ASTM E246-95

(Test Method)Standard Test Methods for Determination of Iron in Iron Ores and Related Materials by Dichromate Titration

Standard Test Methods for Determination of Iron in Iron Ores and Related Materials by Dichromate Titration

SCOPE

1.1 These test methods cover the determination of total iron in iron ores, concentrates, and agglomerates in the concentration range 30 to 95 % iron.

1.2 The test methods in this standard are contained in the sections indicated as follows:

Test Method A--Iron by the Hydrogen Sulfide Reduction Dichromate Titration Method (30 to 75 % Fe)

Test Method B--Iron by the Stannous Chloride Reduction Dichromate Titration Method (35 to 95 % Fe)

Test Method C--Iron by the Silver Reduction Dichromate Titration Method (35 to 95 % Fe)

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazards statements are given in Section 5 and in special "Warning" paragraphs throughout these test methods.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 246 – 95

Standard Test Method for

Iron in Iron Ores and Related Materials by Hydrogen Sulfide

Reduction and Dichromate Titration

This standard is issued under the fixed designation E 246; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope mate solution using sodium diphenylamine sulfonate as the

indicator.

1.1 This test method covers the determination of total iron

in iron ores, concentrates, and agglomerates in the concentra-

4. Significance and Use

tion range from 30 to 75 %.

4.1 This test method is intended to be used for compliance

1.2 This standard does not purport to address all of the

with compositional specifications for iron content. It is as-

safety concerns, if any, associated with its use. It is the

sumed that all who use these procedures will be trained

responsibility of the user of this standard to establish appro-

analysts, capable of performing common laboratory procedures

priate safety and health practices and determine the applica-

skillfully and safely. It is expected that work will be performed

bility of regulatory limitations prior to use.

in a properly equipped laboratory and that proper waste

2. Referenced Documents disposal procedures will be followed. Appropriate quality

control practices must be followed, such as those described in

2.1 ASTM Standards:

2 Guide E 882.

D 1193 Specification for Reagent Water

E 276 Test Methods for Particle Size or Screen Analysis at

5. Interferences

No. 4 (4.75-mm) Sieve and Finer for Metal Bearing Ores

3 5.1 None of the elements normally found in iron ores

and Related Materials

interfere with this test method. These include vanadium,

E 877 Practice for Sampling and Sample Preparation of Iron

4 copper, and small amounts of molybdenum, which occasion-

Ores and Related Materials

ally occur in iron ores.

E 882 Guide for Accountability and Quality Control in the

Chemical Analysis Laboratory

6. Apparatus

3. Summary of Test Method 6.1 Analytical Balance and Weights—The balance used to

weigh the sample shall be sensitive to 0.05 mg and shall have

3.1 The sample is dissolved in hydrochloric acid. The

a precision of 0.1 mg. Analytical weights shall be of precision

insoluble residue is removed by filtration, ignited, and treated

grade or calibrated against a set of certified standard weights.

for the recovery of iron, and added to the main solution. To this

6.2 Buret—The buret used to titrate the reduced solution

solution containing all the iron, sulfuric acid is added and the

shall be of precision grade, calibrated to tenths of a millilitre,

solution evaporated to fumes to expel chlorides. The salts are

and shall be read to 0.05 mL.

dissolved in water, the solution heated to boiling, and the iron

6.3 Hydrogen Sulfide Generator—Hydrogen sulfide shall be

reduced by a rapid stream of hydrogen sulfide. The precipitated

obtained from a cylinder of the compressed gas or from a Kipp

sulfides are filtered and washed with an acid-sulfide wash

generator. A consistent flow of 1 L/min shall be maintained and

solution until free of iron. The filtrate is then boiled to expel the

the gas passed through a water trap to remove any salts.

hydrogen sulfide, cooled, and titrated with potassium dichro-

6.4 Glassware—Beakers or flasks used in the analysis of the

sample shall be of chemical-resistant glass and free of etched

This test method is under the jurisdiction of ASTM Committee E-1 on

surfaces. Before using, all glassware shall be cleaned in hot,

Analytical Chemistry for Metals, Ores, and Related Materials and is the direct

dilute hydrochloric acid and thoroughly rinsed in water.

responsibility of Subcommittee E01.02 on Ores, Slags, Refractories, Cement, and

Related Oxide Materials.

7. Reagents and Materials

Current edition approved April 15, 1995. Published June 1995. Originally

published as E 246 – 64 T. Last previous edition E 246 – 68 (1989).

7.1 Purity of Reagents—Reagent grade chemicals shall be

Annual Book of ASTM Standards, Vol 11.01.

used in all tests. Unless otherwise indicated, it is intended that

Annual Book of ASTM Standards, Vol 03.05.

Annual Book of ASTM Standards, Vol 03.06.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

E 246

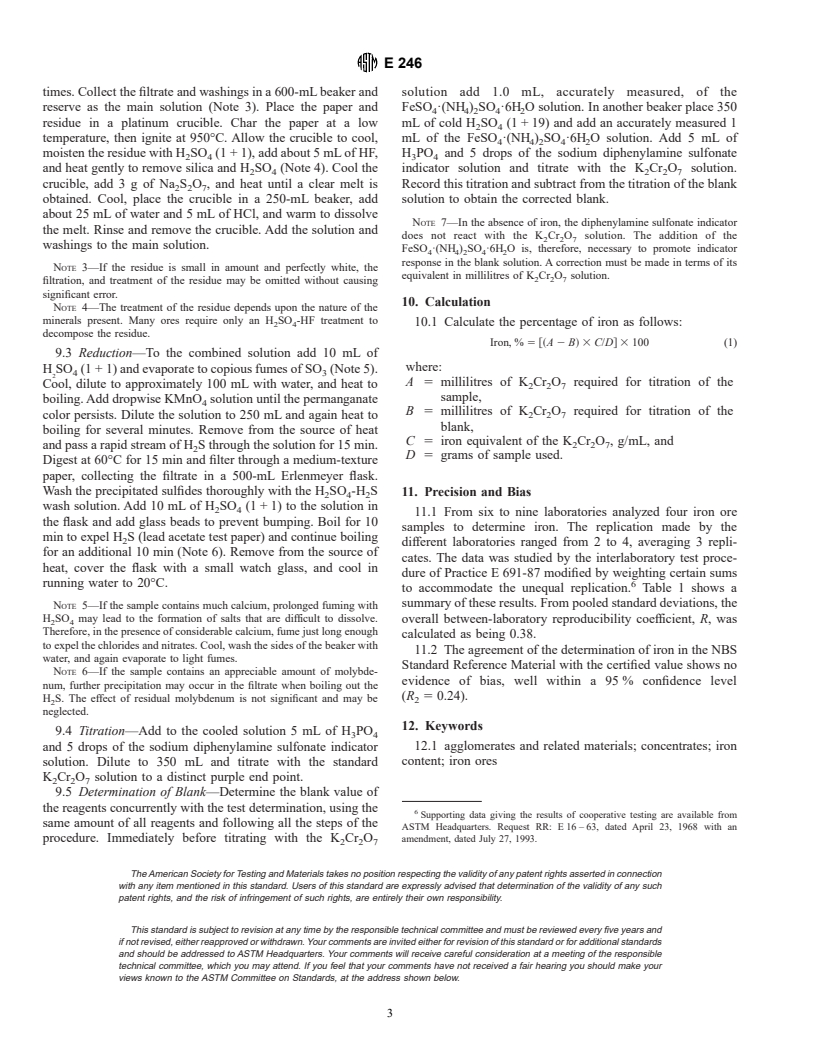

TABLE 1 Precision Data

Repeatability Reproducibility

Number of Iron Found

Sample

R R

I 2

Laboratories %

s s

r R

(2.8 s ) (2.8 s )

r R

Seine River Ore 9 57.52 0.125 0.35 0.126 0.35

Knob Lake Ore 9 58.45 0.097 0.27 0.136 0.38

NBS 27d (64.96 % Fe) 6 65.01 0.057 0.16 0.085 0.24

Chilean Iron Ore 9 66.11 0.102 0.29 0.172 0.48

A

Pooled standard deviations 0.101 0.137

A

Weighted by degrees of freedom, n for s and (n − 1) for s where n 5 number of laboratories.

r R

all reagents shall conform to the specifications of the Commit- 7.12 Sodium Diphenylamine Sulfonate Indicator Solution—

tee on Analytical Reagents of the American Chemical Society, Dissolve 0.3 g of sodium diphenylamine sulfonate in 100 mL

where such specifications are available. Other grades may be of water. Store in a dark-colored bottle.

used, provided it is first ascertained that the reagent is of 7.13 Sodium Pyrosulfate (Na S O ).

2 2 7

sufficiently high purity to permit its use without lessening the 7.14 Sulfuric Acid (1 + 1)—Carefully mix 1 volume of

accuracy of the determination. concentrated sulfuric acid (H SO , sp gr 1.84) with 1 volume

2 4

7.2 Purity of Water—Unless otherwise indicated, references of water.

to water shall be understood to mean reagent water conforming 7.15 Sulfuric Acid (1 + 19)—Carefully mix 1 volume of

to Specification D 1193. concentrated sulfuric acid (H SO , sp gr 1.84) with 19 volumes

2 4

7.3 Ferrous Ammonium Sulfate Solution (approximately of water.

0.10 N)—Dissolve 40 g of ferrous ammonium sulfate 7.16 Sulfuric Acid-Hydrogen Sulfide Wash Solution—Add

(FeSO ·(NH ) SO ·6H O) in sulfuric acid (1 + 19). Transfer to 20 mL of concentrated sulfuric acid (H SO , sp gr 1.84) to 900

4 4 2 4 2 2 4

a 1-L flask and dilute to volume with the same acid. When the mL of water, cool, dilute to 1 L, and pass a rapid stream of H S

sample solution is ready for titration, standardize the through it for at least 10 min.

FeSO ·(NH ) SO ·6H O solution against the standard potas-

4 4 2 4 2

8. Sampling, Test Specimen, and Test Unit

sium dichromate (0.1000 N), as described in 9.5. Calculate the

8.1 The test unit shall be collected and prepared in accor-

millilitres of standard potassium dichromate equivalent to 1

dance with Practice E 877.

mL of the FeSO ·(NH ) SO ·6H O solution.

4 4 2 4 2

8.2 The test unit shall be pulverized or ground so that at

7.4 Hydrochloric Acid (sp gr 1.19)—Concentrated hydro-

least 95 % passes a No. 100 (150 μ-m) sieve in accordance with

chloric acid (HCl).

Test Method E 276.

7.5 Hydrochloric Acid (1 + 50)—Mix 1 volume of HCl (sp

gr 1.19) with 50 volumes of water.

NOTE 1—Some ores, such as specular hematities, may require finer

7.6 Hydrofluoric Acid (48 %)—Concentrated hydrofluoric

grinding to pass a No. 200 (75-μm) sieve.

acid (HF).

9. Procedure

7.7 Hydrogen Sulfide (H S).

7.8 Nitric Acid (85 %)—Concentrated nitric acid (HNO ).

9.1 Transfer approximately 0.50 g of the test specimen to a

7.9 Phosphoric Acid (sp gr 1.69)—Concentrated phosphoric

small weighing bottle previously dried at about 105°C. Dry the

acid (H PO ).

bottle and contents for1hat105 to 110°C (Note 2). Cap the

3 4

7.10 Potassium Dichromate, Standard Solution (0.1000

bottle and cool to room temperature in a desiccator. Momen-

N)—Transfer 4.9035 g of primary standard grade potassium

tarily release the cap to equalize the pressure and weigh the

dichromate (K Cr O ), previously ground in an agate mortar,

capped bottle and sample to the nearest 0.1 mg. Repeat the

2 2 7

and dried at 105 to 110°C, to a 1-L volumetric flask. Dissolve

drying and weighing until there is no further weight loss.

in water and dilute to 1 L. If preferred, this solution may be

Transfer the test specimen to a 250-mL

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.