ASTM E2248-18

(Test Method)Standard Test Method for Impact Testing of Miniaturized Charpy V-notch Specimens

Standard Test Method for Impact Testing of Miniaturized Charpy V-notch Specimens

SIGNIFICANCE AND USE

5.1 There are cases where it is impractical or impossible to prepare standard CVN specimens. MCVN specimens are an alternative approach for characterizing notched specimen impact behavior. Typical applications include MCVN specimens prepared from the broken halves of previously tested specimens, from thin product form material, or from material cut from in-service components.

5.2 This test method establishes the requirements for performing impact tests on MCVN specimens fabricated from metallic materials. Minimum requirements are given for measurement and recording equipment such that similar sensitivity and comparable measurements, as compared to standard CVN tests, are achieved. The user should be aware that the transition region temperature dependence data obtained from MCVN specimens are not directly comparable to those obtained from full-size standard Charpy V-notch specimens and suitable correlation procedures have to be employed to obtain ductile-to-brittle transition temperature (DBTT) data equivalent to those obtained using CVN specimens. In all instances, correlations will have to be developed to relate upper shelf energy (USE) data from MCVN test to CVN comparable energy levels. Application of MCVN test data to the evaluation of ferritic material behavior is the responsibility of the user of this test method. MCVN test data should not be used directly to determine the lowest allowable operating temperature for an in-service material. The data must be interpreted within the framework of a fracture mechanics assessment.

5.3 While this test method treats the use of an instrumented striker as an option, the use of instrumentation in the impact test is recommended and is fully described in Test Method E2298. In order to establish the force-displacement diagram, it is necessary to measure the impact force as a function of time during contact of the striker with the specimen. The area under the force-displacement curve is a measure of instrumented absorbed...

SCOPE

1.1 This test method describes notched-bar impact testing of metallic materials using Miniaturized Charpy V-notch (MCVN) specimens and test apparatus. It provides: (a) a description of the apparatus, (b) requirements for inspection and calibration, (c) safety precautions, (d) sampling, (e) dimensions and preparation of specimens, (f) testing procedures, and (g) precision and bias.

1.2 This test method concerns Miniaturized Charpy V-notch specimens, for which all linear dimensions, including length and notch depth, are reduced with respect to a standard Charpy V-notch impact test specimen in accordance with Test Methods E23. These are not the same as sub-size specimens, described in Annex A3 of Test Methods E23, for which length, notch angle and notch depth are the same as for the standard Charpy V-notch specimen. See also 1.5 below.

1.3 Comparison of the MCVN data with standard Charpy V-notch (CVN) data or application of the MCVN data, or both, to the evaluation of ferritic material behavior is the responsibility of the user of this test method and is not explicitly covered by this test method.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This test method does not address testing of sub-size specimens as discussed in Test Methods E23. The reader should understand the distinction between miniature and subsize. Miniature specimens are shorter that sub-size specimens so that more tests can be conducted per unit volume of material. Moreover, miniature specimens are designed so that the stress fields which control fracture are similar to those of standard Test Methods E23 specimens.

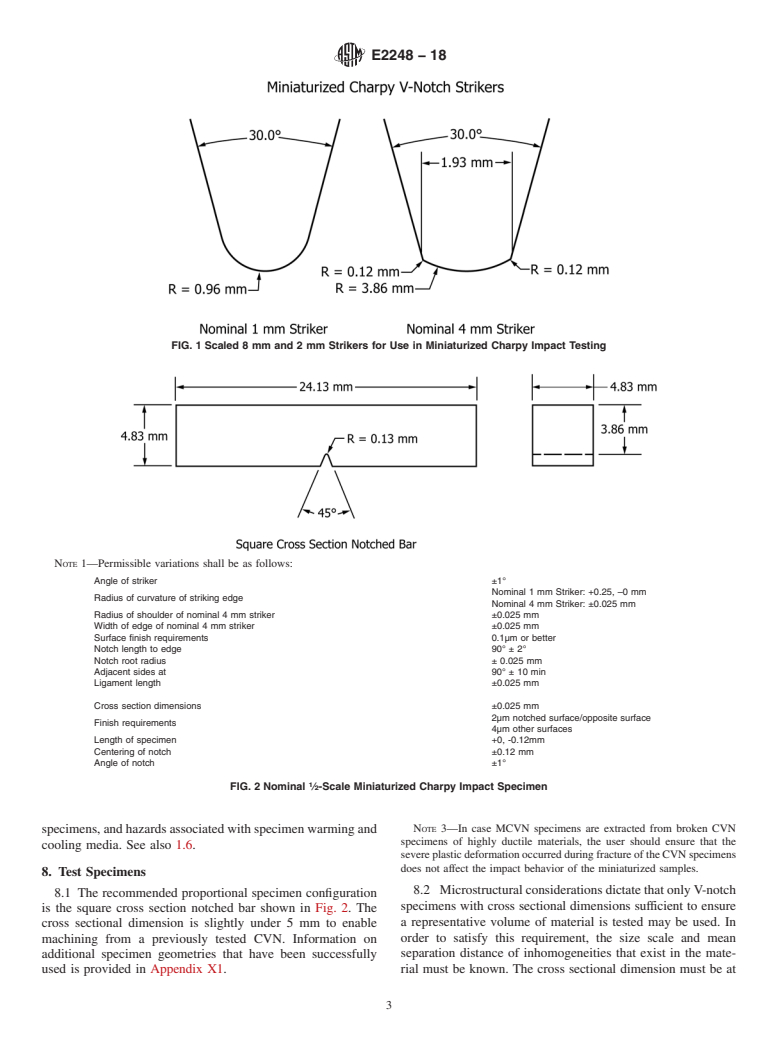

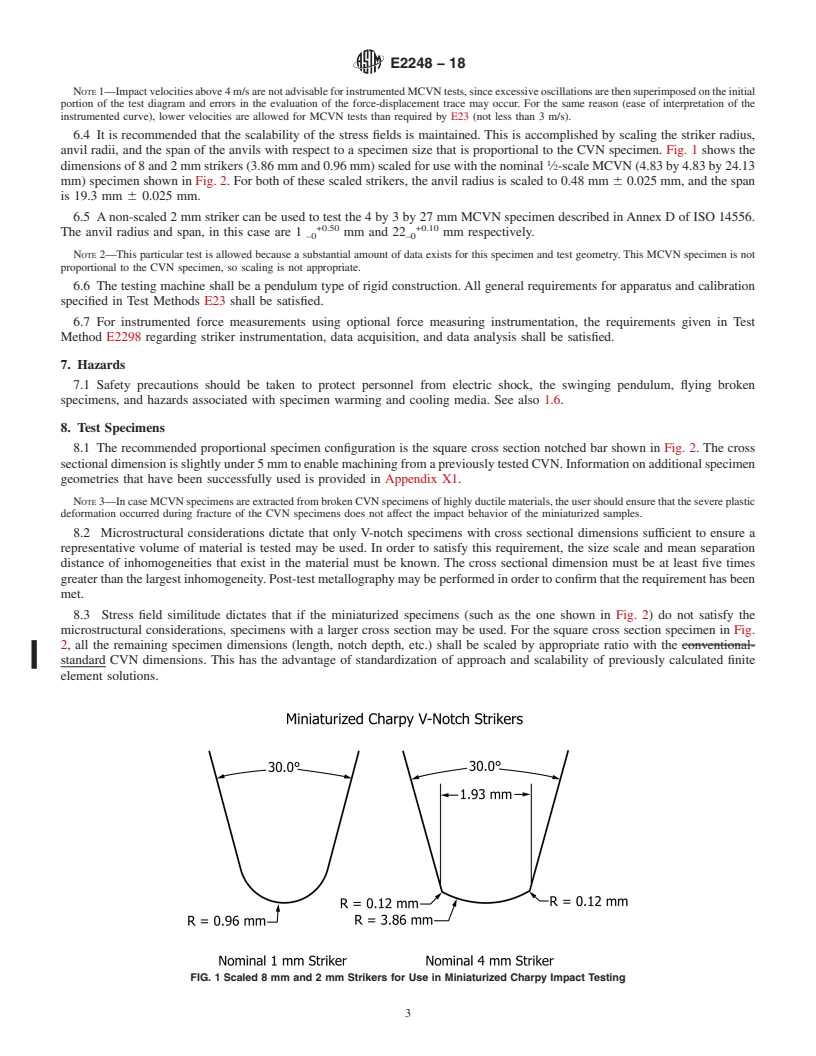

1.6 The MCVN test may be performed using a typical Test Methods E23 test machine with suitably modified anvils and striker or using a smaller capacity machine.

1.7 This standard does not purport to address all of the safety concerns, if any, ass...

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E2248 − 18

Standard Test Method for

1

Impact Testing of Miniaturized Charpy V-notch Specimens

This standard is issued under the fixed designation E2248; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 1.7 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 Thistestmethoddescribesnotched-barimpacttestingof

responsibility of the user of this standard to establish appro-

metallic materials using Miniaturized Charpy V-notch

priate safety, health, and environmental practices and deter-

(MCVN) specimens and test apparatus. It provides: (a)a

mine the applicability of regulatory limitations prior to use.

description of the apparatus, (b) requirements for inspection

1.8 This international standard was developed in accor-

andcalibration,(c)safetyprecautions,(d)sampling,(e)dimen-

dance with internationally recognized principles on standard-

sions and preparation of specimens, (f) testing procedures, and

ization established in the Decision on Principles for the

(g) precision and bias.

Development of International Standards, Guides and Recom-

1.2 ThistestmethodconcernsMiniaturizedCharpyV-notch

mendations issued by the World Trade Organization Technical

specimens, for which all linear dimensions, including length

Barriers to Trade (TBT) Committee.

andnotchdepth,arereducedwithrespecttoastandardCharpy

2. Referenced Documents

V-notchimpacttestspecimeninaccordancewithTestMethods

2

E23. These are not the same as sub-size specimens, described

2.1 ASTM Standards:

in Annex A3 of Test Methods E23, for which length, notch

E23Test Methods for Notched Bar Impact Testing of Me-

angle and notch depth are the same as for the standard Charpy

tallic Materials

V-notch specimen. See also 1.5 below.

E177Practice for Use of the Terms Precision and Bias in

ASTM Test Methods

1.3 Comparison of the MCVN data with standard Charpy

E691Practice for Conducting an Interlaboratory Study to

V-notch(CVN)dataorapplicationoftheMCVNdata,orboth,

Determine the Precision of a Test Method

to the evaluation of ferritic material behavior is the responsi-

E2298Test Method for Instrumented Impact Testing of

bility of the user of this test method and is not explicitly

Metallic Materials

covered by this test method.

3

2.2 ISO Standards:

1.4 The values stated in SI units are to be regarded as

ISO 14556Steel -- Charpy V-notch pendulum impact test --

standard. No other units of measurement are included in this

Instrumented test method

standard.

3. Terminology

1.5 This test method does not address testing of sub-size

specimens as discussed in Test Methods E23. The reader

3.1 Definitions of terms Common to Mechanical Testing:

should understand the distinction between miniature and sub-

3.1.1 absorbed energy [FL], n—work spent to fracture a

size. Miniature specimens are shorter that sub-size specimens

specimen in a single pendulum swing, as measured by a

so that more tests can be conducted per unit volume of

compensated indicating device

material. Moreover, miniature specimens are designed so that

3.1.2 instrumented absorbed energy, W[FL], n—workspent

t

the stress fields which control fracture are similar to those of

to fracture a specimen in a single pendulum swing, as calcu-

standard Test Methods E23 specimens.

lated by integrating the force-displacement curve.

1.6 The MCVN test may be performed using a typical Test

3.1.3 lateral expansion [L], n—the maximum increase in

Methods E23 test machine with suitably modified anvils and

thickness of the specimen as a result of the impact test,

striker or using a smaller capacity machine.

expressed in mm.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

1

This test method is under the jurisdiction of ASTM Committee E28 on contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Mechanical Testing and is the direct responsibility of Subcommittee E28.07 on Standards volume information, refer to the standard’s Document Summary page on

Impact Testing. the ASTM website.

3

Current edition approved June 1, 2018. Published September 2018. Originally Available from International Organization for Standardization (ISO), 1, ch. de

approved in 2009. Last previous edition approved in 2015 as E2248–15. DOI: la Voie-Creuse, Case postale 56, CH-1211, Geneva 20, Switzerland, http://

10.1520/E2248-18. www.iso.org.

*A Summary of Changes section appears at the end

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E2248 − 15 E2248 − 18

Standard Test Method for

Impact Testing of Miniaturized Charpy V-NotchV-notch

1

Specimens

This standard is issued under the fixed designation E2248; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method describes notched-bar impact testing of metallic materials using Miniaturized Charpy V-NotchV-notch

(MCVN) specimens and test apparatus. It provides: (a) a description of the apparatus, (b) requirements for inspection and

calibration, (c) safety precautions, (d) sampling, (e) dimensions and preparation of specimens, (f) testing procedures, and (g)

precision and bias.

1.2 This standard test method concerns Miniaturized Charpy V-NotchV-notch specimens, for which all linear dimensions,

including length and notch depth, are reduced with respect to a type A standardstandard Charpy V-notch impact test specimen in

accordance with Test Methods E23. These are not the same as sub-size specimens, described in Annex A3 of Test Methods E23,

for which length, notch angle and notch depth are the same as for the standard type A Charpy V-notch specimen. See also 1.5 below.

1.3 Comparison of the MCVN data with conventionalstandard Charpy V-NotchV-notch (CVN) data or application of the

MCVN data, or both, to the evaluation of ferritic material behavior is the responsibility of the user of this test method and is not

explicitly covered by this test method.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard test method does not address testing of sub-size specimens as discussed in Test Methods E23. The reader

should understand the distinction between miniature and subsize. Miniature specimens are shorter that sub-size specimens so that

more tests can be conducted per unit volume of material. Moreover, miniature specimens are designed so that the stress fields

which control fracture are similar to those of conventionalstandard Test Methods E23 specimens.

1.6 The MCVN test may be performed using a typical Test Methods E23 test machine with suitably modified anvils and striker

or using a smaller capacity machine.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.8 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

A370 Test Methods and Definitions for Mechanical Testing of Steel Products

E23 Test Methods for Notched Bar Impact Testing of Metallic Materials

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

E2298 Test Method for Instrumented Impact Testing of Metallic Materials

3

2.2 ISO Standards:

ISO 148 Metallic materials -- Charpy pendulum impact test -- Part 1: Test method

ISO 14556 Steel -- Charpy V-notch pendulum impact test -- Instrumented test method

1

This test method is under the jurisdiction of ASTM Committee E28 on Mechanical Testing and is the direct responsibility of Subcommittee E28.07 on Impact Testing.

Current edition approved Oct. 1, 2015June 1, 2018. Published December 2015September 2018. Originally approved in 2009. Last previous edition approved in 20132015

as E2248–13.–15. DOI: 10.1520/E2248-15.10.1520/E2248-18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from International Organization for Standardization (ISO), 1, ch. de la Voie-Creuse, Case postale 56, CH-1211, Geneva 20, Switzerland, http://www.iso.org.

*A Summary of Changes section appears at the end of this standard

Copyrigh

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.