ASTM D6587-00

(Test Method)Standard Test Method for Yarn Number Using Automatic Tester

Standard Test Method for Yarn Number Using Automatic Tester

SCOPE

1.1 This test method covers the measurement of yarn number of filament and spun yarns using automated testers. Some of the instruments are stand-alone and others are optional modules for instruments that perform additional tests.

1.1.1 The instruments are capable of measuring yarn numbers up to 4000 dtex (3600 denier).

Note 1--For determination of yarn number by use of reel and balance, refer to Test Method D1907.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. Within the text, the inch-pound units are in parentheses. The values stated in each system are not exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in inaccuracies of results.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6587–00

Standard Test Method for

Yarn Number Using Automatic Tester

This standard is issued under the fixed designation D 6587; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.2 denier, n—the unit of linear density, equal to the mass

in grams of 9000 m of fiber, yarn, or other textile strand, that

1.1 This test method covers the measurement of yarn

is used in a direct yarn numbering system.

number of filament and spun yarns using automated testers.

3.1.3 linear density, n—mass per unit length.

Someoftheinstrumentsarestand-aloneandothersareoptional

3.1.4 tex, n—the unit of linear density, equal to the mass in

modules for instruments that perform additional tests.

grams of 1000 m of fiber, yarn, or other textile strand, that is

1.1.1 The instruments are capable of measuring yarn num-

used in a direct yarn numbering system.

bers up to 4000 dtex (3600 denier).

3.1.5 yarn number, n—a measure of the liner density of a

NOTE 1—For determination of yarn number by use of reel and balance,

yarn, expressed as “mass per unit length” or “length per unit

refer to Test Method D 1907.

mass,” depending on the yarn numbering system.

1.2 The values stated in either SI units or inch-pound units

3.1.6 yarn numbering system, n—a system expressing the

are to be regarded separately as standard. Within the text, the

size of a yarn as a relationship between its length and

inch-pound units are in parentheses. The values stated in each

associated mass. (See also yarn number, direct yarn numbering

system are not exact equivalents; therefore, each system shall

system, and indirect yarn numbering system.)

be used independently of the other. Combining values from the

3.1.7 For definitions of other textile terms used in this test

two systems may result in inaccuracies of results.

method, see Terminology D 123.

1.3 This standard does not purport to address all of the

4. Summary of Test Method

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

4.1 A specified length of yarn (specimen) is automatically

priate safety and health practices and determine the applica-

stripped directly from the package, cut, and weighed. The yarn

bility of regulatory limitations prior to use.

number is calculated by an interfaced computer, displayed on a

monitor, and may be printed. The yarn number can be reported

2. Referenced Documents

in tex, denier, or cotton count units.

2.1 ASTM Standards:

5. Significance and Use

D 123 Terminology Relating to Textiles

D 1776 Practice for Conditioning Textiles for Testing

5.1 This test method for yarn number is satisfactory for

D 1907 Test Method for Yarn Number by the Skein

acceptance of commercial shipments and is used in the trade.

Method

5.1.1 In case of a dispute arising from differences in

D 2258 Practice for Sampling Yarn for Testing

reported test results when using this Test Method for accep-

tance testing of commercial shipments, the purchaser and the

3. Terminology

supplier should either use the referee Test Method D 1907 for

3.1 Definitions used in this test method are those in Termi-

yarn number or conduct comparative tests to determine if there

nology D 123-95a and are to be replaced if they differ from

is a statistical bias between their laboratories. Competent

those in the 95a edition.

statistical assistance is recommended for the investigation of

3.1.1 cotton count, n—an indirect yarn numbering system

bias.As a minimum, the two parties should take a group of test

generally used in the cotton system equal to the number of

specimens that are as homogeneous as possible and that are

840-yd lengths of yarn per pound.

from a lot of material of the type in question. The test

specimens should then be randomly assigned in equal numbers

to each laboratory for testing.The average results from the two

This test method is under the jurisdiction ofASTM Committee D13 onTextiles

laboratories should be compared using appropriate statistical

and is the direct responsibility of Subcommittee D13.58 on Terminology.

analysis and a probability level chosen by the two parties

Current edition approved Sept. 10, 2000. Published November 2000.

Annual Book of ASTM Standards, Vol 07.01. before the testing is begun. If a bias is found, either its cause

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D6587

must be found and corrected or the purchaser and the supplier 7.2 Laboratory Sample—As a laboratory sample for accep-

must agree to interpret future test results with consideration to tance testing, take at random from each shipping unit in the lot

the known bias. sample the number of packages directed in an applicable

5.2 This test method is also used for the quality control for material specification or other agreement between the pur-

both filament and spun yarns. chaser and the supplier such as an agreement to use Practice

D 2258. Preferably, the same number of packages should be

6. Apparatus

taken from each shipping unit in the lot sample. If differing

6.1 Automatic Yarn Numbering Instrument, with interfaced

numbers of packages are to be taken from shipping units in the

computer. lot sample, determine at random which shipping units are to

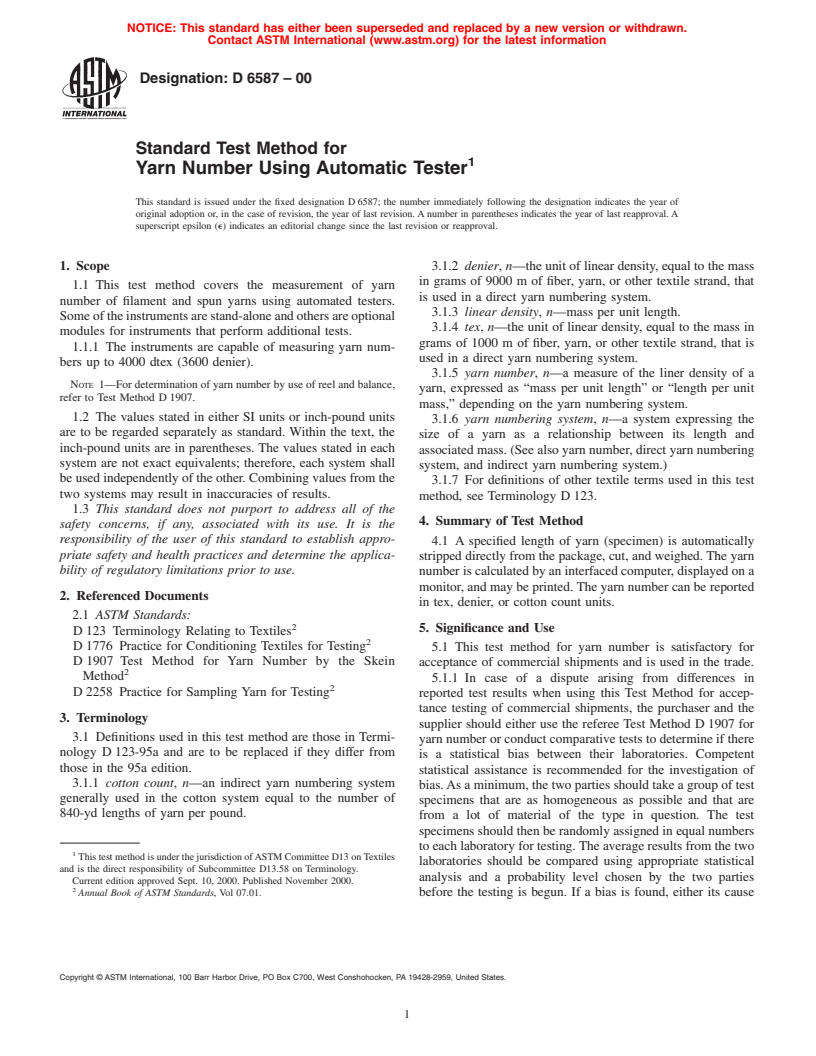

6.1.1 ACW (Automatic Cut and Weigh) Yarn Tester, Series

have each number of packages drawn.

T for textile yarns, Series BCF for bulked continuous filament 7.3 Test Specimen—Test one specimen from each package

(BCF) carpet yarns, and Series I for industrial yarns. See Fig.

of filament yarn and five specimens from each package of spun

1. The different series testers have different systems for yarn. See Table 1 for the length of yarn in a specimen.

tensioning yarns and different yarn running speeds.

8. Conditioning

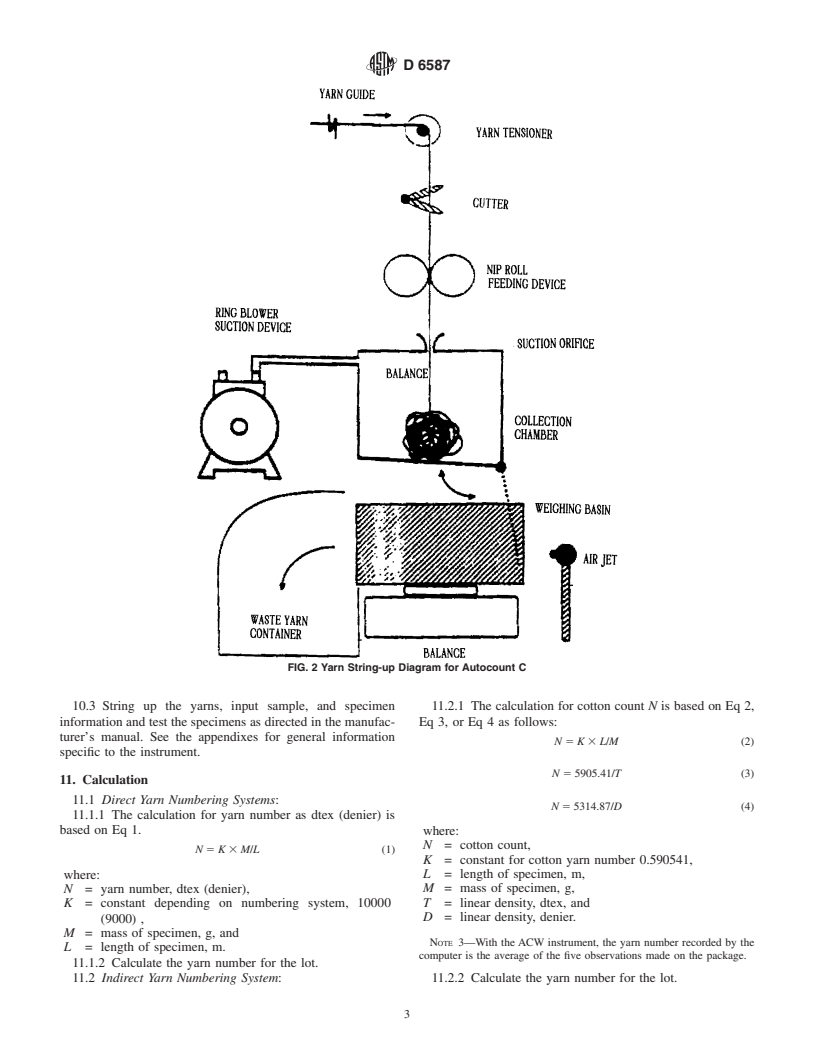

6.1.2 Autocount C —See Fig. 2.

6.1.3 Autocount TTA —See Fig. 3.

8.1 Condition the packages in the standard atmosphere for

6.1.4 Yarn Count Analyzer (YCA) —See Fig. 4.

testing textiles, which is 21 6 1°C (70 6 2°F) and 65 62%

6.2 Calibration Weights—Two grams and others as needed

relative humidity, for not less than 4 h. See Practice D 1776.

to cover the dtex (denier) ranges of interest.

9. Preparation and Calibration of Apparatus

7. Sampling

9.1 Set up and calibrate the tester using the manufacturer’s

7.1 Lot Sample—As a lot sample for acceptance testing,

manual and the appropriate appendix of this test method.

take at random the number of shipping units directed in an

applicable material specification or other agreement between

10. Procedure

the purchaser and the supplier, such as an agreement to use

10.1 Check each package for cleanliness, overthrown ends,

Practice D 2258. Consider shipping cases or other shipping

and any package formation which might interfere with the

units to be the primary sampling units.

free-running of the yarn from the package.

NOTE 2—An adequate specification or other agreement between the 10.2 Position packages to be tested with the thread line

purchaser and the supplier requires taking into account the variability

passing in a straight line from the package to the inlet tube

between shipping units, between packages or ends within a shipping unit,

without snags or additional tension added. Packages may be

and between specimens from a single package to provide a sampling plan

beneathorabovetheinletjetortube,aspositiondoesnotaffect

with a meaningful producer’s risk, consumer’s risk, acceptable quality

the results.

level, and limiting quality level.

10.2.1 If the instrument uses a package changer, place the

packageinacreelandstringuptheyarninamannertoprevent

snagging or tangling of the ends and excessive tension on the

Available from W. Fritz Mezger, Inc., 155 Hall St., Spartanburg, SC 29302-

1523 and Lenzing Technik GrmbH & Co KG, 4860 Lenzing, Austria.

yarn.

Available from Lawson Hemphill Sales, PO Drawer 6388, Spartanburg, SC

10.2.2 Prestripping packages is not necessary because the

29304 and Textechno, Dohrweg 65, D41066, Monchengladbach, Germany.

5 instruments can be set to prestrip for a specified time before

Available from Lawson Hemphill Sales, P.O. Drawer 6388, Spartanburg, SC

testing.

29304.

FIG. 1 Yarn String-up Diagram for ACW (Automatic-Cut-and-Weigh) Tester

D6587

FIG. 2 Yarn String-up Diagram for Autocount C

10.3 String up the yarns, input sample, and specimen 11.2.1 The calculation for cotton count N is based on Eq 2,

information and test the specimens as directed in the manufac- Eq 3, or Eq 4 as follows:

turer’s manual. See the appendixes for general information

N 5 K 3 L/M (2)

specific to the instrument.

N 5 5905.41/T

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.