ASTM E23-16

(Test Method)Standard Test Methods for Notched Bar Impact Testing of Metallic Materials

Standard Test Methods for Notched Bar Impact Testing of Metallic Materials

SIGNIFICANCE AND USE

4.1 These test methods of impact testing relate specifically to the behavior of metal when subjected to a single application of a force resulting in multi-axial stresses associated with a notch, coupled with high rates of loading and in some cases with high or low temperatures. For some materials and temperatures the results of impact tests on notched specimens, when correlated with service experience, have been found to predict the likelihood of brittle fracture accurately. Further information on significance appears in Appendix X1.

SCOPE

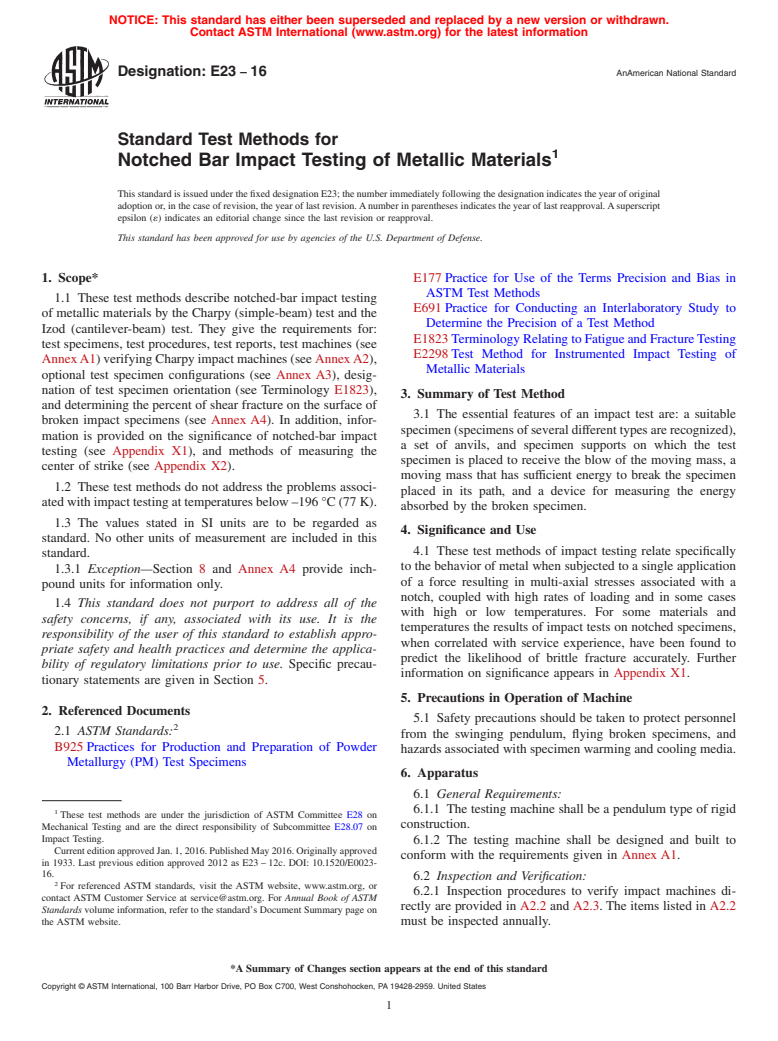

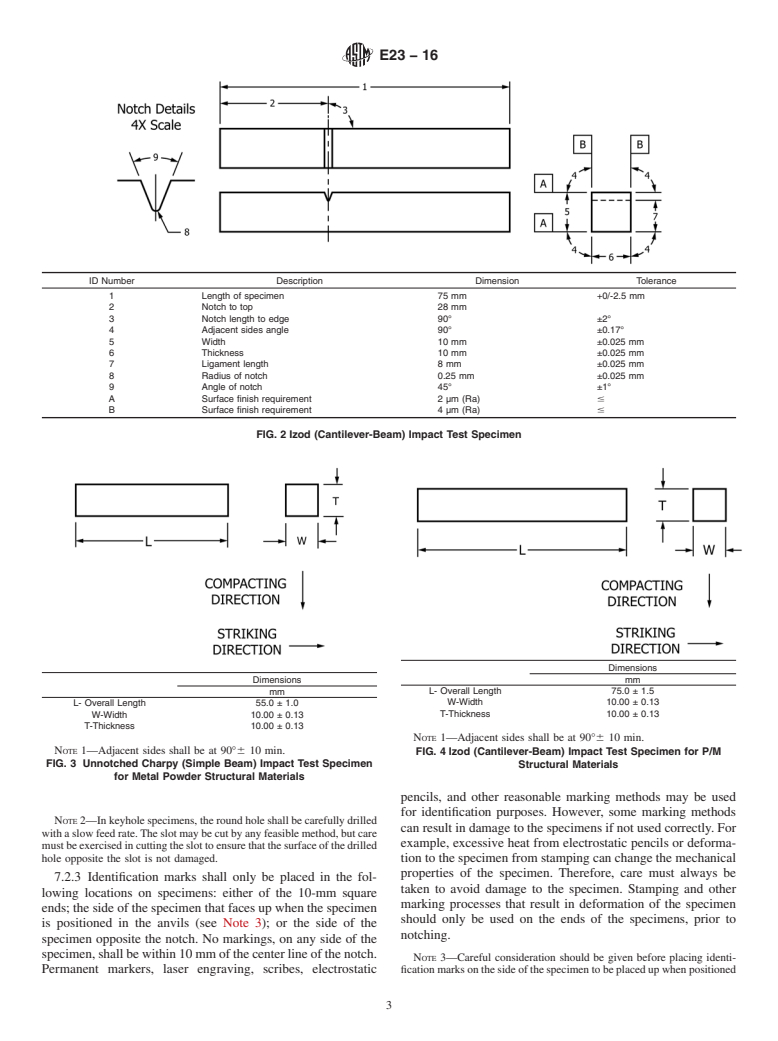

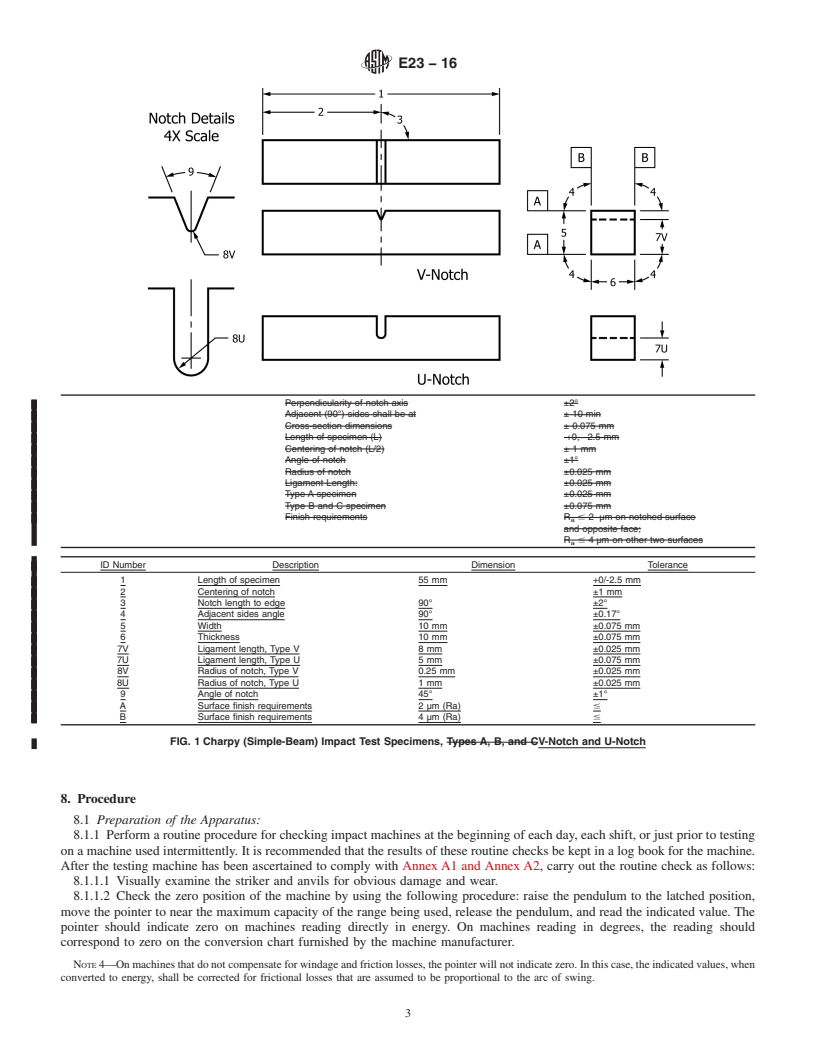

1.1 These test methods describe notched-bar impact testing of metallic materials by the Charpy (simple-beam) test and the Izod (cantilever-beam) test. They give the requirements for: test specimens, test procedures, test reports, test machines (see Annex A1) verifying Charpy impact machines (see Annex A2), optional test specimen configurations (see Annex A3), designation of test specimen orientation (see Terminology E1823), and determining the percent of shear fracture on the surface of broken impact specimens (see Annex A4). In addition, information is provided on the significance of notched-bar impact testing (see Appendix X1), and methods of measuring the center of strike (see Appendix X2).

1.2 These test methods do not address the problems associated with impact testing at temperatures below –196 °C (77 K).

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3.1 Exception—Section 8 and Annex A4 provide inch-pound units for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Section 5.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E23 − 16 AnAmerican National Standard

Standard Test Methods for

1

Notched Bar Impact Testing of Metallic Materials

ThisstandardisissuedunderthefixeddesignationE23;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* E177Practice for Use of the Terms Precision and Bias in

ASTM Test Methods

1.1 These test methods describe notched-bar impact testing

E691Practice for Conducting an Interlaboratory Study to

of metallic materials by the Charpy (simple-beam) test and the

Determine the Precision of a Test Method

Izod (cantilever-beam) test. They give the requirements for:

E1823TerminologyRelatingtoFatigueandFractureTesting

test specimens, test procedures, test reports, test machines (see

E2298Test Method for Instrumented Impact Testing of

AnnexA1)verifyingCharpyimpactmachines(seeAnnexA2),

Metallic Materials

optional test specimen configurations (see Annex A3), desig-

nation of test specimen orientation (see Terminology E1823),

3. Summary of Test Method

and determining the percent of shear fracture on the surface of

3.1 The essential features of an impact test are: a suitable

broken impact specimens (see Annex A4). In addition, infor-

specimen(specimensofseveraldifferenttypesarerecognized),

mation is provided on the significance of notched-bar impact

a set of anvils, and specimen supports on which the test

testing (see Appendix X1), and methods of measuring the

specimen is placed to receive the blow of the moving mass, a

center of strike (see Appendix X2).

moving mass that has sufficient energy to break the specimen

1.2 These test methods do not address the problems associ-

placed in its path, and a device for measuring the energy

atedwithimpacttestingattemperaturesbelow–196°C(77K).

absorbed by the broken specimen.

1.3 The values stated in SI units are to be regarded as

4. Significance and Use

standard. No other units of measurement are included in this

4.1 These test methods of impact testing relate specifically

standard.

to the behavior of metal when subjected to a single application

1.3.1 Exception—Section 8 and Annex A4 provide inch-

of a force resulting in multi-axial stresses associated with a

pound units for information only.

notch, coupled with high rates of loading and in some cases

1.4 This standard does not purport to address all of the

with high or low temperatures. For some materials and

safety concerns, if any, associated with its use. It is the

temperatures the results of impact tests on notched specimens,

responsibility of the user of this standard to establish appro-

when correlated with service experience, have been found to

priate safety and health practices and determine the applica-

predict the likelihood of brittle fracture accurately. Further

bility of regulatory limitations prior to use. Specific precau-

information on significance appears in Appendix X1.

tionary statements are given in Section 5.

5. Precautions in Operation of Machine

2. Referenced Documents

5.1 Safety precautions should be taken to protect personnel

2

2.1 ASTM Standards:

from the swinging pendulum, flying broken specimens, and

B925Practices for Production and Preparation of Powder

hazardsassociatedwithspecimenwarmingandcoolingmedia.

Metallurgy (PM) Test Specimens

6. Apparatus

6.1 General Requirements:

6.1.1 The testing machine shall be a pendulum type of rigid

1

These test methods are under the jurisdiction of ASTM Committee E28 on

construction.

Mechanical Testing and are the direct responsibility of Subcommittee E28.07 on

Impact Testing.

6.1.2 The testing machine shall be designed and built to

CurrenteditionapprovedJan.1,2016.PublishedMay2016.Originallyapproved

conform with the requirements given in Annex A1.

in 1933. Last previous edition approved 2012 as E23–12c. DOI: 10.1520/E0023-

16.

6.2 Inspection and Verification:

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

6.2.1 Inspection procedures to verify impact machines di-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

rectly are provided in A2.2 and A2.3. The items listed in A2.2

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. must be inspected annually.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E23−16

6.2.2 The procedures to verify Charpy machines indirectly, 7.1.4 The specimens commonly found suitabl

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E23 − 12c E23 − 16 An American National Standard

Standard Test Methods for

1

Notched Bar Impact Testing of Metallic Materials

This standard is issued under the fixed designation E23; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope Scope*

1.1 These test methods describe notched-bar impact testing of metallic materials by the Charpy (simple-beam) test and the Izod

(cantilever-beam) test. They give the requirements for: test specimens, test procedures, test reports, test machines (see Annex A1)

verifying Charpy impact machines (see Annex A2), optional test specimen configurations (see Annex A3), designation of test

specimen orientation (see Terminology E1823), and determining the percent of shear fracture on the surface of broken impact

specimens (see Annex A4). In addition, information is provided on the significance of notched-bar impact testing (see Appendix

X1), and methods of measuring the center of strike (see Appendix X2).

1.2 These test methods do not address the problems associated with impact testing at temperatures below –196 °C (77 K).

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3.1 Exception—Section 8 and Annex A4 provide inch-pound units for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. Specific precautionary statements are given in Section 5.

2. Referenced Documents

2

2.1 ASTM Standards:

B925 Practices for Production and Preparation of Powder Metallurgy (PM) Test Specimens

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E604 Test Method for Dynamic Tear Testing of Metallic Materials

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

E1823 Terminology Relating to Fatigue and Fracture Testing

E2298 Test Method for Instrumented Impact Testing of Metallic Materials

3. Summary of Test Method

3.1 The essential features of an impact test are: a suitable specimen (specimens of several different types are recognized), a set

of anvils, and specimen supports on which the test specimen is placed to receive the blow of the moving mass, a moving mass

that has sufficient energy to break the specimen placed in its path, and a device for measuring the energy absorbed by the broken

specimen.

4. Significance and Use

4.1 These test methods of impact testing relate specifically to the behavior of metal when subjected to a single application of

a force resulting in multi-axial stresses associated with a notch, coupled with high rates of loading and in some cases with high

or low temperatures. For some materials and temperatures the results of impact tests on notched specimens, when correlated with

service experience, have been found to predict the likelihood of brittle fracture accurately. Further information on significance

appears in Appendix X1.

1

These test methods are under the jurisdiction of ASTM Committee E28 on Mechanical Testing and are the direct responsibility of Subcommittee E28.07 on Impact

Testing.

Current edition approved Nov. 15, 2012Jan. 1, 2016. Published January 2013May 2016. Originally approved in 1933. Last previous edition approved 2012 as

E23 – 12b.E23 – 12c. DOI: 10.1520/E0023-12C.10.1520/E0023-16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E23 − 16

5. Precautions in Operation of Machine

5.1 Safety precautions should be taken to protect personnel from the swinging pendulum, flying broken specimens, and hazards

associated with specimen warming and cooling media.

6.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.