ASTM D5859-96

(Test Method)Standard Test Method for Determining the Traction of Footwear on Painted Surfaces Using the Variable Incidence Tester

Standard Test Method for Determining the Traction of Footwear on Painted Surfaces Using the Variable Incidence Tester

SCOPE

1.1 This test method covers the measurement of the traction of footwear on painted walkway surfaces under both dry and wet conditions in the laboratory and the field.

1.2 The values stated in inch-pound units are to be regarded as the standard. The SI values given in parentheses are provided for information only.

1.3 This test method does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

Designation:D5859–96

Standard Test Method for

Determining the Traction of Footwear on Painted Surfaces

Using the Variable Incidence Tester

This standard is issued under the fixed designation D 5859; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the measurement of the traction

of footwear on painted walkway surfaces under both dry and

wet conditions in the laboratory and the field.

1.2 The values stated in inch-pound units are to be regarded

as the standard. The SI values given in parentheses are

provided for information only.

1.3 This test method does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

2. Terminology

2.1 Description of Terms Specific to This Standard:

2.1.1 friction—the resistance developed between the physi-

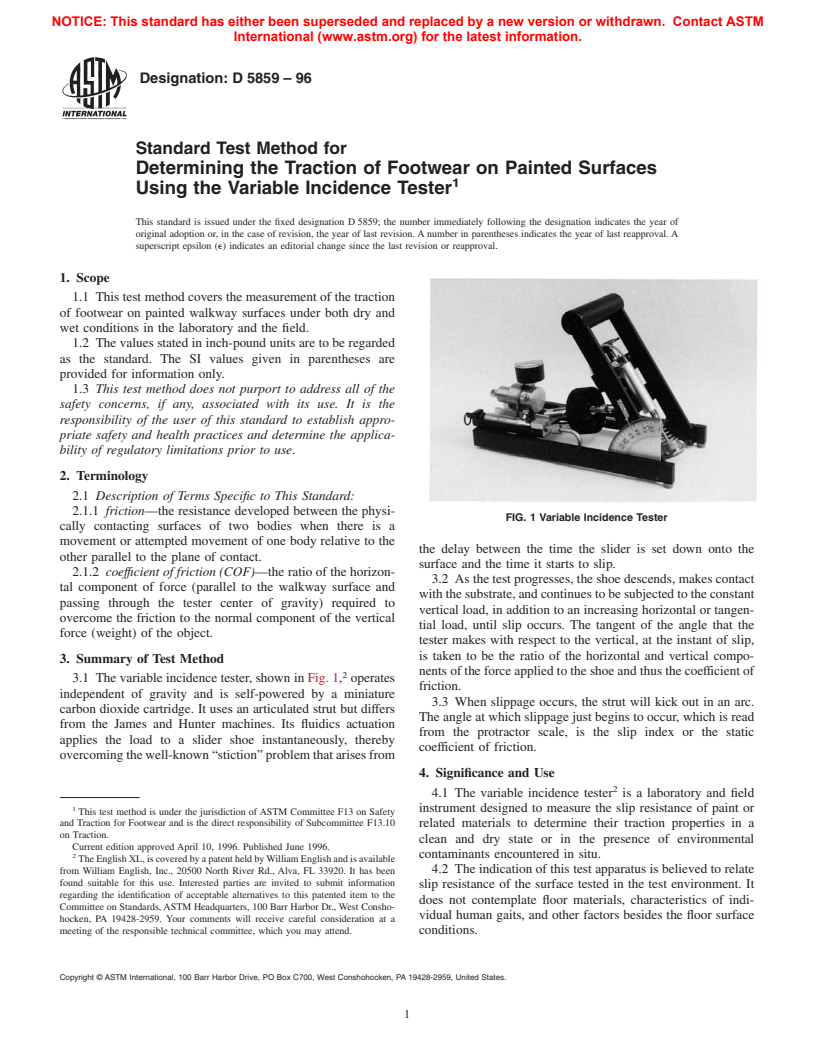

FIG. 1 Variable Incidence Tester

cally contacting surfaces of two bodies when there is a

movement or attempted movement of one body relative to the

the delay between the time the slider is set down onto the

other parallel to the plane of contact.

surface and the time it starts to slip.

2.1.2 coeffıcient of friction (COF)—the ratio of the horizon-

3.2 As the test progresses, the shoe descends, makes contact

tal component of force (parallel to the walkway surface and

withthesubstrate,andcontinuestobesubjectedtotheconstant

passing through the tester center of gravity) required to

vertical load, in addition to an increasing horizontal or tangen-

overcome the friction to the normal component of the vertical

tial load, until slip occurs. The tangent of the angle that the

force (weight) of the object.

tester makes with respect to the vertical, at the instant of slip,

is taken to be the ratio of the horizontal and vertical compo-

3. Summary of Test Method

nents of the force applied to the shoe and thus the coefficient of

3.1 The variable incidence tester, shown in Fig. 1, operates

friction.

independent of gravity and is self-powered by a miniature

3.3 When slippage occurs, the strut will kick out in an arc.

carbon dioxide cartridge. It uses an articulated strut but differs

The angle at which slippage just begins to occur, which is read

from the James and Hunter machines. Its fluidics actuation

from the protractor scale, is the slip index or the static

applies the load to a slider shoe instantaneously, thereby

coefficient of friction.

overcomingthewell-known“stiction”problemthatarisesfrom

4. Significance and Use

4.1 The variable incidence tester is a laboratory and field

instrument designed to measure the slip resistance of paint or

This test method is under the jurisdiction of ASTM Committee F13 on Safety

and Traction for Footwear and is the direct responsibility of Subcommittee F13.10

related materials to determine their traction properties in a

on Traction.

clean and dry state or in the presence of environmental

Current edition approved April 10, 1996. Published June 1996.

2 contaminants encountered in situ.

TheEnglishXL,iscoveredbyapatentheldbyWilliamEnglishandisavailable

4.2 The indication of this test apparatus is believed to relate

from William English, Inc., 20500 North River Rd., Alva, FL 33920. It has been

found suitable for this use. Interested parties are invited to submit information

slip resistance of the surface tested in the test environment. It

regarding the identification of acceptable alternatives to this patented item to the

does not contemplate floor materials, characteristics of indi-

Committee on Standards,ASTM Headquarters, 100 Barr Harbor Dr., West Consho-

vidual human gaits, and other factors besides the floor surface

hocken, PA 19428-2959. Your comments will receive careful consideration at a

meeting of the responsible technical committee, which you may attend. conditions.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

D5859–96

4.3 The relative slip resistance of a floor surface may be be slightly beveled to remove any sharp edges. Sanding

measured under wet or dry conditions or in the presence of particles should then be dusted off with a clean paint brush.

other environmental contaminants using the specific foot 6.3 Following initial preparation, the foot is screwed onto

assembly. the nut on the universal joint. Screw the joint together until

snug and then back off ⁄4 turn.

5. Apparatus

2 7. Reagents and Materials

5.1 Variable Incidence Tester —The tester is constructed as

7.1 Silicon Carbide Paper, 400-grit wet or dry.

follows:

7.2 Cleaner.

5.1.1 Chassis—A rigid welded aluminum frame fabricated

7.3 Standard Slider Pad.

from ⁄8 by 1-in. (9 by 25-mm) flat bar fitted with three

7.4 Rags, Sponge or Paper Towels.

slip-resistant feet that rest on the test surface.

7.5 Distilled Water.

5.1.2 Mast Assembly—A rigid welded aluminum frame

7.6 Hand-Pumped Spray Bottle.

fabricated from ⁄4 by 1-in. (6 by 25-mm) flat bar attached to

7.7 Paint Brush.

the chassis with a hinge joint that permits it to be inclined from

7.8 Two (2) Part Epoxy Adhesive.

vertical 90° to 45°.

7.9 Soft Fiber Bristle Brush.

5.1.3 Handle—A 1-in. (25-mm) diameter aluminum tube

7.10 Double-Stick Tape.

bolted to the top of the mast assembly that can be used to lift

and carry the tester and is grasped to apply a downward force

8. Tester Operational Check

to the tester to prevent sliding on the test surface while

8.1 Place the tester on a flat surface.

operating.

8.2 Insert a pressurized gas cartridge into its holder on the

5.1.4 Actuating Cylinder—A miniature pneumatic cylinder

chassis and tighten the clamp screw until pressure registers on

is mounted to the mast assembly by a hinged joint to permit

the gage.

swinging of the universal foot when slippage occurs.

8.3 Cycle the tester twice to verify that the piston shaft

5.1.5 Universal Foot Assembly—A universal joint between

moves freely and stabilizes the working pressure.

the slider disc and the piston rod of the actuating cylinder

permitstheoperatingforcetoapplytheslidertothetestsurface

9. Procedure (Dry)

in a manner not unlike the human foot in walking.Acoil spring

9.1 The test area or test specimens shall not be less than 2

brings the universal foot to approximate neutral alignment

in. (5 cm ).

following each power stroke.

9.2 Before testing is begun, clean the test surface with a soft

5.1.6 Articulated Strut—The actuating cylinder and univer-

fiber bristle brush and cleaner at a dilution rate of one part

sal foot assembly comprise the articulated strut. It is the

cleaner to ten parts distilled water. Rinse the surface with

movement of this assembly about its hinge pin that permits the

distilled wa

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.