ASTM C769-15(2020)e1

(Test Method)Standard Test Method for Sonic Velocity in Manufactured Carbon and Graphite Materials for Use in Obtaining an Approximate Value of Young's Modulus

Standard Test Method for Sonic Velocity in Manufactured Carbon and Graphite Materials for Use in Obtaining an Approximate Value of Young's Modulus

SIGNIFICANCE AND USE

5.1 Sonic velocity measurements are useful for comparing materials with similar elastic properties, dimensions, and microstructure.

5.2 Eq 1 provides an accurate value of Young’s modulus only for isotropic, non-attenuative, and non-dispersive materials of infinite dimensions. For non-isotropic graphite, Eq 1 can be modified to take into account the Poisson’s ratios in all directions. As graphite is a strongly attenuative material, the value of Young’s modulus obtained with Eq 1 will be dependent on specimen length. If the specimen lateral dimensions are not large compared to the wavelength of the propagated pulse, then the value of Young’s modulus obtained with Eq 1 will be dependent on the specimen lateral dimensions. The accuracy of the Young's modulus calculated from Eq 1 will also depend upon the uncertainty in Poisson's ratio and its impact on the evaluation of the Poisson's factor in Eq 2. However, a value for Young's modulus can be obtained for many applications, which is often in good agreement with the value obtained by other more accurate methods, such as in Test Method C747. The technical issues and typical values of corresponding uncertainties are discussed in detail in STP 1578.5

5.3 If the grain size of the carbon or graphite is greater than or about equal to the wavelength of the sonic pulse, the method may not be providing a value of Young’s modulus representative of the bulk material. Therefore, it would be recommended to test a lower frequency (longer wavelength) to demonstrate that the range of obtained velocity values are within an acceptable level of accuracy. Significant signal attenuation should be expected when the grain size of the material is greater than or about equal to the wavelength of the transmitted sonic pulse or the material is more porous than would be expected for an as-manufactured graphite.

Note 1: Due to frequency dependent attenuation in graphite, the wavelength of the sonic pulse through the test specimen is not nec...

SCOPE

1.1 This test method covers a procedure for measuring the sonic velocity in manufactured carbon and graphite which can be used to obtain an approximate value of Young's modulus.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

´1

Designation: C769 − 15 (Reapproved 2020)

Standard Test Method for

Sonic Velocity in Manufactured Carbon and Graphite

Materials for Use in Obtaining an Approximate Value of

Young’s Modulus

This standard is issued under the fixed designation C769; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Editorially updated 3.1.2 in December 2020.

1. Scope 3. Terminology

1.1 This test method covers a procedure for measuring the 3.1 Definitions:

sonic velocity in manufactured carbon and graphite which can 3.1.1 elastic modulus, n—the ratio of stress to strain, in the

be used to obtain an approximate value of Young’s modulus. stress range where Hooke’s law is valid.

3.1.2 Young’s modulus (E), n—the elastic modulus in ten-

1.2 The values stated in SI units are to be regarded as

sion or compression.

standard. No other units of measurement are included in this

standard.

3.2 Definitions of Terms Specific to This Standard:

1.3 This standard does not purport to address all of the 3.2.1 endcorrectiontime(T ),n—thenon-zerotimeofflight

e

safety concerns, if any, associated with its use. It is the (correction factor), measured in seconds, that may arise by

responsibility of the user of this standard to establish appro- extrapolation of the pulse travel time, corrected for zero time,

priate safety, health, and environmental practices and deter- back to zero sample length.

mine the applicability of regulatory limitations prior to use.

3.2.2 longitudinal sonic pulse, n—asonicpulseinwhichthe

1.4 This international standard was developed in accor-

displacements are in the direction of propagation of the pulse.

dance with internationally recognized principles on standard-

3.2.3 pulse travel time, (T), n—the total time, measured in

t

ization established in the Decision on Principles for the

seconds, required for the sonic pulse to traverse the specimen

Development of International Standards, Guides and Recom-

being tested, and for the associated electronic signals to

mendations issued by the World Trade Organization Technical

traversethetransducercouplingmediumandelectroniccircuits

Barriers to Trade (TBT) Committee.

of the pulse-propagation system.

3.2.4 zero time, (T ), n—the travel time (correction factor),

2. Referenced Documents

measured in seconds, associated with the transducer coupling

2.1 ASTM Standards:

medium and electronic circuits in the pulse-propagation sys-

C559 Test Method for Bulk Density by Physical Measure-

tem.

ments of Manufactured Carbon and Graphite Articles

C747 Test Method for Moduli of Elasticity and Fundamental 4. Summary of Test Method

Frequencies of Carbon and Graphite Materials by Sonic

4.1 The velocity of longitudinal sound waves passing

Resonance

through the test specimen is determined by measuring the

IEEE/ASTM SI 10 Standard for Use of the International

distance through the specimen and dividing by the time lapse,

System of Units (SI) (the Modern Metric System)

3,4

between the transmitted pulse and the received pulse. Pro-

vided the wavelength of the transmitted pulse is a sufficiently

small fraction of the sample lateral dimensions, a value of

This test method is under the jurisdiction of ASTM Committee D02 on

Young’s modulus for isotropic graphite can then be obtained

Petroleum Products, Liquid Fuels, and Lubricantsand is the direct responsibility of

using Eq 1 and Eq 2:

Subcommittee D02.F0 on Manufactured Carbon and Graphite Products.

Current edition approved Nov. 1, 2020. Published December 2020. Originally E 5 C ρV (1)

v

approved in 1980. Last previous edition approved in 2015 as C769 – 15. DOI:

10.1520/C0769-15R20E01.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Schreiber, Anderson, and Soga, Elastic Constants and Their Measurement,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM McGraw-HillBookCo.,1221AvenueoftheAmericas,NewYork,NY10020,1973.

Standards volume information, refer to the standard’s Document Summary page on AmericanInstituteofPhysicsHandbook,3rded.,McGraw-HillBookCo.,1221

the ASTM website. Avenue of the Americas, New York, NY 10020, 1972, pp. 3–98ff.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

C769 − 15 (2020)

the same as the wavelength of the transmitting transducer.

where:

E = Young’s modulus of elasticity, Pa, 5.4 Ifthesampleisonlyafewgrainsthick,theacceptability

ρ = density, kg/m , of the method’s application should be demonstrated by initially

V = longitudinal signal velocity, m/s, and

performing measurements on a series of tests covering a range

C = Poisson’s factor.

v of sample lengths between the proposed test length and a test

length incorporating sufficient grains to adequately represent

The Poisson’s factor, C , is related to Poisson’s ratio, ν,by

ν

the bulk material.

the equation:

11ν 1 2 2ν

~ !~ !

C 5 (2)

6. Apparatus

ν

1 2 ν

6.1 Driving Circuit, consisting of an ultrasonic pulse gen-

If Poisson’s ratio is unknown, it can be assumed as an

erator.

approximation in the method. For nuclear graphites, a typical

6.1.1 The user should select a pulse frequency to suit the

Poisson’s ratio of 0.2 corresponds to a Poisson’s factor of 0.9.

material microstructure and specimen elastic properties and

If the wavelength is not a small fraction of the sample lateral

dimensions being tested. High frequencies are attenuated by

dimensions, and instead is much larger than the specimen

carbon and graphite materials and, while typical practicable

lateral dimensions, then theYoung’s modulus, E is given by Eq

frequencies lie in the range 0.5 MHz to 2.6 MHz, the user may

1 with C set to one rather than being determined by Eq 2.

ν

show that frequencies outside this range are acceptable.

5. Significance and Use

6.2 Transducer, input, with suitable coupling medium (see

8.5).

5.1 Sonic velocity measurements are useful for comparing

materials with similar elastic properties, dimensions, and

6.3 Transducer, output, with suitable coupling medium (see

microstructure.

8.5).

6.3.1 The signal output will depend upon the characteristics

5.2 Eq 1 provides an accurate value of Young’s modulus

of the chosen transducers and pulser-receiver and the test

only for isotropic, non-attenuative, and non-dispersive materi-

material.Itisrecommendedthattheuseranalysestheinputand

als of infinite dimensions. For non-isotropic graphite, Eq 1 can

output frequency spectra to determine optimum conditions.

be modified to take into account the Poisson’s ratios in all

Band pass filters and narrow band transducers may be used to

directions. As graphite is a strongly attenuative material, the

simplify the signal output which could improve the measure-

value of Young’s modulus obtained with Eq 1 will be depen-

ment of the time of flight.

dentonspecimenlength.Ifthespecimenlateraldimensionsare

not large compared to the wavelength of the propagated pulse,

6.4 Computer, with analogue to digital converter, or

then the value of Young’s modulus obtained with Eq 1 will be

oscilloscope, and external trigger from driving circuit.

dependentonthespecimenlateraldimensions.Theaccuracyof

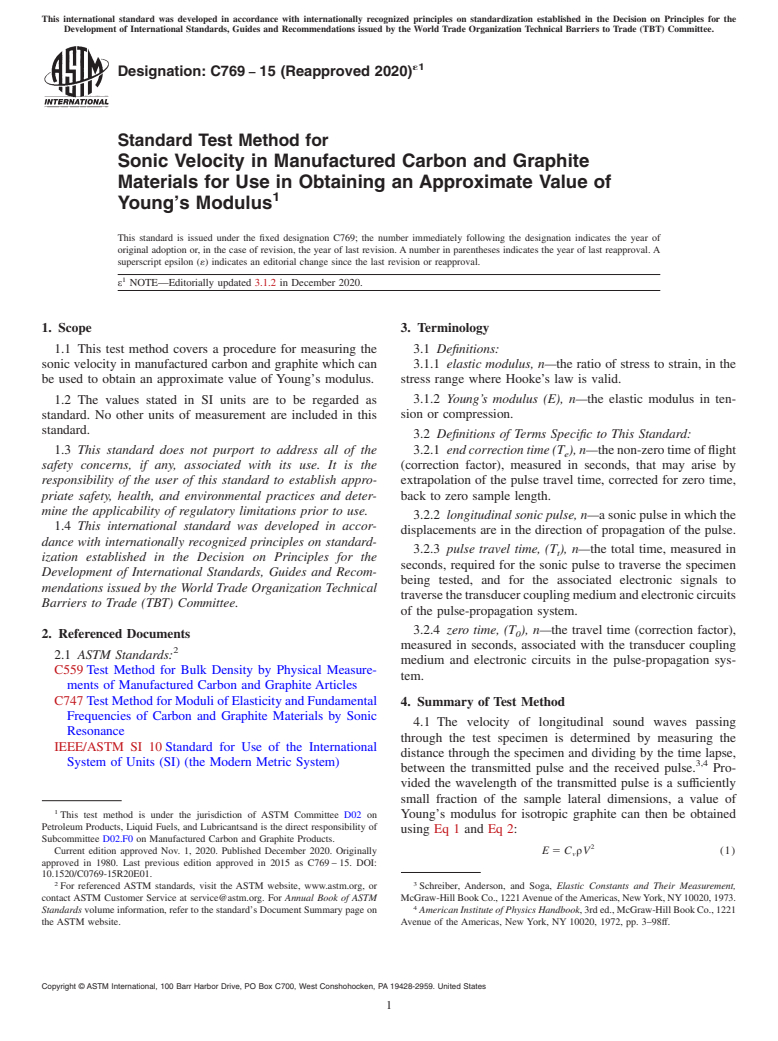

6.5 See Fig. 1 for a typical schematic setup.

the Young’s modulus calculated from Eq 1 will also depend

upon the uncertainty in Poisson’s ratio and its impact on the NOTE 2—Some manufacturers combine items 6.1 and 6.4 into a single

package with direct time readout. Such apparatus can operate

evaluationofthePoisson’sfactorinEq2.However,avaluefor

satisfactorily, provided the frequency of the propagated pulse is already

Young’s modulus can be obtained for many applications,

known, in order to check that wavelength requirements for the method are

which is often in good agreement with the value obtained by

satisfied.

other more accurate methods, such as in Test Method C747.

The technical issues and typical values of corresponding

7. Test Specimen

uncertainties are discussed in detail in STP 1578.

7.1 Selection and Preparation of Specimens—Take special

5.3 If the grain size of the carbon or graphite is greater than

care to assure obtaining representative specimens that are

or about equal to the wavelength of the sonic pulse, the method

straight, uniform in cross section, and free of extraneous

may not be providing a value of Young’s modulus representa-

liquids. The specimen end faces shall be perpendicular to the

tive of the bulk material. Therefore, it would be recommended

specimencylindricalsurfacetowithin0.125 mmtotalindicator

to test a lower frequency (longer wavelength) to demonstrate

reading.

that the range of obtained velocity values are within an

7.2 Measurement of Weight and Dimensions—Determine

acceptable level of accuracy. Significant signal attenuation

the weight and the average specimen dimensions to within

should be expected when the grain size of the material is

60.2 %.

greaterthanoraboutequaltothewavelengthofthetransmitted

sonic pulse or the material is more porous than would be 7.3 Limitations on Dimensions—These cannot be precisely

expected for an as-manufactured graphite. specified as they will depend upon the properties of the

material being tested and the experimental setup (for example,

NOTE 1—Due to frequency dependent attenuation in graphite, the

transducer frequency). In order to satisfy the theory that

wavelength of the sonic pulse through the test specimen is not necessarily

supports Eq 1, as a guide, the specimen should have a diameter

that is at least a factor five, greater than the wavelength of

ASTM Selected Technical Papers, STP 1578, Graphite Testing for Nuclear

sound in the material under test. In practice, the length of the

Applications: The Significance of Test Specimen Volume and Geometry and the

specimen will be determined taking account of the comments

Statistical Significance of Test Specimen Population, 2014, edited by Tzelepi and

Carroll. in 5.3 and 5.4.

´1

C769 − 15 (2020)

FIG. 1 Basic Experimental Arrangement for the Ultrasonic Pulsed-Wave Transit Time Technique

cellulose, petroleum jelly, high vacuum greases and water-based ultra-

7.4 Limitations on Ultrasonic Pulse Frequency—Generally

sonic couplants. However these may be difficult to remove subsequently.

speaking, a better accuracy of time of flight will be obtained at

Distilled water can provide a very satisfactory coupling medium without

higher frequencies. However, attenuation increases at higher

significantendeffects,andsurfacewatermayberemovedsubsequentlyby

frequencies leading to weak and distorted signals.

drying. Manufacturers offer rubber-tipped transducers suitable for nonin-

vasive measurements. With these transducers either good load control or

8. Procedure

accurate determination of the rubber length is essential during measure-

ment if good reproducibility is to be achieved.

8.1 For any given apparatus and choice of coupling

medium, it is necessary to follow procedures to quantify the 8.6 Bring transducer faces into intimate contact but do not

zerotime,T ,andendcorrectiontime,T ,correctionfactors.T

exceed manufacturer’s recommended contact pressures.

0 e 0

will be dependent upon the type of transducers and their

8.7 Followthevendor’sinstructionstoadjusttheinstrumen-

performance over time and should be regularly checked (see

tation to match the transducer frequency to give good visual

8.8).Itmustbequantifiedifthetestsetupischanged.T should

e

amplitude resolution.

be small and reflects the interaction between the coupling

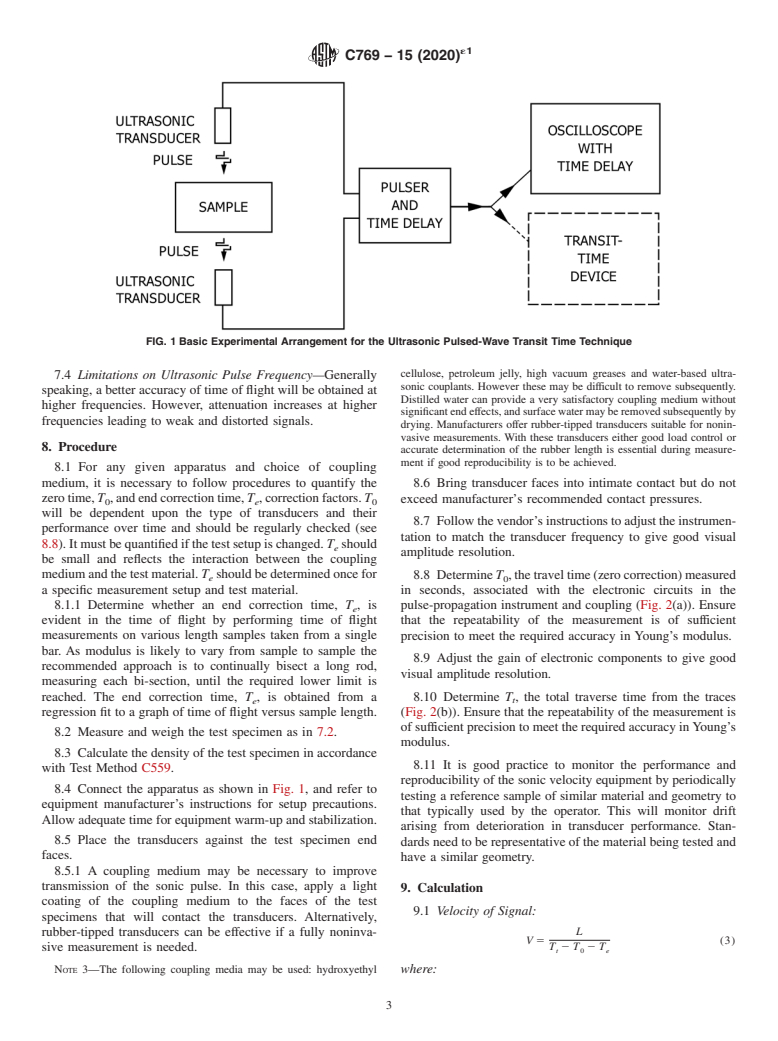

mediumandthetestmaterial.T shouldbedeterminedoncefor 8.8 DetermineT ,thetraveltime(zerocorrection)measured

e 0

a specific measurement setup and test material. in seconds, associated with the electronic circuits in the

8.1.1 Determine whether an end correction time, T,is pulse-propagation instrument and coupling (Fig. 2(a)). Ensure

e

evident in the time of flight by performing time of flight that the repeatability of the measurement is of sufficient

measurements on various length samples taken from a single precision to meet the required accuracy in Young’s modulus.

bar. As modulus is likely to vary from sample to sample the

8.9 Adjust the gain of electronic components to give good

recommended approach is to continually bisect a long rod,

visual amplitude resolution.

measuring each bi-section, until the required lower limit is

8.10 Determine T, the total traverse time from the traces

reached. The end correction time, T , is obtained from a

e t

regression fit to a graph of time of flight versus sample length. (Fig. 2(b)). Ensure that the repeatability of the measurement is

of sufficient precision to meet the required accuracy inYoung’s

8.2 Measure and weigh the test specimen as in 7.2.

modulus.

8.3 Calculate the density of the test specimen in accordance

8.11 It is good practice to monitor the performance and

with Test Method C559.

reproducibility of the sonic velocity equipment by periodically

8.4 Connect the apparatus as shown in Fig. 1, and refer to

testing a reference sample of similar material and geometry to

equipment manufacturer’s instructions for setup precautions.

that typically used by the operator. This will monitor drift

Allow adequate time for equipment warm-up and stabilization.

arising from deterioration in transducer performance. Stan-

8.5 Place the transducers against the test specimen end

dards need to be representative of the material being tested and

faces.

have a similar geometry.

8.5.1 A coupling medium may be necessary to improve

transmission of the sonic pulse. In this case, apply a light

9. Calculation

coating of the coupling medium to the faces of the test

9.1 Velocity of Signal:

specimens that will contact the transducers. Alternatively,

L

rubber-tipped transducers can be effective if a fully noninva-

V 5 (3)

T 2 T 2 T

sive measurement is needed.

t 0 e

NOTE 3—The following coupling media may be used: hydroxyethyl where:

´1

C769 − 15 (2020)

FIG. 2 Schematic Illustrating (a) Zero Time (T ) Measurement for Face to Face Contact Between Transducers and (b) Pulse Travel Time

(T ) Measurement for the Sample Positioned Between the Transducers, based upon a Simplified Received Wave Signal and the Ideal-

t

ized Case where the Onset of the First Peak has been Detected

9.3 Conversion Factors—See IEEE/ASTM SI 10.

V = velocity of signal, m/s,

L = specimen length,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.