ASTM D5390-93(1997)

(Test Method)Standard Test Method for Open Channel Flow Measurement of Water with Palmer-Bowlus Flumes

Standard Test Method for Open Channel Flow Measurement of Water with Palmer-Bowlus Flumes

SCOPE

1.1 This test method covers measurement of the volumetric flowrate of water and wastewater in sewers and other open channels with Palmer-Bowlus flumes.

1.2 The values stated in inch-pound units are to be regarded as the standard. The SI units given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

Designation: D 5390 – 93 (Reapproved 1997)

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Test Method for

Open-Channel Flow Measurement of Water with Palmer-

Bowlus Flumes

This standard is issued under the fixed designation D 5390; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope method refer to Terminology D 1129.

3.2 Definitions of Terms Specific to This Standard:

1.1 This test method covers measurement of the volumetric

3.2.1 boundary layer displacement thickness—the boundary

flowrate of water and wastewater in sewers and other open

layer is a layer of fluid flow adjacent to a solid surface (in this

channels with Palmer-Bowlus flumes.

case, the flume throat) in which, owing to viscous friction, the

1.2 The values stated in inch-pound units are to be regarded

velocity increases from zero at the stationary surface to an

as the standard. The SI units given in parentheses are for

essentially frictionless-flow value at the edge of the layer. The

information only.

displacement thickness is a distance normal to the solid surface

1.3 This standard does not purport to address all of the

that the surface and flow streamlines can be considered to have

safety concerns, if any, associated with its use. It is the

been displaced by virtue of the boundary-layer formation.

responsibility of the user of this standard to establish appro-

3.2.2 critical flow—open channel flow in which the energy

priate safety and health practices and determine the applica-

expressed in terms of depth plus velocity head, is a minimum

bility of regulatory limitations prior to use.

for a given flowrate and channel. The Froude number is unity

2. Referenced Documents

at critical flow.

3.2.3 Froude number—a dimensionless number expressing

2.1 ASTM Standards:

the ratio of inertial to gravity forces in free-surface flow. It is

D 1129 Terminology Relating to Water

equal to the average velocity divided by the square root of the

D 1941 Test Method for Open Channel Flow Measurement

product of the average depth and the acceleration due to

of Water with the Parshall Flume

gravity.

D 2777 Practice for Determination of Precision and Bias of

3.2.4 head—the depth of flow referenced to the floor of the

Applicable Methods of Committee D-19 on Water

throat measured at an appropriate location upstream of the

D 3858 Test Method for Open-Channel Flow Measurement

flume; this depth plus the velocity head is often termed the total

of Water by Velocity-Area Methods

head or total energy head.

D 5242 Test Method for Open Channel Flow Measurement

3.2.5 hydraulic jump—an abrupt transition from supercriti-

of Water with Thin-Plate Weirs

cal flow to subcritical or tranquil flow, accompanied by

2.2 ISO Standards:

considerable turbulence or gravity waves, or both.

ISO 4359 Liquid Flow Measurement in Open Channels—

3.2.6 long-throated flume—a flume in which the prismatic

Rectangular, Trapezoidal and U-Shaped Flumes

throat is long enough relative to the head for essentially critical

ISO 555 Liquid Flow Measurements in Open Channels—

flow to develop on the crest.

Dilution Methods for Measurement of Steady Flow—

3.2.7 primary instrument—the device (in this case the

Constant Rate Injection Method

flume) that creates a hydrodynamic condition that can be

2.3 ASME Standard:

sensed by the secondary instrument.

Fluid Meters— Their Theory and Application

3.2.8 Reynolds number—a dimensionless number express-

3. Terminology

ing the ratio of inertial to viscous forces in a flow. In a flume

throat the pertinent Reynolds number is equal to the (critical)

3.1 Definitions—For definitions of terms used in this test

throat velocity multiplied by the throat length and divided by

the kinematic viscosity of the water.

3.2.9 scow float—an in-stream float for depth sensing,

This test method is under the jurisdiction of ASTM Committee D-19 on Water

and is the direct responsibility of Subcommittee D19.07 on Sediments, Geomor-

usually mounted on a hinged cantilever.

phology, and Open-Channel Flow.

3.2.10 secondary instrument—in this case, a device that

Current edition approved April 15, 1993. Published June 1993.

measures the depth of flow (referenced to the throat elevation)

Annual Book of ASTM Standards, Vol 11.01.

Available from American National Standards Institute, 11 West 42nd Street,

at an appropriate location upstream of the flume. The second-

13th Floor, New York, NY 10036.

ary instrument may also convert this measured head to an

Available from American Society of Mechanical Engineers, 345 E. 47th Street,

indicated flowrate, or could totalize flowrate.

New York, NY 10017.

D 5390

3.2.11 stilling well—a small free-surface reservoir con- formed by constricted sidewalls or a bottom rise, or both.

nected through a restricted passage to the approach channel Sloped ramps form gradual transitions between the throat and

upstream of the flume so that a head measurement can be made the upstream and downstream sections. See Fig. 1. The flume

under quiescent conditions. was developed primarily for use in sewers but it is adaptable

3.2.12 subcritical flow—open channel flow that is deeper to other open channels as well. There is no standardized shape

and at lower velocity than critical flow for the same flowrate; for Palmer-Bowlus flumes and, as long-throated flumes, they

sometimes called tranquil flow. can be designed to fit specific hydraulic situations using the

3.2.13 submergence—a condition where the depth of flow theory outlined in 7.2.3.

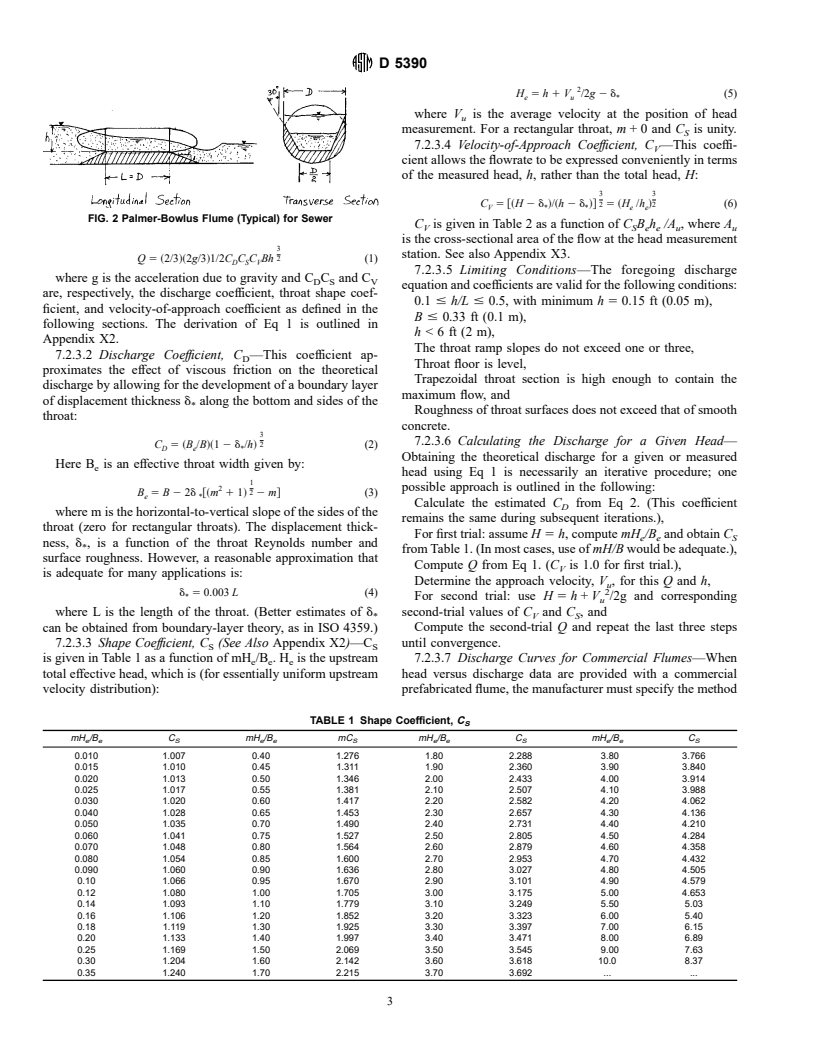

immediately downstream of the flume is large enough to affect 7.2.1.2 Prefabricated Flumes—Prefabricated flumes with

the flow through the flume so that the flowrate can no longer be trapezoidal or rectangular throats and with circular or U-shaped

related to a single upstream head. outside forms are commercially available for use in sewers.

3.2.14 supercritical flow—open channel flow that is shal- Although there is no fixed shape for Palmer-Bowlus flumes,

lower and at higher velocity than critical flow for the same many manufacturers of trapezoidal-throated flumes use the

flowrate. proportions shown in Fig. 2. These prefabricated flumes are

3.2.15 tailwater—the water elevation immediately down- also available in several configurations depending on how they

stream of the flume. are to be installed, for example, whether they will be placed in

3.2.16 throat—the constricted portion of the flume. the channel at the base of an existing manhole, inserted into the

3.2.17 velocity head—the square of the average velocity pipe immediately downstream of the manhole, or incorporated

divided by twice the acceleration due to gravity. into new construction. The size of these prefabricated flumes is

customarily referenced to the diameter of the receiving pipe

4. Summary of Test Method

rather than to the throat width. Refer to manufacturers’

4.1 In Palmer-Bowlus flumes, critical free-surface flow is literature for flume details.

developed in a prismatic throat so that the flowrate is a unique

7.2.1.3 Because the dimensions of prefabricated flumes may

function of a single measured upstream head for a given throat differ depending upon the manufacturer or the configuration, or

shape and upstream channel geometry. This function can be

both, it is important that users check interior dimensions

obtained theoretically for ideal (frictionless) flows and adjust- carefully before installation and insure that these dimensions

ments for non-ideal conditions can be obtained experimentally

are not affected by the installation process.

or estimated from fluid-mechanics considerations. 7.2.1.4 A Palmer-Bowlus flume can be fabricated in a pipe

by raising the invert (see Fig. X3.1). Floor slabs that can be

5. Significance and Use

grouted into existing sewers are commercially available, as are

5.1 Although Palmer-Bowlus flumes can be used in many

prefabricated slab-pipe combinations for insertion into larger

types of open channels, they are particularly adaptable for

pipes. Details may be obtained from the manufacturers’ litera-

permanent or temporary installation in circular sewers. Com-

ture. Discharge equations for this throat shape are given in

mercial flumes are available for use in sewers from 4 in. to 6

Appendix X1.

ft (0.1 to 1.8 m) in diameter.

7.2.2 Head Measurement Location—The head, h, on the

5.2 A properly designed and operated Palmer-Bowlus is

flume is measured at a distance upstream of the throat-

capable of providing accurate flow measurements while intro-

approach ramp that is preferably equal to three times the

ducing a relatively small head loss and exhibiting good

maximum head. When the maximum head is restricted to

sediment and debris-passing characteristics.

one-half the throat length, as is recommended in this test

method, an upstream distance equal to the maximum head will

6. Interferences

usually be adequate to avoid the drawdown curvature of the

6.1 Flumes are applicable only to open-channel flow and

flow profile.

become inoperative under full-pipe flow conditions.

7.2.3 Discharge Relations:

6.2 The flume becomes inoperative if downstream condi-

7.2.3.1 The volumetric flowrate, Q, through a Palmer-

tions cause submergence (see 7.3.2).

Bowlus flume of bottom throat width, B, operating under a

head, h, above the throat floor is:

7. Apparatus

7.1 A Palmer-Bowlus flume measuring system consists of

the flume itself (the primary), with its immediate upstream and

Palmer, H. K., and Bowlus, F. D., “Adaptation of Venturi Flumes to Flow

downstream channels, and a depth or head measuring device

Measurements in Conduits,” Trans. ASCE, Vol 101, 1936, pp. 1195–1216.

(the secondary). The secondary device can range from a simple

scale or gage for manual readings to an instrument that

continuously senses the head, converts it to a flowrate, and

displays or transmits a readout or record of the instantaneous

flowrate or the totalized flow, or both.

7.2 The Palmer-Bowlus Flume:

7.2.1 General Configuration:

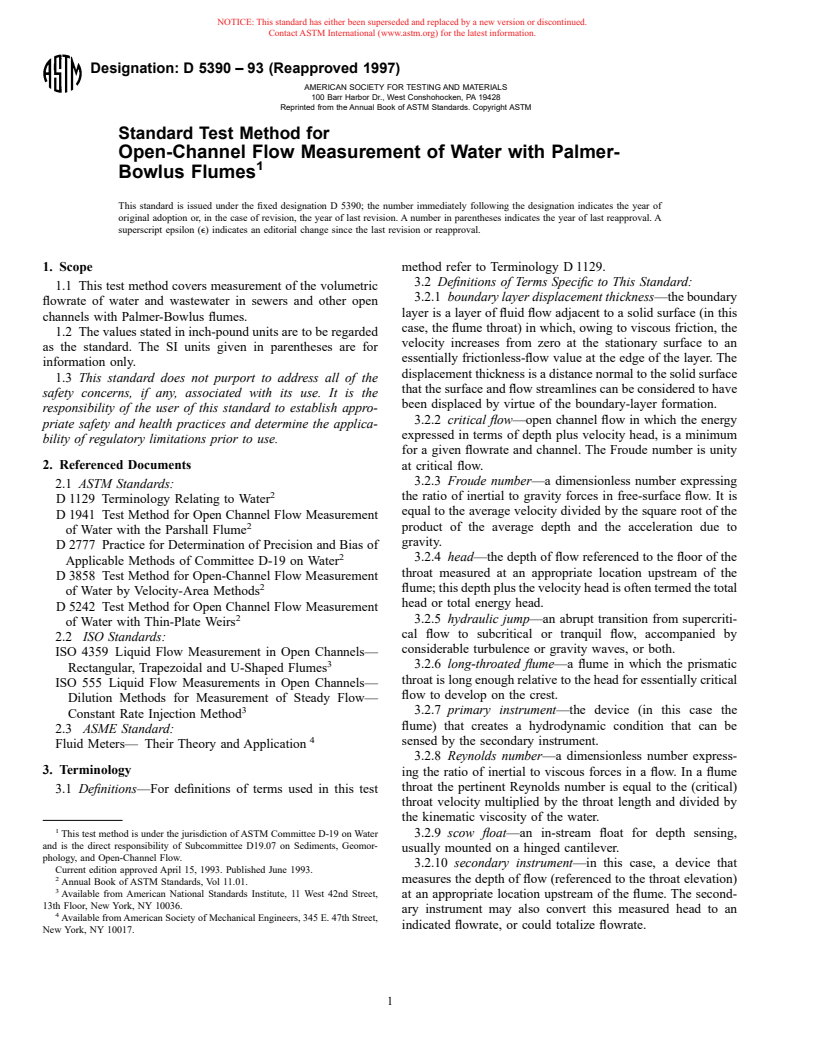

7.2.1.1 The Palmer-Bowlus flume is a class of long-throated

FIG. 1 Generalized Palmer-Bowlus (Long-Throated) Flume in a

flume in which critical flow is developed in a throat that is Rectangular Channel

D 5390

H 5 h 1 V /2g2d (5)

e u *

where V is the average velocity at the position of head

u

measurement. For a rectangular throat, m + 0 and C is unity.

S

7.2.3.4 Velocity-of-Approach Coeffıcient, C —This coeffi-

V

cient allows the flowrate to be expressed conveniently in terms

of the measured head, h, rather than the total head, H:

3 3

2 2

C 5 @~H2d !/~h2d !# 5 ~H /h ! (6)

V * * e e

FIG. 2 Palmer-Bowlus Flume (Typical) for Sewer

C is given in Table 2 as a function of C B h /A , where A

V S e e u u

is the cross-sectional area of the flow at the head measurement

station. See also Appendix X3.

Q 5 ~2/3!~2g/3!1/2C C C Bh 2 (1)

D S V

7.2.3.5 Limiting Conditions—The foregoing discharge

where g is the acceleration due to gravity and C C and C

D S V

equation and coefficients are valid for the following conditions:

are, respectively, the discharge coefficient, throat shape coef-

0.1 # h/L # 0.5, with minimum h 5 0.15 ft (0.05 m),

ficient, and velocity-of-approach coefficient as defined in the

B # 0.33 ft (0.1 m),

following sections. The derivation of Eq 1 is outlined in

h <6ft(2m),

Appendix X2.

The throat ramp slopes do not exceed one or three,

7.2.3.2 Discharge Coeffıcient, C —This coefficient ap-

D

Throat floor is level,

proximates the effect of viscous friction on the theoretical

Trapezoidal throat section is high enough to contain the

discharge by allowing for the development of a boundary layer

maximum flow, and

of displacement thickness d along the bottom and sides of the

*

Roughness of throat surfaces does not exceed that of smooth

throat:

concrete.

7.2.3.6 Calculating the Discharge for a Given Head—

C 5 B /B 12d /h 2 (2)

~ !~ !

D e *

Obtaining the theoretical discharge for a given or measured

Here B is an effective throat width given by:

e

head using Eq 1 is necessarily an iterative procedure; one

2 possible approach is outlined in the following:

B 5 B 2 2d @~m 1 1! 2 m# (3)

e *

Calculate the estimated C from Eq 2. (This coefficient

D

where m is the horizontal-to-vertical slope of the sides of the

remains the same during subsequent iterations.),

throat (zero for rectangular throats). The displacement thick-

For first trial: assume H 5 h, compute mH /B and obtain C

e e S

ness, d , is a function of the throat Reynolds number and

*

from Table 1. (In most cases, use of mH/B would be adequate.),

surface roughness. However, a reasonable approximation that

Compute Q from Eq 1. (C is 1.0 for first trial.),

V

is adequate for many applications is:

Determine the approach velocity, V , for this Q and h,

u

d 5 0.003 L (4)

*

For second trial: use H 5 h + V /2g and corresponding

u

second-trial values of C and C , and

where L is the length of the throat. (Better estimates of d

* V S

can be obtained from boundary-layer theory, as in ISO 4359.) Compute the second-trial Q and repeat the last three steps

7.2.3.3 Shape Coeffıcient, C (See Also Appendix X2)—C until convergence.

S S

is given in Table 1 as a function of mH /B .H is the upstream 7.2.3.7 Discharge Curves for Commercial Flumes—When

e e e

total effective head, which is (for essentially uniform upstream head versus discharge data are provided with a commercial

velocity distribution): prefabricated flume, the manufacturer must specify the method

TABLE 1 Shape Coefficient, C

S

mH /B C mH /B mC mH /B C mH /B C

e e S e e S e e S e e S

0.010 1.007 0.40 1.276 1.80 2.288 3.80 3.766

0.015 1.010 0.45 1.311 1.90 2.360 3.90 3.840

0.020 1.013 0.50 1.346 2.00 2.433 4.00 3.914

0.025 1.017 0.55 1.381 2.10 2.507 4.10 3.988

0.030 1.020 0.60 1.417 2.20 2.582 4.20 4.062

0.040 1.028 0.65 1.453 2.30 2.657 4.30 4.136

0.050 1.035 0.70 1.490 2.40 2.731 4.40 4.210

0.060 1.041 0.75 1.527 2.50 2.805 4.50 4.284

0.070 1.048 0.80 1.564 2.60 2.879 4.60 4.358

0.080 1.054 0.85 1.600 2.70 2.953 4.70 4.432

0.090 1.060 0.90 1.636 2.80 3.027 4.80 4.505

0.10 1.066 0.95 1.670 2.90 3.101 4.90 4.579

0.12 1.080 1.00 1.705 3.00 3.175 5.00 4.653

0.14 1.093 1.10 1.779 3.10 3.249 5.50 5.03

0.16 1.106 1.20 1.852 3.20 3.323 6.00 5.40

0.18 1.119 1.30 1.925 3.30 3.397 7.00 6.15

0.20 1.133 1.40 1.997 3.40 3.471 8.00 6.89

0.25 1.169 1.50 2.069 3.50 3.545 9.00 7.63

0.30 1.204 1.60 2.142 3.60 3.618 10.0 8.37

0.35 1.240 1.70 2.215 3.70 3.692 . .

D 5390

TABLE 2 Velocity-of-Approach Coefficient, C TABLE 3 Critical Depth in Throat

V

C C h /A C mH /B d /H mH /B d /H

S e e u V e e e e e e e e

0.1 1.002 0.00 0.667 2.00 0.762

0.2

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.