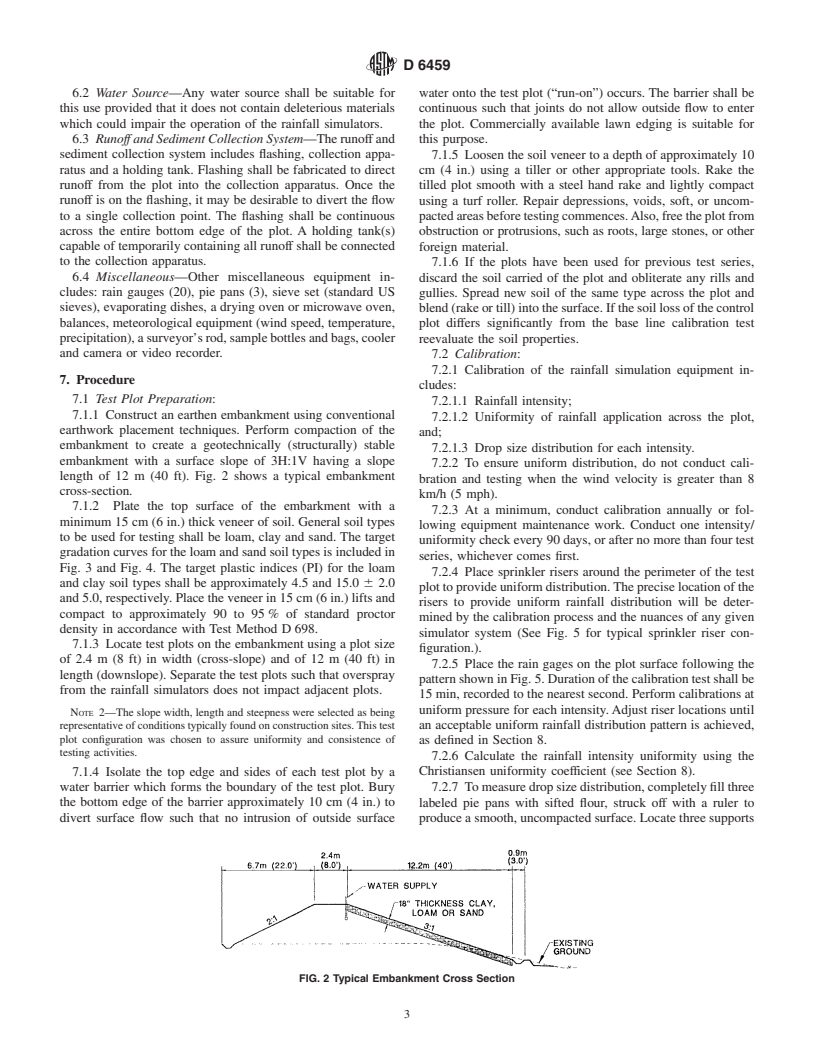

7.1.1 Construct an earthen embankment using conventional

7.2.1.2 Uniformity of rainfall application across the plot,

earthwork placement techniques. Perform compaction of the

and;

embankment to create a geotechnically (structurally) stable

7.2.1.3 Drop size distribution for each intensity.

embankment with a surface slope of 3H:1V having a slope

7.2.2 To ensure uniform distribution, do not conduct cali-

length of 12 m (40 ft). Fig. 2 shows a typical embankment

bration and testing when the wind velocity is greater than 8

cross-section.

km/h (5 mph).

7.1.2 Plate the top surface of the embarkment with a

7.2.3 At a minimum, conduct calibration annually or fol-

minimum 15 cm (6 in.) thick veneer of soil. General soil types

lowing equipment maintenance work. Conduct one intensity/

to be used for testing shall be loam, clay and sand. The target

uniformity check every 90 days, or after no more than four test

gradation curves for the loam and sand soil types is included in

series, whichever comes first.

Fig. 3 and Fig. 4. The target plastic indices (PI) for the loam

7.2.4 Place sprinkler risers around the perimeter of the test

and clay soil types shall be approximately 4.5 and 15.0 6 2.0

plottoprovideuniformdistribution.Thepreciselocationofthe

and 5.0, respectively. Place the veneer in 15 cm (6 in.) lifts and

risers to provide uniform rainfall distribution will be deter-

compact to approximately 90 to 95 % of standard proctor

mined by the calibration process and the nuances of any given

density in accordance with Test Method D 698.

simulator system (See Fig. 5 for typical sprinkler riser con-

7.1.3 Locate test plots on the embankment using a plot size

figuration.).

of 2.4 m (8 ft) in width (cross-slope) and of 12 m (40 ft) in

7.2.5 Place the rain gages on the plot surface following the

length (downslope). Separate the test plots such that overspray

patternshowninFig.5.Durationofthecalibrationtestshallbe

from the rainfall simulators does not impact adjacent plots.

15 min, recorded to the nearest second. Perform calibrations at

uniform pressure for each intensity.Adjust riser locations until

NOTE 2—The slope width, length and steepness were selected as being

representativeofconditionstypicallyfoundonconstructionsites.Thistest an acceptable uniform rainfall distribution pattern is achieved,

plot configuration was chosen to assure uniformity and consistence of

as defined in Section 8.

testing activities.

7.2.6 Calculate the rainfall intensity uniformity using the

7.1.4 Isolate the top edge and sides of each test plot by a Christiansen uniformity coefficient (see Section 8).

water barrier which forms the boundary of the test plot. Bury 7.2.7 Tomeasuredropsizedistribution,completelyfillthree

the bottom edge of the barrier approximately 10 cm (4 in.) to labeled pie pans with sifted flour, struck off with a ruler to

divert surface flow such that no intrusion of outside surface produce a smooth, uncompacted surface. Locate three supports

FIG. 2 Typical Embankment Cross Section

D 6459

FIG. 3 Typical Loam Grain Size Distribution

FIG. 4 Typical Sand Grain Size Distribution

approximately 20-cm (8- in.) high (for example, 1-gal cans) shakingthestackfor2min.Cullforeignmatterandanydouble

along the vertical centerline of the test plot, and at the pellets from each sieve and record the total weight and pellet

horizontal quarter points. Place the filled pie pans on the count for each size. (1)

supports (horizontal, not parallel to the ground) and cover. At 7.2.8 Repeat the raindrop size calibration procedure (7.2.7)

the desired test intensity, remove the cover briefly so that drops three times for each desired intensity.

impinge on the flour to form pellets. Recover the pans after 7.2.9 Determine raindrop fall height by measuring the

only a few seconds and before the drops start to touch each average height of the raindrop trajectory using a surveyor’s

other. Repeat this procedure at each desired intensity. Air-dry rod. Hold the rod vertically in the spray of a single riser and

the flour pellets for a minimum of 12 h. Screen each sample of measure the wetted height. Repeat the height measurement for

these semi-dry pellets by emptying the entire contents of the each desired intensity.

pan onto a 70 mesh sieve to carefully remove as much loose 7.3 Pre-Test Documentation:

flour as possible. Then transfer the remaining pellets to

evaporating dishes and heat in an oven at approximately 43°C

(110°F) for 2 h. Record the total weight of the hard flour

The boldface numbers given in parentheses refer to a list of references at the

pellets. Sieve the pellets through standard soil sieves by end of the text.

D 6459

FIG. 5 Typical Sprinkler Riser Configuration

7.3.1 Maintain a test folder for each test cycle, including present along the perimeter barrier and be cut to fit, as

information on: site conditions; geotechnical and soil condi- necessary, to cover the plot.

tions; meteorological data; ECB product type, description and 7.4.3 Take photographs or videotapes, or both of the cov-

installation procedure, and; photo documentation. ered plot prior to testing.

7.3.2 Include the following subjective site information: 7.5 Test Operation and Data Collection:

general visual conditions of the plot to be tested; general 7.5.1 Include the following test data: operator name and

meteorological information; plot treatment; photographs o

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.