ASTM C831-98(2003)

(Test Method)Standard Test Methods for Residual Carbon, Apparent Residual Carbon, and Apparent Carbon Yield in Coked Carbon-Containing Brick and Shapes

Standard Test Methods for Residual Carbon, Apparent Residual Carbon, and Apparent Carbon Yield in Coked Carbon-Containing Brick and Shapes

SIGNIFICANCE AND USE

These test methods are designed for use with carbon-containing products. The residual carbon content of a coked carbon containing brick or shape is an indication of how much carbon may be available, in service, to resist slag attack on, or oxidation loss of, that body. Apparent carbon yield gives an estimate of the relative efficiency of the total carbonaceous matter to be retained as residual carbon.

Residual carbon has a direct bearing on several properties of a pitch or resin containing refractory such as ignited porosity, density, strength, and thermal conductivity.

These test methods are suitable for product development, manufacturing control and specification acceptance.

These test methods are very sensitive to specimen size, coking rates, etc., therefore, strict compliance with these test methods is critical.

Appreciable amounts of reducible components, such as Fe2O3, will have a noticeable effect on the results. Thus, values obtained by these test methods will be different when brick removed from service is tested. This must be kept in mind when attempting to use these test methods in an absolute sense.

Oxidizable components such as metals and carbides can have a noticeable effect on the results. This must be kept in mind when using the second procedure, which is based on measuring weight loss after igniting the coked specimens.

Testing of brick or shapes that contain magnesium metal presents special problems since this metal is highly volatile and substantial amounts of the magnesium can be lost from the sample during the coking procedure. This must be kept in mind when interpreting the results of testing of brick that contain magnesium. In addition, magnesium can react readily with atmospheric humidity. This must be kept in mind when storing brick that contain magnesium.

SCOPE

1.1 These test methods cover the determination of residual carbon content in carbon-bearing brick and shapes after a prescribed coking treatment. They provide two procedures. The first procedure is based on the combustion of carbon and its measurement as carbon dioxide. However, when using the first procedure for articles that contain silicon carbide or other carbides, no distinction will be made between carbon present in the form of a carbide and carbon present as elemental carbon. The second procedure provides a method for calculating apparent residual carbon (on the basis of weight loss after igniting the coked specimens), apparent carbonaceous material content, and apparent carbon yield. If the second procedure is used for brick or shapes that contain metallic additives or carbides, it must be recognized that there will be a weight gain associated with the oxidation of the metals, or carbides, or both. Such a weight gain can change the results substantially and this must be kept in mind when interpreting the data.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C 831–98 (Reapproved2003)

Standard Test Methods for

Residual Carbon, Apparent Residual Carbon, and Apparent

Carbon Yield in Coked Carbon-Containing Brick and

Shapes

This standard is issued under the fixed designation C 831; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 2906 Practice for Statements on Precision and Bias for

Textiles

1.1 These test methods cover the determination of residual

E 11 Specification for Wire-Cloth Sieves for Testing Pur-

carbon content in carbon-bearing brick and shapes after a

poses

prescribed coking treatment. They provide two procedures.

The first procedure is based on the combustion of carbon and

3. Significance and Use

its measurement as carbon dioxide. However, when using the

3.1 These test methods are designed for use with carbon-

first procedure for articles that contain silicon carbide or other

containing products. The residual carbon content of a coked

carbides,nodistinctionwillbemadebetweencarbonpresentin

carbon containing brick or shape is an indication of how much

the form of a carbide and carbon present as elemental carbon.

carbon may be available, in service, to resist slag attack on, or

The second procedure provides a method for calculating

oxidation loss of, that body. Apparent carbon yield gives an

apparent residual carbon (on the basis of weight loss after

estimate of the relative efficiency of the total carbonaceous

igniting the coked specimens), apparent carbonaceous material

matter to be retained as residual carbon.

content, and apparent carbon yield. If the second procedure is

3.2 Residual carbon has a direct bearing on several proper-

used for brick or shapes that contain metallic additives or

ties of a pitch or resin containing refractory such as ignited

carbides, it must be recognized that there will be a weight gain

porosity, density, strength, and thermal conductivity.

associated with the oxidation of the metals, or carbides, or

3.3 These test methods are suitable for product develop-

both. Such a weight gain can change the results substantially

ment, manufacturing control and specification acceptance.

and this must be kept in mind when interpreting the data.

3.4 These test methods are very sensitive to specimen size,

1.2 The values stated in inch-pound units are to be regarded

coking rates, etc., therefore, strict compliance with these test

as the standard. The values given in parentheses are for

methods is critical.

information only.

3.5 Appreciable amounts of reducible components, such as

1.3 This standard does not purport to address all of the

Fe O , will have a noticeable effect on the results.Thus, values

2 3

safety concerns, if any, associated with its use. It is the

obtained by these test methods will be different when brick

responsibility of the user of this standard to establish appro-

removed from service is tested. This must be kept in mind

priate safety and health practices and determine the applica-

when attempting to use these test methods in an absolute sense.

bility of regulatory limitations prior to use.

3.6 Oxidizable components such as metals and carbides can

2. Referenced Documents have a noticeable effect on the results. This must be kept in

mind when using the second procedure, which is based on

2.1 ASTM Standards:

measuring weight loss after igniting the coked specimens.

C 571 Methods for Chemical Analysis of Carbon and

3.7 Testing of brick or shapes that contain magnesium metal

Carbon-Ceramic Refractories

presentsspecialproblemssincethismetalishighlyvolatileand

substantial amounts of the magnesium can be lost from the

sample during the coking procedure.This must be kept in mind

These test methods are under the jurisdiction of ASTM Committee C08 on

when interpreting the results of testing of brick that contain

Refractories and are the direct responsibility of Subcommittee C08.04 on Chemical

magnesium. In addition, magnesium can react readily with

Behaviors.

Current edition approved November 2003. Published January 2004. Originally atmospheric humidity. This must be kept in mind when storing

approved in 1976. Last previous edition C 831 – 98.

brick that contain magnesium.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4. Apparatus

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 4.1 For Coking:

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C 831–98 (2003)

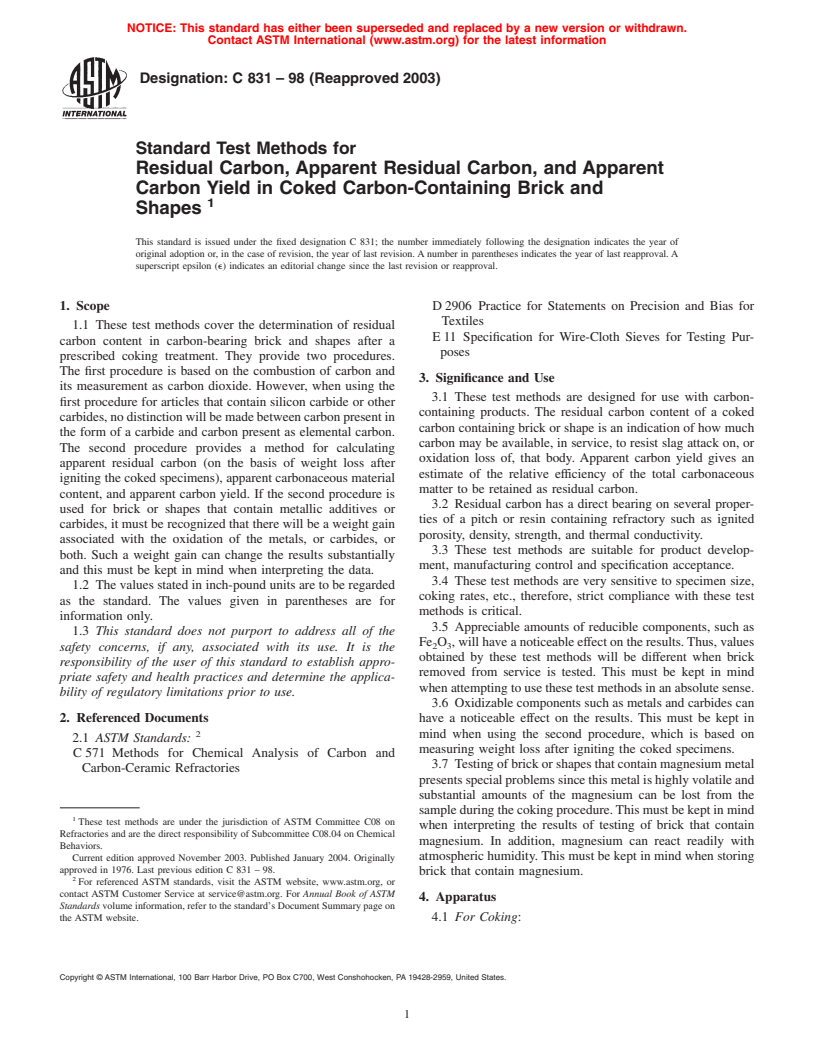

4.1.1 Gas or Electric Furnace with heating chamber ca- 4.2.3 CO -Absorption Train as described in Fig. 4 and in

pable of receiving the coking box shown in Fig. 1. Method C 571

NOTE 1—Samples should not be subjected to thermal gradients greater

NOTE 2—Commercial automatic and semi-automatic carbon determi-

than 40°F (22°C) during heatup. In electric furnaces with silicon carbide

nators may replace the apparatus described in 4.2.2 and 4.2.3.

heating elements, the length of the box should be parallel to these

elements.

4.3 The precision obtained with these instruments shall

meet the requirements specified in Section 10.

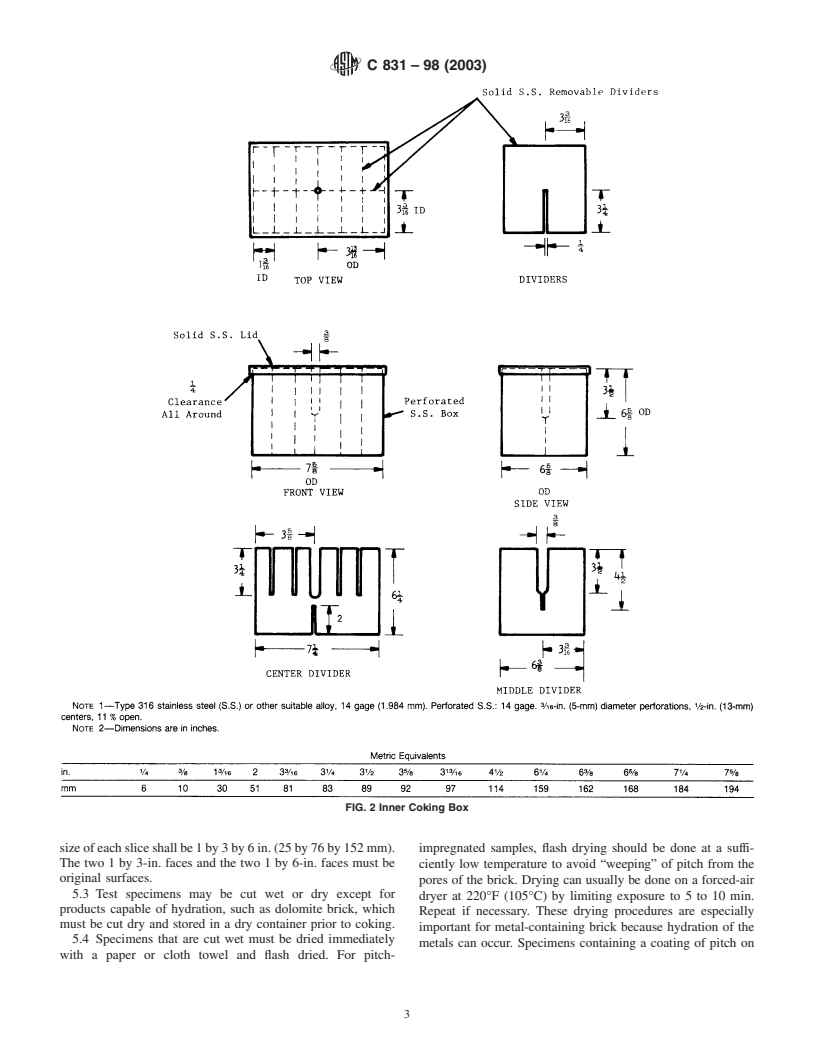

4.1.2 Inner and Outer Box, stainless steel (or equivalent

alloy), as shown in Figs. 1-3.

5. Preparation of Test Specimens

4.2 For CO Absorption:

4.2.1 Laboratory Pulverizer designed to provide a sealed,

5.1 This method assumes that the number of specimens

dustproof grinding chamber, and having a capacity of at least

tested will be a statistically valid sample of the entire lot of

50 g of sample.

brick or shapes being evaluated. The exact number is usually

4.2.2 Combustion-Tube Furnace capable of operating at

arrived at by mutual agreement between parties concerned.

183°F (1000°C)

5.2 Although sample brick from either the 4 ⁄2-in. (114-mm)

or the 6-in. (152-mm) series may be tested, it is preferable to

use the larger size for the test. Cut slices 1 6 ⁄32 in. (25 6 0.8

Typical grinders are: Blueler Mill, Applied Research Laboratories, Sunland,

mm) in thickness perpendicular to the length at the mid-section

CA; Laboratory Disc Mill, Angstrom, Inc., Bellville, MI; and Shatter Box, Spex

of each sample brick or shape.As shown in Fig. 5, the nominal

Industries, Inc., Metuchen, NJ.

FIG. 1 Outer Coking Box (Dimensions are in Inches)

C 831–98 (2003)

FIG. 2 Inner Coking Box

sizeofeachsliceshallbe1by3by6in.(25by76by152mm). impregnated samples, flash drying should be done at a suffi-

The two 1 by 3-in. faces and the two 1 by 6-in. faces must be ciently low temperature to avoid “weeping” of pitch from the

original surfaces.

pores of the brick. Drying can usually be done on a forced-air

5.3 Test specimens may be cut wet or dry except for

dryer at 220°F (105°C) by limiting exposure to 5 to 10 min.

products capable of hydration, such as dolomite brick, which

Repeat if necessary. These drying procedures are especially

must be cut dry and stored in a dry container prior to coking.

important for metal-containing brick because hydration of the

5.4 Specimens that are cut wet must be dried immediately

metals can occur. Specimens containing a coating of pitch on

with a paper or cloth towel and flash dried. For pitch-

C 831–98 (2003)

FIG. 3 Coking Box Arrangement

FIG. 4 CO -Absorption Train

uncut surfaces, as is typical of an impregnation process, must 6. Procedure for Coking

be scraped clean prior to drying.

6.1 Place the test specimens randomly into the inner box,

5.5 Weigh all specimens after drying to constant weight

Fig. 2

(60.2g), recording weight to the nearest 0.1 g. This weight is

“as-received weight, A,” (This step may be omitted if residual

NOTE 3—Burned pitch-impregnated magnesite brick should not be

carbon is to be determined by CO absorption, as indicated in

coked with tempered, tar-bonded, or dolomite brick because of carbon

1.1.) pickup by the impregnated samples and disruption of the bottom of

C 831–98 (2003)

FIG. 5 Location of Test Specimen

tempered samples. Pitch-bonded, pitch-bonded tempered magnesite brick

6.10 Samples that contain dolomite or aluminum metal

and dolomite brick may be coked in the same box or coking run.

should be stored in a sealed container containing dessicant in

NOTE 4—The number of samples coked per run should be constant

the time interval between coking and measurement of carbon

within a laboratory. Dummy uncoked samples consistent with Note 3 may

content. This is to prevent hydration of dolomite or aluminum

be used to fill any empty positions in the inner box.

carbide. The aluminum carbide is formed by reaction between

6.2 Place the inner box into the center of the outer box (Fig.

aluminum and carbon in the shape during the coking operation.

3), on the bottom of which has first been placed a ⁄2-in.

Aluminum carbide can react with a water source such as

(13-mm) slab of carbon, covered with a thin layer of dust-free

atmospheric humidity to form methane. Care should be taken

metallurgical-grade coke breeze (No. 14 (1.40–mm) sieve size)

since methane can be an explosion hazard.

(Note 5). To ensure that the coke breeze is free of moisture

which could oxidize carbon during cooking, dry the coke at CO ABSORPTION (FIRST ALTERNATIVE

PROCEDURE)

400°F (205°C) for 24 h, and keep in a closed container at room

temperature until needed.

7. Preparation of Sample

NOTE 5—Detailed requirements for sieves are given in Specification E

7.1 Asampleconsistsofasinglesliceormultiplespecimens

of brick prepared as described in Sections 5 and 6.

6.3 Place the thermocouple well into the center of the inner

7.2 Crush the sample in a laboratory jaw crusher, or other

box and put the lid on the inner box. The thermocouple well

impact-type crusher, to pass a No. 4 (4.75-mm) sieve (Note 5).

must be long enough to extend above the cover of the outer

Thoroughly mix the crushed sa

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.