ASTM D6747-12

(Guide)Standard Guide for Selection of Techniques for Electrical Detection of Leaks in Geomembranes

Standard Guide for Selection of Techniques for Electrical Detection of Leaks in Geomembranes

SIGNIFICANCE AND USE

4.1 Leaks are typically related to the quality of the sub-grade material, quality of the cover material, care in the cover material installation and quality of geomembrane installation.

4.2 Experience demonstrates that geomembranes can have leaks caused during their installation and placement of material(s) on the geomembrane.

4.3 The damage to a geomembrane can be detected using electrical leak location systems. Such systems have been used successfully to locate leaks in electrically-insulating geomembranes such as polyethylene, polypropylene, polyvinyl chloride, chlorosulfonated polyethylene and bituminous geomembranes installed in basins, ponds, tanks, ore and waste pads, and landfill cells.

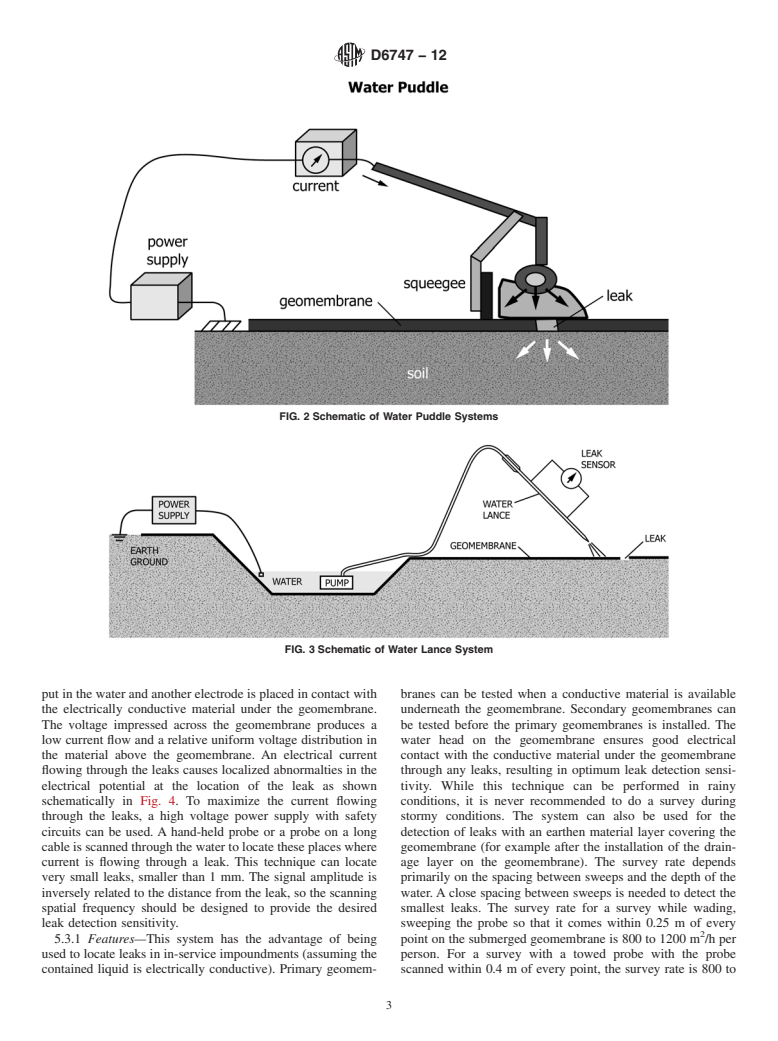

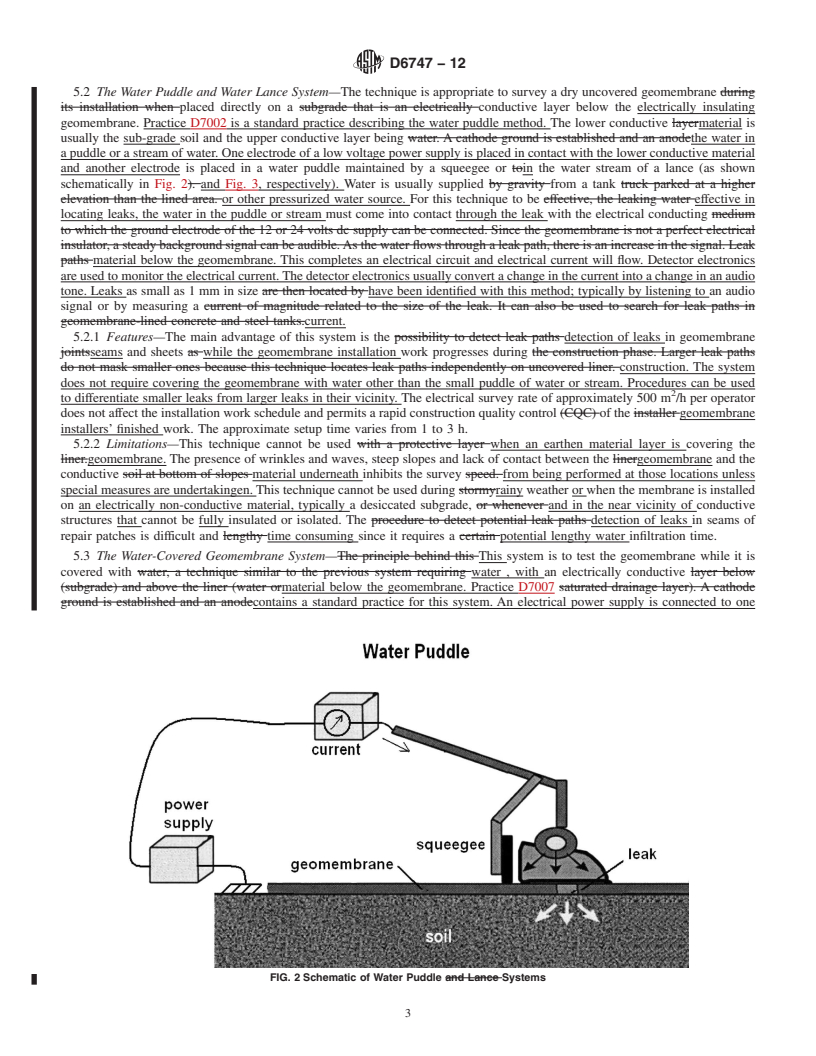

4.4 The principle behind these techniques is to place a voltage across a synthetic geomembrane and then locate areas where electrical current flows through discontinuities in the geomembrane (as shown schematically in Fig. 1). Other electrical leak paths such as prevent pipe penetrations, flange bolts, steel drains, and batten strips on concrete and other extraneous electrical paths should be electrically isolated or insulated to prevent masking of leak signals caused by electrical current flowing through those electrical paths. The only electrical paths should be through leaks in the geomembrane. This electric detection method of locating leaks in geomembranes can be performed on exposed geomembranes, on geomembranes covered with water or on geomembranes covered with an earthen material layer, or both.

SCOPE

1.1 This standard guide is intended to assist individuals or groups in assessing different options available for locating leaks in installed geomembranes using electrical methods. For clarity, this document uses the term leak to mean holes, punctures, tears, knife cuts, seam defects, cracks and similar breaches through an installed geomembrane.

1.2 This guide does not cover systems that are restricted to seam testing only, nor does it cover systems that may detect leaks non-electrically. It does not cover systems that only detect the presence, but not the location of leaks.

1.3 Warning—The electrical methods used for geomembrane leak location could use high voltages, resulting in the potential for electrical shock or electrocution. This hazard might be increased because operations might be conducted in or near water. In particular, a high voltage could exist between the water or earth material and earth ground, or any grounded conductor. These procedures are potentially very dangerous, and can result in personal injury or death. The electrical methods used for geomembrane leak location should be attempted only by qualified and experienced personnel. Appropriate safety measures must be taken to protect the leak location operators as well as other people at the site.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6747 − 12

StandardGuide for

Selection of Techniques for Electrical Detection of Leaks in

1

Geomembranes

This standard is issued under the fixed designation D6747; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D7002 Practice for Leak Location on Exposed Geomem-

branes Using the Water Puddle System

1.1 This standard guide is intended to assist individuals or

D7007 Practices for Electrical Methods for Locating Leaks

groups in assessing different options available for locating

in Geomembranes Covered with Water or Earth Materials

leaks in installed geomembranes using electrical methods. For

D7240 Practice for Leak Location using Geomembranes

clarity, this document uses the term leak to mean holes,

with an Insulating Layer in Intimate Contact with a

punctures, tears, knife cuts, seam defects, cracks and similar

Conductive Layer via Electrical Capacitance Technique

breaches through an installed geomembrane.

(Conductive Geomembrane Spark Test)

1.2 This guide does not cover systems that are restricted to

3. Terminology

seam testing only, nor does it cover systems that may detect

leaks non-electrically. It does not cover systems that only

3.1 For general definitions used in this document, refer to

detect the presence, but not the location of leaks.

D4439.

1.3 Warning—The electrical methods used for geomem-

3.2 Definitions of Terms Specific to This Standard:

brane leak location could use high voltages, resulting in the

3.2.1 electrical leak location, n—a method which uses

potential for electrical shock or electrocution. This hazard

electrical current or electrical potential to detect and locate

might be increased because operations might be conducted in

leaks.

or near water. In particular, a high voltage could exist between

3.2.2 leak, n—for the purposes of this document, a leak is

the water or earth material and earth ground, or any grounded

any unintended opening, perforation, breach, slit, tear,

conductor. These procedures are potentially very dangerous,

puncture, crack, or seam breach. Significant amounts of liquids

and can result in personal injury or death. The electrical

or solids may or may not flow through a leak. Scratches,

methods used for geomembrane leak location should be

gouges, dents, or other aberrations that do not completely

attempted only by qualified and experienced personnel.Appro-

penetrate the geomembrane are not considered to be leaks.

priate safety measures must be taken to protect the leak

Leaks detected during surveys have been grouped into five

location operators as well as other people at the site.

categories:

1.4 This standard does not purport to address all of the

3.2.2.1 holes—round shaped voids with downward or up-

safety concerns, if any, associated with its use. It is the

ward protruding rims.

responsibility of the user of this standard to establish appro-

3.2.2.2 tears—linear or areal voids with irregular edge

priate safety and health practices and determine the applica-

borders.

bility of regulatory requirements prior to use.

3.2.2.3 linear cuts—linear voids with neat close edges.

2. Referenced Documents

3.2.2.4 seam defects—area of partial or total separation

2

between sheets.

2.1 ASTM Standards:

D4439 Terminology for Geosynthetics

3.2.2.5 burned through zones—voids created by melting

polymer during welding.

4. Significance and Use

1

This guide is under the jurisdiction ofASTM Committee D35 on Geosynthetics

and is the direct responsibility of Subcommittee D35.10 on Geomembranes.

4.1 Leaks are typically related to the quality of the sub-

Current edition approved Feb. 15, 2012. Published February 2012. Originally

grade material, quality of the cover material, care in the cover

approved in 2002. Last previous edition approved in 2002 as D6747–04. DOI:

material installation and quality of geomembrane installation.

10.1520/D6747-12.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

4.2 Experience demonstrates that geomembranes can have

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

leaks caused during their installation and placement of mate-

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. rial(s) on the geomembrane.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D6747 − 12

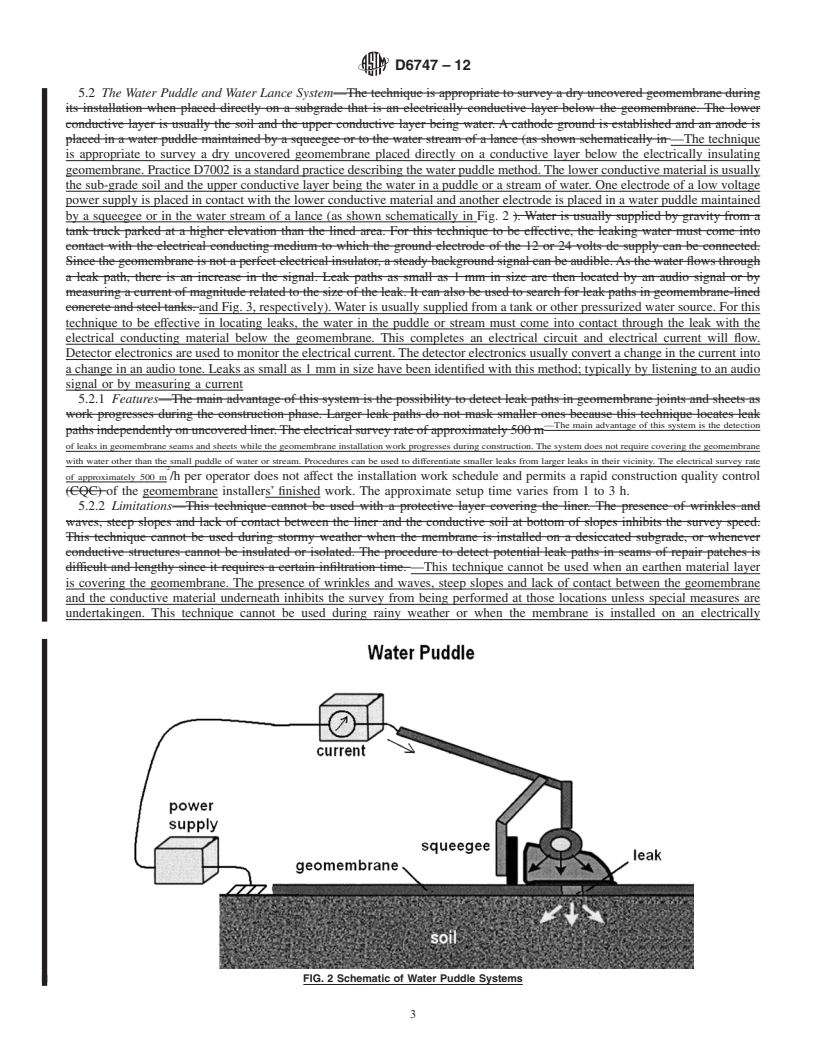

4.3 The damage to a geomembrane can be detected using other pressurized water source. For this technique to be

electrical leak location systems. Such systems hav

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D6747 − 04 D6747 − 12

Standard Guide for

Selection of Techniques for Electrical Detection of Potential

1

Leak Paths Leaks in Geomembranes

This standard is issued under the fixed designation D6747; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This standard guide is intended to assist individuals or groups in assessing different options available for locating potential

leak paths leaks in installed geomembranes through the use of using electrical methods. For clarity, this document uses the term

potential leak path to mean holes, punctures, tears, knife cuts, seam defects, cracks and similar breaches over the partial or entire

area of through an installed geomembrane.

1.2 This guide does not cover systems that are restricted to seam testing only, nor does it cover systems that may detect leaks

non-electrically. It does not cover systems that only detect the presence, but not the location of leaks.

1.3 Warning—The electrical methods used for geomembrane leak location could use high voltages, resulting in the potential

for electrical shock or electrocution. This hazard might be increased because operations might be conducted in or near water. In

particular, a high voltage could exist between the water or earth material and earth ground, or any grounded conductor. These

procedures are potentially very dangerous, and can result in personal injury or death. The electrical methods used for geomembrane

leak location should be attempted only by qualified and experienced personnel. Appropriate safety measures must be taken to

protect the leak location operators as well as other people at the site.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

requirements prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D4439 Terminology for Geosynthetics

D7002 Practice for Leak Location on Exposed Geomembranes Using the Water Puddle System

D7007 Practices for Electrical Methods for Locating Leaks in Geomembranes Covered with Water or Earth Materials

D7240 Practice for Leak Location using Geomembranes with an Insulating Layer in Intimate Contact with a Conductive Layer

via Electrical Capacitance Technique (Conductive Geomembrane Spark Test)

3. Terminology

3.1 For general definitions used in this document, refer to D4439.

3.2 Definitions:Definitions of Terms Specific to This Standard:

3.2.1 electrical leak location, n—anya method which uses electrical current or electrical potential to detect and locate potential

leak paths.leaks.

3.1.2 geomembrane, n—an essentially impermeable membrane used with foundation, soil, rock, earth or any other geotechnical

engineering related material as an integral part of a manmade project, structure, or system.

3.1.3 geosynthetic, n—a planar product manufactured from polymeric material used with soil, rock, earth, or other geotechnical

engineering related material as an integral part of a manmade project, structure, or system.

1

This guide is under the jurisdiction of ASTM Committee D35 on Geosynthetics and is the direct responsibility of Subcommittee D35.10 on Geomembranes.

Current edition approved Nov. 1, 2004Feb. 15, 2012. Published November 2004February 2012. Originally approved in 2002. Last previous edition approved in 2002 as

e1

D6747–02–04. DOI: 10.1520/D6747-04.10.1520/D6747-12.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D6747 − 12

3.2.2 potential leak paths, leak, n—for the purposes of this document, a potential leak path is any unintended opening,

perforation, breach, slit, tear, puncture, crack, or seam breach. Significant amounts of liquids or solids may or may not flow through

a leak. Scratches, gouges, dents, or other aberrations that do not completely penetrate the geomembrane are not conside

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D6747–04 Designation:D6747–12

Standard Guide for

Selection of Techniques for Electrical Detection of Potential

1

Leak PathsLeaks in Geomembranes

This standard is issued under the fixed designation D6747; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This standard guide is intended to assist individuals or groups in assessing different options available for locating potential

leak paths leaks in installed geomembranes through the use of using electrical methods. For clarity, this document uses the term

potential leak path to mean holes, punctures, tears, knife cuts, seam defects, cracks and similar breaches over the partial or entire

area ofthrough an installed geomembrane.

1.2 This guide does not cover systems that are restricted to seam testing only, nor does it cover systems that may detect leaks

non-electrically. It does not cover systems that only detect the presence, but not the location of leaks.

1.3

1.3 Warning—The electrical methods used for geomembrane leak location could use high voltages, resulting in the

potential for electrical shock or electrocution. This hazard might be increased because operations might be conducted in

or near water. In particular, a high voltage could exist between the water or earth material and earth ground, or any

grounded conductor. These procedures are potentially very dangerous, and can result in personal injury or death. The

electrical methods used for geomembrane leak location should be attempted only by qualified and experienced personnel.

Appropriate safety measures must be taken to protect the leak location operators as well as other people at the site.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

requirements prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D4439Terminology for Geosynthetics

D4439 Terminology for Geosynthetics

D7002 Practice for Leak Location on Exposed Geomembranes Using the Water Puddle System

D7007 Practices for Electrical Methods for Locating Leaks in Geomembranes Covered with Water or Earth Materials

D7240 Practice for Leak Location using Geomembranes with an Insulating Layer in Intimate Contact with a Conductive Layer

via Electrical Capacitance Technique (Conductive Geomembrane Spark Test)

3. Terminology

3.1Definitions:

3.1.1electrical leak location, n—any method which uses electrical current or electrical potential to detect and locate potential

leak paths.

3.1.2geomembrane, n—an essentially impermeable membrane used with foundation, soil, rock, earth or any other geotechnical

engineering related material as an integral part of a manmade project, structure, or system.

3.1.3geosynthetic, n—a planar product manufactured from polymeric material used with soil, rock, earth, or other geotechnical

engineering related material as an integral part of a manmade project, structure, or system.

3.1.4potential leak paths, n—for the purposes of this document, a potential leak path is any unintended opening, perforation,

breach, slit, tear, puncture, crack, or seam breach. Scratches, gouges, dents, or other aberrations that do not completely penetrate

thegeomembranearenotconsidered.Leakpathsdetectedduringsurveyshavebeengroupedintofivecategories:(1)Holes—round

1

This guide is under the jurisdiction of ASTM Committee D35 on Geosynthetics and is the direct responsibility of Subcommittee D35.10 on Geomembranes .

e1

Current edition approved Nov. 1, 2004. Published November 2004. Originally approved in 2002. Last previous edition approved in 2002 as D6747–02 DOI:

10.1520/D6747-04.

Current edition approved Feb. 15, 2012. Published February 2012. Originally approved in 2002. Last previous edition approved in 2002 as D6747–04. DOI:

10.1520/D6747-12.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.