ASTM D7972-14(2020)

(Test Method)Standard Test Method for Flexural Strength of Manufactured Carbon and Graphite Articles Using Three-Point Loading at Room Temperature

Standard Test Method for Flexural Strength of Manufactured Carbon and Graphite Articles Using Three-Point Loading at Room Temperature

SIGNIFICANCE AND USE

4.1 This test method provides a framework for material development, quality control, characterization, and design data generation purposes. The user needs to assess the applicability of the method on the specific material and for the intended use, as shown by the interlaboratory study.

4.2 This test method determines the maximum loading on a graphite specimen with simple beam geometry in three–point bending, and it provides a means for the calculation of flexural strength at ambient temperature and environmental conditions.

4.3 The flexure stress is computed based on simple beam theory with assumptions that the material is isotropic and homogeneous, the moduli of elasticity in tension and compression are identical, and the material is linearly elastic. For materials with large grains, the minimum specimen dimension should be significantly larger than the maximum grain size (see Guide D7775).

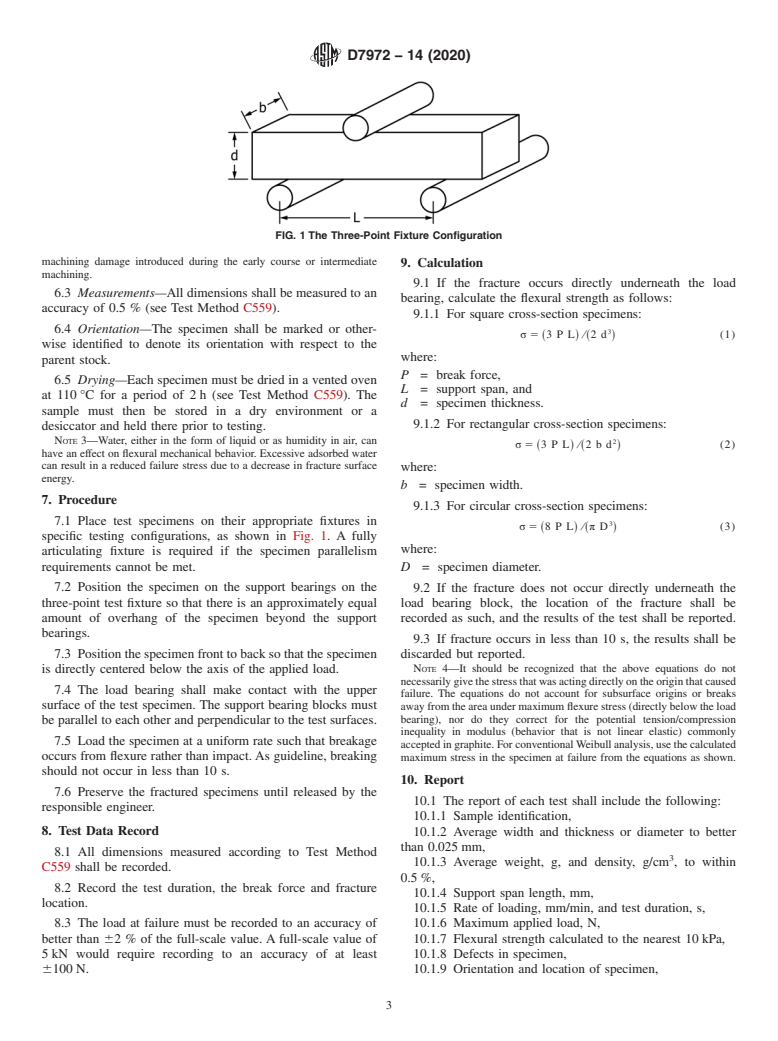

4.4 Flexural strength of a group of test specimens is influenced by several parameters associated with the test procedure. Such factors include the loading rate, test environment, specimen size, specimen preparation, and test fixtures. Specimen sizes and fixtures should be chosen to reduce errors due to material variability or testing parameters, such as friction and non-parallelism of specimen surfaces.

4.5 The flexural strength of a manufactured graphite or carbon material is dependent on both its inherent resistance to fracture and the size and severity of flaws. Variations in these cause a natural scatter in test results for a sample of test specimens. Fractographic analysis of fracture surfaces, although beyond the scope of this standard, is highly recommended for all purposes, especially if the data will be used for design as discussed in Practices C1239 and C1322.

4.6 The three-point test configuration exposes only a very small portion of the specimen to the maximum stress. Therefore, three-point flexural strengths are likely to be much greater than four-po...

SCOPE

1.1 This test method covers determination of the flexural strength of manufactured carbon and graphite articles using a square, rectangular or cylindrical beam in three-point loading at room temperature.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D7972 −14 (Reapproved 2020)

Standard Test Method for

Flexural Strength of Manufactured Carbon and Graphite

1

Articles Using Three-Point Loading at Room Temperature

This standard is issued under the fixed designation D7972; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Fracture Origins in Advanced Ceramics

D7775 Guide for Measurements on Small Graphite Speci-

1.1 This test method covers determination of the flexural

mens

strength of manufactured carbon and graphite articles using a

E4 Practices for Force Verification of Testing Machines

square, rectangular or cylindrical beam in three-point loading

E691 Practice for Conducting an Interlaboratory Study to

at room temperature.

Determine the Precision of a Test Method

1.2 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this

3. Terminology

standard.

3.1 Definitions:

1.3 This standard does not purport to address all of the

3.1.1 flexural strength, n—a measure of the ultimate load

safety concerns, if any, associated with its use. It is the

carrying capacity of a specified beam in bending.

responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter- 3.1.2 grain, n—in manufactured (synthetic) carbon and

graphite, particle of filler material (usually coke or graphite) in

mine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accor- the starting mix formulation. Also referred to as granular

material, filler particle, or aggregate material.

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom- 4. Significance and Use

mendations issued by the World Trade Organization Technical

4.1 This test method provides a framework for material

Barriers to Trade (TBT) Committee.

development, quality control, characterization, and design data

generation purposes. The user needs to assess the applicability

2. Referenced Documents

of the method on the specific material and for the intended use,

2

2.1 ASTM Standards:

as shown by the interlaboratory study.

C78 Test Method for Flexural Strength of Concrete (Using

4.2 This test method determines the maximum loading on a

Simple Beam with Third-Point Loading)

graphite specimen with simple beam geometry in three–point

C559 Test Method for Bulk Density by Physical Measure-

bending, and it provides a means for the calculation of flexural

ments of Manufactured Carbon and Graphite Articles

strength at ambient temperature and environmental conditions.

C1161 Test Method for Flexural Strength of Advanced

Ceramics at Ambient Temperature

4.3 The flexure stress is computed based on simple beam

C1239 Practice for Reporting Uniaxial Strength Data and

theory with assumptions that the material is isotropic and

Estimating Weibull Distribution Parameters forAdvanced

homogeneous, the moduli of elasticity in tension and compres-

Ceramics

sion are identical, and the material is linearly elastic. For

C1322 Practice for Fractography and Characterization of

materials with large grains, the minimum specimen dimension

shouldbesignificantlylargerthanthemaximumgrainsize(see

Guide D7775).

1

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

4.4 Flexural strength of a group of test specimens is

Subcommittee D02.F0 on Manufactured Carbon and Graphite Products.

influenced by several parameters associated with the test

Current edition approved May 1, 2020. Published June 2020. Originally

procedure. Such factors include the loading rate, test

approved in 2014. Last previous edition approved in 2014 as D7972 – 14. DOI:

10.1520/D7972-14R20.

environment, specimen size, specimen preparation, and test

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

fixtures. Specimen sizes and fixtures should be chosen to

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

reduce errors due to material variability or testing parameters,

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. such as friction and non-parallelism of specimen surfaces.

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.