ASTM D5456-14b

(Specification)Standard Specification for Evaluation of Structural Composite Lumber Products

Standard Specification for Evaluation of Structural Composite Lumber Products

ABSTRACT

This specification recognizes the complexity of structural glued products. This specification, or parts thereof, shall be applicable to structural composite lumber portions of manufactured structural components. Tests shall be performed to determine the properties of the material in accordance to the following test methods: moisture content measurement; bending; tension parallel to grain; compression parallel to grain; compression perpendicular to grain; longitudinal shear; connections; bond quality; product durability; edgewise bending durability; lateral edge nail durability; thickness swell; and density gradient through the thickness.

SCOPE

1.1 This specification recognizes the complexity of structural glued products. Consequently, this specification covers both specific procedures and statements of intent that sampling and analysis must relate to the specific product.

1.2 This specification was developed in the light of currently manufactured products as defined in 3.2. Materials that do not conform to the definitions are beyond the scope of this specification. A brief discussion is found in Appendix X2.

1.3 Details of manufacturing procedures are beyond the scope of this specification.

Note 1: There is some potential for manufacturing variables to affect the properties of members that are loaded for sustained periods of time. Users of this specification are advised to consider the commentary on this topic in Appendix X2.

1.4 This specification primarily considers end use in dry service conditions, such as with most protected framing members, where the average equilibrium moisture content for solid-sawn lumber is less than 16 %. The conditioning environment of 6.3 is considered representative of such uses.

1.5 The performance of structural composite lumber is affected by wood species, wood element size and shape, and adhesive and production parameters. Therefore, products produced by each individual manufacturer shall be evaluated to determine their product properties, regardless of the similarity in characteristics to products produced by other manufacturers. Where a manufacturer produces product in more than one facility, each production facility shall be evaluated independently. For additional production facilities, any revisions to the full qualification program in accordance with this specification shall be approved by the independent qualifying agency.

1.6 This specification is intended to provide manufacturers, regulatory agencies, and end users with a means to evaluate a composite lumber product intended for use as a structural material.

1.7 This specification covers initial qualification sampling, mechanical and physical tests, analysis, and design value assignments. Requirements for a quality-control program and cumulative evaluations are included to ensure maintenance of allowable design values for the product.

1.8 This specification, or parts thereof, shall be applicable to structural composite lumber portions of manufactured structural components.

1.9 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.10 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D5456 −14b

Standard Specification for

Evaluation of Structural Composite Lumber Products

This standard is issued under the fixed designation D5456; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Structural composite lumber is intended for use as an engineering material for a variety of end-use

applications. The composition of the lumber varies by wood species, adhesive composition, wood

element size, shape, and arrangement. To provide the intended performance, composite lumber

products require: (1) an evaluation of the mechanical and physical properties and their response to

end-use environments, and (2) establishment of and conformance to standard performance specifica-

tions for quality.

Procedures contained in this specification are also to be used for establishing the design properties

and for checking the effectiveness of property assignment and quality assurance procedures.

The quality assurance sections in this specification are intended to serve as a basis for designing

quality-control programs specific to each product. The objective is to ensure that design values

established in the qualification process are maintained.

This specification is arranged as follows:

Section

Qualification 6

Determination of Allowable Design 7

Stresses

Independent Inspection 8

Quality Assurance 10

1. Scope 1.4 This specification primarily considers end use in dry

service conditions, such as with most protected framing

1.1 This specification recognizes the complexity of struc-

members, where the average equilibrium moisture content for

tural glued products. Consequently, this specification covers

solid-sawn lumber is less than 16%. The conditioning envi-

bothspecificproceduresandstatementsofintentthatsampling

ronment of 6.3 is considered representative of such uses.

and analysis must relate to the specific product.

1.5 The performance of structural composite lumber is

1.2 This specification was developed in the light of cur-

affected by wood species, wood element size and shape, and

rently manufactured products as defined in 3.2. Materials that

adhesive and production parameters. Therefore, products pro-

do not conform to the definitions are beyond the scope of this

duced by each individual manufacturer shall be evaluated to

specification. A brief discussion is found in Appendix X2.

determine their product properties, regardless of the similarity

1.3 Details of manufacturing procedures are beyond the

incharacteristicstoproductsproducedbyothermanufacturers.

scope of this specification.

Where a manufacturer produces product in more than one

facility, each production facility shall be evaluated indepen-

NOTE 1—There is some potential for manufacturing variables to affect

the properties of members that are loaded for sustained periods of time. dently.Foradditionalproductionfacilities,anyrevisionstothe

Users of this specification are advised to consider the commentary on this

full qualification program in accordance with this specification

topic in Appendix X2.

shall be approved by the independent qualifying agency.

1.6 This specification is intended to provide manufacturers,

regulatory agencies, and end users with a means to evaluate a

This specification is under the jurisdiction ofASTM Committee D07 on Wood

composite lumber product intended for use as a structural

andisthedirectresponsibilityofSubcommitteeD07.02onLumberandEngineered

material.

Wood Products.

Current edition approved Oct. 1, 2014. Published December 2014. Originally

1.7 This specification covers initial qualification sampling,

approved in 1993. Last previous edition approved in 2014 as D5456–14a. DOI:

10.1520/D5456-14B. mechanical and physical tests, analysis, and design value

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5456−14b

assignments. Requirements for a quality-control program and Wood Products for Use Under Exterior Exposure Condi-

cumulative evaluations are included to ensure maintenance of tions

allowable design values for the product. D2718Test Methods for Structural Panels in Planar Shear

(Rolling Shear)

1.8 Thisspecification,orpartsthereof,shallbeapplicableto

D2915Practice for Sampling and Data-Analysis for Struc-

structural composite lumber portions of manufactured struc-

tural Wood and Wood-Based Products

tural components.

D3201Test Method for Hygroscopic Properties of Fire-

1.9 Thevaluesstatedininch-poundunitsaretoberegarded

Retardant Wood and Wood-Based Products

as standard. The values given in parentheses are mathematical

D3755Test Method for Dielectric Breakdown Voltage and

conversions to SI units that are provided for information only

DielectricStrengthofSolidElectricalInsulatingMaterials

and are not considered standard.

Under Direct-Voltage Stress

1.10 This standard does not purport to address all of the

D4300Test Methods for Ability of Adhesive Films to

safety concerns, if any, associated with its use. It is the Support or Resist the Growth of Fungi

responsibility of the user of this standard to establish appro-

D4442Test Methods for Direct Moisture Content Measure-

priate safety and health practices and determine the applica-

ment of Wood and Wood-Base Materials

bility of regulatory limitations prior to use. D4761Test Methods for Mechanical Properties of Lumber

and Wood-Base Structural Material

2. Referenced Documents

D4933Guide for Moisture Conditioning of Wood and

Wood-Based Materials

2.1 ASTM Standards:

D5055Specification for Establishing and Monitoring Struc-

C177Test Method for Steady-State Heat Flux Measure-

tural Capacities of Prefabricated Wood I-Joists

ments and Thermal Transmission Properties by Means of

D5457SpecificationforComputingReferenceResistanceof

the Guarded-Hot-Plate Apparatus

Wood-Based Materials and Structural Connections for

C384Test Method for Impedance andAbsorption ofAcous-

Load and Resistance Factor Design

tical Materials by Impedance Tube Method

D5764Test Method for Evaluating Dowel-Bearing Strength

C423TestMethodforSoundAbsorptionandSoundAbsorp-

of Wood and Wood-Based Products

tion Coefficients by the Reverberation Room Method

D6815SpecificationforEvaluationofDurationofLoadand

D9Terminology Relating to Wood and Wood-Based Prod-

Creep Effects of Wood and Wood-Based Products

ucts

D7247Test Method for Evaluating the Shear Strength of

D143Test Methods for Small Clear Specimens of Timber

AdhesiveBondsinLaminatedWoodProductsatElevated

D150Test Methods forAC Loss Characteristics and Permit-

Temperatures

tivity (Dielectric Constant) of Solid Electrical Insulation

D7480Guide for Evaluating the Attributes of a Forest

D198Test Methods of Static Tests of Lumber in Structural

Management Plan

Sizes

E84Test Method for Surface Burning Characteristics of

D245Practice for Establishing Structural Grades and Re-

Building Materials

lated Allowable Properties for Visually Graded Lumber

E96/E96MTest Methods for Water Vapor Transmission of

D669Test Method for Dissipation Factor and Permittivity

Materials

Parallel with Laminations of Laminated Sheet and Plate

E119Test Methods for Fire Tests of Building Construction

Materials (Withdrawn 2012)

and Materials

D1037Test Methods for Evaluating Properties of Wood-

2.2 CSA Standards:

Base Fiber and Particle Panel Materials

CSAStandardsforWoodAdhesivesO112-M Series

D1583Test Method for Hydrogen Ion Concentration of Dry

CSA O325Construction Sheathing

Adhesive Films

2.3 ISO/IEC Standards:

D1666Test Methods for Conducting Machining Tests of

ISO/IEC Guide 65General Requirements for Bodies Oper-

Wood and Wood-Base Panel Materials

ating Product Certification Systems

D1761Test Methods for Mechanical Fasteners in Wood

ISO/IEC 17020General Criteria for the Operation of Vari-

D2132Test Method for Dust-and-FogTracking and Erosion

ous Types of Bodies Performing Inspection

Resistance of Electrical Insulating Materials

ISO/IEC 17025General Requirements for the Competence

D2394TestMethodsforSimulatedServiceTestingofWood

of Testing and Calibration Laboratories

and Wood-Base Finish Flooring

ISO/IEC 17065ConformityAssessment – Requirements for

D2395TestMethodsforDensityandSpecificGravity(Rela-

Bodies Certifying Products, Processes and Services

tive Density) of Wood and Wood-Based Materials

2.4 Other Standard:

D2559Specification for Adhesives for Bonded Structural

US Product Standard PS 2Performance Standard forWood-

Based Structural-Use Panels

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from Canadian Standards Association (CSA), 5060 Spectrum Way,

the ASTM website. Mississauga, ON L4W 5N6, Canada, http://www.csa.ca.

3 5

The last approved version of this historical standard is referenced on Available from International Organization for Standardization (ISO), 1, ch. de

www.astm.org. la Voie-Creuse, CP 56, CH-1211 Geneva 20, Switzerland, http://www.iso.org.

D5456−14b

3. Terminology

3.1 Definitions—Standard definitions of wood terms are

given in Terminology D9.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 Exposure 1 durability—a bond classification for

wood-based products that are not permanently exposed to the

weather.

3.2.1.1 Discussion—Wood-based products classified as Ex-

posure 1 are intended to resist the effects of moisture on

structural performance due to construction delays or other

conditions of similar severity.

3.2.2 structural composite lumber (SCL)—in this

specification, structural composite lumber (SCL) is any of

laminated veneer lumber (LVL), parallel strand lumber (PSL),

laminated strand lumber (LSL), oriented strand lumber (OSL),

or laminated veneer bamboo (LVB), which are intended for

structural use and bonded with an exterior adhesive.

3.2.2.1 laminated strand lumber (LSL)—a composite of

wood strand elements with wood fibers primarily oriented

along the longitudinal axis of the member, where the least

dimensionofthewoodstrandelementsis0.10in.(2.54mm)or

less and their average lengths are a minimum of 150 times the

least dimension of the wood strand elements.

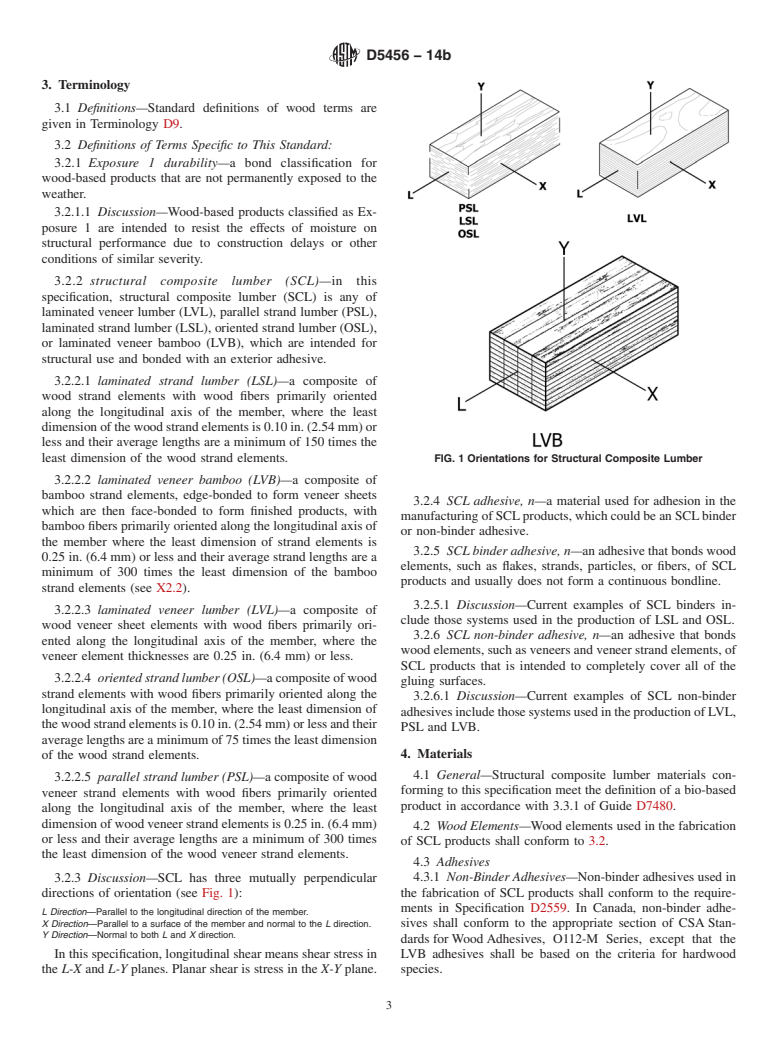

FIG. 1Orientations for Structural Composite Lumber

3.2.2.2 laminated veneer bamboo (LVB)—a composite of

bamboo strand elements, edge-bonded to form veneer sheets

3.2.4 SCL adhesive, n—a material used for adhesion in the

which are then face-bonded to form finished products, with

manufacturingofSCLproducts,whichcouldbeanSCLbinder

bamboofibersprimarilyorientedalongthelongitudinalaxisof

or non-binder adhesive.

the member where the least dimension of strand elements is

3.2.5 SCL binder adhesive, n—anadhesivethatbondswood

0.25 in. (6.4 mm) or less and their average strand lengths are a

elements, such as flakes, strands, particles, or fibers, of SCL

minimum of 300 times the least dimension of the bamboo

products and usually does not form a continuous bondline.

strand elements (see X2.2).

3.2.5.1 Discussion—Current examples of SCL binders in-

3.2.2.3 laminated veneer lumber (LVL)—a composite of

clude those systems used in the production of LSL and OSL.

wood veneer sheet elements with wood fibers primarily ori-

3.2.6 SCL non-binder adhesive, n—an adhesive that bonds

ented along the longitudinal axis of the member, where the

woodelements,suchasveneersandveneerstrandelements,of

veneer element thicknesses are 0.25 in. (6.4 mm) or less.

SCL products that is intended to completely cover all of the

3.2.2.4 orientedstrandlumber(OSL)—acompositeofwood

gluing surfaces.

strand elements with wood fibers primarily oriented along the

3.2.6.1 Discussion—Current examples of SCL non-binder

longitudinal axis of the member, where the least dimension of

adhesivesincludethosesystemsusedintheproductionofLVL,

thewoodstrandelementsis0.10in.(2.54mm)orlessandtheir

PSL and LVB.

averagelengthsareaminimumof75timestheleastdimension

4. Materials

of the wood strand elements.

4.1 General—Structural composite lumber materials con-

3.2.2.5 parallel strand lumber (PSL)—a composite of wood

forming to this specification meet the definition of a bio-based

veneer strand elements with wood fibers primarily oriented

product in accordance with 3.3.1 of Guide D7480.

along the longitudinal axis of the member, where the least

dimensionofwoodveneerstrandelementsis0.25in.(6.4mm)

4.2 Wood Elements—Wood elements used in the fabrication

or less and their average lengths are a minimum of 300 times

of SCL products shall conform to 3.2.

the least dimension of the wood veneer strand elements.

4.3 Adhesives

4.3.1 Non-Binder Adhesives—Non-binderadhesivesusedin

3.2.3 Discussion—SCL has three mutually perpendicular

directions of orientation (see Fig. 1): the fabrication of SCL products shall conform to the require-

ments in Specification D2559. In Canada, non-binder adhe-

L Direction—Parallel to the longitudinal direction of the member.

X Direction—Parallel to a surface of the member and normal to the L direction.

sives shall conform to the appropriate section of CSAStan-

Y Direction—Normal to both L and X direction.

dardsforWoodAdhesives, O112-M Series, except that the

Inthisspecification,longitudinalshearmeansshearstressin LVB adhesives shall be based on the criteria for hardwood

the L-X and L-Y planes. Planar shear is stress in the X-Y plane. species.

D5456−14b

4.3.2 Binder Adhesive—Binder adhesives, when used, shall (2)The highest grade of the LSLor OSLproducts shall be

be evaluated to meet the requirements specifed in Annex A5 tested.

(see Note 2). (3)The LSL and OSL specimen shear tests shall be

conducted in the L-X plane and shall be loaded parallel to the

NOTE 2—AnnexA5 requirements meet or exceed the requirements for

wood grain or strands.

Exposure 1; other conditions are beyond the scope of this specification.

(4)For the LSL and OSL specimens, the minimum target

See the commentary and the section on Design and Mechanical Property

Concerns in Appendix X2 for further information. bondline or shear plane temperature shall be 428°F (220°C).

For the solid wood control specimens, the minimum target

4.3.3 Non-Binder and Binder Adhesives—All adhesives

temperature at the shear plane shall be 428°F (220°C).

usedforSCLshallbequalifiedforheatdurabilityperformance

(5)The minimum target temperatures of Item (4) shall be

in accordance with 4.3.4. X2.2.4 provides additional informa-

maintained for a minimum of 10 min or until achieving a

tion.

residual strength ratio for th

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D5456 − 14a D5456 − 14b

Standard Specification for

Evaluation of Structural Composite Lumber Products

This standard is issued under the fixed designation D5456; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Structural composite lumber is intended for use as an engineering material for a variety of end-use

applications. The composition of the lumber varies by wood species, adhesive composition, wood

element size, shape, and arrangement. To provide the intended performance, composite lumber

products require: (1) an evaluation of the mechanical and physical properties and their response to

end-use environments, and (2) establishment of and conformance to standard performance specifica-

tions for quality.

Procedures contained in this specification are also to be used for establishing the design properties

and for checking the effectiveness of property assignment and quality assurance procedures.

The quality assurance sections in this specification are intended to serve as a basis for designing

quality-control programs specific to each product. The objective is to ensure that design values

established in the qualification process are maintained.

This specification is arranged as follows:

Section

Qualification 6

Determination of Allowable Design 7

Stresses

Independent Inspection 8

Quality Assurance 10

1. Scope

1.1 This specification recognizes the complexity of structural glued products. Consequently, this specification covers both

specific procedures and statements of intent that sampling and analysis must relate to the specific product.

1.2 This specification was developed in the light of currently manufactured products as defined in 3.2. Materials that do not

conform to the definitions are beyond the scope of this specification. A brief discussion is found in Appendix X1X2.

1.3 Details of manufacturing procedures are beyond the scope of this specification.

NOTE 1—There is some potential for manufacturing variables to affect the properties of members that are loaded for sustained periods of time. Users

of this specification are advised to consider the commentary on this topic in Appendix X1X2.

1.4 This specification primarily considers end use in dry service conditions, such as with most protected framing members,

where the average equilibrium moisture content for solid-sawn lumber is less than 16 %. The conditioning environment of 6.3 is

considered representative of such uses.

1.5 The performance of structural composite lumber is affected by wood species, wood element size and shape, and adhesive

and production parameters. Therefore, products produced by each individual manufacturer shall be evaluated to determine their

product properties, regardless of the similarity in characteristics to products produced by other manufacturers. Where a

manufacturer produces product in more than one facility, each production facility shall be evaluated independently. For additional

production facilities, any revisions to the full qualification program in accordance with this specification shall be approved by the

independent qualifying agency.

This specification is under the jurisdiction of ASTM Committee D07 on Wood and is the direct responsibility of Subcommittee D07.02 on Lumber and Engineered Wood

Products.

Current edition approved May 1, 2014Oct. 1, 2014. Published June 2014December 2014. Originally approved in 1993. Last previous edition approved in 2014 as

D5456 – 14.D5456 – 14a. DOI: 10.1520/D5456-14a.10.1520/D5456-14B.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5456 − 14b

1.6 This specification is intended to provide manufacturers, regulatory agencies, and end users with a means to evaluate a

composite lumber product intended for use as a structural material.

1.7 This specification covers initial qualification sampling, mechanical and physical tests, analysis, and design value

assignments. Requirements for a quality-control program and cumulative evaluations are included to ensure maintenance of

allowable design values for the product.

1.8 This specification, or parts thereof, shall be applicable to structural composite lumber portions of manufactured structural

components.

1.9 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.10 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

C177 Test Method for Steady-State Heat Flux Measurements and Thermal Transmission Properties by Means of the

Guarded-Hot-Plate Apparatus

C384 Test Method for Impedance and Absorption of Acoustical Materials by Impedance Tube Method

C423 Test Method for Sound Absorption and Sound Absorption Coefficients by the Reverberation Room Method

D9 Terminology Relating to Wood and Wood-Based Products

D143 Test Methods for Small Clear Specimens of Timber

D150 Test Methods for AC Loss Characteristics and Permittivity (Dielectric Constant) of Solid Electrical Insulation

D198 Test Methods of Static Tests of Lumber in Structural Sizes

D245 Practice for Establishing Structural Grades and Related Allowable Properties for Visually Graded Lumber

D669 Test Method for Dissipation Factor and Permittivity Parallel with Laminations of Laminated Sheet and Plate Materials

(Withdrawn 2012)

D1037 Test Methods for Evaluating Properties of Wood-Base Fiber and Particle Panel Materials

D1583 Test Method for Hydrogen Ion Concentration of Dry Adhesive Films

D1666 Test Methods for Conducting Machining Tests of Wood and Wood-Base Panel Materials

D1761 Test Methods for Mechanical Fasteners in Wood

D2132 Test Method for Dust-and-Fog Tracking and Erosion Resistance of Electrical Insulating Materials

D2394 Test Methods for Simulated Service Testing of Wood and Wood-Base Finish Flooring

D2395 Test Methods for Density and Specific Gravity (Relative Density) of Wood and Wood-Based Materials

D2559 Specification for Adhesives for Bonded Structural Wood Products for Use Under Exterior Exposure Conditions

D2718 Test Methods for Structural Panels in Planar Shear (Rolling Shear)

D2915 Practice for Sampling and Data-Analysis for Structural Wood and Wood-Based Products

D3201 Test Method for Hygroscopic Properties of Fire-Retardant Wood and Wood-Based Products

D3755 Test Method for Dielectric Breakdown Voltage and Dielectric Strength of Solid Electrical Insulating Materials Under

Direct-Voltage Stress

D4300 Test Methods for Ability of Adhesive Films to Support or Resist the Growth of Fungi

D4442 Test Methods for Direct Moisture Content Measurement of Wood and Wood-Base Materials

D4761 Test Methods for Mechanical Properties of Lumber and Wood-Base Structural Material

D4933 Guide for Moisture Conditioning of Wood and Wood-Based Materials

D5055 Specification for Establishing and Monitoring Structural Capacities of Prefabricated Wood I-Joists

D5457 Specification for Computing Reference Resistance of Wood-Based Materials and Structural Connections for Load and

Resistance Factor Design

D5764 Test Method for Evaluating Dowel-Bearing Strength of Wood and Wood-Based Products

D6815 Specification for Evaluation of Duration of Load and Creep Effects of Wood and Wood-Based Products

D7247 Test Method for Evaluating the Shear Strength of Adhesive Bonds in Laminated Wood Products at Elevated

Temperatures

D7480 Guide for Evaluating the Attributes of a Forest Management Plan

E84 Test Method for Surface Burning Characteristics of Building Materials

E96/E96M Test Methods for Water Vapor Transmission of Materials

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

The last approved version of this historical standard is referenced on www.astm.org.

D5456 − 14b

E119 Test Methods for Fire Tests of Building Construction and Materials

2.2 CSA Standards:

CSA Standards for Wood Adhesives O112-M Series

CSA O325 Construction Sheathing

2.3 OtherISO/IEC Standards:

ISO/IEC Guide 65 General Requirements for Bodies Operating Product Certification Systems

ISO/IEC 17020 General Criteria for the Operation of Various Types of Bodies Performing Inspection

US Product Standard PS 2ISO/IEC 17025 Performance Standard for Wood-Based Structural-Use PanelsGeneral Requirements

for the Competence of Testing and Calibration Laboratories

ISO/IEC 17065 Conformity Assessment – Requirements for Bodies Certifying Products, Processes and Services

2.4 Other Standard:

US Product Standard PS 2 Performance Standard for Wood-Based Structural-Use Panels

3. Terminology

3.1 Definitions—Standard definitions of wood terms are given in Terminology D9.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 Exposure 1 durability—a bond classification for wood-based products that are not permanently exposed to the weather.

Available from Canadian Standards Association (CSA), 5060 Spectrum Way, Mississauga, ON L4W 5N6, Canada, http://www.csa.ca.

Available from International Organization for Standardization (ISO), 1, ch. de la Voie-Creuse, CP 56, CH-1211 Geneva 20, Switzerland, http://www.iso.org.

3.2.1.1 Discussion—

Wood-based products classified as Exposure 1 are intended to resist the effects of moisture on structural performance due to

construction delays or other conditions of similar severity.

3.2.2 structural composite lumber (SCL)—in this specification, structural composite lumber (SCL) is any of laminated veneer

lumber (LVL), parallel strand lumber (PSL), laminated strand lumber (LSL), oriented strand lumber (OSL), or laminated veneer

bamboo (LVB), which are intended for structural use and bonded with an exterior adhesive.

3.2.2.1 laminated strand lumber (LSL)—a composite of wood strand elements with wood fibers primarily oriented along the

longitudinal axis of the member, where the least dimension of the wood strand elements is 0.10 in. (2.54 mm) or less and their

average lengths are a minimum of 150 times the least dimension of the wood strand elements.

3.2.2.2 laminated veneer bamboo (LVB)—a composite of bamboo strand elements, edge-bonded to form veneer sheets which

are then face-bonded to form finished products, with bamboo fibers primarily oriented along the longitudinal axis of the member

where the least dimension of strand elements is 0.25 in. (6.4 mm) or less and their average strand lengths are a minimum of 300

times the least dimension of the bamboo strand elements (see X1.2X2.2).

3.2.2.3 laminated veneer lumber (LVL)—a composite of wood veneer sheet elements with wood fibers primarily oriented along

the longitudinal axis of the member, where the veneer element thicknesses are 0.25 in. (6.4 mm) or less.

3.2.2.4 oriented strand lumber (OSL)—a composite of wood strand elements with wood fibers primarily oriented along the

longitudinal axis of the member, where the least dimension of the wood strand elements is 0.10 in. (2.54 mm) or less and their

average lengths are a minimum of 75 times the least dimension of the wood strand elements.

3.2.2.5 parallel strand lumber (PSL)—a composite of wood veneer strand elements with wood fibers primarily oriented along

the longitudinal axis of the member, where the least dimension of wood veneer strand elements is 0.25 in. (6.4 mm) or less and

their average lengths are a minimum of 300 times the least dimension of the wood veneer strand elements.

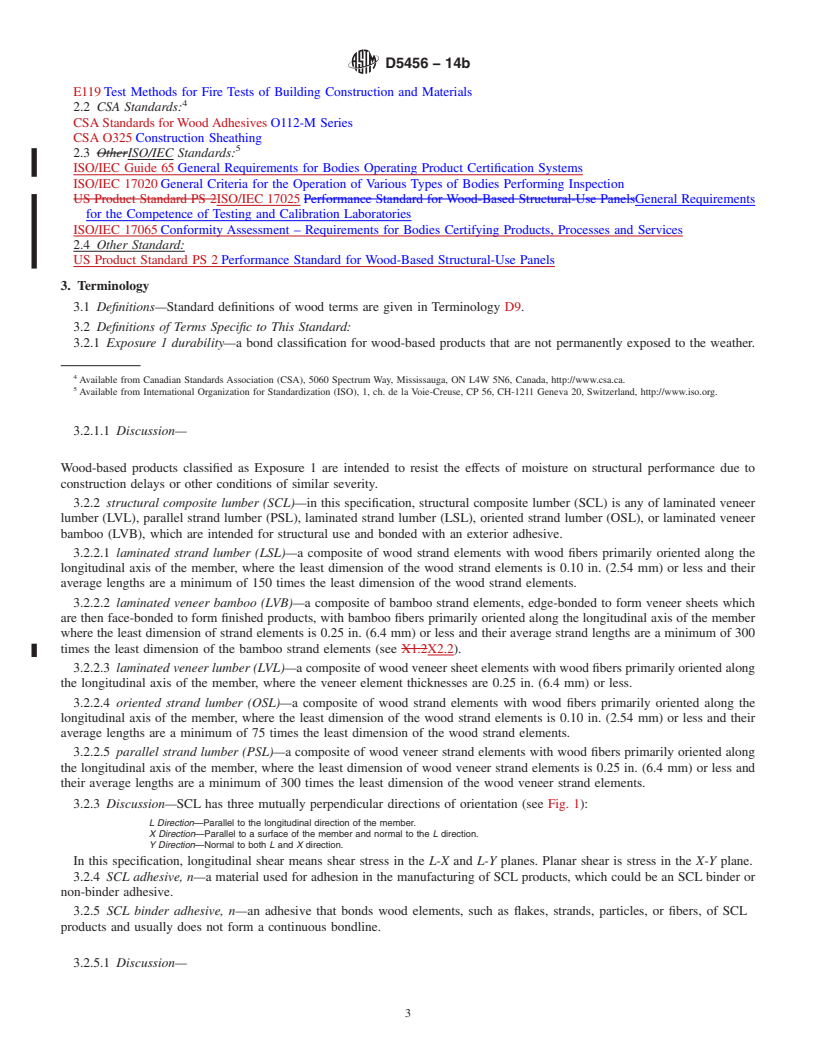

3.2.3 Discussion—SCL has three mutually perpendicular directions of orientation (see Fig. 1):

L Direction—Parallel to the longitudinal direction of the member.

X Direction—Parallel to a surface of the member and normal to the L direction.

Y Direction—Normal to both L and X direction.

In this specification, longitudinal shear means shear stress in the L-X and L-Y planes. Planar shear is stress in the X-Y plane.

3.2.4 SCL adhesive, n—a material used for adhesion in the manufacturing of SCL products, which could be an SCL binder or

non-binder adhesive.

3.2.5 SCL binder adhesive, n—an adhesive that bonds wood elements, such as flakes, strands, particles, or fibers, of SCL

products and usually does not form a continuous bondline.

3.2.5.1 Discussion—

D5456 − 14b

FIG. 1 Orientations for Structural Composite Lumber

Current examples of SCL binders include those systems used in the production of LSL and OSL.

3.2.6 SCL non-binder adhesive, n—an adhesive that bonds wood elements, such as veneers and veneer strand elements, of SCL

products that is intended to completely cover all of the gluing surfaces.

3.2.6.1 Discussion—

Current examples of SCL non-binder adhesives include those systems used in the production of LVL, PSL and LVB.

4. Materials

4.1 General—Structural composite lumber materials conforming to this specification meet the definition of a bio-based product

in accordance with 3.3.1 of Guide D7480.

4.2 Wood Elements—Wood elements used in the fabrication of SCL products shall conform to 3.2.

4.3 Adhesives

4.3.1 Non-Binder Adhesives—Non-binder adhesives used in the fabrication of SCL products shall conform to the requirements

in Specification D2559. In Canada, non-binder adhesives shall conform to the appropriate section of CSA Stan-

dards for Wood Adhesives, O112-M Series, except that the LVB adhesives shall be based on the criteria for hardwood species.

4.3.2 Binder Adhesive—Binder adhesives, when used, shall be evaluated to meet the requirements specifed in Annex A5 (see

Note 2).

NOTE 2—Annex A5 requirements meet or exceed the requirements for Exposure 1; other conditions are beyond the scope of this specification. See the

commentary and the section on Design and Mechanical Property Concerns in Appendix X1X2 for further information.

4.3.3 Non-Binder and Binder Adhesives—All adhesives used for SCL shall be qualified for he

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.