ASTM F880-98

(Specification)Standard Specification for Stainless Steel Socket-Set Screws

Standard Specification for Stainless Steel Socket-Set Screws

SCOPE

1.1 This specification covers the requirements for austenitic grade stainless steel socket-set screws (SSS), sizes 0.060 through 0.500 in. in two conditions, AF and CW.

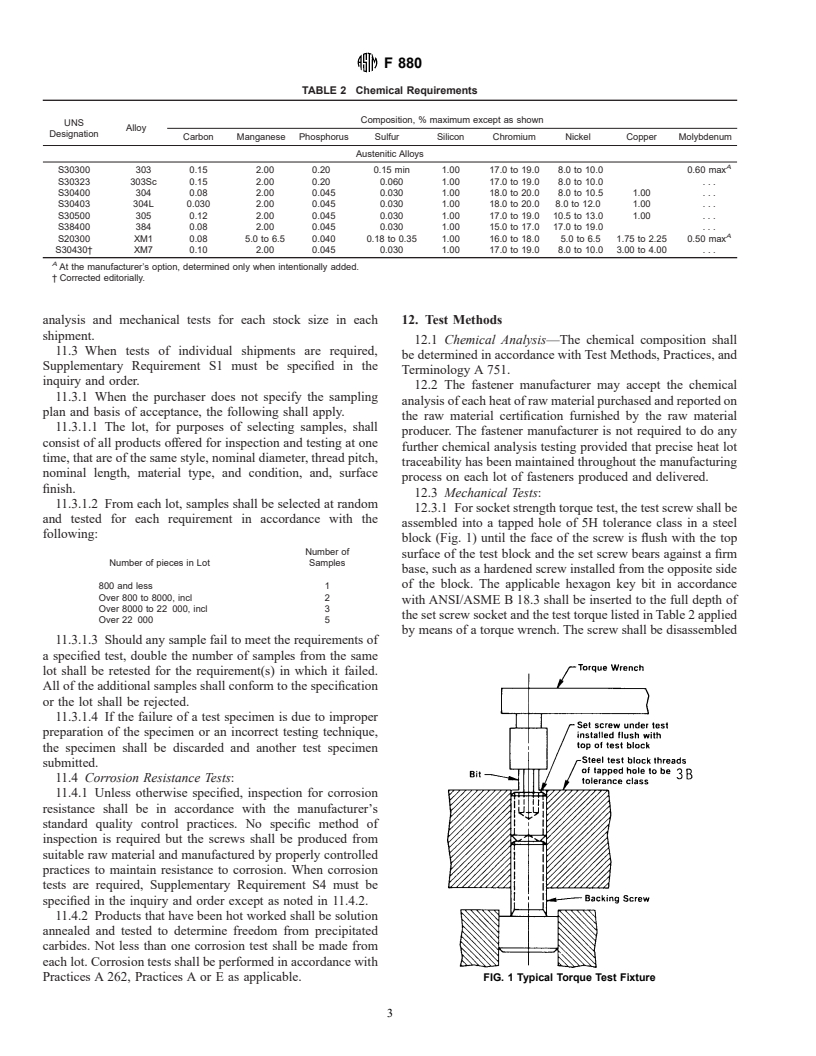

1.2 The following hazards caveat pertains only to Test Method Section, Section 12 of this specification. This standard does not purport to address (all of) the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1—A complete metric companion to Specification F880 has been developed—F880M; therefore, no metric equivalents are shown in this specification.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: F 880 – 98

Standard Specification for

1

Stainless Steel Socket-Set Screws

This standard is issued under the fixed designation F 880; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope F 593 Specification for Stainless Steel Bolts, Hex Cap

7

Screws, and Studs

1.1 This specification covers the requirements for austenitic

F 788/F788M Specification for Surface Discontinuities of

grade stainless steel socket-set screws (SSS), sizes 0.060

7

Bolts, Screws, and Studs, Inch and Metric Series

through 0.500 in. in two conditions, AF and CW.

F 1470 Guide for Fastener Sampling for Specific Mechani-

1.2 The following hazards caveat pertains only to Test

7

cal Properties and Performance Inspection

Method Section, Section 12 of this specification. This standard

8

2.2 ANSI/ASME Standard:

does not purport to address (all of) the safety problems

B 18.3 Socket Cap, Shoulder and Set Screws, Inch Series

associated with its use. It is the responsibility of the user of this

standard to establish appropriate safety and health practices

3. Classification

and determine the applicability of regulatory limitations prior

3.1 The designation of the alloy group and condition for the

to use.

two materials and conditions of this specification shall be

NOTE 1—A complete metric companion to Specification F 880 has been

consistent with the stainless steel designations in Specification

developed—F 880M; therefore, no metric equivalents are shown in this

F 593.

specification.

3.2 The austenitic stainless steel socket set screw shall be

designated F 880 Group 1 Condition AF (solution annealed) or

2. Referenced Documents

F 880 Group 1 Condition CW (cold worked).

2.1 ASTM Standards:

A 262 Practices for Detecting Susceptibility to Intergranu-

4. Ordering Information

2

lar Attack in Austenitic Stainless Steels

4.1 Orders for material under this specification shall include

A 342 Test Methods for Permeability of Feebly Magnetic

the following information:

3

Materials

4.1.1 Quantity (number of screws).

A 380 Practice for Cleaning and Descaling Stainless Steel

4.1.2 Dimensions, including nominal thread designation,

2

Parts, Equipment, and Systems

thread pitch, nominal screw length (inches) and point configu-

A 555/A555M Specification for General Requirements for

ration. A standard part number may be used for this definition.

2

Stainless and Heat-Resisting Steel Wire and Wire Rods

4.1.3 Name of the screw (SSS).

A 751 Test Methods, Practices, and Terminology for

4.1.4 Condition AF/CW.

2

Chemical Analysis of Steel Products

4.1.5 Surface finish, if required. If a finish other than

A 967 Specification for Chemical Passivation Treatments

passivation is required, it must be specified on the order or

2

for Stainless Steel Parts

product standard.

4

D 3951 Practice for Commercial Packaging

4.1.6 ASTM specification and year of issue.

E 18 Test Methods for Rockwell Hardness and Rockwell

4.1.7 Any special or supplemental requirements.

5

Superficial Hardness of Metallic Materials

4.2 Example—50 000 pieces 0.250-20 3 0.375 cone point

E 353 Test Methods for Chemical Analysis of Stainless,

SSS CW ASTM F 880-86.

Heat-Resisting, Maraging, and Other Similar Chromium-

6

Nickel-Iron Alloys

5. Materials and Manufacture

5.1 The screw may be forged, formed, extruded, machined,

1

This specification is under the jurisdiction of ASTM Committee F-16 on

or ground to meet the dimensional characteristics and perfor-

Fasteners and is the direct responsibility of Subcommittee F16.04 on Nonferrous

mance requirements.

Fasteners.

5.2 Heat Treatment—Austenitic alloys Group 1 Condition

Current edition approved Oct. 10, 1998. Published December 1998. Originally

published as F 880-86. Last previous edition F 880-97.

AF screw shall be annealed by heating to 1900 6 50°F to

2

Annual Book of ASTM Standards, Vol 01.03.

3

Annual Book of ASTM Standards, Vol 03.04.

4 7

Annual Book of ASTM Standards, Vol 15.09. Annual Book of ASTM Standards, Vol 01.08.

5 8

Annual Book of ASTM Standards, Vol 03.01. Available from American National Standards Institute, 11 West 42nd Street,

6

Annual Book of ASTM Standards, Vol 03.05. 13th Floor, New York, NY 10036.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F 880

obtain maximum corrosion resistance and minimum perme- 8.1.1 Rod, bar, and wire in the austenitic alloy groups 1,2,

ability. The screws shall be held for a sufficient time at and 3, except the free-machining grades, 303

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.