ASTM E1277-96

(Test Method)Standard Test Method for Chemical Analysis of Zinc-5% Aluminum-Mischmetal Alloys by ICP Emission Spectrometry

Standard Test Method for Chemical Analysis of Zinc-5% Aluminum-Mischmetal Alloys by ICP Emission Spectrometry

SCOPE

1.1 This test method covers the chemical analysis of zinc alloys having chemical compositions within the following limits: Element Concentration Range, % Aluminum 3.0-8.0 Antimony 0.002 max Cadmium 0.025 max Cerium 0.03-0.10 Copper 0.10 max Iron 0.10 max Lanthanum 0.03-0.10 Lead 0.026 max Magnesium 0.05 max Silicon 0.015 max Tin 0.002 max Titanium 0.02 max Zirconium 0.02 max

1.2 Included are procedures for elements in the following concentration ranges: Element Concentration Range, % Aluminum 3.0-8.0 Cadmium 0.0016-0.025 Cerium 0.005-0.10 Iron 0.0015-0.10 Lanthanum 0.009-0.10 Lead 0.002-0.026

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific safety hazards statements are given in Section 9.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 1277 – 96

Standard Test Method for

Chemical Analysis of Zinc-5 % Aluminum-Mischmetal Alloys

by ICP Emission Spectrometry

This standard is issued under the fixed designation E 1277; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope E 50 Practices for Apparatus, Reagents, and Safety Precau-

tions for Chemical Analysis of Metals

1.1 This test method covers the chemical analysis of zinc

E 55 Practice for Sampling Wrought Nonferrous Metals for

alloys having chemical compositions within the following

Determination of Chemical Composition

limits:

E 88 Practice for Sampling Nonferrous Metals and Alloys

Element Concentration Range, %

in Cast Form for Determination of Chemical Composition

Aluminum 3.0–8.0

E 173 Practice for Conducting Interlaboratory Studies of

Antimony 0.002 max

Methods for Chemical Analysis of Metals

Cadmium 0.025 max

E 876 Practice for Use of Statistics in the Evaluation of

Cerium 0.03–0.10

Copper 0.10 max

Spectrometric Data

Iron 0.10 max

Lanthanum 0.03–0.10

3. Summary of Test Method

Lead 0.026 max

Magnesium 0.05 max

3.1 The sample is dissolved in mixed acids. The sample

Silicon 0.015 max

solution is introduced into the plasma source of an ICP

Tin 0.002 max

spectrometer and the intensities at selected wavelengths from

Titanium 0.02 max

Zirconium 0.02 max

the plasma emission spectrum are compared to the intensities at

the same wavelengths measured with calibration solutions.

1.2 Included are procedures for elements in the following

concentration ranges:

4. Significance and Use

Element Concentration Range, %

4.1 This test method for the chemical analysis of metals and

Aluminum 3.0–8.0

alloys is primarily intended to test such materials for compli-

Cadmium 0.0016–0.025

ance with compositional specifications. It is assumed that all

Cerium 0.005–0.10

Iron 0.0015–0.10 those who use this test method will be trained analysts capable

Lanthanum 0.009–0.10

of performing common laboratory procedures skillfully and

Lead 0.002–0.026

safely. It is expected that work will be performed in a properly

1.3 This standard does not purport to address all of the

equipped laboratory.

safety concerns, if any, associated with its use. It is the

5. Apparatus

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- 5.1 Inductively-Coupled Argon Plasma (ICP) Atomic Emis-

bility of regulatory limitations prior to use. Specific safety sion Spectrometer—The instrument is equipped with an argon-

hazards statements are given in Section 7. plasma source, a sample transport system for introducing the

test sample and calibration solutions into the plasma. The

2. Referenced Documents

monochromator or polychromator must be capable of isolating

2.1 ASTM Standards: the required wavelengths shown in Table 1 for measurement of

D 1193 Specification for Reagent Water

their intensities by a linear photometer. Multielement pro-

E 29 Practice for Using Significant Digits in Test Data to

grammed analysis including automatic data acquisition and

Determine Conformance With Specifications

computer-controlled calibration and anlaysis calculations may

be used if available, provided that, in addition to calculated

results, the instrument records intensity readings each time a

This test method is under the jurisdiction of ASTM Committee E-1 on test sample or calibration solution is presented to the instru-

Analytical Chemistry for Metals, Ores, and Related Materials and is the direct

ment.

responsibility of Subcommittee E01.05 on Zn, Sn, Pb, Be, and Other Metals.

Current edition approved Oct. 10, 1996. Published December 1996. Originally

published as E 1277 – 91. Last previous edition E 1277 – 91.

2 4

Annual Book of ASTM Standards, Vol 11.01. Annual Book of ASTM Standards, Vol 3.05.

3 5

Annual Book of ASTM Standards, Vol 14.02. Annual Book of ASTM Standards, Vol 03.06.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E 1277

A

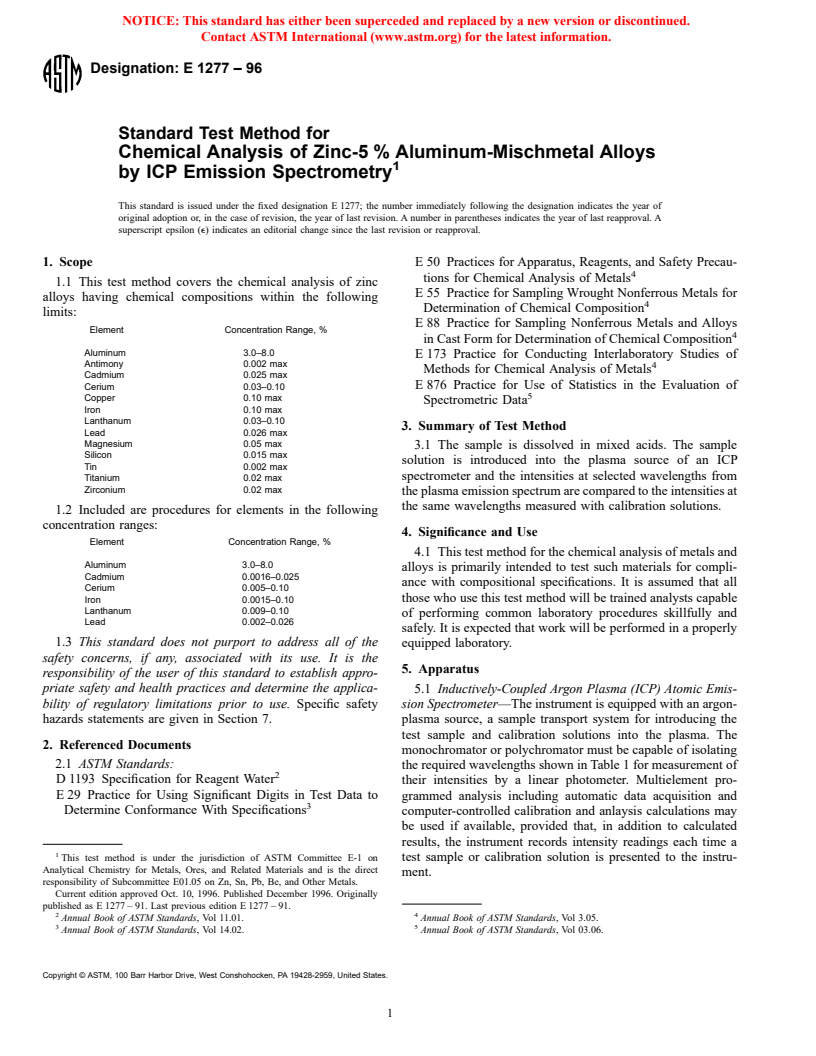

TABLE 1 Wavelengths and Instrument Conditions

6.4 Boric Acid Solution (3 g/100 mL)—Dissolve 3.0 g of

Element Wavelength Time, s No. Integ. BCor1 BCor2 boric acid (H BO ) in 100 mL of boiling water.

3 3

6.5 Cadmium, Standard Solution (1 mL = 1.00 mg Cd)—

Al 3092.7 1.0 3 . .

Cd 2265.02 .5 3 2264.46 2265.58

Transfer 1.000 g of cadmium (purity: 99.95 % min) to a

Ce 4186.6 .5 2 . .

250-mL beaker. Cover and add 40 mL of HNO (1 + 1) and 10

Fe 2599.4 .5 2 . .

La 3988.5 .5 2 3987.54 3989.06 mL of HCl. After dissolution is complete, heat to boiling to

Pb 2832.97 1.0 3 . 2833.36

remove oxides of nitrogen. Cool, transfer to a 1-L volumetric

A

The tabulated conditions were those found satisfactory on one instrument.

flask, add 240 mL of HCl, dilute to volume, and mix. Store in

Wavelengths are expressed in angstroms. Time = seconds for each integration,

a polyethylene bottle.

No. Integ. = number of integrations averaged for each reading, and BCor1 and

BCor2 are off-peak background correction wavelengths. 6.6 Cerium, Standard Solution A (1 mL = 1.00 mg Ce)—

Dry ceric ammonium nitrate ((NH ) Ce(NO ) , also known as

4 2 3 6

ammonium hexanitrato cerate) (purity: 99.95 % min) for4hat

85°C and cool to room temperature in a desiccator. Dissolve

NOTE 1—All elements (including aluminum) are calibrated as linear

3.913 g of dry ceric ammonium nitrate in 100 mL of HCl

functions of intensity. If the instrument cannot be set to measure

aluminum and ignore other elements in calibration solutions No. 1 and No. (1 + 9). Transfer to a 1-L volumetric flask, add 240 mL of HCl

4, then a separate determination of aluminum must be made using

and 20 mL of HNO , dilute to volume, and mix. Store in a

calibration solutions No. 1, No. 2 and No. 4. The other elements can then

polyethylene bottle.

be determined together in another run using only calibration solutions No.

6.7 Cerium, Standard Solution B (1 mL = 0.010 mg Ce)—

2 and No. 3. Use the calibration solutions prepared in 10.1 in determining

Using a pipet, transfer 1.00 mL of Cerium Standard Solution A

the instrument settings for the elements in this matrix. Follow the

to a 100-mL volumetric flask. Dilute to volume with dilution

manufacturer’s instructions to set the wavelengths and parameters to

solution and mix.

provide as large a difference between the intensity readings for the high

6.8 Dilution Solution—Half fill a 2-L volumetric flask with

and low calibration concentrations as is consistent with stable instrument

readings. If there is a question of linearity of the instrument’s response water. Add 500 mL of HCl and 40 mL of HNO , swirl to mix,

over the range of solution concentrations given, a third standard, equidis-

dilute to the mark, and mix.

tant between the two listed standards, must be measured to verify linearity.

6.9 Iron, Standard Solution A (1 mL = 1.00 mg Fe)—

Transfer 1.000 g of iron (purity: 99.95 % min) to a 250-mL

6. Reagents

beaker, cover, and add 100 mL of HCl (1 + 1). Boil gently to

complete dissolution. Cool and transfer to a 1-L volumetric

6.1 Purity of Reagents—Unless otherwise indicated, all

flask, add 200 mL of HCl and 20 mL of HNO , dilute to

reagents used in this test method shall conform to the “Reagent

volume, and mix. Store in the polyethylene bottle.

Grade” Specifications of the American Chemical Society.

6.10 Iron, Standard Solution B (1 mL = 0.010 mg Fe)—

Other chemicals may be used provided that it is first ascer-

Using a pipet, transfer 1.00 mL of Iron Standard Solution A to

tained that the reagent used is of sufficiently high purity to

a 100-mL volumetric flask. Dilute to volume with dilution

permit its use without lessening the accuracy of the determi-

solution and mix.

nation.

6.11 Lanthanum, Standard Solution A (1 mL = 0.010 mg

6.2 Purity of Water—Unless otherwise indicated, references

La)—Ignite lanthanum oxide (La O ) (purity: 99.9 % min) for

2 3

to water shall be understood to mean reagent water as defined

1 h at 1000°C and cool to room temperature in a desiccator.

by Type II of Specification D 1193.

Dissolve 1.173 g of dry lanthanum oxide in 100 mL of HCl

6.3 Aluminum, Standard Solution (1 mL = 20.0 mg Al)—

(1 + 9) and transfer to a 1-L volumetric flask. Add 240 mL of

Transfer 2.0000 g of aluminum (purity: 99.999 % min) to a

HCl and 20 mL of HNO , dilute to volume, and mix. Store in

250-mL beaker. Cover, add 50 mL of HCl (1 + 1) and a small

a polyethylene bottle.

crystal of mercuric nitrate. Heat gently to accelerate the

6.12 Lanthanum, Standard Solution B (1 mL = 0.010 mg

reaction, but avoid temperatures high enough to cause a

La)—Using a pipet, transfer 1.00 mL of Lanthanum Standard

noticeable volume loss. If the reaction slows, add more

Solution A to a 100-mL volumetric flask. Dilute to volume with

mercuric salt as needed. A number of hours may be required to

dilution solution and mix.

complete the dissolution (only a small droplet of mercury will

6.13 Lead, Standard Solution (1 mL = 1.00 mg Pb)—

remain undissolved). Transfer the solution to a 100-mL volu-

Transfer 1.000 g of lead (purity: 99.9 % min) to a 250-mL

metric flask, dilute to volume, and mix. Store in a polyethylene

beaker, cover, and add 40 mL of HNO (1 + 1). Boil gently to

bottle. complete dissolution and to remove oxides of nitrogen. Cool,

transfer to a 1-L volumetric flask, add 250 mL of HCl, dilute to

volume, and mix. Store in a polyethylene bottle.

6.14 Zinc Matrix Solution (50 mL = 3.75 g Zinc Matrix

Reagent Chemicals, American Chemical Society Specifications, American

Standard)—Transfer 18.75 g 6 0.10 g of Zinc Matrix Standard

Chemical Society, Washington, DC. For suggestions on the testing of reagents not

to a 250-mL plastic beaker. Cover and add about 50 mL of

listed by the American Chemical Society, see Analar Standards for Laboratory

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

water. Add 62.5 mL of HCl and heat enough to maintain the

and National Formulary, U.S. Pharmaceutical Convention, Inc. (USPC), Rockville,

reaction but not enough to evaporate the solution. When most

MD.

of the material has dissolved, add 5.0 mL of HNO . When all

solids have dissolved, remove from the heat and allow to cool.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E 1277

A,B

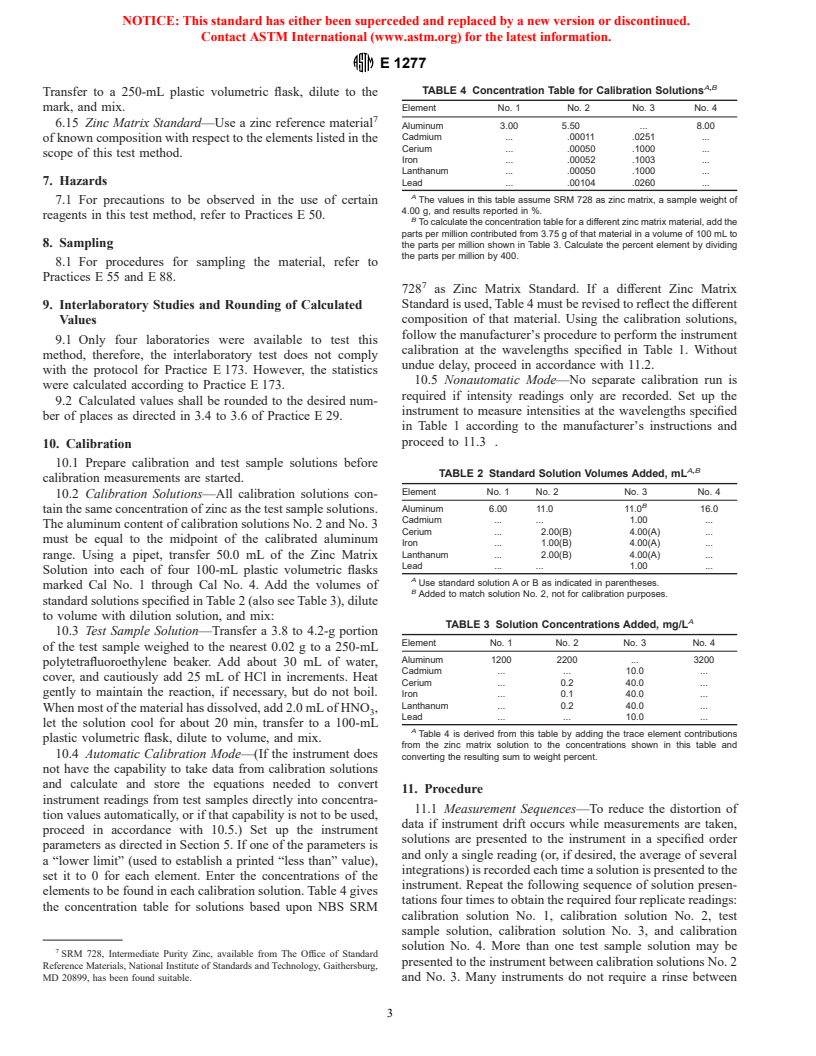

TABLE 4 Concentration Table for Calibration Solutions

Transfer to a 250-mL plastic volumetric flask, dilute to the

mark, and mix. Element No. 1 No. 2 No. 3 No. 4

6.15 Zinc Matrix Standard—Use a zinc reference material

Aluminum 3.00 5.50 . 8.00

Cadmium . .00011 .0251 .

of known composition with respect to the elements listed in the

Cerium . .00050 .1000 .

scope of this test method.

Iron . .00052 .1003 .

Lanthanum . .00050 .1000 .

7. Hazards

Lead . .00104 .0260 .

A

7.1 For precautions to be observed in the use of certain The values in this table assume SRM 728 as zinc matrix, a sample weight of

4.00 g, and results reported in %.

reagents in this test method, refer to Practices E 50.

B

To calculate the concentration table for a different zinc matrix material, add the

parts per million contributed from 3.75 g of that material in a volume of 100 mL to

8. Sampling the parts per million shown in Table 3. Calculate the percent element by dividing

the parts per million by 400.

8.1 For procedures for sampling the material, refer to

Practices E 55 and E 88.

728 as Zinc Matrix Standard. If a different Zinc Matrix

9. Interlaboratory Studies and Rounding of Calculated Standard is used, Table 4 must be revised to reflect the different

composition of that material. Using the calibration solutions,

Values

follow the manufacturer’s procedure to perform the instrument

9.1 Only four laboratories were available to test this

calibration at the wavelengths specified in Table 1. Without

method, therefore, the interlaboratory test does not comply

undue delay, proceed in accordance with 11.2.

with the protocol for Practice E 173. However, the statistics

10.5 Nonautomatic Mode—No separate calibration run is

were calculated according to Practice E 173.

required if intensity readings only are recorded. Set up the

9.2 Calculated values shall be rounded to the desired num-

instrument to measure intensities at the wavelengths specified

ber of places as directed in 3.4 to 3.6 of Practice E 29.

in Table 1 according to the manufacturer’s instructions and

proceed to 11.3 .

10. Calibration

10.1 Prepare calibration and test sample solutions before

A,B

TABLE 2 Standard Solution Volumes Added, mL

calibration measurements are started.

Element No. 1 No. 2 No. 3 No. 4

10.2 Calibration Solutions—All calibration solutions con-

B

Aluminum 6.00 11.0 11.0 16.0

tain the same concentration of zinc as the test sample solutions.

Cadmium . . 1.00 .

The aluminum content of calibration solutions No. 2 and No. 3

Cerium . 2.00(B) 4.00(A) .

must be equal to the midpoint of the calibrated aluminum

Iron . 1.00(B) 4.00(A) .

Lanthanum . 2.00(B) 4.00(A) .

range. Using a pipet, transfer 50.0 mL of the Zinc Matrix

Lead . . 1.00 .

Solution into each of four 100-mL plastic volumetric flasks

A

Use standard solution A or B as indicated in parentheses.

marked Cal No. 1 through Cal No. 4. Add the volumes of

B

Added to match solution No. 2, not for calibration purposes.

standard solutions specified in Table 2 (also see Table 3), dilute

to volume with dilution solution, and mix:

A

TABLE 3 Solution Concentrations Added, mg/L

10.3 Test Sample Solution—Transfer a 3.8 to 4.2-g portion

Element No. 1 No. 2 No. 3 No. 4

of the test sample weighed to the nearest 0.02 g to a 250-mL

Aluminum 1200 2200 . 3200

polytetrafluoroethylene beaker. Add about 30 mL of water,

Cadmium . . 10.0 .

cover, and cautiously add 25 mL of HCl in increments. Heat

Cerium . 0.2 40.0 .

gently to maintain the reaction, if necessary, but do not boil. Iron . 0.1 40.0 .

Lanthanum . 0.2 40.0 .

When most of the material has dissolved, add 2.0 mL of HNO ,

Lead . . 10.0 .

let the solution cool for about 20 min, transfer to a 100-mL

A

Table 4 is derived from this table by adding the trace element contributions

plastic volumetric flask, dilute to volume, and mix.

from the zinc matrix solution t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.